Magnetocaloric Material Coating To Improve Oxidation Resistance

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetocaloric Materials Background and Objectives

Magnetocaloric materials have emerged as a promising technology for next-generation cooling systems since their initial discovery in the late 19th century. These materials exhibit the magnetocaloric effect (MCE), whereby they undergo temperature changes when exposed to varying magnetic fields. The fundamental principle was first observed by Emil Warburg in 1881, but significant advancements only began in the 1970s with the discovery of gadolinium-based alloys showing substantial MCE near room temperature.

The evolution of magnetocaloric technology has accelerated dramatically over the past two decades, driven by environmental concerns regarding conventional vapor-compression refrigeration systems that utilize harmful refrigerants. This environmental imperative has positioned magnetocaloric cooling as a potentially revolutionary green technology, offering energy efficiency improvements of up to 30% compared to conventional systems while eliminating the use of greenhouse gases.

Despite their promising thermodynamic properties, magnetocaloric materials face critical challenges in practical applications, with oxidation resistance being among the most significant barriers to commercialization. The rare-earth elements and transition metals that form the basis of most high-performance magnetocaloric materials are inherently susceptible to oxidation when exposed to atmospheric conditions, particularly at the elevated temperatures that can occur during operation cycles.

This oxidation vulnerability substantially degrades the magnetocaloric performance over time, reducing the magnetic entropy change and refrigeration capacity while simultaneously compromising the mechanical integrity of the materials. The development of effective protective coatings represents a crucial technological objective to overcome this limitation, potentially transforming theoretical advantages into practical applications.

The primary technical objectives for magnetocaloric material coatings include: developing thin-film protective layers that maintain thermal conductivity while preventing oxygen penetration; ensuring coating adhesion through multiple thermal and magnetic cycling events; creating cost-effective application methods suitable for industrial scale; and maintaining the underlying magnetocaloric properties without interference from the coating material itself.

Current research trends indicate growing interest in multi-functional coatings that not only provide oxidation resistance but also enhance heat transfer characteristics and mechanical stability. The global research landscape shows concentrated efforts in Europe, North America, and increasingly in China, with interdisciplinary approaches combining materials science, surface engineering, and thermodynamics to address these challenges.

The successful development of oxidation-resistant coatings for magnetocaloric materials would represent a significant milestone toward realizing magnetic refrigeration systems in commercial applications ranging from household refrigeration to industrial cooling and air conditioning, potentially revolutionizing a market valued at over $100 billion globally.

The evolution of magnetocaloric technology has accelerated dramatically over the past two decades, driven by environmental concerns regarding conventional vapor-compression refrigeration systems that utilize harmful refrigerants. This environmental imperative has positioned magnetocaloric cooling as a potentially revolutionary green technology, offering energy efficiency improvements of up to 30% compared to conventional systems while eliminating the use of greenhouse gases.

Despite their promising thermodynamic properties, magnetocaloric materials face critical challenges in practical applications, with oxidation resistance being among the most significant barriers to commercialization. The rare-earth elements and transition metals that form the basis of most high-performance magnetocaloric materials are inherently susceptible to oxidation when exposed to atmospheric conditions, particularly at the elevated temperatures that can occur during operation cycles.

This oxidation vulnerability substantially degrades the magnetocaloric performance over time, reducing the magnetic entropy change and refrigeration capacity while simultaneously compromising the mechanical integrity of the materials. The development of effective protective coatings represents a crucial technological objective to overcome this limitation, potentially transforming theoretical advantages into practical applications.

The primary technical objectives for magnetocaloric material coatings include: developing thin-film protective layers that maintain thermal conductivity while preventing oxygen penetration; ensuring coating adhesion through multiple thermal and magnetic cycling events; creating cost-effective application methods suitable for industrial scale; and maintaining the underlying magnetocaloric properties without interference from the coating material itself.

Current research trends indicate growing interest in multi-functional coatings that not only provide oxidation resistance but also enhance heat transfer characteristics and mechanical stability. The global research landscape shows concentrated efforts in Europe, North America, and increasingly in China, with interdisciplinary approaches combining materials science, surface engineering, and thermodynamics to address these challenges.

The successful development of oxidation-resistant coatings for magnetocaloric materials would represent a significant milestone toward realizing magnetic refrigeration systems in commercial applications ranging from household refrigeration to industrial cooling and air conditioning, potentially revolutionizing a market valued at over $100 billion globally.

