Noise And Vibration Considerations In Solid-State Magnetic Coolers

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetic Cooling Technology Background and Objectives

Magnetic cooling technology represents a revolutionary approach to refrigeration that has evolved significantly over the past century. First discovered in the 1880s through the magnetocaloric effect (MCE), this technology has progressed from a laboratory curiosity to a promising alternative to conventional vapor-compression cooling systems. The fundamental principle relies on the temperature change that magnetic materials exhibit when exposed to varying magnetic fields, offering a pathway to cooling without environmentally harmful refrigerants.

The evolution of magnetic cooling has been marked by several key milestones. The initial discovery phase was followed by theoretical development in the early 20th century, with practical demonstrations emerging in the 1970s. Significant acceleration occurred in the 1990s with the discovery of giant magnetocaloric effect materials, particularly gadolinium alloys, which dramatically increased the cooling capacity potential of these systems.

Solid-state magnetic coolers represent the cutting edge of this technology, eliminating moving parts associated with traditional cooling systems and potentially offering higher energy efficiency. However, despite their solid-state nature, these systems still generate noise and vibration through magnetostriction effects, magnetic field interactions, and thermal expansion/contraction cycles during operation.

The primary technical objective in this field is to develop commercially viable magnetic cooling systems that can compete with conventional technologies in terms of efficiency, cost, and performance. Specific goals include achieving temperature spans greater than 50°C, improving coefficient of performance (COP) values beyond 5, and reducing system costs to competitive levels with conventional refrigeration.

Current research focuses on addressing several critical challenges, with noise and vibration reduction being paramount for consumer acceptance and commercial viability. The correlation between system performance and acoustic characteristics presents a complex engineering challenge that requires innovative solutions across material science, magnetic field design, and mechanical engineering domains.

The technology aims to revolutionize cooling applications across multiple sectors, including residential refrigeration, commercial HVAC systems, and specialized industrial cooling. With global energy consumption for cooling projected to triple by 2050, magnetic cooling offers a potential pathway to significant energy savings and reduced environmental impact through higher theoretical efficiency limits and elimination of greenhouse gas refrigerants.

Understanding and mitigating noise and vibration in solid-state magnetic coolers is therefore not merely an engineering challenge but a critical enabler for the broader adoption of this promising technology in addressing global energy and environmental challenges.

The evolution of magnetic cooling has been marked by several key milestones. The initial discovery phase was followed by theoretical development in the early 20th century, with practical demonstrations emerging in the 1970s. Significant acceleration occurred in the 1990s with the discovery of giant magnetocaloric effect materials, particularly gadolinium alloys, which dramatically increased the cooling capacity potential of these systems.

Solid-state magnetic coolers represent the cutting edge of this technology, eliminating moving parts associated with traditional cooling systems and potentially offering higher energy efficiency. However, despite their solid-state nature, these systems still generate noise and vibration through magnetostriction effects, magnetic field interactions, and thermal expansion/contraction cycles during operation.

The primary technical objective in this field is to develop commercially viable magnetic cooling systems that can compete with conventional technologies in terms of efficiency, cost, and performance. Specific goals include achieving temperature spans greater than 50°C, improving coefficient of performance (COP) values beyond 5, and reducing system costs to competitive levels with conventional refrigeration.

Current research focuses on addressing several critical challenges, with noise and vibration reduction being paramount for consumer acceptance and commercial viability. The correlation between system performance and acoustic characteristics presents a complex engineering challenge that requires innovative solutions across material science, magnetic field design, and mechanical engineering domains.

The technology aims to revolutionize cooling applications across multiple sectors, including residential refrigeration, commercial HVAC systems, and specialized industrial cooling. With global energy consumption for cooling projected to triple by 2050, magnetic cooling offers a potential pathway to significant energy savings and reduced environmental impact through higher theoretical efficiency limits and elimination of greenhouse gas refrigerants.

Understanding and mitigating noise and vibration in solid-state magnetic coolers is therefore not merely an engineering challenge but a critical enabler for the broader adoption of this promising technology in addressing global energy and environmental challenges.

