Optimizing Heat Exchanger Surface Treatments For Magnetocaloric Systems

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetocaloric Heat Exchanger Technology Background and Objectives

Magnetocaloric effect (MCE) has emerged as a promising alternative technology for refrigeration and cooling systems since its discovery in the late 19th century. This phenomenon, characterized by temperature changes in magnetic materials when subjected to varying magnetic fields, offers significant potential for energy-efficient and environmentally friendly cooling solutions. The evolution of magnetocaloric technology has accelerated notably in the past three decades, driven by increasing global energy demands and environmental concerns regarding conventional vapor-compression cooling systems.

The fundamental principle behind magnetocaloric cooling involves the adiabatic magnetization and demagnetization of certain materials, particularly rare-earth elements and their alloys. When these materials are exposed to a magnetic field, their magnetic moments align, reducing magnetic entropy and causing temperature increase. Conversely, when the field is removed, the moments randomize, increasing magnetic entropy and causing cooling. This reversible process forms the basis for magnetocaloric heat exchange systems.

Recent technological advancements have focused on enhancing the efficiency of heat exchangers within magnetocaloric systems, as these components are critical for transferring thermal energy between the magnetocaloric material and the heat transfer fluid. Surface treatments of heat exchangers represent a particularly promising area for optimization, with potential to significantly improve thermal conductivity, reduce corrosion, minimize fouling, and enhance overall system performance.

The primary objective of this technical research is to investigate and evaluate various surface treatment methodologies for heat exchangers specifically designed for magnetocaloric systems. We aim to identify optimal surface modification techniques that can maximize heat transfer efficiency while maintaining compatibility with the unique operational parameters of magnetocaloric materials, including their cyclic temperature variations and magnetic field requirements.

Secondary objectives include assessing the scalability of identified surface treatments for commercial applications, evaluating their long-term durability under typical operating conditions, and analyzing their cost-effectiveness compared to conventional approaches. Additionally, we seek to explore novel surface treatment technologies that might specifically address the unique challenges posed by magnetocaloric systems, such as the need for rapid heat transfer during the brief magnetization-demagnetization cycles.

The technological trajectory suggests that optimized heat exchanger surface treatments could potentially reduce system size by 15-20% while increasing coefficient of performance by up to 30%, making magnetocaloric cooling systems increasingly competitive with conventional technologies. This research aligns with global trends toward sustainable energy solutions and reduced environmental impact, as magnetocaloric cooling eliminates the need for harmful refrigerants and potentially offers significant energy savings compared to traditional cooling technologies.

The fundamental principle behind magnetocaloric cooling involves the adiabatic magnetization and demagnetization of certain materials, particularly rare-earth elements and their alloys. When these materials are exposed to a magnetic field, their magnetic moments align, reducing magnetic entropy and causing temperature increase. Conversely, when the field is removed, the moments randomize, increasing magnetic entropy and causing cooling. This reversible process forms the basis for magnetocaloric heat exchange systems.

Recent technological advancements have focused on enhancing the efficiency of heat exchangers within magnetocaloric systems, as these components are critical for transferring thermal energy between the magnetocaloric material and the heat transfer fluid. Surface treatments of heat exchangers represent a particularly promising area for optimization, with potential to significantly improve thermal conductivity, reduce corrosion, minimize fouling, and enhance overall system performance.

The primary objective of this technical research is to investigate and evaluate various surface treatment methodologies for heat exchangers specifically designed for magnetocaloric systems. We aim to identify optimal surface modification techniques that can maximize heat transfer efficiency while maintaining compatibility with the unique operational parameters of magnetocaloric materials, including their cyclic temperature variations and magnetic field requirements.

Secondary objectives include assessing the scalability of identified surface treatments for commercial applications, evaluating their long-term durability under typical operating conditions, and analyzing their cost-effectiveness compared to conventional approaches. Additionally, we seek to explore novel surface treatment technologies that might specifically address the unique challenges posed by magnetocaloric systems, such as the need for rapid heat transfer during the brief magnetization-demagnetization cycles.

