Magnetocaloric System Design: Permanent Magnet Arrays Vs Electromagnets

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetocaloric Technology Background and Objectives

Magnetocaloric technology represents a revolutionary approach to cooling systems that has evolved significantly over the past century. The magnetocaloric effect (MCE), first discovered by Emil Warburg in 1881, describes the temperature change of a magnetic material when exposed to a changing magnetic field. This phenomenon remained largely academic until the late 20th century when its potential for energy-efficient refrigeration began to be seriously explored.

The fundamental principle behind magnetocaloric cooling involves the alignment of magnetic moments within certain materials when subjected to a magnetic field, resulting in heat generation. When the magnetic field is removed, these moments randomize, absorbing heat from the surrounding environment. This reversible process forms the basis of magnetic refrigeration cycles that can potentially replace conventional vapor-compression systems.

Recent decades have witnessed accelerated development in magnetocaloric materials, particularly after the discovery of giant magnetocaloric effect materials in the 1990s. Gadolinium and its alloys initially dominated research, but environmental and cost concerns have shifted focus toward rare-earth-lean or rare-earth-free alternatives such as La(Fe,Si)13-based compounds, Fe2P-type materials, and Heusler alloys.

The technological evolution of magnetocaloric systems has been marked by increasing efficiency and practicality. Early prototypes demonstrated proof-of-concept but lacked commercial viability due to limitations in magnetic field generation, heat transfer efficiency, and system integration. Modern designs have progressively addressed these challenges through innovative approaches to magnetic field sources and regenerator designs.

A critical decision point in magnetocaloric system design involves the choice between permanent magnet arrays and electromagnets for generating the required magnetic field. Permanent magnets offer energy efficiency advantages by eliminating continuous power consumption but present challenges in field modulation and system size. Conversely, electromagnets provide greater control over field strength and timing but require continuous electrical input, potentially offsetting energy efficiency gains.

The primary objectives of current magnetocaloric technology research include: developing high-performance, environmentally friendly and cost-effective magnetocaloric materials; optimizing magnetic field generation systems for maximum efficiency and minimum size; enhancing heat transfer mechanisms within regenerators; and creating integrated systems capable of competing with conventional cooling technologies in terms of cost, reliability, and performance.

Industry goals extend beyond mere technical feasibility to achieving practical systems with cooling capacities suitable for commercial and residential applications, while maintaining competitive energy efficiency metrics. The ultimate aim is to develop magnetocaloric cooling systems that can reduce global energy consumption and greenhouse gas emissions associated with conventional refrigeration and air conditioning.

The fundamental principle behind magnetocaloric cooling involves the alignment of magnetic moments within certain materials when subjected to a magnetic field, resulting in heat generation. When the magnetic field is removed, these moments randomize, absorbing heat from the surrounding environment. This reversible process forms the basis of magnetic refrigeration cycles that can potentially replace conventional vapor-compression systems.

Recent decades have witnessed accelerated development in magnetocaloric materials, particularly after the discovery of giant magnetocaloric effect materials in the 1990s. Gadolinium and its alloys initially dominated research, but environmental and cost concerns have shifted focus toward rare-earth-lean or rare-earth-free alternatives such as La(Fe,Si)13-based compounds, Fe2P-type materials, and Heusler alloys.

The technological evolution of magnetocaloric systems has been marked by increasing efficiency and practicality. Early prototypes demonstrated proof-of-concept but lacked commercial viability due to limitations in magnetic field generation, heat transfer efficiency, and system integration. Modern designs have progressively addressed these challenges through innovative approaches to magnetic field sources and regenerator designs.

A critical decision point in magnetocaloric system design involves the choice between permanent magnet arrays and electromagnets for generating the required magnetic field. Permanent magnets offer energy efficiency advantages by eliminating continuous power consumption but present challenges in field modulation and system size. Conversely, electromagnets provide greater control over field strength and timing but require continuous electrical input, potentially offsetting energy efficiency gains.

The primary objectives of current magnetocaloric technology research include: developing high-performance, environmentally friendly and cost-effective magnetocaloric materials; optimizing magnetic field generation systems for maximum efficiency and minimum size; enhancing heat transfer mechanisms within regenerators; and creating integrated systems capable of competing with conventional cooling technologies in terms of cost, reliability, and performance.