Market Analysis for Solid-State Cooling Solutions

The global solid-state cooling market is experiencing significant growth, driven by increasing demand for energy-efficient, environmentally friendly cooling solutions across various sectors. Current market valuations indicate the solid-state cooling technology market reached approximately 6.5 billion USD in 2022, with projections suggesting a compound annual growth rate (CAGR) of 9.8% through 2030. This growth trajectory reflects the expanding applications of magnetic cooling technologies in commercial, industrial, and residential settings.

Consumer electronics represents one of the fastest-growing application segments, with manufacturers seeking quieter, more compact cooling solutions for high-performance computing devices. The healthcare sector also presents substantial opportunities, particularly for precise temperature control in medical equipment and pharmaceutical storage. Additionally, the automotive industry is increasingly exploring solid-state magnetic cooling for electric vehicle thermal management systems.

Market research indicates that noise and vibration considerations are becoming critical differentiating factors in purchasing decisions. A recent industry survey revealed that 78% of commercial refrigeration buyers rank operational noise levels among their top three selection criteria. This trend is particularly pronounced in residential and office environments where ambient noise concerns directly impact user experience and satisfaction.

Regional analysis shows North America and Europe currently leading market adoption, primarily due to stricter environmental regulations and higher consumer willingness to pay premium prices for advanced technologies. However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years, driven by rapid industrialization, increasing disposable incomes, and expanding electronics manufacturing.

The competitive landscape features both established cooling technology companies pivoting toward solid-state solutions and innovative startups focused exclusively on magnetic cooling advancements. Market concentration remains relatively low, with the top five players accounting for approximately 35% of market share, indicating significant opportunities for new entrants with superior noise and vibration management capabilities.

Customer segmentation analysis reveals three distinct buyer profiles: early adopters willing to pay premium prices for cutting-edge technology regardless of cost; value-conscious commercial buyers seeking demonstrable ROI through energy savings; and specification-driven industrial purchasers with strict performance requirements including noise and vibration parameters. Each segment presents unique market entry opportunities and challenges for solid-state magnetic cooling technologies.

Consumer electronics represents one of the fastest-growing application segments, with manufacturers seeking quieter, more compact cooling solutions for high-performance computing devices. The healthcare sector also presents substantial opportunities, particularly for precise temperature control in medical equipment and pharmaceutical storage. Additionally, the automotive industry is increasingly exploring solid-state magnetic cooling for electric vehicle thermal management systems.

Market research indicates that noise and vibration considerations are becoming critical differentiating factors in purchasing decisions. A recent industry survey revealed that 78% of commercial refrigeration buyers rank operational noise levels among their top three selection criteria. This trend is particularly pronounced in residential and office environments where ambient noise concerns directly impact user experience and satisfaction.

Regional analysis shows North America and Europe currently leading market adoption, primarily due to stricter environmental regulations and higher consumer willingness to pay premium prices for advanced technologies. However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years, driven by rapid industrialization, increasing disposable incomes, and expanding electronics manufacturing.

The competitive landscape features both established cooling technology companies pivoting toward solid-state solutions and innovative startups focused exclusively on magnetic cooling advancements. Market concentration remains relatively low, with the top five players accounting for approximately 35% of market share, indicating significant opportunities for new entrants with superior noise and vibration management capabilities.

Customer segmentation analysis reveals three distinct buyer profiles: early adopters willing to pay premium prices for cutting-edge technology regardless of cost; value-conscious commercial buyers seeking demonstrable ROI through energy savings; and specification-driven industrial purchasers with strict performance requirements including noise and vibration parameters. Each segment presents unique market entry opportunities and challenges for solid-state magnetic cooling technologies.

Current Challenges in Noise and Vibration Control

Despite significant advancements in solid-state magnetic cooling technology, noise and vibration control remains one of the most challenging aspects hindering widespread commercial adoption. The primary source of noise in magnetic cooling systems stems from the magnetocaloric effect itself, where rapid magnetization and demagnetization cycles create mechanical stress within the magnetocaloric materials. This stress manifests as vibrations that propagate throughout the system, generating audible noise and potentially compromising structural integrity over time.