The technological trajectory suggests that optimized heat exchanger surface treatments could potentially reduce system size by 15-20% while increasing coefficient of performance by up to 30%, making magnetocaloric cooling systems increasingly competitive with conventional technologies. This research aligns with global trends toward sustainable energy solutions and reduced environmental impact, as magnetocaloric cooling eliminates the need for harmful refrigerants and potentially offers significant energy savings compared to traditional cooling technologies.

Market Analysis for Magnetocaloric Cooling Applications

The global magnetocaloric cooling market is experiencing significant growth, driven by increasing environmental concerns and the search for energy-efficient alternatives to conventional vapor-compression refrigeration systems. Current market valuations estimate the magnetocaloric cooling sector to reach approximately 300 million USD by 2025, with a compound annual growth rate exceeding 20% between 2020-2025. This growth trajectory is supported by substantial investments in research and development from both private corporations and government entities.

The primary market segments for magnetocaloric cooling applications include commercial refrigeration, domestic appliances, automotive climate control systems, and specialized industrial cooling. Commercial refrigeration represents the largest current market share, with supermarkets and food processing facilities showing particular interest due to potential energy savings of 20-30% compared to conventional systems.

Geographically, North America and Europe lead in market development and adoption, with countries like Germany, Denmark, and the United States hosting major research centers and commercial pilots. The Asia-Pacific region, particularly China and Japan, is rapidly increasing investments in this technology, positioning itself as the fastest-growing regional market with projected growth rates exceeding the global average by 5-7 percentage points.

Key market drivers include increasingly stringent environmental regulations on conventional refrigerants, rising energy costs, and growing consumer preference for environmentally friendly technologies. The EU F-Gas Regulation and similar policies worldwide are creating regulatory pressure that favors alternative cooling technologies like magnetocaloric systems.

Market barriers remain significant, including high initial system costs (currently 2-3 times that of conventional systems), technical challenges in scaling the technology, and limited awareness among potential end-users. The optimization of heat exchanger surface treatments represents a critical factor in overcoming these barriers, as it directly impacts system efficiency and cost-effectiveness.

Consumer and industrial demand patterns indicate growing interest in sustainable cooling solutions, with surveys showing that 65% of commercial refrigeration users would consider magnetocaloric technology if performance metrics matched conventional systems and payback periods were under five years. This presents a clear market opportunity for optimized magnetocaloric systems with enhanced heat exchanger performance.

Market forecasts suggest that breakthroughs in heat exchanger surface treatments could accelerate market adoption by reducing system costs by 30-40% and improving performance metrics to competitive levels with conventional cooling technologies, potentially expanding the addressable market by an order of magnitude within the next decade.

The primary market segments for magnetocaloric cooling applications include commercial refrigeration, domestic appliances, automotive climate control systems, and specialized industrial cooling. Commercial refrigeration represents the largest current market share, with supermarkets and food processing facilities showing particular interest due to potential energy savings of 20-30% compared to conventional systems.

Geographically, North America and Europe lead in market development and adoption, with countries like Germany, Denmark, and the United States hosting major research centers and commercial pilots. The Asia-Pacific region, particularly China and Japan, is rapidly increasing investments in this technology, positioning itself as the fastest-growing regional market with projected growth rates exceeding the global average by 5-7 percentage points.

Key market drivers include increasingly stringent environmental regulations on conventional refrigerants, rising energy costs, and growing consumer preference for environmentally friendly technologies. The EU F-Gas Regulation and similar policies worldwide are creating regulatory pressure that favors alternative cooling technologies like magnetocaloric systems.

Market barriers remain significant, including high initial system costs (currently 2-3 times that of conventional systems), technical challenges in scaling the technology, and limited awareness among potential end-users. The optimization of heat exchanger surface treatments represents a critical factor in overcoming these barriers, as it directly impacts system efficiency and cost-effectiveness.

Consumer and industrial demand patterns indicate growing interest in sustainable cooling solutions, with surveys showing that 65% of commercial refrigeration users would consider magnetocaloric technology if performance metrics matched conventional systems and payback periods were under five years. This presents a clear market opportunity for optimized magnetocaloric systems with enhanced heat exchanger performance.