Industry goals extend beyond mere technical feasibility to achieving practical systems with cooling capacities suitable for commercial and residential applications, while maintaining competitive energy efficiency metrics. The ultimate aim is to develop magnetocaloric cooling systems that can reduce global energy consumption and greenhouse gas emissions associated with conventional refrigeration and air conditioning.

Market Analysis for Magnetocaloric Cooling Systems

The global magnetocaloric cooling systems market is experiencing significant growth, driven by increasing environmental concerns and stringent regulations on conventional refrigeration technologies. Current market valuations indicate the sector is worth approximately 300 million USD, with projections suggesting expansion to reach 2.5 billion USD by 2030, representing a compound annual growth rate of 23.7% during the forecast period.

The residential segment currently dominates market demand, accounting for nearly 45% of total installations. Commercial applications follow closely at 35%, while industrial applications represent the remaining 20%. This distribution reflects the versatility of magnetocaloric cooling systems across various sectors, with particular growth potential in commercial refrigeration and automotive air conditioning.

Regional analysis reveals North America and Europe as leading markets, collectively representing over 60% of global demand. This dominance stems from stricter environmental regulations and greater consumer willingness to adopt green technologies. The Asia-Pacific region, particularly China and Japan, is emerging as the fastest-growing market with annual growth rates exceeding 28%, driven by rapid industrialization and increasing environmental awareness.

Consumer demand patterns indicate a strong preference for energy-efficient cooling solutions, with surveys showing that 78% of commercial buyers consider energy efficiency a primary purchase factor. Additionally, 65% of residential consumers express willingness to pay premium prices for environmentally friendly cooling technologies, suggesting a robust market for magnetocaloric systems despite their currently higher initial costs compared to conventional technologies.

Market barriers include high initial investment costs, with magnetocaloric systems typically priced 2.5-3 times higher than conventional cooling systems. Limited awareness among potential end-users and the need for specialized installation and maintenance expertise also constrain market growth. However, these barriers are gradually diminishing as production scales up and technology matures.

Competitive landscape analysis reveals increasing market consolidation, with major players focusing on strategic partnerships to enhance technological capabilities. The permanent magnet array segment currently holds approximately 58% market share compared to electromagnet-based systems at 42%, though this gap is narrowing as electromagnet technology advances and addresses efficiency concerns.

Future market trends suggest increasing integration with smart home and building management systems, with interoperability becoming a key selling point. Additionally, hybrid systems combining magnetocaloric technology with conventional cooling methods are gaining traction as transitional solutions in markets sensitive to initial investment costs.

The residential segment currently dominates market demand, accounting for nearly 45% of total installations. Commercial applications follow closely at 35%, while industrial applications represent the remaining 20%. This distribution reflects the versatility of magnetocaloric cooling systems across various sectors, with particular growth potential in commercial refrigeration and automotive air conditioning.

Regional analysis reveals North America and Europe as leading markets, collectively representing over 60% of global demand. This dominance stems from stricter environmental regulations and greater consumer willingness to adopt green technologies. The Asia-Pacific region, particularly China and Japan, is emerging as the fastest-growing market with annual growth rates exceeding 28%, driven by rapid industrialization and increasing environmental awareness.

Consumer demand patterns indicate a strong preference for energy-efficient cooling solutions, with surveys showing that 78% of commercial buyers consider energy efficiency a primary purchase factor. Additionally, 65% of residential consumers express willingness to pay premium prices for environmentally friendly cooling technologies, suggesting a robust market for magnetocaloric systems despite their currently higher initial costs compared to conventional technologies.

Market barriers include high initial investment costs, with magnetocaloric systems typically priced 2.5-3 times higher than conventional cooling systems. Limited awareness among potential end-users and the need for specialized installation and maintenance expertise also constrain market growth. However, these barriers are gradually diminishing as production scales up and technology matures.

Competitive landscape analysis reveals increasing market consolidation, with major players focusing on strategic partnerships to enhance technological capabilities. The permanent magnet array segment currently holds approximately 58% market share compared to electromagnet-based systems at 42%, though this gap is narrowing as electromagnet technology advances and addresses efficiency concerns.

Future market trends suggest increasing integration with smart home and building management systems, with interoperability becoming a key selling point. Additionally, hybrid systems combining magnetocaloric technology with conventional cooling methods are gaining traction as transitional solutions in markets sensitive to initial investment costs.