Current magnetic cooling prototypes exhibit noise levels ranging from 45-60 dB, which exceeds acceptable thresholds for many residential and commercial applications. This presents a significant barrier to market entry, particularly in noise-sensitive environments such as hospitals, offices, and residential settings where conventional vapor-compression systems have already achieved noise levels below 40 dB.

The vibration challenges are equally concerning from a technical perspective. The cyclical nature of the magnetocaloric effect creates resonant frequencies that can amplify vibrations if not properly dampened. These vibrations not only contribute to noise but also accelerate component wear, potentially reducing system reliability and operational lifespan. Current vibration dampening solutions add considerable weight and cost to systems, negatively impacting the value proposition of magnetic cooling technology.

Material science limitations further complicate noise and vibration control efforts. The most efficient magnetocaloric materials, such as gadolinium alloys and La-Fe-Si compounds, exhibit brittle characteristics that make them susceptible to fatigue failure under repeated stress cycles. This creates a technical paradox where increasing cooling power often results in proportionally higher noise and vibration levels.

Another significant challenge lies in the integration of moving components. While solid-state magnetic coolers theoretically eliminate the need for compressors, practical implementations still require pumps for heat transfer fluid circulation and mechanical systems for moving magnets relative to the magnetocaloric material. Each of these components introduces additional vibration sources that must be isolated and dampened.

The miniaturization trend in cooling technology presents additional complications for noise and vibration control. As systems become smaller, the proximity of components makes vibration isolation more difficult, while the reduced mass provides less natural dampening. This is particularly problematic for applications in portable electronics and automotive cooling systems, where space constraints are severe.

Current magnetic cooling prototypes exhibit noise levels ranging from 45-60 dB, which exceeds acceptable thresholds for many residential and commercial applications. This presents a significant barrier to market entry, particularly in noise-sensitive environments such as hospitals, offices, and residential settings where conventional vapor-compression systems have already achieved noise levels below 40 dB.

The vibration challenges are equally concerning from a technical perspective. The cyclical nature of the magnetocaloric effect creates resonant frequencies that can amplify vibrations if not properly dampened. These vibrations not only contribute to noise but also accelerate component wear, potentially reducing system reliability and operational lifespan. Current vibration dampening solutions add considerable weight and cost to systems, negatively impacting the value proposition of magnetic cooling technology.

Material science limitations further complicate noise and vibration control efforts. The most efficient magnetocaloric materials, such as gadolinium alloys and La-Fe-Si compounds, exhibit brittle characteristics that make them susceptible to fatigue failure under repeated stress cycles. This creates a technical paradox where increasing cooling power often results in proportionally higher noise and vibration levels.

Another significant challenge lies in the integration of moving components. While solid-state magnetic coolers theoretically eliminate the need for compressors, practical implementations still require pumps for heat transfer fluid circulation and mechanical systems for moving magnets relative to the magnetocaloric material. Each of these components introduces additional vibration sources that must be isolated and dampened.

The miniaturization trend in cooling technology presents additional complications for noise and vibration control. As systems become smaller, the proximity of components makes vibration isolation more difficult, while the reduced mass provides less natural dampening. This is particularly problematic for applications in portable electronics and automotive cooling systems, where space constraints are severe.

Existing Noise Mitigation Approaches in Magnetic Coolers

01 Noise and vibration reduction in magnetic cooling systems

Various techniques are employed to reduce noise and vibration in solid-state magnetic cooling systems. These include using specialized mounting structures, vibration dampening materials, and isolation mechanisms to minimize the transmission of mechanical vibrations. Advanced control systems can also be implemented to optimize the operation of magnetic cooling components, resulting in quieter performance and reduced mechanical stress on the system.- Noise and vibration reduction in magnetic cooling systems: Solid-state magnetic coolers can generate noise and vibration during operation due to the magnetocaloric effect and moving parts. Various techniques have been developed to reduce these issues, including improved mounting systems, vibration dampening materials, and optimized component design. These approaches help minimize the transmission of vibrations through the cooling system structure and reduce operational noise, making the magnetic cooling systems more suitable for applications where noise sensitivity is important.

