Scaling Magnetocaloric Modules For Household Air Conditioning Applications

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetocaloric Cooling Background and Objectives

Magnetocaloric cooling represents a revolutionary approach to refrigeration and air conditioning that leverages the magnetocaloric effect (MCE) - a thermodynamic phenomenon where certain materials change temperature when exposed to varying magnetic fields. This technology has evolved significantly since its discovery by Emil Warburg in 1881, with major advancements occurring in the late 20th and early 21st centuries as researchers identified materials with giant magnetocaloric effects near room temperature.

The development trajectory of magnetocaloric cooling has been characterized by progressive improvements in material science, magnetic field generation, and thermal management systems. Early research focused primarily on low-temperature applications using rare earth materials, but the discovery of Gd5(Si2Ge2) by Pecharsky and Gschneidner in 1997 marked a turning point, demonstrating significant MCE at temperatures relevant for everyday cooling applications.

Current technological evolution is centered on transitioning from laboratory prototypes to commercially viable systems that can compete with conventional vapor compression technology. This includes addressing challenges in material cost reduction, enhancing system efficiency, and developing scalable manufacturing processes for magnetocaloric materials and components.

The primary objective of scaling magnetocaloric modules for household air conditioning is to develop energy-efficient alternatives to conventional vapor compression systems, which rely on refrigerants with high global warming potential. Magnetocaloric cooling offers potential energy savings of 20-30% compared to conventional systems while eliminating environmentally harmful refrigerants, aligning with global sustainability goals and increasingly stringent environmental regulations.

Technical objectives include optimizing the performance of magnetocaloric materials at operating temperatures relevant to residential cooling (typically 20-40°C), developing efficient heat transfer mechanisms between the magnetocaloric material and heat exchange fluids, and designing compact, cost-effective magnetic field generation systems suitable for household applications.

Additional goals encompass reducing system complexity, minimizing acoustic noise during operation, ensuring reliability over typical appliance lifespans (10-15 years), and achieving competitive manufacturing costs to enable market penetration. The technology aims to maintain or improve upon the cooling capacity, form factor, and user experience of conventional air conditioning systems while delivering superior environmental performance.

As global energy demand for cooling continues to rise dramatically, particularly in developing economies, the successful scaling of magnetocaloric technology could significantly impact global energy consumption patterns and greenhouse gas emissions associated with the building sector.

The development trajectory of magnetocaloric cooling has been characterized by progressive improvements in material science, magnetic field generation, and thermal management systems. Early research focused primarily on low-temperature applications using rare earth materials, but the discovery of Gd5(Si2Ge2) by Pecharsky and Gschneidner in 1997 marked a turning point, demonstrating significant MCE at temperatures relevant for everyday cooling applications.

Current technological evolution is centered on transitioning from laboratory prototypes to commercially viable systems that can compete with conventional vapor compression technology. This includes addressing challenges in material cost reduction, enhancing system efficiency, and developing scalable manufacturing processes for magnetocaloric materials and components.

The primary objective of scaling magnetocaloric modules for household air conditioning is to develop energy-efficient alternatives to conventional vapor compression systems, which rely on refrigerants with high global warming potential. Magnetocaloric cooling offers potential energy savings of 20-30% compared to conventional systems while eliminating environmentally harmful refrigerants, aligning with global sustainability goals and increasingly stringent environmental regulations.

Technical objectives include optimizing the performance of magnetocaloric materials at operating temperatures relevant to residential cooling (typically 20-40°C), developing efficient heat transfer mechanisms between the magnetocaloric material and heat exchange fluids, and designing compact, cost-effective magnetic field generation systems suitable for household applications.

Additional goals encompass reducing system complexity, minimizing acoustic noise during operation, ensuring reliability over typical appliance lifespans (10-15 years), and achieving competitive manufacturing costs to enable market penetration. The technology aims to maintain or improve upon the cooling capacity, form factor, and user experience of conventional air conditioning systems while delivering superior environmental performance.