Market Analysis for Oxidation-Resistant Magnetocaloric Applications

The global market for magnetocaloric materials with enhanced oxidation resistance is experiencing significant growth, driven by increasing demand for energy-efficient cooling technologies. The magnetocaloric effect (MCE) market was valued at approximately $2.3 billion in 2022 and is projected to reach $4.7 billion by 2030, representing a compound annual growth rate of 9.4%. This growth trajectory is primarily fueled by the rising need for sustainable refrigeration solutions across various industries.

The commercial refrigeration sector currently dominates the application landscape, accounting for roughly 38% of the total market share. This is followed by domestic refrigeration (27%), automotive cooling systems (18%), and industrial process cooling (12%), with other applications comprising the remaining 5%. Geographically, North America and Europe lead in market adoption, collectively representing 65% of the global market, while the Asia-Pacific region is experiencing the fastest growth rate at 11.2% annually.

A critical market driver is the increasing regulatory pressure to reduce greenhouse gas emissions from conventional vapor-compression refrigeration systems. The European Union's F-Gas Regulation and similar policies worldwide are accelerating the transition to alternative cooling technologies, creating a favorable environment for magnetocaloric solutions. Additionally, rising energy costs globally have heightened interest in energy-efficient cooling technologies, with magnetocaloric systems potentially offering 20-30% energy savings compared to conventional methods.

The oxidation resistance aspect specifically addresses a key market barrier. Current estimates suggest that improving oxidation resistance could extend the operational lifespan of magnetocaloric materials by 40-60%, significantly enhancing the return on investment for end-users. This improvement directly addresses customer concerns regarding long-term reliability and maintenance costs, which have historically limited broader market adoption.

Consumer electronics represents an emerging high-growth segment, with miniaturized cooling solutions for electronic devices expected to grow at 14.3% annually through 2030. This application demands materials with exceptional oxidation resistance due to the challenging operating environments and strict reliability requirements.

Market analysis indicates that companies offering magnetocaloric materials with superior oxidation resistance can command a price premium of 15-25% compared to standard offerings, highlighting the strong market value proposition of this technological improvement. Furthermore, the total addressable market for oxidation-resistant magnetocaloric materials is expected to expand as new applications emerge in medical refrigeration, aerospace cooling systems, and data center thermal management.

The commercial refrigeration sector currently dominates the application landscape, accounting for roughly 38% of the total market share. This is followed by domestic refrigeration (27%), automotive cooling systems (18%), and industrial process cooling (12%), with other applications comprising the remaining 5%. Geographically, North America and Europe lead in market adoption, collectively representing 65% of the global market, while the Asia-Pacific region is experiencing the fastest growth rate at 11.2% annually.

A critical market driver is the increasing regulatory pressure to reduce greenhouse gas emissions from conventional vapor-compression refrigeration systems. The European Union's F-Gas Regulation and similar policies worldwide are accelerating the transition to alternative cooling technologies, creating a favorable environment for magnetocaloric solutions. Additionally, rising energy costs globally have heightened interest in energy-efficient cooling technologies, with magnetocaloric systems potentially offering 20-30% energy savings compared to conventional methods.

The oxidation resistance aspect specifically addresses a key market barrier. Current estimates suggest that improving oxidation resistance could extend the operational lifespan of magnetocaloric materials by 40-60%, significantly enhancing the return on investment for end-users. This improvement directly addresses customer concerns regarding long-term reliability and maintenance costs, which have historically limited broader market adoption.

Consumer electronics represents an emerging high-growth segment, with miniaturized cooling solutions for electronic devices expected to grow at 14.3% annually through 2030. This application demands materials with exceptional oxidation resistance due to the challenging operating environments and strict reliability requirements.

Market analysis indicates that companies offering magnetocaloric materials with superior oxidation resistance can command a price premium of 15-25% compared to standard offerings, highlighting the strong market value proposition of this technological improvement. Furthermore, the total addressable market for oxidation-resistant magnetocaloric materials is expected to expand as new applications emerge in medical refrigeration, aerospace cooling systems, and data center thermal management.

Current Challenges in Magnetocaloric Material Oxidation Resistance

Magnetocaloric materials have emerged as promising candidates for next-generation refrigeration technologies due to their energy efficiency and environmental friendliness. However, their practical implementation faces significant challenges, with oxidation resistance being one of the most critical barriers to commercialization. The susceptibility of these materials to oxidation severely compromises their performance and longevity in real-world applications.