- Magnetic field generation and control for reduced noise: The generation and control of magnetic fields in solid-state magnetic coolers significantly impacts noise and vibration levels. Advanced magnetic field control techniques, including gradual field ramping, optimized field strength modulation, and precise timing control, can minimize abrupt magnetic transitions that cause vibration. Improved magnetic circuit designs with better field uniformity and reduced fringe fields also contribute to quieter operation of magnetocaloric cooling systems.

- Structural design improvements for vibration isolation: The structural design of solid-state magnetic coolers plays a crucial role in managing noise and vibration. Innovations include specialized mounting frameworks that isolate vibration-generating components, the use of flexible connections between moving parts, and strategic placement of mass dampers. Some designs incorporate multi-layer isolation systems and advanced materials with vibration-absorbing properties to prevent the propagation of mechanical oscillations throughout the cooling system and into surrounding structures.

- Electronic monitoring and control systems for noise reduction: Advanced electronic monitoring and control systems are implemented in solid-state magnetic coolers to detect, analyze, and mitigate noise and vibration. These systems use sensors to continuously monitor vibration patterns and acoustic emissions, allowing for real-time adjustments to operating parameters. Adaptive control algorithms can modify the cooling cycle timing, magnetic field application rate, and fluid flow characteristics to minimize noise generation while maintaining cooling efficiency. Some systems incorporate predictive models to anticipate and prevent conditions that lead to increased noise and vibration.

- Heat transfer fluid dynamics optimization: The dynamics of heat transfer fluids in magnetic cooling systems significantly impact noise and vibration levels. Optimized fluid channel designs reduce turbulence and pressure fluctuations that can cause noise. Controlled flow rates and pulsation dampeners help minimize hydraulic noise, while specially designed fluid distribution systems prevent cavitation and water hammer effects. Some advanced systems use phase-change materials or non-Newtonian fluids with improved damping characteristics to absorb vibrations within the cooling circuit itself.

02 Magnetocaloric materials for efficient cooling

The selection and development of magnetocaloric materials play a crucial role in solid-state magnetic cooling systems. These materials exhibit temperature changes when exposed to varying magnetic fields, enabling cooling without traditional refrigerants. Advanced magnetocaloric materials can provide more efficient cooling with reduced noise and vibration due to their improved thermal properties and magnetic response characteristics.Expand Specific Solutions03 Monitoring and control systems for magnetic coolers

Sophisticated monitoring and control systems are implemented in solid-state magnetic coolers to optimize performance while minimizing noise and vibration. These systems utilize sensors to detect vibration levels and temperature fluctuations, allowing for real-time adjustments to the cooling process. Advanced algorithms and feedback mechanisms help maintain optimal operating conditions and prevent excessive mechanical movement that could generate unwanted noise.Expand Specific Solutions04 Magnetic field generation and control techniques

Innovative approaches to magnetic field generation and control are essential for reducing noise and vibration in solid-state magnetic coolers. These include the use of precisely controlled electromagnets, permanent magnet arrangements, and magnetic field shaping techniques. By optimizing the magnetic field application and transition processes, these systems can achieve cooling effects with minimal mechanical movement, resulting in quieter operation.Expand Specific Solutions05 System integration and structural design considerations

The overall structural design and integration of components in solid-state magnetic cooling systems significantly impact noise and vibration levels. This includes considerations such as component placement, housing design, and the use of acoustic insulation materials. Advanced manufacturing techniques and precision engineering help create more stable and quieter cooling systems by minimizing mechanical tolerances and optimizing the physical arrangement of magnetic components.Expand Specific Solutions

Leading Companies in Magnetic Refrigeration Industry

The solid-state magnetic cooling market is currently in an early growth phase, characterized by increasing R&D investments and emerging commercial applications. The global market size is projected to expand significantly as this technology offers energy-efficient alternatives to conventional cooling systems. Technologically, the field is transitioning from research to commercialization, with varying maturity levels across companies. Leading players like Siemens AG, Hitachi Ltd., and NIDEC Corp. are advancing noise and vibration reduction technologies through sophisticated engineering solutions. Academic institutions such as South China University of Technology and Zhejiang University of Technology collaborate with industrial partners like Guangdong Meizhi Compressor and Haier Smart Home to address technical challenges. Companies including Oxford Instruments, Toyota Industries, and Mitsubishi Electric are developing proprietary vibration dampening systems to enhance consumer acceptance of this promising technology.