Current Challenges in Magnetic Field Generation

Generating efficient and powerful magnetic fields remains one of the most significant challenges in magnetocaloric system design. Current magnetic field generation technologies face several critical limitations that impede the widespread adoption of magnetocaloric cooling systems. The primary challenge lies in achieving high magnetic field strengths (typically 1-2 Tesla) while maintaining energy efficiency and system compactness.

Permanent magnet arrays, though offering zero energy consumption during steady-state operation, face fundamental physical constraints in field strength. The maximum field achievable with commercially available NdFeB magnets is approximately 1.4 Tesla, which limits the temperature span and cooling power of magnetocaloric systems. Additionally, these arrays are typically bulky and heavy, with the Halbach cylinder configuration requiring significant amounts of expensive rare-earth materials, driving up system costs substantially.

Electromagnet-based systems can generate stronger and more controllable magnetic fields but suffer from significant energy inefficiency. The power consumption required for continuous field generation often negates the efficiency advantages of the magnetocaloric effect itself. Copper losses due to Joule heating in the windings create parasitic heat loads that must be managed, further complicating system design. Superconducting electromagnets offer a potential solution but introduce additional complexities related to cryogenic cooling requirements.

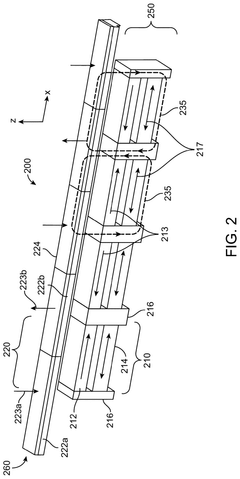

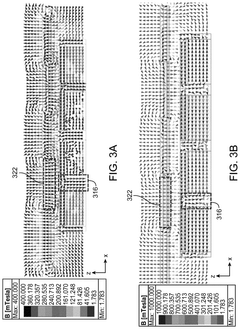

Field uniformity presents another critical challenge. Both permanent magnet arrays and electromagnets struggle to create homogeneous magnetic fields across the entire active magnetocaloric material volume. This non-uniformity leads to reduced system performance as portions of the material experience suboptimal field strengths, resulting in incomplete phase transitions and diminished cooling capacity.

The dynamic aspects of field generation pose additional difficulties. Magnetocaloric systems require rapid field changes to achieve practical cooling power densities. Permanent magnet systems must incorporate mechanical movement to create field variations, introducing reliability concerns, mechanical losses, and noise. Electromagnet systems can change fields electronically but face limitations in switching speed due to inductance and eddy current effects.

Thermal management of the field generation system itself represents a significant engineering challenge. Heat generated in electromagnet windings or from mechanical movement in permanent magnet systems must be effectively isolated from the cooling circuit to prevent performance degradation. This often necessitates complex thermal management subsystems that increase overall system complexity and cost.

Material constraints further complicate field generation. High-performance permanent magnets rely on increasingly scarce rare-earth elements, raising sustainability concerns. Meanwhile, electromagnet systems require large quantities of copper and specialized core materials to achieve acceptable performance, contributing to resource intensity and environmental impact.

Permanent magnet arrays, though offering zero energy consumption during steady-state operation, face fundamental physical constraints in field strength. The maximum field achievable with commercially available NdFeB magnets is approximately 1.4 Tesla, which limits the temperature span and cooling power of magnetocaloric systems. Additionally, these arrays are typically bulky and heavy, with the Halbach cylinder configuration requiring significant amounts of expensive rare-earth materials, driving up system costs substantially.

Electromagnet-based systems can generate stronger and more controllable magnetic fields but suffer from significant energy inefficiency. The power consumption required for continuous field generation often negates the efficiency advantages of the magnetocaloric effect itself. Copper losses due to Joule heating in the windings create parasitic heat loads that must be managed, further complicating system design. Superconducting electromagnets offer a potential solution but introduce additional complexities related to cryogenic cooling requirements.

Field uniformity presents another critical challenge. Both permanent magnet arrays and electromagnets struggle to create homogeneous magnetic fields across the entire active magnetocaloric material volume. This non-uniformity leads to reduced system performance as portions of the material experience suboptimal field strengths, resulting in incomplete phase transitions and diminished cooling capacity.

The dynamic aspects of field generation pose additional difficulties. Magnetocaloric systems require rapid field changes to achieve practical cooling power densities. Permanent magnet systems must incorporate mechanical movement to create field variations, introducing reliability concerns, mechanical losses, and noise. Electromagnet systems can change fields electronically but face limitations in switching speed due to inductance and eddy current effects.