Market forecasts suggest that breakthroughs in heat exchanger surface treatments could accelerate market adoption by reducing system costs by 30-40% and improving performance metrics to competitive levels with conventional cooling technologies, potentially expanding the addressable market by an order of magnitude within the next decade.

Current Surface Treatment Technologies and Challenges

Current surface treatment technologies for heat exchangers in magnetocaloric systems can be broadly categorized into mechanical, chemical, and advanced coating methods. Mechanical treatments include sandblasting, shot peening, and mechanical polishing, which primarily modify surface roughness to enhance heat transfer efficiency. These methods are relatively cost-effective but often lack precision control over surface properties at the micro and nano scales required for optimal magnetocaloric performance.

Chemical treatments such as acid etching, alkaline cleaning, and chemical passivation offer more refined surface modification capabilities. Particularly, chemical etching has shown promise in creating controlled microstructures that enhance nucleate boiling and reduce fouling in magnetocaloric heat exchangers. However, these processes frequently involve environmentally hazardous chemicals and may compromise material integrity through corrosion or hydrogen embrittlement.

Advanced coating technologies represent the current state-of-the-art approach. Thermal spray coatings, physical vapor deposition (PVD), and chemical vapor deposition (CVD) enable the application of specialized materials with tailored thermal and magnetic properties. Notably, hydrophobic and hydrophilic coatings have demonstrated significant improvements in heat transfer coefficients by altering wetting characteristics and bubble dynamics in two-phase heat exchange systems relevant to magnetocaloric applications.

A significant challenge in current surface treatment technologies lies in achieving uniform treatment across complex geometries typical in advanced magnetocaloric heat exchangers. Conventional methods often result in inconsistent surface properties, creating thermal "hot spots" that reduce overall system efficiency and potentially accelerate material degradation through thermal cycling.

Durability presents another major obstacle, as magnetocaloric systems undergo frequent thermal cycling between ambient and operating temperatures. Many current surface treatments exhibit degradation over time, with coating delamination and surface property changes occurring after repeated thermal cycles. This degradation is particularly problematic in magnetocaloric applications where consistent performance is critical for maintaining energy efficiency advantages.

Cost-effectiveness remains a substantial barrier to widespread implementation. Advanced surface treatments that deliver optimal performance often involve multi-step processes requiring specialized equipment and expertise, significantly increasing production costs. This economic factor has limited the commercial viability of otherwise promising technologies, particularly for large-scale applications where material volumes are substantial.

Compatibility between surface treatments and the unique requirements of magnetocaloric materials presents perhaps the most specialized challenge. Many conventional treatments developed for traditional heat exchangers fail to account for the magnetic properties and specialized thermal requirements of magnetocaloric materials, potentially interfering with the magnetocaloric effect itself.

Chemical treatments such as acid etching, alkaline cleaning, and chemical passivation offer more refined surface modification capabilities. Particularly, chemical etching has shown promise in creating controlled microstructures that enhance nucleate boiling and reduce fouling in magnetocaloric heat exchangers. However, these processes frequently involve environmentally hazardous chemicals and may compromise material integrity through corrosion or hydrogen embrittlement.

Advanced coating technologies represent the current state-of-the-art approach. Thermal spray coatings, physical vapor deposition (PVD), and chemical vapor deposition (CVD) enable the application of specialized materials with tailored thermal and magnetic properties. Notably, hydrophobic and hydrophilic coatings have demonstrated significant improvements in heat transfer coefficients by altering wetting characteristics and bubble dynamics in two-phase heat exchange systems relevant to magnetocaloric applications.

A significant challenge in current surface treatment technologies lies in achieving uniform treatment across complex geometries typical in advanced magnetocaloric heat exchangers. Conventional methods often result in inconsistent surface properties, creating thermal "hot spots" that reduce overall system efficiency and potentially accelerate material degradation through thermal cycling.