As global energy demand for cooling continues to rise dramatically, particularly in developing economies, the successful scaling of magnetocaloric technology could significantly impact global energy consumption patterns and greenhouse gas emissions associated with the building sector.

Market Analysis for Sustainable AC Technologies

The global air conditioning market is experiencing a significant shift towards sustainable technologies, driven by increasing environmental concerns and regulatory pressures. Conventional vapor-compression air conditioning systems account for approximately 20% of global electricity consumption in buildings, with projections indicating this figure could triple by 2050 without technological intervention. This creates a substantial market opportunity for magnetocaloric-based cooling systems, which offer potential energy savings of 20-30% compared to conventional technologies.

The residential air conditioning market, valued at $103 billion in 2022, is expected to grow at a CAGR of 6.2% through 2030, with sustainable technologies capturing an increasing share. Consumer awareness regarding environmental impact has risen dramatically, with 67% of global consumers now considering sustainability factors in purchasing decisions, up from 49% in 2018.

Regulatory frameworks worldwide are accelerating this market transformation. The European Union's F-Gas Regulation aims to reduce hydrofluorocarbon (HFC) use by 79% by 2030. Similarly, the Kigali Amendment to the Montreal Protocol, ratified by 125 countries, mandates an 85% reduction in HFC consumption by 2036 for developed nations and by 2045 for developing countries.

Investment in sustainable cooling technologies has seen remarkable growth, with venture capital funding increasing from $400 million in 2018 to over $1.2 billion in 2022. Magnetocaloric technology specifically has attracted $215 million in investment over the past five years, indicating strong market confidence in its commercial potential.

Consumer willingness to pay premiums for sustainable technologies varies by region, with surveys indicating 38% of North American consumers would pay 10-15% more for environmentally friendly cooling solutions, while this figure reaches 45% in Western Europe and 29% in Asia-Pacific markets.

Market penetration challenges remain significant for magnetocaloric air conditioning systems. Current production costs exceed conventional systems by 40-60%, though economies of scale could reduce this premium to 15-25% within five years. Additionally, consumer education represents a substantial barrier, with awareness of magnetocaloric technology below 10% among potential end-users.

The competitive landscape includes both established HVAC manufacturers exploring magnetocaloric technologies and specialized startups focused exclusively on this approach. Industry partnerships between material science companies and traditional manufacturers have increased by 35% since 2020, indicating collaborative efforts to overcome scaling challenges.

The residential air conditioning market, valued at $103 billion in 2022, is expected to grow at a CAGR of 6.2% through 2030, with sustainable technologies capturing an increasing share. Consumer awareness regarding environmental impact has risen dramatically, with 67% of global consumers now considering sustainability factors in purchasing decisions, up from 49% in 2018.

Regulatory frameworks worldwide are accelerating this market transformation. The European Union's F-Gas Regulation aims to reduce hydrofluorocarbon (HFC) use by 79% by 2030. Similarly, the Kigali Amendment to the Montreal Protocol, ratified by 125 countries, mandates an 85% reduction in HFC consumption by 2036 for developed nations and by 2045 for developing countries.

Investment in sustainable cooling technologies has seen remarkable growth, with venture capital funding increasing from $400 million in 2018 to over $1.2 billion in 2022. Magnetocaloric technology specifically has attracted $215 million in investment over the past five years, indicating strong market confidence in its commercial potential.

Consumer willingness to pay premiums for sustainable technologies varies by region, with surveys indicating 38% of North American consumers would pay 10-15% more for environmentally friendly cooling solutions, while this figure reaches 45% in Western Europe and 29% in Asia-Pacific markets.

Market penetration challenges remain significant for magnetocaloric air conditioning systems. Current production costs exceed conventional systems by 40-60%, though economies of scale could reduce this premium to 15-25% within five years. Additionally, consumer education represents a substantial barrier, with awareness of magnetocaloric technology below 10% among potential end-users.