Thermal management of the field generation system itself represents a significant engineering challenge. Heat generated in electromagnet windings or from mechanical movement in permanent magnet systems must be effectively isolated from the cooling circuit to prevent performance degradation. This often necessitates complex thermal management subsystems that increase overall system complexity and cost.

Material constraints further complicate field generation. High-performance permanent magnets rely on increasingly scarce rare-earth elements, raising sustainability concerns. Meanwhile, electromagnet systems require large quantities of copper and specialized core materials to achieve acceptable performance, contributing to resource intensity and environmental impact.

Comparative Analysis of Magnet Array Solutions

01 Permanent magnet configurations for magnetocaloric systems

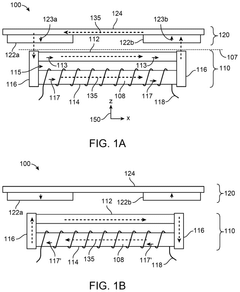

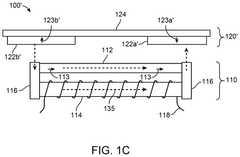

Permanent magnet arrangements are used in magnetocaloric systems to generate the required magnetic fields without continuous energy input. These configurations often involve specific geometric arrangements of magnets to create high-intensity magnetic fields in the active region where the magnetocaloric material is placed. Various designs include Halbach arrays, rotating permanent magnet assemblies, and other optimized configurations that maximize field strength while minimizing the amount of magnetic material required.- Permanent magnet configurations for magnetocaloric systems: Various permanent magnet configurations can be used to generate the magnetic field required for magnetocaloric systems. These configurations include Halbach arrays, rotating permanent magnets, and other specialized arrangements that create high magnetic field gradients. The designs focus on optimizing field strength while minimizing the volume and weight of magnetic material required, which improves system efficiency and reduces costs.

- Magnetic field cycling mechanisms: Magnetocaloric systems require efficient methods to cycle the magnetic field between high and low values. Various mechanisms have been developed, including rotating magnetic assemblies, reciprocating magnetic structures, and flow-based systems where the magnetocaloric material moves through stationary magnetic field regions. These mechanisms are designed to maximize the frequency of field cycling while minimizing energy consumption.

- Superconducting magnets for high-field applications: Superconducting magnets offer the ability to generate extremely high magnetic fields for advanced magnetocaloric applications. These systems utilize superconducting materials cooled to cryogenic temperatures to create intense magnetic fields with minimal power consumption. The designs include various coil configurations and cooling systems to maintain superconductivity while providing the necessary field strength and uniformity for efficient magnetocaloric effect.

- Integrated cooling and magnetic field generation systems: Integrated systems combine magnetic field generation with efficient heat transfer mechanisms. These designs incorporate heat exchangers, fluid flow channels, and thermal management components directly into the magnetic field generation assembly. By optimizing the spatial arrangement of these components, these systems maximize the temperature span and cooling power of magnetocaloric devices while minimizing energy consumption and system size.

- Novel magnetic field control strategies: Advanced control strategies for magnetic field generation in magnetocaloric systems focus on optimizing the field profile, timing, and intensity. These approaches include variable field strength control, pulsed field application, and adaptive field modulation based on system performance feedback. By precisely controlling the magnetic field parameters, these strategies enhance the efficiency and performance of magnetocaloric cooling and heating applications.

02 Magnetic field generation with reduced energy consumption

Energy-efficient methods for generating magnetic fields in magnetocaloric systems focus on reducing the power requirements for field generation. These approaches include using superconducting magnets, optimized electromagnetic designs, and hybrid systems that combine permanent magnets with electromagnets. The goal is to minimize the energy input required for field generation, which is critical for the overall efficiency of magnetocaloric cooling or heating systems.Expand Specific Solutions03 Dynamic magnetic field generation techniques

Dynamic field generation methods involve creating time-varying magnetic fields to enhance the performance of magnetocaloric systems. These techniques include rotating magnetic assemblies, reciprocating field generators, and pulsed field systems. By controlling the timing and intensity of the magnetic field application, these systems can optimize the magnetocaloric effect and improve the overall efficiency of heat transfer in cooling or heating applications.Expand Specific Solutions04 Integration of magnetic field generators with heat exchange systems

