Cooling Power Density Benchmarks For Magnetocaloric Modules

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetocaloric Cooling Technology Background and Objectives

Magnetocaloric cooling technology represents a revolutionary approach to refrigeration that has gained significant attention over the past few decades. This technology harnesses the magnetocaloric effect (MCE), a thermodynamic phenomenon where certain materials change temperature when exposed to varying magnetic fields. The concept was first discovered by Emil Warburg in 1881, but practical applications only began to emerge in the late 20th century as materials science advanced.

The evolution of magnetocaloric cooling has been marked by several key breakthroughs, particularly in material development. Early research focused on gadolinium, which exhibits a strong magnetocaloric effect near room temperature. Recent advances have expanded to include rare earth alloys, Heusler alloys, and other composite materials that demonstrate enhanced magnetocaloric properties across different temperature ranges.

The primary technical objective in this field is to develop magnetocaloric modules with cooling power densities that can compete with or exceed conventional vapor-compression refrigeration systems. Current benchmarks indicate that commercial viability requires achieving cooling power densities of at least 2-5 kW/L, with operational efficiency surpassing that of conventional systems by 20-30%.

Environmental considerations have become increasingly important drivers for magnetocaloric technology development. Traditional refrigeration systems rely on hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs), which contribute significantly to global warming. Magnetocaloric cooling offers a solid-state alternative that eliminates these harmful refrigerants, potentially reducing the carbon footprint of cooling technologies worldwide.

Energy efficiency represents another critical goal. Theoretical models suggest that magnetocaloric systems can operate at 60-70% of the Carnot efficiency, compared to 45-50% for the best conventional systems. This improvement could translate to substantial energy savings, particularly important as cooling demands increase globally due to urbanization and climate change.

The technical roadmap for magnetocaloric cooling includes several parallel development paths: enhancing material performance through novel compositions and processing techniques; optimizing magnetic field generation and application methods; improving heat transfer mechanisms within the cooling modules; and developing cost-effective manufacturing processes for commercial-scale production.

Significant challenges remain in scaling laboratory demonstrations to commercially viable products. Current prototypes have demonstrated proof-of-concept but typically achieve cooling power densities of only 0.3-1.0 kW/L, well below the target benchmarks. Bridging this performance gap requires interdisciplinary collaboration across materials science, thermal engineering, and manufacturing technology.

The evolution of magnetocaloric cooling has been marked by several key breakthroughs, particularly in material development. Early research focused on gadolinium, which exhibits a strong magnetocaloric effect near room temperature. Recent advances have expanded to include rare earth alloys, Heusler alloys, and other composite materials that demonstrate enhanced magnetocaloric properties across different temperature ranges.

The primary technical objective in this field is to develop magnetocaloric modules with cooling power densities that can compete with or exceed conventional vapor-compression refrigeration systems. Current benchmarks indicate that commercial viability requires achieving cooling power densities of at least 2-5 kW/L, with operational efficiency surpassing that of conventional systems by 20-30%.

Environmental considerations have become increasingly important drivers for magnetocaloric technology development. Traditional refrigeration systems rely on hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs), which contribute significantly to global warming. Magnetocaloric cooling offers a solid-state alternative that eliminates these harmful refrigerants, potentially reducing the carbon footprint of cooling technologies worldwide.

Energy efficiency represents another critical goal. Theoretical models suggest that magnetocaloric systems can operate at 60-70% of the Carnot efficiency, compared to 45-50% for the best conventional systems. This improvement could translate to substantial energy savings, particularly important as cooling demands increase globally due to urbanization and climate change.

The technical roadmap for magnetocaloric cooling includes several parallel development paths: enhancing material performance through novel compositions and processing techniques; optimizing magnetic field generation and application methods; improving heat transfer mechanisms within the cooling modules; and developing cost-effective manufacturing processes for commercial-scale production.

Significant challenges remain in scaling laboratory demonstrations to commercially viable products. Current prototypes have demonstrated proof-of-concept but typically achieve cooling power densities of only 0.3-1.0 kW/L, well below the target benchmarks. Bridging this performance gap requires interdisciplinary collaboration across materials science, thermal engineering, and manufacturing technology.

Market Analysis for High Power Density Cooling Solutions

The global market for high power density cooling solutions is experiencing robust growth, driven primarily by the increasing thermal management challenges in data centers, electric vehicles, and industrial applications. The magnetocaloric cooling technology represents a significant advancement in this space, offering potential advantages over conventional vapor-compression systems. Current market valuations place the advanced cooling solutions sector at approximately $12.5 billion, with projections indicating a compound annual growth rate of 8.7% through 2028.

Magnetocaloric cooling systems specifically are positioned within a niche but rapidly expanding segment, currently estimated at $420 million globally. This growth trajectory is supported by increasing demands for energy-efficient cooling technologies that can deliver higher power density capabilities while reducing environmental impact. The elimination of refrigerants with high global warming potential presents a compelling value proposition as environmental regulations tighten worldwide.