The competitive landscape includes both established HVAC manufacturers exploring magnetocaloric technologies and specialized startups focused exclusively on this approach. Industry partnerships between material science companies and traditional manufacturers have increased by 35% since 2020, indicating collaborative efforts to overcome scaling challenges.

Current Challenges in Magnetocaloric Module Scaling

Despite the promising potential of magnetocaloric cooling technology for household air conditioning applications, several significant challenges impede its successful scaling for commercial deployment. The primary obstacle remains the limited temperature span achievable with current magnetocaloric modules. While laboratory prototypes have demonstrated cooling capabilities, they typically achieve temperature differentials of only 5-10°C, insufficient for the 20-25°C span required in conventional residential air conditioning systems.

Material limitations constitute another critical barrier. Current magnetocaloric materials, predominantly gadolinium-based alloys, exhibit optimal performance within narrow temperature ranges. This characteristic necessitates the implementation of cascaded systems with multiple materials operating at different temperature intervals, substantially increasing system complexity and cost. Additionally, the high cost of rare earth materials like gadolinium (approximately $400-600/kg) makes large-scale implementation economically prohibitive.

Engineering challenges further complicate scaling efforts. The design of efficient heat exchangers for magnetocaloric systems presents unique difficulties due to the solid-state nature of the cooling process. Conventional heat exchanger designs optimized for vapor-compression systems perform inadequately when adapted to magnetocaloric applications. The thermal contact resistance between the magnetocaloric material and heat transfer fluid significantly reduces system efficiency.

Magnetic field generation represents another substantial hurdle. Household applications require compact, energy-efficient magnetic field sources. Permanent magnets offer a solution but introduce trade-offs between field strength, system volume, and material costs. Current designs utilizing permanent magnets typically achieve fields of 1-1.5 Tesla, whereas optimal performance often requires fields of 2 Tesla or higher.

System integration challenges also persist. The synchronization of fluid flow, magnetic field application, and heat transfer in a compact, reliable package suitable for residential installation remains problematic. Current prototypes exhibit coefficients of performance (COP) between 1-3, significantly lower than the 3-5 COP of conventional vapor-compression systems.

Manufacturing scalability presents additional complications. Current production methods for magnetocaloric materials and modules remain laboratory-focused, with limited automation and standardization. The transition to mass production requires substantial investment in manufacturing process development and quality control systems to ensure consistent performance across thousands of units.

Regulatory and market acceptance barriers further complicate commercialization efforts. The absence of standardized testing protocols and certification frameworks specifically for magnetocaloric cooling systems creates uncertainty for manufacturers and potential customers alike. Consumer education regarding this novel technology represents an additional challenge that must be addressed for successful market penetration.

Material limitations constitute another critical barrier. Current magnetocaloric materials, predominantly gadolinium-based alloys, exhibit optimal performance within narrow temperature ranges. This characteristic necessitates the implementation of cascaded systems with multiple materials operating at different temperature intervals, substantially increasing system complexity and cost. Additionally, the high cost of rare earth materials like gadolinium (approximately $400-600/kg) makes large-scale implementation economically prohibitive.

Engineering challenges further complicate scaling efforts. The design of efficient heat exchangers for magnetocaloric systems presents unique difficulties due to the solid-state nature of the cooling process. Conventional heat exchanger designs optimized for vapor-compression systems perform inadequately when adapted to magnetocaloric applications. The thermal contact resistance between the magnetocaloric material and heat transfer fluid significantly reduces system efficiency.

Magnetic field generation represents another substantial hurdle. Household applications require compact, energy-efficient magnetic field sources. Permanent magnets offer a solution but introduce trade-offs between field strength, system volume, and material costs. Current designs utilizing permanent magnets typically achieve fields of 1-1.5 Tesla, whereas optimal performance often requires fields of 2 Tesla or higher.