The integration of magnetic field generators with heat exchange components is crucial for effective magnetocaloric systems. These designs coordinate the magnetic field application with fluid flow through the magnetocaloric material to optimize heat transfer. Advanced systems incorporate regenerative heat exchangers, specialized flow channels, and synchronized control systems to maximize the temperature change achieved through the magnetocaloric effect while ensuring efficient heat transfer to or from the working fluid.Expand Specific Solutions05 Novel materials and structures for magnetic field generation

Innovative materials and structural designs are being developed to enhance magnetic field generation in magnetocaloric systems. These include advanced soft magnetic materials with high permeability, composite structures that concentrate magnetic flux, and novel geometries that optimize field distribution. Some approaches also involve the use of nanostructured materials or metamaterials to achieve desired magnetic field characteristics with reduced mass and volume requirements.Expand Specific Solutions

Leading Companies in Magnetocaloric Technology

The magnetocaloric system design market is currently in a growth phase, with increasing interest in both permanent magnet arrays and electromagnet solutions. The global market size is expanding as energy-efficient cooling technologies gain traction, projected to reach significant scale by 2030. Technologically, the field shows moderate maturity with ongoing innovation. Leading players demonstrate varying levels of specialization: Astronautics Corporation has established expertise in magnetic refrigeration systems, while companies like TDK, Hitachi, and Siemens leverage their broader materials and engineering capabilities. Academic institutions including KAIST and National University of Defense Technology contribute fundamental research, while specialized firms like maglab AG focus on magnetic system design specifically for energy efficiency applications. The competition between permanent magnet arrays and electromagnet approaches continues to drive innovation in this emerging field.

Siemens AG

Technical Solution: Siemens has developed advanced magnetocaloric system designs exploring both permanent magnet arrays and electromagnet technologies for cooling applications. Their permanent magnet-based systems utilize sophisticated Halbach array configurations that create concentrated magnetic fields of 1.2-1.5 Tesla in the active region while minimizing stray fields. These systems incorporate precision-engineered magnetic circuits that optimize the field gradient experienced by the magnetocaloric material during the thermodynamic cycle. For electromagnet-based solutions, Siemens leverages their expertise in electrical systems to create highly efficient pulsed magnetic field generators with advanced thermal management for the electromagnetic coils. Their systems feature integrated power electronics that precisely control field strength and timing to optimize the magnetocaloric effect. Siemens has also pioneered cascaded magnetocaloric systems that operate across multiple temperature ranges by using different magnetocaloric materials in series, each optimized for specific temperature windows. Their designs incorporate sophisticated fluid handling systems that maximize heat transfer efficiency between the magnetocaloric material and the heat transfer medium.

Strengths: Extensive experience in thermal management and system integration; global manufacturing and support infrastructure; strong power electronics expertise. Weaknesses: Focus on industrial applications may limit innovation in consumer-scale systems; corporate size may result in longer development cycles; solutions may prioritize reliability and serviceability over maximum theoretical performance.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer-Gesellschaft has pioneered research in magnetocaloric cooling systems with dual-track development in both permanent magnet and electromagnet technologies. Their permanent magnet array designs feature rotary magnetic refrigeration systems that move magnetocaloric materials through stationary magnetic field regions, eliminating the need for moving magnets and reducing mechanical complexity. These systems typically achieve temperature spans of 20-25K in a single stage using carefully optimized gadolinium-based alloys as the active material. Their electromagnet-based approach focuses on pulsed-field systems that can generate magnetic fields exceeding 2 Tesla, enabling the use of materials with smaller magnetocaloric effects but better cost efficiency. Fraunhofer has also developed hybrid systems that combine permanent magnets for baseline fields with electromagnet boosters for enhanced performance during peak demand periods, optimizing energy consumption while maintaining cooling capacity.

Strengths: Extensive R&D capabilities; strong integration with industrial partners for commercialization; advanced material development expertise. Weaknesses: Research-oriented approach may result in higher costs for initial implementations; some solutions may prioritize performance over commercial viability; complex systems may require specialized maintenance.

Key Patents in Magnetic Field Source Design

System and method for generating magnetic fields using an electromagnet array and a permanent magnet

PatentWO2025057139A1

Innovation

- A system comprising an actuation unit with an electromagnet array, an external permanent magnet, and a robotic manipulator, combined with a localization unit using Hall-effect sensors and a computing unit for designing magnetic field configurations, to generate desired magnetic fields for controlling magnetic objects.