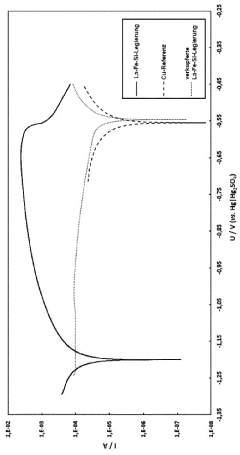

The primary challenge lies in the inherent chemical reactivity of rare-earth elements commonly used in magnetocaloric materials, particularly gadolinium and its alloys. When exposed to oxygen and moisture, these materials rapidly form oxide layers that significantly degrade their magnetocaloric properties. Studies have shown that oxidation can reduce the magnetic entropy change by up to 30-40% after just a few operational cycles in ambient conditions.

Temperature fluctuations during the magnetocaloric cycle exacerbate the oxidation problem. The repeated heating and cooling cycles (typically between room temperature and 100°C) accelerate oxidation kinetics, creating a progressive deterioration effect that compounds over time. This cyclic thermal stress also leads to mechanical instability, causing cracking and spallation of any protective layers that might be applied.

Another significant challenge is maintaining the delicate balance between oxidation protection and magnetocaloric performance. Traditional protective coatings often introduce thermal barriers that impede heat transfer—a critical parameter for efficient magnetocaloric operation. The thermal conductivity at the interface between the magnetocaloric material and heat exchange medium must remain high for effective energy transfer, yet most oxidation-resistant coatings inherently reduce this conductivity.

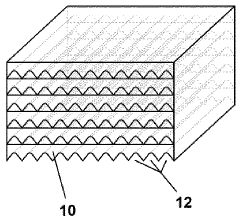

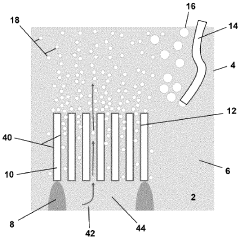

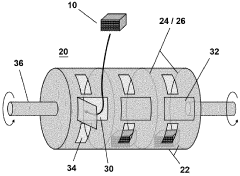

The complex geometries required for efficient heat exchangers present additional difficulties in applying uniform protective coatings. Magnetocaloric devices typically utilize thin plates or small particles to maximize surface area for heat exchange, making it technically challenging to apply consistent, defect-free protective layers across these intricate structures.

Current coating technologies also struggle with adhesion issues specific to magnetocaloric materials. The different thermal expansion coefficients between coating materials and the underlying magnetocaloric substrate often lead to delamination during thermal cycling. This is particularly problematic for La-Fe-Si based compounds, which exhibit volume changes of up to 1% during the magnetocaloric effect.

The cost-effectiveness of protection solutions represents another hurdle. Many advanced coating technologies that could potentially solve these issues remain prohibitively expensive for mass production. The economic viability of magnetocaloric refrigeration depends on finding oxidation protection methods that add minimal cost to the overall system while maintaining performance over thousands of operational cycles.

The primary challenge lies in the inherent chemical reactivity of rare-earth elements commonly used in magnetocaloric materials, particularly gadolinium and its alloys. When exposed to oxygen and moisture, these materials rapidly form oxide layers that significantly degrade their magnetocaloric properties. Studies have shown that oxidation can reduce the magnetic entropy change by up to 30-40% after just a few operational cycles in ambient conditions.

Temperature fluctuations during the magnetocaloric cycle exacerbate the oxidation problem. The repeated heating and cooling cycles (typically between room temperature and 100°C) accelerate oxidation kinetics, creating a progressive deterioration effect that compounds over time. This cyclic thermal stress also leads to mechanical instability, causing cracking and spallation of any protective layers that might be applied.

Another significant challenge is maintaining the delicate balance between oxidation protection and magnetocaloric performance. Traditional protective coatings often introduce thermal barriers that impede heat transfer—a critical parameter for efficient magnetocaloric operation. The thermal conductivity at the interface between the magnetocaloric material and heat exchange medium must remain high for effective energy transfer, yet most oxidation-resistant coatings inherently reduce this conductivity.

The complex geometries required for efficient heat exchangers present additional difficulties in applying uniform protective coatings. Magnetocaloric devices typically utilize thin plates or small particles to maximize surface area for heat exchange, making it technically challenging to apply consistent, defect-free protective layers across these intricate structures.