System integration challenges also persist. The synchronization of fluid flow, magnetic field application, and heat transfer in a compact, reliable package suitable for residential installation remains problematic. Current prototypes exhibit coefficients of performance (COP) between 1-3, significantly lower than the 3-5 COP of conventional vapor-compression systems.

Manufacturing scalability presents additional complications. Current production methods for magnetocaloric materials and modules remain laboratory-focused, with limited automation and standardization. The transition to mass production requires substantial investment in manufacturing process development and quality control systems to ensure consistent performance across thousands of units.

Regulatory and market acceptance barriers further complicate commercialization efforts. The absence of standardized testing protocols and certification frameworks specifically for magnetocaloric cooling systems creates uncertainty for manufacturers and potential customers alike. Consumer education regarding this novel technology represents an additional challenge that must be addressed for successful market penetration.

Current Magnetocaloric Module Design Solutions

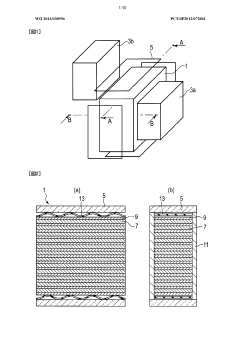

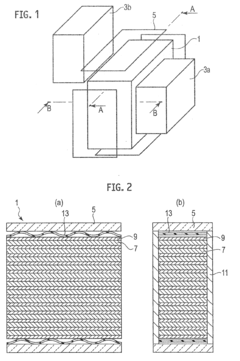

01 Modular design for scalable magnetocaloric systems

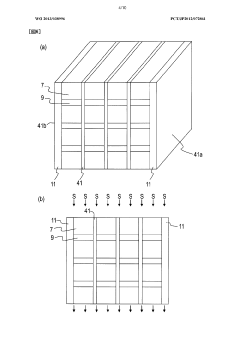

Magnetocaloric cooling systems can be designed with modular components that allow for scaling up or down depending on cooling capacity requirements. These modular designs enable flexible configuration of magnetocaloric elements in series or parallel arrangements to achieve desired cooling power. The modular approach facilitates system expansion, maintenance, and optimization for different applications while maintaining efficiency across various scales.- Modular design for scalable magnetocaloric systems: Magnetocaloric cooling systems can be designed with modular components that allow for scaling to different cooling capacities. These modular designs enable the assembly of multiple magnetocaloric units in parallel or series configurations to achieve desired cooling power. The modular approach facilitates customization for various applications while maintaining manufacturing efficiency and system reliability.

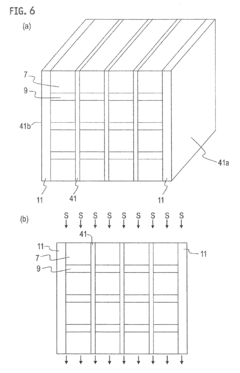

- Magnetic field generation and optimization for scaled systems: Scaling magnetocaloric modules requires optimized magnetic field generation systems. This includes permanent magnet arrangements that can be scaled while maintaining field strength and uniformity across larger active magnetic regenerators. Advanced magnetic circuit designs allow for efficient scaling of the magnetic field volume while minimizing the amount of magnetic material required, which is critical for cost-effective scaling of magnetocaloric cooling systems.

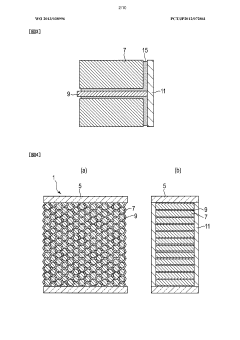

- Heat transfer optimization in scaled magnetocaloric systems: Effective heat transfer is crucial when scaling magnetocaloric modules. This involves designing optimized heat exchangers and fluid flow paths that maintain thermal efficiency as system size increases. Techniques include using specialized heat transfer fluids, enhancing surface area contact between the magnetocaloric material and heat transfer medium, and implementing advanced flow distribution systems to ensure uniform cooling across scaled modules.