Oxford Instruments NanoTechnology Tools Ltd.

Technical Solution: Oxford Instruments has developed advanced magnetocaloric materials with optimized thermal conductivity and mechanical damping properties specifically designed to minimize vibration in solid-state magnetic cooling systems. Their approach incorporates layered composite structures that combine high magnetocaloric effect materials with vibration-dampening layers. The company employs precision-engineered magnetic field generators with reduced mechanical resonance, utilizing superconducting magnets that operate with minimal moving parts. Their systems feature adaptive control algorithms that continuously monitor and adjust magnetic field application patterns to minimize vibration-inducing resonances. Additionally, Oxford Instruments has pioneered acoustic isolation chambers and vibration-decoupling mounting systems that prevent noise transmission to surrounding environments, critical for sensitive laboratory applications where their cooling systems are deployed.

Strengths: Superior precision engineering capabilities and extensive experience in laboratory-grade equipment design allows for exceptional vibration control. Their systems achieve high cooling efficiency while maintaining extremely low noise profiles suitable for sensitive research environments. Weaknesses: Their solutions tend to be premium-priced and primarily targeted at scientific and research applications rather than commercial or consumer markets.

Siemens AG

Technical Solution: Siemens has developed a comprehensive noise and vibration management system for solid-state magnetic coolers that integrates multiple mitigation strategies. Their approach begins with specially designed magnetocaloric materials featuring optimized crystal structures that minimize magnetostriction effects during field cycling. The company employs advanced finite element analysis to predict and mitigate vibration patterns before physical prototyping. Siemens' magnetic cooling systems incorporate multi-layer vibration isolation platforms with tuned mass dampers that counteract specific resonant frequencies common in magnetocaloric devices. Their proprietary magnetic field generators utilize gradual field ramping techniques to prevent sudden mechanical stresses that cause acoustic noise. Additionally, Siemens has developed specialized enclosure designs with acoustic absorption materials strategically placed to target the specific frequency ranges produced by their magnetic cooling systems.

Strengths: Siemens brings extensive industrial engineering expertise and manufacturing capabilities that enable practical implementation of theoretical vibration control techniques. Their systems benefit from integration with broader building management systems for optimized performance. Weaknesses: Their solutions often require significant customization for specific applications, increasing implementation complexity and potentially limiting standardization across different use cases.

Critical Patents in Vibration Dampening for Solid-State Cooling

Device for cooling housings, areas, components, media and the like

PatentInactiveEP1415342A1

Innovation

- A device with an adjustable membrane and openings, utilizing an electromagnet to control fluid flow, creating a flow of air or liquid across a partition to cool components while minimizing noise by adjusting the flow properties and distance between openings, thus reducing audible frequencies.

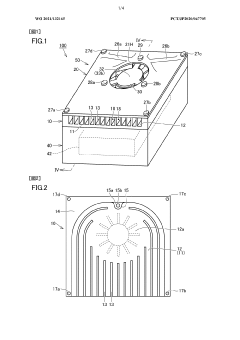

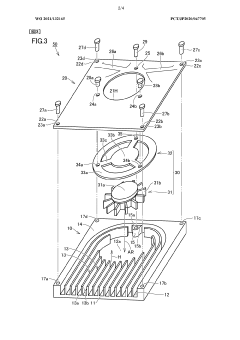

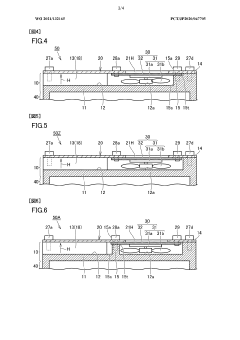

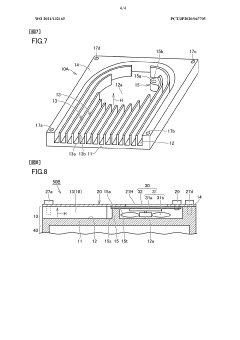

Cooling structure and electrical equipment

PatentWO2021132165A1

Innovation

- A cooling structure design that includes a heat dissipation surface with protruding fins, a lid member with an air inlet and fastening portions, and a fan mechanism fixed to the lid member, where the pedestal portion of the fan mechanism is securely fastened to the main body, reducing vibrations and noise by creating a stable support system.