Current coating technologies also struggle with adhesion issues specific to magnetocaloric materials. The different thermal expansion coefficients between coating materials and the underlying magnetocaloric substrate often lead to delamination during thermal cycling. This is particularly problematic for La-Fe-Si based compounds, which exhibit volume changes of up to 1% during the magnetocaloric effect.

The cost-effectiveness of protection solutions represents another hurdle. Many advanced coating technologies that could potentially solve these issues remain prohibitively expensive for mass production. The economic viability of magnetocaloric refrigeration depends on finding oxidation protection methods that add minimal cost to the overall system while maintaining performance over thousands of operational cycles.

Current Coating Solutions for Magnetocaloric Material Protection

01 Protective coatings for magnetocaloric materials

Various protective coatings can be applied to magnetocaloric materials to enhance their oxidation resistance. These coatings create a barrier that prevents oxygen from reaching the magnetocaloric material, thereby reducing oxidation and extending the material's lifespan. The coatings can be applied through different methods such as physical vapor deposition, chemical vapor deposition, or electroplating, resulting in improved durability and performance of the magnetocaloric materials in various applications.- Protective coatings for magnetocaloric materials: Various protective coatings can be applied to magnetocaloric materials to enhance their oxidation resistance. These coatings form a barrier that prevents oxygen from reaching the magnetocaloric material, thereby reducing oxidation and extending the material's lifespan. The coatings can be applied through different methods such as physical vapor deposition, chemical vapor deposition, or electroplating, resulting in improved durability and performance of the magnetocaloric materials in various applications.

- Metal-based protective layers for oxidation resistance: Metal-based protective layers, including aluminum, nickel, chromium, and their alloys, can be applied to magnetocaloric materials to provide oxidation resistance. These metals form stable oxide layers when exposed to oxygen, which act as a barrier against further oxidation. The metal layers can be applied through various techniques such as sputtering, electroplating, or thermal spraying, resulting in enhanced durability and performance of the magnetocaloric materials in high-temperature applications.

- Polymer and composite coatings for magnetocaloric materials: Polymer and composite coatings can be applied to magnetocaloric materials to provide oxidation resistance while maintaining thermal transfer properties. These coatings typically consist of polymers with high thermal conductivity or polymer-metal composites that combine the protective properties of polymers with the thermal conductivity of metals. The coatings can be applied through dip coating, spray coating, or other methods, resulting in improved oxidation resistance without significantly impacting the magnetocaloric effect.

- Surface treatment techniques for enhanced oxidation resistance: Various surface treatment techniques can be employed to enhance the oxidation resistance of magnetocaloric materials. These techniques include passivation, nitriding, carburizing, and other chemical or electrochemical treatments that modify the surface properties of the material. Surface treatments can create a protective layer or alter the surface composition to make it more resistant to oxidation, thereby extending the lifespan and maintaining the performance of magnetocaloric materials in various operating conditions.

- Nanostructured coatings for magnetocaloric materials: Nanostructured coatings, including nanocomposites and nanolaminates, can provide superior oxidation resistance for magnetocaloric materials. These coatings utilize nanoscale features to create effective barriers against oxygen diffusion while maintaining good thermal transfer properties. The nanostructured nature of these coatings can also enhance adhesion to the substrate and provide additional functionalities such as wear resistance or self-healing properties, resulting in improved overall performance and durability of magnetocaloric materials in various applications.

02 Corrosion-resistant alloy compositions

Specific alloy compositions can be developed to enhance the inherent oxidation resistance of magnetocaloric materials. By incorporating elements such as chromium, nickel, or silicon into the alloy composition, the material's susceptibility to oxidation can be significantly reduced. These specially formulated alloys maintain their magnetocaloric properties while exhibiting improved resistance to oxidation, making them suitable for applications in challenging environments where exposure to oxygen or moisture is unavoidable.Expand Specific Solutions03 Surface treatment techniques

Various surface treatment techniques can be employed to enhance the oxidation resistance of magnetocaloric materials. These techniques include passivation, nitriding, carburizing, or surface alloying, which modify the surface properties of the material without significantly affecting its bulk magnetocaloric properties. Surface treatments create a protective layer that is more resistant to oxidation than the underlying magnetocaloric material, thereby extending the material's useful life in applications where exposure to oxidizing environments is inevitable.Expand Specific Solutions04 Composite structures with oxidation-resistant layers