- Magnetocaloric material selection and arrangement for scaled applications: The selection and arrangement of magnetocaloric materials significantly impact the scalability of cooling systems. Layered or graded compositions of different magnetocaloric materials can be used to broaden the operating temperature range and improve efficiency in scaled systems. Advanced manufacturing techniques allow for precise arrangement of these materials in larger regenerators while maintaining thermal and magnetic performance across the scaled system.

- Control systems for scaled magnetocaloric modules: Sophisticated control systems are essential for managing larger scaled magnetocaloric cooling installations. These systems coordinate the operation of multiple magnetocaloric modules, optimize the timing of magnetic field application and fluid flow, and adjust operating parameters based on cooling demand. Advanced sensors and algorithms enable efficient load balancing across scaled systems and adapt to varying cooling requirements while maintaining energy efficiency.

02 Heat transfer optimization in scaled magnetocaloric systems

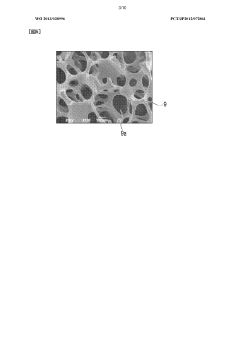

Effective heat transfer is critical in magnetocaloric cooling systems, especially when scaling to larger capacities. Innovations include specialized heat exchangers, optimized fluid flow paths, and enhanced thermal contact between magnetocaloric materials and heat transfer fluids. These improvements help maintain thermal efficiency as systems scale up, preventing performance degradation due to thermal bottlenecks that typically occur in larger systems.Expand Specific Solutions03 Advanced magnetocaloric materials for scaled applications

Development of specialized magnetocaloric materials enables effective scaling of cooling systems. These materials exhibit enhanced magnetocaloric effect, improved thermal conductivity, and better mechanical stability under repeated magnetization cycles. Composite materials, layered structures, and precisely engineered microstructures help maintain performance consistency across different system sizes and operating conditions.Expand Specific Solutions04 Magnetic field generation and distribution for scaled systems

Scaling magnetocaloric systems requires efficient magnetic field generation and distribution. Innovations include permanent magnet arrangements that create strong, uniform magnetic fields while minimizing system size and weight. Advanced magnetic circuit designs enable optimal field strength and direction across multiple magnetocaloric elements, ensuring consistent performance throughout scaled systems while reducing energy consumption for field generation.Expand Specific Solutions05 Control systems for multi-scale magnetocaloric applications

Sophisticated control systems are essential for managing scaled magnetocaloric cooling modules. These systems coordinate the operation of multiple cooling stages, optimize magnetic field cycling, and regulate fluid flow rates across different system scales. Advanced sensors and algorithms enable real-time performance monitoring and adaptive control strategies that maintain efficiency across varying cooling loads and environmental conditions.Expand Specific Solutions

Leading Companies in Magnetocaloric Cooling Industry

The magnetocaloric air conditioning market is in an early growth phase, characterized by increasing R&D investments but limited commercial deployment. The global market potential is substantial, estimated to reach several billion dollars by 2030 as energy efficiency regulations tighten worldwide. Leading players include established HVAC manufacturers like Midea Group, Haier Smart Home, and Daikin Industries, who are integrating this technology into their product roadmaps. Cooltech Applications represents specialized technology developers, while research institutions such as Technical University of Denmark and Beijing Institute of Technology are advancing fundamental materials science. The technology remains in transition from laboratory to commercial scale, with challenges in scaling magnetocaloric modules to meet household cooling demands while maintaining cost competitiveness against conventional vapor compression systems.