Magnetic systems incorporating electropermanent magnet arrays

PatentPendingUS20250111972A1

Innovation

- A magnetic system that includes a fixed magnet array with permanent magnets and a switchable magnet array using electropermanent magnets (EPMs), allowing the system to switch between attractive, repulsive, and neutral magnetic states by controlling the EPMs.

Energy Efficiency Considerations

Energy efficiency represents a critical factor in evaluating magnetocaloric cooling systems, particularly when comparing permanent magnet arrays versus electromagnet designs. The fundamental energy consumption patterns of these two approaches differ significantly, with important implications for overall system efficiency and operational costs.

Permanent magnet arrays offer inherent energy advantages as they require no continuous power input to generate their magnetic fields. Once manufactured and properly installed, these magnets maintain their field strength without additional energy consumption. This characteristic makes permanent magnet systems particularly attractive for long-term operation, eliminating the parasitic energy losses associated with field generation in electromagnet-based alternatives.

However, the energy efficiency analysis must extend beyond field generation to consider the complete thermodynamic cycle. Permanent magnet systems typically require mechanical movement to create the necessary field variation for the magnetocaloric effect. These moving components introduce friction losses, mechanical wear, and additional energy requirements for motors and actuators that must be factored into efficiency calculations.

Electromagnet-based systems present a contrasting efficiency profile. While they demand continuous electrical input to maintain magnetic fields, they offer precise electronic control over field strength and timing without mechanical movement. Modern power electronics have significantly improved electromagnet efficiency through advanced control algorithms and reduced resistive losses in coil designs.

The cooling requirements for both systems also impact overall energy efficiency. Electromagnet systems generate substantial heat during operation, necessitating additional cooling infrastructure that consumes energy. Conversely, permanent magnet arrays avoid this heat generation but may require more complex thermal management systems to optimize the magnetocaloric effect.

System scale represents another crucial consideration in efficiency comparisons. Permanent magnet arrays typically demonstrate better efficiency at smaller scales, while electromagnet systems may achieve superior performance in larger industrial applications where the control advantages outweigh the continuous power requirements.

Recent advances in superconducting electromagnets have introduced new efficiency possibilities, potentially offering the control benefits of electromagnets with dramatically reduced power consumption. However, the energy required for cryogenic cooling of these systems must be carefully balanced against the operational energy savings.

The complete energy efficiency assessment must ultimately incorporate manufacturing energy inputs, operational lifetime, and end-of-life considerations to determine the true efficiency of each approach across the full product lifecycle.

Permanent magnet arrays offer inherent energy advantages as they require no continuous power input to generate their magnetic fields. Once manufactured and properly installed, these magnets maintain their field strength without additional energy consumption. This characteristic makes permanent magnet systems particularly attractive for long-term operation, eliminating the parasitic energy losses associated with field generation in electromagnet-based alternatives.

However, the energy efficiency analysis must extend beyond field generation to consider the complete thermodynamic cycle. Permanent magnet systems typically require mechanical movement to create the necessary field variation for the magnetocaloric effect. These moving components introduce friction losses, mechanical wear, and additional energy requirements for motors and actuators that must be factored into efficiency calculations.

Electromagnet-based systems present a contrasting efficiency profile. While they demand continuous electrical input to maintain magnetic fields, they offer precise electronic control over field strength and timing without mechanical movement. Modern power electronics have significantly improved electromagnet efficiency through advanced control algorithms and reduced resistive losses in coil designs.

The cooling requirements for both systems also impact overall energy efficiency. Electromagnet systems generate substantial heat during operation, necessitating additional cooling infrastructure that consumes energy. Conversely, permanent magnet arrays avoid this heat generation but may require more complex thermal management systems to optimize the magnetocaloric effect.

System scale represents another crucial consideration in efficiency comparisons. Permanent magnet arrays typically demonstrate better efficiency at smaller scales, while electromagnet systems may achieve superior performance in larger industrial applications where the control advantages outweigh the continuous power requirements.

Recent advances in superconducting electromagnets have introduced new efficiency possibilities, potentially offering the control benefits of electromagnets with dramatically reduced power consumption. However, the energy required for cryogenic cooling of these systems must be carefully balanced against the operational energy savings.

The complete energy efficiency assessment must ultimately incorporate manufacturing energy inputs, operational lifetime, and end-of-life considerations to determine the true efficiency of each approach across the full product lifecycle.