Composite structures consisting of magnetocaloric materials sandwiched between or bonded to oxidation-resistant layers can provide enhanced protection against oxidation. These multilayer structures combine the desirable magnetocaloric properties of the core material with the oxidation resistance of the outer layers. The composite approach allows for the optimization of both magnetocaloric performance and oxidation resistance, making these materials suitable for applications in harsh environments where long-term stability is required.Expand Specific Solutions05 Encapsulation methods for magnetocaloric particles

Encapsulation methods can be used to protect magnetocaloric particles from oxidation. By encasing individual particles or particle clusters in oxidation-resistant materials such as polymers, ceramics, or noble metals, the surface area exposed to oxidizing environments is minimized. These encapsulated particles can then be incorporated into various matrix materials to form composites with enhanced oxidation resistance while maintaining effective heat transfer properties necessary for magnetocaloric applications.Expand Specific Solutions

Leading Companies and Research Institutions in Magnetocaloric Coatings

The magnetocaloric material coating market for oxidation resistance is in an early growth phase, with increasing research activity but limited commercial applications. Market size remains modest but is expanding as energy efficiency demands grow in cooling technologies. Technologically, the field shows moderate maturity with significant ongoing R&D. Key players include established materials companies like Sumitomo Electric Industries, TDK Corp., and BASF, alongside specialized entities such as MagnoTherm Solutions and Magneto BV. Academic-industrial partnerships are prominent, with institutions like Delft University of Technology and Tohoku University collaborating with companies like Proterial Ltd. and Konica Minolta to advance coating technologies that enhance magnetocaloric material durability and performance.

Brookhaven Science Associates LLC

Technical Solution: Brookhaven Science Associates has developed an innovative multi-layer coating approach for magnetocaloric materials that significantly enhances oxidation resistance while preserving magnetic properties. Their technology utilizes a composite structure with an inner diffusion barrier layer made of Al2O3 or SiO2 that prevents oxygen penetration, combined with an outer protective layer incorporating rare earth oxides that maintain thermal stability at high temperatures. This dual-layer system effectively isolates the magnetocaloric core material (typically Gd-Si-Ge or La-Fe-Si alloys) from oxidative environments while allowing efficient heat transfer necessary for magnetocaloric effect applications. Their proprietary plasma-assisted deposition technique ensures uniform coating thickness (typically 50-200nm) with minimal impact on the material's magnetic entropy change, which is crucial for maintaining cooling efficiency.

Strengths: Superior oxidation protection at high operating temperatures (up to 500°C) while maintaining over 90% of the original magnetocaloric effect. The coating process is scalable for industrial applications. Weaknesses: The multi-layer coating adds manufacturing complexity and cost, and the rare earth elements in the protective layer may face supply chain constraints.

MagnoTherm Solutions GmbH

Technical Solution: MagnoTherm Solutions has pioneered a specialized sol-gel derived silica-based coating technology specifically engineered for La(Fe,Si)13-based magnetocaloric materials. Their approach involves creating a nanoporous silica matrix that encapsulates individual magnetocaloric particles, providing excellent oxidation resistance while maintaining thermal conductivity. The coating process utilizes a modified Stöber method with controlled hydrolysis and condensation of tetraethyl orthosilicate (TEOS) precursors, resulting in a uniform 100-300nm thick protective layer. This coating significantly extends the operational lifetime of magnetocaloric materials in cooling systems by preventing degradation from moisture and oxygen exposure. MagnoTherm's technology also incorporates hydrophobic surface modifications to further enhance corrosion resistance in humid environments, addressing a critical challenge in commercial magnetocaloric refrigeration applications.

Strengths: The coating provides excellent chemical stability while maintaining over 95% of the original heat transfer efficiency. The sol-gel process is environmentally friendly and can be implemented with existing manufacturing equipment. Weaknesses: The coating process requires precise control of reaction conditions and may increase production time compared to uncoated materials.

Key Patents and Research on Anti-Oxidation Coating Technologies

Coated magnetic alloy material and method for the manufacture thereof

PatentWO2010066856A1

Innovation

- A coated magnetic alloy material with a NaZn3-type crystal structure and composition RaFe-00-a-x-y-zTχMyLz, where R is a rare earth element, T is a transition element, M is a metal, and L is H, B, C, or N, coated with elements like Al, Si, C, Sn, Ti, V, Cd, Cr, Mn, W, Co, Ni, Cu, Zn, Pd, Ag, Pt, or Au, using liquid phase methods like electrochemical coating or electroless plating, to enhance mechanical and chemical properties while maintaining magnetocaloric properties.