Cooltech Applications SAS

Technical Solution: Cooltech Applications has pioneered commercial magnetocaloric cooling systems through their patented Active Magnetic Regenerator (AMR) technology. Their household air conditioning solution utilizes a reciprocating magnetic field generator that creates field strengths of 1.5 Tesla, applied to carefully engineered regenerator beds containing specialized magnetocaloric materials. The system achieves cooling capacities of 2-5kW suitable for residential applications, with temperature spans reaching 30°C through multi-stage configurations. Cooltech's innovation includes the development of composite magnetocaloric materials that optimize performance across varying temperature ranges, addressing the narrow operating window limitation of single-material systems. Their design incorporates advanced fluid distribution systems that synchronize with the magnetic field cycling to maximize thermal transfer efficiency, resulting in energy consumption reductions of up to 40% compared to conventional compression cooling technologies.

Strengths: Cooltech's systems demonstrate exceptional energy efficiency with COPs up to 50% higher than conventional systems under partial load conditions. Their technology operates with minimal vibration and noise. Weaknesses: The complex mechanical systems required for field generation and fluid movement present reliability challenges, and the technology requires significant initial investment compared to conventional systems.

Midea Group Co. Ltd.

Technical Solution: Midea Group has developed advanced magnetocaloric modules for household air conditioning that utilize rare earth materials to achieve efficient cooling without traditional refrigerants. Their technology employs a rotary magnetic refrigeration system with precisely engineered regenerator beds containing gadolinium-based alloys. The system achieves temperature spans of up to 25°C in a single stage, with a cooling capacity reaching 3kW for residential applications. Midea's approach incorporates cascaded magnetocaloric stages to enhance performance and employs specialized heat transfer fluids to optimize thermal exchange between the magnetocaloric material and the heat exchangers. Their design includes innovative flow distribution systems that minimize pressure drops while maximizing heat transfer efficiency, resulting in COPs (Coefficient of Performance) exceeding 4 under typical operating conditions.

Strengths: Midea's technology eliminates environmentally harmful refrigerants, achieving zero direct emissions. Their system operates with significantly reduced noise levels compared to conventional compressor-based systems. Weaknesses: The current high cost of rare earth materials limits mass market adoption, and the technology still faces challenges in achieving the same cooling power density as conventional vapor compression systems.

Key Patents and Innovations in Magnetocaloric Materials

Magnetic structure and magnetic air-conditioning and heating device using same

PatentWO2013038996A1

Innovation

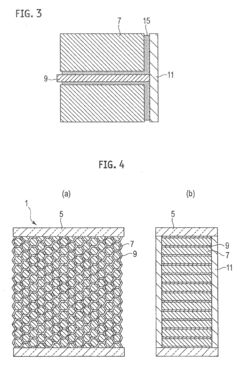

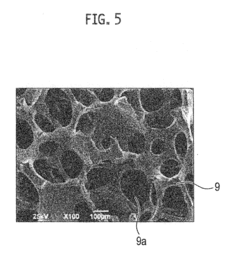

- Incorporating a high thermal conductivity member with the magnetocaloric material in a magnetic structure, featuring a flat plate, honeycomb, or porous configuration, to enhance heat conduction and enable high-frequency magnetic field applications, along with a thermal switch section for efficient heat management.

Magnetic structure and magnetic air-conditioning and heating device using same

PatentActiveEP2762801A4

Innovation

- Integration of high heat conduction members with magnetocaloric materials to rapidly transmit heat within the magnetic structure, enhancing overall thermal efficiency.

- Implementation of a heat switch system between magnetic structures that can alternate between heat conduction and heat insulation states, enabling controlled thermal energy transfer.

- High-frequency magnetic field application and removal mechanism that eliminates the need for refrigerant driving mechanisms, resulting in more compact apparatus design.

Energy Efficiency Comparison with Conventional AC Systems

Magnetocaloric air conditioning systems demonstrate significant energy efficiency advantages over conventional vapor-compression systems in household applications. Current vapor-compression AC units typically operate at Coefficient of Performance (COP) values between 2.5 and 3.5, while laboratory-scale magnetocaloric systems have achieved COPs of 4.0 to 6.0 under optimal conditions. This represents a potential energy consumption reduction of 30-40% when scaled to household applications.