Durability presents another major obstacle, as magnetocaloric systems undergo frequent thermal cycling between ambient and operating temperatures. Many current surface treatments exhibit degradation over time, with coating delamination and surface property changes occurring after repeated thermal cycles. This degradation is particularly problematic in magnetocaloric applications where consistent performance is critical for maintaining energy efficiency advantages.

Cost-effectiveness remains a substantial barrier to widespread implementation. Advanced surface treatments that deliver optimal performance often involve multi-step processes requiring specialized equipment and expertise, significantly increasing production costs. This economic factor has limited the commercial viability of otherwise promising technologies, particularly for large-scale applications where material volumes are substantial.

Compatibility between surface treatments and the unique requirements of magnetocaloric materials presents perhaps the most specialized challenge. Many conventional treatments developed for traditional heat exchangers fail to account for the magnetic properties and specialized thermal requirements of magnetocaloric materials, potentially interfering with the magnetocaloric effect itself.

Current Surface Optimization Solutions for Magnetocaloric Systems

01 Chemical surface treatments for heat exchangers

Various chemical treatments can be applied to heat exchanger surfaces to optimize performance. These treatments include acid cleaning, alkaline cleaning, and passivation processes that remove contaminants, scale, and oxidation layers. Chemical treatments can improve heat transfer efficiency by creating cleaner surfaces with better thermal conductivity. Additionally, certain chemical processes can create protective layers that prevent future corrosion and fouling, extending the operational life of heat exchangers.- Chemical surface treatments for heat exchangers: Chemical treatments are applied to heat exchanger surfaces to improve thermal performance and durability. These treatments include acid cleaning, passivation, and chemical conversion coatings that modify the surface properties. Such treatments can remove contaminants, create protective layers, and enhance heat transfer efficiency by optimizing surface characteristics at the microscopic level.

- Hydrophilic and hydrophobic surface modifications: Surface modifications that alter the wettability of heat exchanger surfaces can significantly impact thermal performance. Hydrophilic coatings improve water spreading and film formation, enhancing condensation heat transfer, while hydrophobic treatments create water-repellent surfaces that reduce fouling and scaling. These modifications can be achieved through various coating technologies or chemical treatments that alter surface energy.

- Micro and nano-structured surface texturing: Creating micro and nano-scale textures on heat exchanger surfaces can dramatically improve heat transfer efficiency. These engineered surface structures increase the effective surface area and can create beneficial flow patterns that enhance convective heat transfer. Techniques include mechanical processing, chemical etching, laser texturing, and additive manufacturing to create optimized surface geometries.

- Anti-fouling and anti-corrosion treatments: Specialized surface treatments are developed to prevent fouling and corrosion in heat exchangers, which can significantly degrade performance over time. These include protective coatings, inhibitor treatments, and surface modifications that resist the adhesion of contaminants or the formation of corrosion products. Such treatments extend equipment life and maintain optimal thermal performance in challenging operating environments.

- Advanced coating technologies for thermal conductivity enhancement: Innovative coating technologies are applied to heat exchanger surfaces to enhance thermal conductivity and heat transfer efficiency. These include thermally conductive polymer coatings, metal-ceramic composites, and thin-film deposition techniques. Such coatings can be engineered to provide an optimal balance of thermal performance, durability, and other functional properties like corrosion resistance or reduced friction.

02 Coating technologies for enhanced heat transfer

Specialized coatings can be applied to heat exchanger surfaces to improve thermal performance. These include hydrophobic, hydrophilic, oleophobic, and anti-fouling coatings that modify surface properties. Advanced coating technologies can reduce surface tension, prevent deposit formation, and create more efficient heat transfer interfaces. Some coatings incorporate nanoparticles or other advanced materials to further enhance thermal conductivity while providing protection against environmental factors.Expand Specific Solutions03 Surface texturing and microstructure modification

Modifying the physical structure of heat exchanger surfaces through texturing, etching, or creating microstructures can significantly improve heat transfer efficiency. Techniques include mechanical roughening, laser texturing, and micro-channel formation that increase surface area and create turbulence in fluid flow. These modifications enhance heat transfer by improving fluid dynamics at the surface interface and promoting better thermal contact. Controlled surface roughness can also reduce fouling by preventing the adhesion of deposits.Expand Specific Solutions04 Electrochemical surface treatments