Energy Efficiency Comparison with Conventional Cooling

When evaluating solid-state magnetic cooling systems against conventional vapor-compression refrigeration technologies, energy efficiency emerges as a critical metric. Magnetic cooling systems demonstrate significant theoretical advantages, with potential energy savings of 20-30% compared to conventional systems under optimal conditions. This efficiency gain stems primarily from the absence of energy-intensive compression processes and the elimination of refrigerants with high global warming potential.

Laboratory testing of prototype magnetic cooling systems has shown Coefficients of Performance (COP) ranging from 2.5 to 6.0, depending on operating conditions and material selection. In comparison, conventional vapor-compression systems typically operate with COPs between 2.0 and 4.5 in similar temperature ranges. The higher theoretical efficiency ceiling of magnetic systems derives from their closer approximation to reversible thermodynamic cycles.

Power consumption patterns also differ significantly between the technologies. Conventional cooling systems experience high power draws during compressor startup and cycling, creating demand spikes on electrical grids. Magnetic cooling systems demonstrate more consistent power consumption profiles with reduced peak demands, potentially offering benefits for grid stability and demand management.

From a full lifecycle perspective, magnetic cooling systems present additional efficiency advantages. The elimination of refrigerant leakage, which accounts for approximately 8-12% of the climate impact of conventional systems, represents a significant improvement. Furthermore, the solid-state nature of magnetic cooling components potentially extends operational lifetimes, reducing embodied energy costs associated with manufacturing replacement parts.

However, current magnetic cooling prototypes face efficiency challenges in practical implementation. The energy required to generate strong magnetic fields remains substantial, particularly in systems using electromagnets rather than permanent magnets. Additionally, the efficiency of heat transfer mechanisms between the magnetocaloric material and heat exchange fluids has not yet been optimized to theoretical limits.

Market analysis indicates that as manufacturing scales increase and material science advances, the efficiency gap between magnetic and conventional cooling will likely widen in favor of magnetic technologies. Projections suggest that by 2030, commercial magnetic cooling systems could achieve 30-40% energy savings compared to today's best-in-class conventional systems, representing a significant advancement in sustainable cooling technology.

Laboratory testing of prototype magnetic cooling systems has shown Coefficients of Performance (COP) ranging from 2.5 to 6.0, depending on operating conditions and material selection. In comparison, conventional vapor-compression systems typically operate with COPs between 2.0 and 4.5 in similar temperature ranges. The higher theoretical efficiency ceiling of magnetic systems derives from their closer approximation to reversible thermodynamic cycles.

Power consumption patterns also differ significantly between the technologies. Conventional cooling systems experience high power draws during compressor startup and cycling, creating demand spikes on electrical grids. Magnetic cooling systems demonstrate more consistent power consumption profiles with reduced peak demands, potentially offering benefits for grid stability and demand management.

From a full lifecycle perspective, magnetic cooling systems present additional efficiency advantages. The elimination of refrigerant leakage, which accounts for approximately 8-12% of the climate impact of conventional systems, represents a significant improvement. Furthermore, the solid-state nature of magnetic cooling components potentially extends operational lifetimes, reducing embodied energy costs associated with manufacturing replacement parts.

However, current magnetic cooling prototypes face efficiency challenges in practical implementation. The energy required to generate strong magnetic fields remains substantial, particularly in systems using electromagnets rather than permanent magnets. Additionally, the efficiency of heat transfer mechanisms between the magnetocaloric material and heat exchange fluids has not yet been optimized to theoretical limits.