The primary efficiency gain stems from the fundamental thermodynamic differences between the technologies. Conventional AC systems rely on compression and expansion of refrigerant gases, which inherently generate entropy and reduce efficiency. In contrast, magnetocaloric systems utilize solid-state materials undergoing reversible magnetic phase transitions, eliminating gas compression losses and reducing mechanical energy requirements.

Operational analysis reveals that magnetocaloric systems excel particularly in partial-load conditions, which constitute approximately 70-80% of typical household AC operation time. While conventional systems experience efficiency drops during cycling and part-load operation, magnetocaloric modules maintain relatively consistent performance across varying thermal loads, resulting in superior seasonal energy efficiency ratios (SEER).

Power consumption patterns also differ significantly. Conventional AC systems require high-current startup phases that strain electrical grids, whereas magnetocaloric systems demonstrate more gradual power consumption curves. This characteristic not only reduces peak electricity demand but also extends component lifespan by minimizing thermal and mechanical stress during operation cycles.

Life-cycle assessment studies indicate that magnetocaloric systems could reduce lifetime energy consumption by 25-35% compared to best-in-class conventional units. When considering primary energy sources, this translates to potential greenhouse gas emission reductions of 0.5-1.5 metric tons of CO2 equivalent per household annually, depending on regional electricity generation profiles.

However, these efficiency comparisons must account for scaling challenges. Laboratory prototypes typically operate with small temperature spans and cooling capacities, while household applications require temperature differentials of 20-25°C and cooling capacities of 3-5 kW. Current scaling approaches using cascaded magnetocaloric modules show promising results but introduce additional energy losses at interface points, potentially reducing the efficiency advantage to 15-25% in first-generation commercial units.

The economic implications of these efficiency differences are substantial. Based on average household electricity costs, the projected energy savings could reduce annual cooling expenses by $150-300 per household in temperate climates and $300-600 in hot climates, offering compelling return-on-investment despite higher initial equipment costs.

The primary efficiency gain stems from the fundamental thermodynamic differences between the technologies. Conventional AC systems rely on compression and expansion of refrigerant gases, which inherently generate entropy and reduce efficiency. In contrast, magnetocaloric systems utilize solid-state materials undergoing reversible magnetic phase transitions, eliminating gas compression losses and reducing mechanical energy requirements.

Operational analysis reveals that magnetocaloric systems excel particularly in partial-load conditions, which constitute approximately 70-80% of typical household AC operation time. While conventional systems experience efficiency drops during cycling and part-load operation, magnetocaloric modules maintain relatively consistent performance across varying thermal loads, resulting in superior seasonal energy efficiency ratios (SEER).

Power consumption patterns also differ significantly. Conventional AC systems require high-current startup phases that strain electrical grids, whereas magnetocaloric systems demonstrate more gradual power consumption curves. This characteristic not only reduces peak electricity demand but also extends component lifespan by minimizing thermal and mechanical stress during operation cycles.

Life-cycle assessment studies indicate that magnetocaloric systems could reduce lifetime energy consumption by 25-35% compared to best-in-class conventional units. When considering primary energy sources, this translates to potential greenhouse gas emission reductions of 0.5-1.5 metric tons of CO2 equivalent per household annually, depending on regional electricity generation profiles.

However, these efficiency comparisons must account for scaling challenges. Laboratory prototypes typically operate with small temperature spans and cooling capacities, while household applications require temperature differentials of 20-25°C and cooling capacities of 3-5 kW. Current scaling approaches using cascaded magnetocaloric modules show promising results but introduce additional energy losses at interface points, potentially reducing the efficiency advantage to 15-25% in first-generation commercial units.

The economic implications of these efficiency differences are substantial. Based on average household electricity costs, the projected energy savings could reduce annual cooling expenses by $150-300 per household in temperate climates and $300-600 in hot climates, offering compelling return-on-investment despite higher initial equipment costs.