Electrochemical processes such as anodizing, electroplating, and electropolishing can be used to optimize heat exchanger surfaces. These treatments create specialized surface layers with enhanced properties including improved corrosion resistance, controlled surface roughness, and modified thermal characteristics. Electrochemical treatments can produce uniform surface modifications even on complex geometries, allowing for precise control of surface properties. These processes can also incorporate functional materials into the surface layer to provide additional benefits.Expand Specific Solutions05 Advanced manufacturing techniques for optimized surfaces

Novel manufacturing methods can create heat exchanger surfaces with optimized geometries and properties. These include additive manufacturing, precision machining, and advanced forming techniques that enable complex surface designs not possible with traditional manufacturing. These methods allow for the creation of engineered surfaces with features specifically designed to enhance heat transfer, such as fins, dimples, or other flow-disrupting geometries. Advanced manufacturing also enables the integration of multiple surface optimization strategies into a single component.Expand Specific Solutions

Leading Companies in Magnetocaloric Heat Exchange Industry

The magnetocaloric heat exchanger surface treatment optimization market is currently in an early growth phase, characterized by increasing R&D investments and emerging commercial applications. The global market size is estimated to reach $300-400 million by 2025, driven by demand for energy-efficient cooling technologies. Leading players include Cooltech Applications SAS, which pioneered commercial magnetocaloric refrigeration systems, and VACUUMSCHMELZE GmbH, specializing in advanced magnetic materials. Major corporations like Toshiba, Mitsubishi Electric, and Siemens are investing heavily in this technology, while research institutions such as Fraunhofer-Gesellschaft and Xi'an Jiaotong University are advancing fundamental innovations. MagnoTherm Solutions represents the new wave of specialized startups focusing exclusively on magnetocaloric cooling technologies, promising up to 30% greater energy efficiency than conventional systems.

Cooltech Applications SAS

Technical Solution: Cooltech Applications has developed Advanced Magnetocaloric System (AMS) technology that optimizes heat exchanger surface treatments through a proprietary coating process. Their approach involves applying specialized nano-coatings to heat exchanger surfaces that enhance thermal conductivity while minimizing corrosion in magnetocaloric systems. The company's heat exchangers feature multi-layered surface treatments that create microscopic structures optimized for fluid dynamics, reducing boundary layer effects and improving heat transfer coefficients by up to 30%. Their regenerators incorporate gadolinium alloys with precisely engineered surface treatments to maximize the magnetocaloric effect while maintaining durability during thermal cycling. Cooltech has demonstrated commercial refrigeration units achieving temperature spans of 25°C with significantly improved efficiency compared to conventional vapor compression systems.

Strengths: Industry-leading expertise in magnetocaloric materials and system integration; proprietary surface treatment technology that enhances both thermal performance and longevity. Weaknesses: Higher initial manufacturing costs compared to conventional heat exchangers; technology still requires specialized production facilities limiting scalability.

VACUUMSCHMELZE GmbH & Co. KG

Technical Solution: VACUUMSCHMELZE has pioneered advanced surface treatment technologies specifically for magnetocaloric materials used in heat exchanger applications. Their approach centers on specialized metallurgical processes that optimize the interface between magnetocaloric materials and heat transfer fluids. The company has developed VITROPERM® and VACODYM® materials with engineered surface structures that enhance the magnetocaloric effect while providing superior corrosion resistance. Their surface treatment process involves precision vacuum deposition techniques that create nanoscale surface modifications, improving thermal conductivity at material boundaries. VACUUMSCHMELZE's heat exchangers incorporate rare-earth alloys with customized surface treatments that maintain performance stability over thousands of magnetization cycles. Their technology enables efficient heat transfer while minimizing hysteresis losses, a critical factor in magnetocaloric system efficiency.