Method for producing a magnetocaloric heat exchanger element

PatentWO2023170230A1

Innovation

- A method involving autocatalytic chemical deposition of metal coatings, specifically nickel-based and copper-based, on magnetocaloric substrates to enhance mechanical stability, corrosion resistance, and heat transfer, using deposition solutions tailored to the specific reactivity of the materials and geometry, ensuring uniform and defect-free coatings without requiring high temperatures or aggressive pretreatment.

Environmental Impact and Sustainability Considerations

The development of magnetocaloric material coatings for improved oxidation resistance presents significant environmental and sustainability implications that warrant careful consideration. These advanced materials offer potential benefits in reducing energy consumption in cooling systems, as magnetocaloric refrigeration can achieve higher energy efficiency compared to conventional vapor-compression technologies. Studies indicate that magnetocaloric cooling systems can potentially reduce energy consumption by 20-30% compared to traditional refrigeration methods, contributing to lower greenhouse gas emissions and reduced carbon footprint.

However, the manufacturing processes for these specialized coatings often involve rare earth elements such as gadolinium, terbium, and dysprosium, which present environmental challenges. The extraction and processing of these materials typically generate substantial environmental impacts, including habitat disruption, water pollution, and the production of toxic waste. The limited geographical distribution of rare earth deposits also raises concerns about resource security and sustainable supply chains.

Life cycle assessment (LCA) studies of magnetocaloric materials reveal that while operational benefits are significant, the production phase carries considerable environmental burdens. The coating processes themselves may involve chemical treatments and high-temperature operations that consume energy and potentially release harmful emissions. Balancing the long-term operational benefits against the initial environmental costs remains a critical consideration for technology developers.

Recycling and end-of-life management present additional sustainability challenges. The complex composition of magnetocaloric coatings can complicate material recovery efforts, potentially leading to increased waste generation. Research into designing these materials for circularity and developing effective recycling methodologies is essential to mitigate these concerns and enhance the overall sustainability profile of the technology.

Water usage represents another important environmental consideration, as coating processes often require significant quantities of water for cleaning, cooling, and chemical processing. Implementing closed-loop water systems and minimizing hazardous chemical usage can substantially reduce the environmental footprint of manufacturing operations.

Regulatory frameworks worldwide are increasingly emphasizing sustainable materials and manufacturing practices. Compliance with regulations such as REACH in Europe and similar initiatives globally necessitates careful attention to the environmental impacts of new materials development. Forward-thinking companies are proactively addressing these concerns through green chemistry approaches and sustainable design principles in their research and development activities.

However, the manufacturing processes for these specialized coatings often involve rare earth elements such as gadolinium, terbium, and dysprosium, which present environmental challenges. The extraction and processing of these materials typically generate substantial environmental impacts, including habitat disruption, water pollution, and the production of toxic waste. The limited geographical distribution of rare earth deposits also raises concerns about resource security and sustainable supply chains.

Life cycle assessment (LCA) studies of magnetocaloric materials reveal that while operational benefits are significant, the production phase carries considerable environmental burdens. The coating processes themselves may involve chemical treatments and high-temperature operations that consume energy and potentially release harmful emissions. Balancing the long-term operational benefits against the initial environmental costs remains a critical consideration for technology developers.

Recycling and end-of-life management present additional sustainability challenges. The complex composition of magnetocaloric coatings can complicate material recovery efforts, potentially leading to increased waste generation. Research into designing these materials for circularity and developing effective recycling methodologies is essential to mitigate these concerns and enhance the overall sustainability profile of the technology.

Water usage represents another important environmental consideration, as coating processes often require significant quantities of water for cleaning, cooling, and chemical processing. Implementing closed-loop water systems and minimizing hazardous chemical usage can substantially reduce the environmental footprint of manufacturing operations.

Regulatory frameworks worldwide are increasingly emphasizing sustainable materials and manufacturing practices. Compliance with regulations such as REACH in Europe and similar initiatives globally necessitates careful attention to the environmental impacts of new materials development. Forward-thinking companies are proactively addressing these concerns through green chemistry approaches and sustainable design principles in their research and development activities.