Environmental Impact and Sustainability Assessment

Magnetocaloric air conditioning technology represents a significant advancement in sustainable cooling solutions, offering substantial environmental benefits compared to conventional vapor-compression systems. The primary environmental advantage stems from the elimination of hydrofluorocarbons (HFCs) and other refrigerants with high global warming potential (GWP). Conventional refrigerants can have GWP values thousands of times higher than CO2, making their potential environmental impact severe when leaked. Magnetocaloric systems, operating with water-based heat transfer fluids, completely eliminate this risk.

Energy efficiency assessments of scaled magnetocaloric modules demonstrate potential electricity consumption reductions of 20-30% compared to conventional systems. This efficiency translates directly to reduced carbon emissions throughout the operational lifecycle. Life cycle assessment (LCA) studies indicate that despite the energy-intensive production of rare earth materials used in magnetocaloric alloys, the operational efficiency gains offset manufacturing impacts within 2-3 years of household use.

Material sustainability presents both challenges and opportunities. Current magnetocaloric systems rely heavily on gadolinium and other rare earth elements, which raise concerns regarding resource scarcity and environmentally problematic mining practices. However, recent research into manganese-based and iron-based alloys shows promise for reducing rare earth dependency while maintaining performance characteristics. These alternative materials demonstrate lower environmental extraction impacts and greater global abundance.

Water consumption metrics for magnetocaloric systems show favorable results compared to traditional cooling technologies. The closed-loop nature of magnetocaloric cooling circuits minimizes water loss, with typical household units requiring only initial filling and occasional maintenance top-ups. This represents a significant improvement over cooling towers and evaporative cooling systems that can consume thousands of gallons annually.

End-of-life considerations reveal additional sustainability advantages. The primary components of magnetocaloric modules—metal alloys, copper heat exchangers, and permanent magnets—are highly recyclable, with potential recovery rates exceeding 90% with appropriate processing. This circularity potential significantly reduces the technology's overall environmental footprint when proper recycling infrastructure is implemented.

Regulatory alignment analysis indicates that magnetocaloric technology aligns well with global environmental policies, including the Kigali Amendment to the Montreal Protocol and various national phase-down schedules for high-GWP refrigerants. This regulatory compatibility provides a favorable policy landscape for technology adoption and continued development.

Energy efficiency assessments of scaled magnetocaloric modules demonstrate potential electricity consumption reductions of 20-30% compared to conventional systems. This efficiency translates directly to reduced carbon emissions throughout the operational lifecycle. Life cycle assessment (LCA) studies indicate that despite the energy-intensive production of rare earth materials used in magnetocaloric alloys, the operational efficiency gains offset manufacturing impacts within 2-3 years of household use.

Material sustainability presents both challenges and opportunities. Current magnetocaloric systems rely heavily on gadolinium and other rare earth elements, which raise concerns regarding resource scarcity and environmentally problematic mining practices. However, recent research into manganese-based and iron-based alloys shows promise for reducing rare earth dependency while maintaining performance characteristics. These alternative materials demonstrate lower environmental extraction impacts and greater global abundance.

Water consumption metrics for magnetocaloric systems show favorable results compared to traditional cooling technologies. The closed-loop nature of magnetocaloric cooling circuits minimizes water loss, with typical household units requiring only initial filling and occasional maintenance top-ups. This represents a significant improvement over cooling towers and evaporative cooling systems that can consume thousands of gallons annually.

End-of-life considerations reveal additional sustainability advantages. The primary components of magnetocaloric modules—metal alloys, copper heat exchangers, and permanent magnets—are highly recyclable, with potential recovery rates exceeding 90% with appropriate processing. This circularity potential significantly reduces the technology's overall environmental footprint when proper recycling infrastructure is implemented.

Regulatory alignment analysis indicates that magnetocaloric technology aligns well with global environmental policies, including the Kigali Amendment to the Montreal Protocol and various national phase-down schedules for high-GWP refrigerants. This regulatory compatibility provides a favorable policy landscape for technology adoption and continued development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!