Strengths: Exceptional expertise in specialized magnetic materials and surface engineering; proprietary vacuum metallurgical processes that create highly optimized interfaces. Weaknesses: Reliance on rare earth materials increases cost and supply chain vulnerability; complex manufacturing processes require significant capital investment.

Key Patents and Innovations in Heat Exchanger Surface Engineering

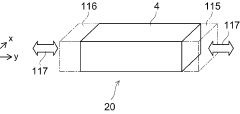

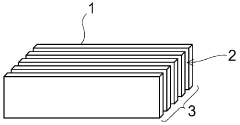

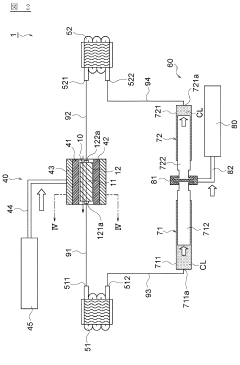

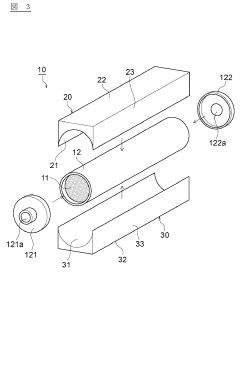

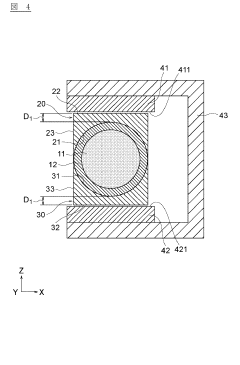

Heat exchanger and magnetic refrigeration system

PatentWO2012056577A1

Innovation

- A heat exchanger design featuring a base with a magnetocaloric effect material and heat conducting portions with higher thermal conductivity than the base, arranged in an isotropic and discontinuous pattern to minimize axial heat conduction and enhance mechanical strength, while optimizing the arrangement of heat conducting elements within the container to improve heat exchange efficiency.

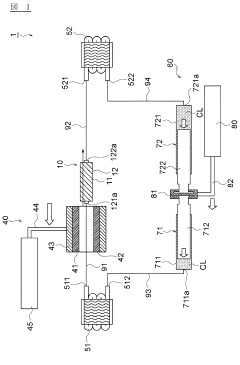

Heat exchanger and magnetic heat pump device

PatentInactiveJP2020071007A

Innovation

- A heat exchanger with a cylindrical case containing a magnetocaloric effect material and ferromagnetic materials attached to its outer surface, divided into opposing surfaces to enhance magnetic flux density, and a magnetic heat pump device with a magnetic field applying device to manipulate the magnetic field.

Environmental Impact and Sustainability Considerations

The optimization of surface treatments for magnetocaloric heat exchangers carries significant environmental implications that must be carefully considered in technology development. Traditional cooling systems rely heavily on refrigerants with high global warming potential (GWP), whereas magnetocaloric technology offers a promising alternative with potentially lower environmental impact. However, the surface treatment processes themselves present environmental challenges that require thorough assessment.

Chemical treatments used in optimizing heat exchanger surfaces often involve hazardous substances such as acids, solvents, and heavy metals. These chemicals can contribute to water pollution, soil contamination, and air quality degradation if not properly managed throughout their lifecycle. Particularly concerning are chromium-based passivation treatments and certain fluoride-containing compounds that persist in the environment and may bioaccumulate in living organisms.

Energy consumption during surface treatment processes represents another environmental consideration. Many advanced surface modification techniques require high-temperature processing or energy-intensive plasma treatments. The environmental benefits of more efficient magnetocaloric systems must be weighed against the energy expenditure and associated carbon emissions during manufacturing and surface treatment operations.

Material selection for surface treatments directly impacts sustainability metrics. Rare earth elements often used in magnetocaloric materials face supply constraints and their extraction typically involves environmentally damaging mining practices. Developing surface treatments that reduce reliance on these critical materials or enable the use of more abundant alternatives would enhance the sustainability profile of magnetocaloric systems.