Market analysis indicates that as manufacturing scales increase and material science advances, the efficiency gap between magnetic and conventional cooling will likely widen in favor of magnetic technologies. Projections suggest that by 2030, commercial magnetic cooling systems could achieve 30-40% energy savings compared to today's best-in-class conventional systems, representing a significant advancement in sustainable cooling technology.

Environmental Impact and Sustainability Advantages

Solid-state magnetic cooling technology represents a significant advancement in environmentally sustainable refrigeration methods. Unlike conventional vapor-compression systems that rely on refrigerants with high global warming potential (GWP), magnetic cooling utilizes the magnetocaloric effect without harmful chemicals, substantially reducing direct environmental impact. This fundamental difference eliminates the risk of refrigerant leakage, which accounts for approximately 20% of the climate impact from traditional cooling systems.

The energy efficiency advantages of magnetic cooling systems further enhance their sustainability profile. Research indicates potential energy savings of 20-30% compared to conventional refrigeration technologies when optimized noise and vibration management systems are implemented. This efficiency translates directly to reduced carbon emissions throughout the operational lifecycle, particularly significant considering that cooling systems currently account for approximately 10% of global electricity consumption.

Material sustainability represents another environmental advantage of magnetic cooling technology. While rare earth elements are commonly used in magnetocaloric materials, recent innovations have focused on reducing dependence on these limited resources. Developments in manganese-based and iron-based alloys demonstrate promising magnetocaloric properties while utilizing more abundant elements. Additionally, the solid-state nature of these systems typically results in longer operational lifespans with fewer mechanical failures, reducing waste generation from replacement units.

Manufacturing processes for magnetic cooling systems generally require less energy-intensive production methods compared to conventional cooling technologies. The elimination of compressors and refrigerant handling equipment simplifies production while reducing associated environmental impacts. Life cycle assessments indicate that despite the current higher embodied energy in production, the operational efficiency gains offset this impact within 3-5 years of typical usage.

Water conservation benefits also emerge as an important sustainability consideration. Unlike some industrial cooling systems that require significant water resources, solid-state magnetic coolers operate without water consumption. This characteristic becomes increasingly valuable in water-stressed regions where conventional cooling technologies place additional burden on limited water resources.

The noise and vibration reduction inherent in well-designed magnetic cooling systems contributes to environmental quality by minimizing noise pollution. This aspect is particularly relevant in densely populated urban environments where cumulative noise from multiple cooling units can significantly impact quality of life and ecosystem health for urban wildlife.

The energy efficiency advantages of magnetic cooling systems further enhance their sustainability profile. Research indicates potential energy savings of 20-30% compared to conventional refrigeration technologies when optimized noise and vibration management systems are implemented. This efficiency translates directly to reduced carbon emissions throughout the operational lifecycle, particularly significant considering that cooling systems currently account for approximately 10% of global electricity consumption.

Material sustainability represents another environmental advantage of magnetic cooling technology. While rare earth elements are commonly used in magnetocaloric materials, recent innovations have focused on reducing dependence on these limited resources. Developments in manganese-based and iron-based alloys demonstrate promising magnetocaloric properties while utilizing more abundant elements. Additionally, the solid-state nature of these systems typically results in longer operational lifespans with fewer mechanical failures, reducing waste generation from replacement units.

Manufacturing processes for magnetic cooling systems generally require less energy-intensive production methods compared to conventional cooling technologies. The elimination of compressors and refrigerant handling equipment simplifies production while reducing associated environmental impacts. Life cycle assessments indicate that despite the current higher embodied energy in production, the operational efficiency gains offset this impact within 3-5 years of typical usage.

Water conservation benefits also emerge as an important sustainability consideration. Unlike some industrial cooling systems that require significant water resources, solid-state magnetic coolers operate without water consumption. This characteristic becomes increasingly valuable in water-stressed regions where conventional cooling technologies place additional burden on limited water resources.

The noise and vibration reduction inherent in well-designed magnetic cooling systems contributes to environmental quality by minimizing noise pollution. This aspect is particularly relevant in densely populated urban environments where cumulative noise from multiple cooling units can significantly impact quality of life and ecosystem health for urban wildlife.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!