Material Science Advancements

Recent advancements in material science have significantly impacted the development of magnetocaloric systems, particularly in the ongoing debate between permanent magnet arrays and electromagnets. The discovery of new magnetocaloric materials with enhanced properties has revolutionized the efficiency potential of both design approaches.

For permanent magnet arrays, the development of rare-earth-free permanent magnets represents a crucial breakthrough. Traditional neodymium-iron-boron (NdFeB) magnets, while powerful, face sustainability challenges due to limited rare earth supplies. Recent research has yielded promising alternatives such as manganese-based compounds and iron-nitride materials that demonstrate comparable magnetic properties without rare earth elements.

Concurrently, high-performance soft magnetic materials have emerged to enhance electromagnet efficiency. Nanocrystalline soft magnetic alloys with reduced hysteresis losses and amorphous metal composites with high magnetic permeability have dramatically improved electromagnet performance while reducing energy consumption during operation cycles.

The field of magnetocaloric materials themselves has witnessed remarkable progress. Beyond the traditional gadolinium-based materials, researchers have developed first-order magnetic phase transition materials (FOPTs) with giant magnetocaloric effects. Notable among these are La-Fe-Si compounds, Heusler alloys, and MnFe(P,Si) materials that demonstrate entropy changes up to 40 J/kg·K, substantially higher than conventional materials.

Composite magnetocaloric materials represent another frontier, combining different materials with complementary Curie temperatures to broaden the operating temperature range. These layered composites enable more efficient heat transfer across wider temperature spans, addressing one of the fundamental limitations in magnetocaloric cooling systems.

Advanced manufacturing techniques have further accelerated material development. Additive manufacturing now enables the creation of complex magnetic structures with optimized geometries for magnetic field generation and heat transfer. Thin-film deposition techniques allow for precise layering of magnetocaloric materials, creating highly efficient exchange surfaces.

Surface engineering innovations have improved the corrosion resistance and thermal conductivity of magnetocaloric materials, extending system lifespans and enhancing heat transfer efficiency. Nano-structured surface treatments have proven particularly effective at maximizing the interface between magnetocaloric materials and heat transfer fluids.

These material science advancements collectively influence the permanent magnet versus electromagnet debate by altering the fundamental performance parameters, cost structures, and sustainability profiles of both approaches, creating new possibilities for next-generation magnetocaloric cooling systems.

For permanent magnet arrays, the development of rare-earth-free permanent magnets represents a crucial breakthrough. Traditional neodymium-iron-boron (NdFeB) magnets, while powerful, face sustainability challenges due to limited rare earth supplies. Recent research has yielded promising alternatives such as manganese-based compounds and iron-nitride materials that demonstrate comparable magnetic properties without rare earth elements.

Concurrently, high-performance soft magnetic materials have emerged to enhance electromagnet efficiency. Nanocrystalline soft magnetic alloys with reduced hysteresis losses and amorphous metal composites with high magnetic permeability have dramatically improved electromagnet performance while reducing energy consumption during operation cycles.

The field of magnetocaloric materials themselves has witnessed remarkable progress. Beyond the traditional gadolinium-based materials, researchers have developed first-order magnetic phase transition materials (FOPTs) with giant magnetocaloric effects. Notable among these are La-Fe-Si compounds, Heusler alloys, and MnFe(P,Si) materials that demonstrate entropy changes up to 40 J/kg·K, substantially higher than conventional materials.

Composite magnetocaloric materials represent another frontier, combining different materials with complementary Curie temperatures to broaden the operating temperature range. These layered composites enable more efficient heat transfer across wider temperature spans, addressing one of the fundamental limitations in magnetocaloric cooling systems.

Advanced manufacturing techniques have further accelerated material development. Additive manufacturing now enables the creation of complex magnetic structures with optimized geometries for magnetic field generation and heat transfer. Thin-film deposition techniques allow for precise layering of magnetocaloric materials, creating highly efficient exchange surfaces.

Surface engineering innovations have improved the corrosion resistance and thermal conductivity of magnetocaloric materials, extending system lifespans and enhancing heat transfer efficiency. Nano-structured surface treatments have proven particularly effective at maximizing the interface between magnetocaloric materials and heat transfer fluids.

These material science advancements collectively influence the permanent magnet versus electromagnet debate by altering the fundamental performance parameters, cost structures, and sustainability profiles of both approaches, creating new possibilities for next-generation magnetocaloric cooling systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!