Lifecycle assessment (LCA) studies indicate that optimized surface treatments can extend the operational lifespan of magnetocaloric heat exchangers, thereby reducing waste generation and resource consumption associated with system replacement. Treatments that prevent corrosion and fouling not only improve performance but also contribute to sustainability through extended service life and reduced maintenance requirements.

Water consumption during surface preparation and treatment processes presents additional environmental challenges, particularly in water-stressed regions. Advanced techniques such as dry mechanical treatments or water-efficient chemical processes can significantly reduce the water footprint of magnetocaloric system manufacturing. Closed-loop water recycling systems have demonstrated potential to reduce freshwater consumption by up to 80% in some surface treatment applications.

Regulatory frameworks increasingly emphasize environmental compliance for manufacturing processes. The development of surface treatments must therefore align with evolving environmental standards such as REACH in Europe and similar regulations worldwide. Environmentally benign alternatives to traditional surface treatments, including bio-based coatings and green chemistry approaches, represent promising research directions that could enhance both performance and sustainability of magnetocaloric systems.

Chemical treatments used in optimizing heat exchanger surfaces often involve hazardous substances such as acids, solvents, and heavy metals. These chemicals can contribute to water pollution, soil contamination, and air quality degradation if not properly managed throughout their lifecycle. Particularly concerning are chromium-based passivation treatments and certain fluoride-containing compounds that persist in the environment and may bioaccumulate in living organisms.

Energy consumption during surface treatment processes represents another environmental consideration. Many advanced surface modification techniques require high-temperature processing or energy-intensive plasma treatments. The environmental benefits of more efficient magnetocaloric systems must be weighed against the energy expenditure and associated carbon emissions during manufacturing and surface treatment operations.

Material selection for surface treatments directly impacts sustainability metrics. Rare earth elements often used in magnetocaloric materials face supply constraints and their extraction typically involves environmentally damaging mining practices. Developing surface treatments that reduce reliance on these critical materials or enable the use of more abundant alternatives would enhance the sustainability profile of magnetocaloric systems.

Lifecycle assessment (LCA) studies indicate that optimized surface treatments can extend the operational lifespan of magnetocaloric heat exchangers, thereby reducing waste generation and resource consumption associated with system replacement. Treatments that prevent corrosion and fouling not only improve performance but also contribute to sustainability through extended service life and reduced maintenance requirements.

Water consumption during surface preparation and treatment processes presents additional environmental challenges, particularly in water-stressed regions. Advanced techniques such as dry mechanical treatments or water-efficient chemical processes can significantly reduce the water footprint of magnetocaloric system manufacturing. Closed-loop water recycling systems have demonstrated potential to reduce freshwater consumption by up to 80% in some surface treatment applications.

Regulatory frameworks increasingly emphasize environmental compliance for manufacturing processes. The development of surface treatments must therefore align with evolving environmental standards such as REACH in Europe and similar regulations worldwide. Environmentally benign alternatives to traditional surface treatments, including bio-based coatings and green chemistry approaches, represent promising research directions that could enhance both performance and sustainability of magnetocaloric systems.

Material Science Advancements for Magnetocaloric Applications

Recent advancements in material science have significantly propelled the development of magnetocaloric applications, particularly in the context of heat exchanger surface treatments. The magnetocaloric effect (MCE), characterized by a material's temperature change when exposed to varying magnetic fields, has gained substantial attention for its potential in energy-efficient cooling systems. Material science innovations have focused on enhancing the performance, durability, and efficiency of magnetocaloric materials through sophisticated surface treatments and novel material compositions.

Gadolinium-based alloys have traditionally dominated the magnetocaloric materials landscape, but recent research has shifted toward rare-earth-lean or rare-earth-free alternatives such as La(Fe,Si)13-based compounds, Heusler alloys, and Fe2P-type materials. These alternatives offer comparable magnetocaloric properties while addressing sustainability concerns associated with rare earth elements. Surface engineering techniques, including atomic layer deposition, plasma treatment, and chemical vapor deposition, have been instrumental in optimizing the interface properties of these materials.