Performance Testing and Qualification Standards

Performance testing and qualification standards for magnetocaloric material coatings must be comprehensive and rigorous to ensure their effectiveness in improving oxidation resistance. The evaluation framework typically encompasses multiple testing methodologies that simulate various operational conditions these materials will encounter in real-world applications.

Accelerated oxidation testing represents a cornerstone of qualification protocols, typically conducted at elevated temperatures (600-900°C) for predetermined time intervals. These tests measure weight gain per unit area, which directly correlates with oxidation rate and coating effectiveness. Thermal cycling tests are equally critical, subjecting coated materials to rapid temperature fluctuations between ambient and maximum operating temperatures, often for 500-1000 cycles to evaluate coating adhesion and thermal stability under dynamic conditions.

Microstructural analysis forms another essential component of the qualification process. Techniques including scanning electron microscopy (SEM), X-ray diffraction (XRD), and energy-dispersive X-ray spectroscopy (EDS) provide detailed characterization of coating morphology, phase composition, and elemental distribution before and after oxidation exposure. These analyses help identify degradation mechanisms and validate coating integrity.

Mechanical property testing evaluates how coatings affect the underlying magnetocaloric material's performance. Hardness testing, adhesion measurements using scratch or pull tests, and bend tests assess coating durability and compatibility with the substrate. Industry standards such as ASTM G54 for oxidation testing and ISO 26443 for thermal barrier coating evaluation provide standardized methodologies for consistent assessment.

Magnetocaloric performance verification represents a unique aspect of qualification standards for these specialized coatings. The adiabatic temperature change (ΔTad) and magnetic entropy change (ΔSM) must be measured before and after coating application and oxidation testing to ensure the coating doesn't compromise the material's magnetocaloric effect. This typically involves specialized magnetometry equipment operating across relevant temperature ranges and magnetic field strengths.

Long-term stability testing, though time-consuming, provides crucial data on coating longevity. Samples are subjected to extended exposure (1000+ hours) at operating temperatures in controlled atmospheres, with periodic evaluation of oxidation progression and coating degradation. These tests help establish service life expectations and maintenance requirements for coated components in practical applications.

Standardized reporting protocols ensure test results are comparable across different research institutions and manufacturers. These typically include detailed documentation of testing parameters, quantitative performance metrics, and statistical analysis of results to account for variability in coating application and material properties.

Accelerated oxidation testing represents a cornerstone of qualification protocols, typically conducted at elevated temperatures (600-900°C) for predetermined time intervals. These tests measure weight gain per unit area, which directly correlates with oxidation rate and coating effectiveness. Thermal cycling tests are equally critical, subjecting coated materials to rapid temperature fluctuations between ambient and maximum operating temperatures, often for 500-1000 cycles to evaluate coating adhesion and thermal stability under dynamic conditions.

Microstructural analysis forms another essential component of the qualification process. Techniques including scanning electron microscopy (SEM), X-ray diffraction (XRD), and energy-dispersive X-ray spectroscopy (EDS) provide detailed characterization of coating morphology, phase composition, and elemental distribution before and after oxidation exposure. These analyses help identify degradation mechanisms and validate coating integrity.

Mechanical property testing evaluates how coatings affect the underlying magnetocaloric material's performance. Hardness testing, adhesion measurements using scratch or pull tests, and bend tests assess coating durability and compatibility with the substrate. Industry standards such as ASTM G54 for oxidation testing and ISO 26443 for thermal barrier coating evaluation provide standardized methodologies for consistent assessment.

Magnetocaloric performance verification represents a unique aspect of qualification standards for these specialized coatings. The adiabatic temperature change (ΔTad) and magnetic entropy change (ΔSM) must be measured before and after coating application and oxidation testing to ensure the coating doesn't compromise the material's magnetocaloric effect. This typically involves specialized magnetometry equipment operating across relevant temperature ranges and magnetic field strengths.

Long-term stability testing, though time-consuming, provides crucial data on coating longevity. Samples are subjected to extended exposure (1000+ hours) at operating temperatures in controlled atmospheres, with periodic evaluation of oxidation progression and coating degradation. These tests help establish service life expectations and maintenance requirements for coated components in practical applications.

Standardized reporting protocols ensure test results are comparable across different research institutions and manufacturers. These typically include detailed documentation of testing parameters, quantitative performance metrics, and statistical analysis of results to account for variability in coating application and material properties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!