Nanostructured coatings represent a breakthrough in heat exchanger surface treatments for magnetocaloric systems. These coatings, often composed of ceramic materials, metallic alloys, or composite structures, significantly enhance heat transfer efficiency while providing corrosion resistance. Advanced deposition techniques allow precise control over coating thickness, ranging from nanometers to micrometers, enabling optimization of thermal conductivity without compromising the mechanical integrity of the base material.

Anti-corrosion treatments have emerged as critical for extending the operational lifespan of magnetocaloric systems. Innovative approaches include hydrophobic coatings that prevent moisture accumulation, sacrificial anodic layers that protect against galvanic corrosion, and self-healing polymer coatings that automatically repair minor surface damage. These treatments address the challenging operating conditions of magnetocaloric systems, which often involve temperature cycling and exposure to various heat transfer fluids.

Thermal interface materials (TIMs) have undergone substantial evolution, with graphene-based composites, metal-matrix composites, and phase-change materials showing promising results in reducing thermal resistance at material interfaces. These advanced TIMs facilitate more efficient heat transfer between the magnetocaloric material and the heat exchange medium, thereby improving the overall coefficient of performance of magnetocaloric cooling systems.

Surface texturing techniques, including laser ablation, chemical etching, and mechanical micro-machining, have been employed to create optimized surface topographies that enhance heat transfer through increased surface area and improved fluid dynamics. Research indicates that hierarchical surface structures, combining micro and nano-scale features, can achieve up to 40% improvement in heat transfer coefficients compared to conventional smooth surfaces.

Computational materials science has accelerated the development cycle through predictive modeling of surface-fluid interactions, thermal boundary resistances, and long-term material degradation. Machine learning algorithms have been particularly effective in identifying optimal surface treatment parameters for specific operating conditions, reducing the need for extensive experimental testing.

Gadolinium-based alloys have traditionally dominated the magnetocaloric materials landscape, but recent research has shifted toward rare-earth-lean or rare-earth-free alternatives such as La(Fe,Si)13-based compounds, Heusler alloys, and Fe2P-type materials. These alternatives offer comparable magnetocaloric properties while addressing sustainability concerns associated with rare earth elements. Surface engineering techniques, including atomic layer deposition, plasma treatment, and chemical vapor deposition, have been instrumental in optimizing the interface properties of these materials.

Nanostructured coatings represent a breakthrough in heat exchanger surface treatments for magnetocaloric systems. These coatings, often composed of ceramic materials, metallic alloys, or composite structures, significantly enhance heat transfer efficiency while providing corrosion resistance. Advanced deposition techniques allow precise control over coating thickness, ranging from nanometers to micrometers, enabling optimization of thermal conductivity without compromising the mechanical integrity of the base material.

Anti-corrosion treatments have emerged as critical for extending the operational lifespan of magnetocaloric systems. Innovative approaches include hydrophobic coatings that prevent moisture accumulation, sacrificial anodic layers that protect against galvanic corrosion, and self-healing polymer coatings that automatically repair minor surface damage. These treatments address the challenging operating conditions of magnetocaloric systems, which often involve temperature cycling and exposure to various heat transfer fluids.

Thermal interface materials (TIMs) have undergone substantial evolution, with graphene-based composites, metal-matrix composites, and phase-change materials showing promising results in reducing thermal resistance at material interfaces. These advanced TIMs facilitate more efficient heat transfer between the magnetocaloric material and the heat exchange medium, thereby improving the overall coefficient of performance of magnetocaloric cooling systems.

Surface texturing techniques, including laser ablation, chemical etching, and mechanical micro-machining, have been employed to create optimized surface topographies that enhance heat transfer through increased surface area and improved fluid dynamics. Research indicates that hierarchical surface structures, combining micro and nano-scale features, can achieve up to 40% improvement in heat transfer coefficients compared to conventional smooth surfaces.

Computational materials science has accelerated the development cycle through predictive modeling of surface-fluid interactions, thermal boundary resistances, and long-term material degradation. Machine learning algorithms have been particularly effective in identifying optimal surface treatment parameters for specific operating conditions, reducing the need for extensive experimental testing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!