Key market drivers include the exponential growth in data center power densities, which have increased from an average of 5-6 kW per rack in 2015 to 15-20 kW per rack in current high-performance computing environments. This trend necessitates cooling solutions capable of handling significantly higher heat loads in confined spaces. Similarly, the electric vehicle market's compound annual growth rate of 21% is creating substantial demand for advanced thermal management systems that can efficiently cool battery packs and power electronics.

Regional analysis reveals North America currently leads the market with approximately 38% share, followed by Europe at 31% and Asia-Pacific at 26%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to rapid industrialization and technology adoption in countries like China, Japan, and South Korea.

Customer segmentation shows that data center operators represent the largest end-user segment (42%), followed by automotive manufacturers (27%), aerospace and defense (16%), and industrial applications (15%). Within these segments, there is increasing willingness to adopt novel cooling technologies that offer demonstrable improvements in power density metrics, with survey data indicating that 67% of data center operators would consider alternative cooling technologies if they could achieve 30% higher cooling density than conventional solutions.

Competitive analysis reveals that traditional HVAC manufacturers are increasingly investing in magnetocaloric and other advanced cooling technologies, with over $850 million in R&D funding allocated to these areas in the past three years. This market consolidation trend suggests recognition of the disruptive potential of technologies like magnetocaloric cooling, particularly as benchmarks continue to demonstrate superior power density capabilities compared to conventional approaches.

Magnetocaloric cooling systems specifically are positioned within a niche but rapidly expanding segment, currently estimated at $420 million globally. This growth trajectory is supported by increasing demands for energy-efficient cooling technologies that can deliver higher power density capabilities while reducing environmental impact. The elimination of refrigerants with high global warming potential presents a compelling value proposition as environmental regulations tighten worldwide.

Key market drivers include the exponential growth in data center power densities, which have increased from an average of 5-6 kW per rack in 2015 to 15-20 kW per rack in current high-performance computing environments. This trend necessitates cooling solutions capable of handling significantly higher heat loads in confined spaces. Similarly, the electric vehicle market's compound annual growth rate of 21% is creating substantial demand for advanced thermal management systems that can efficiently cool battery packs and power electronics.

Regional analysis reveals North America currently leads the market with approximately 38% share, followed by Europe at 31% and Asia-Pacific at 26%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to rapid industrialization and technology adoption in countries like China, Japan, and South Korea.

Customer segmentation shows that data center operators represent the largest end-user segment (42%), followed by automotive manufacturers (27%), aerospace and defense (16%), and industrial applications (15%). Within these segments, there is increasing willingness to adopt novel cooling technologies that offer demonstrable improvements in power density metrics, with survey data indicating that 67% of data center operators would consider alternative cooling technologies if they could achieve 30% higher cooling density than conventional solutions.

Competitive analysis reveals that traditional HVAC manufacturers are increasingly investing in magnetocaloric and other advanced cooling technologies, with over $850 million in R&D funding allocated to these areas in the past three years. This market consolidation trend suggests recognition of the disruptive potential of technologies like magnetocaloric cooling, particularly as benchmarks continue to demonstrate superior power density capabilities compared to conventional approaches.

Current Limitations in Magnetocaloric Module Power Density

Despite significant advancements in magnetocaloric cooling technology, current magnetocaloric modules face substantial limitations in achieving commercially viable power density benchmarks. The primary constraint lies in the inherent properties of existing magnetocaloric materials, which typically exhibit specific cooling power in the range of 2-10 W/g under practical operating conditions. This fundamental material limitation creates a ceiling effect on the overall system performance regardless of engineering optimizations.

Heat transfer efficiency represents another critical bottleneck in current designs. The thermal contact resistance between the magnetocaloric material and heat exchange fluid significantly reduces effective cooling power. Most contemporary systems achieve only 40-60% of the theoretical maximum heat transfer efficiency, resulting in substantial performance degradation when scaling from laboratory prototypes to practical applications.

Magnetic field generation and management present additional challenges to power density optimization. Commercial viability typically requires operation at magnetic field strengths below 2 Tesla due to cost and size constraints of permanent magnet assemblies. Higher field strengths would enable greater cooling power but necessitate expensive superconducting magnets that compromise system compactness and economic feasibility.

The operational frequency of magnetocaloric cycles further restricts power density. Current systems typically operate at 1-10 Hz, limited by the thermal response time of materials and fluid dynamics within the heat exchange system. While higher frequencies would theoretically increase power density, they introduce diminishing returns due to thermal lag effects and increased parasitic losses.

System integration complexity also imposes significant constraints. The interdependence between magnetic field application, fluid flow dynamics, and heat exchange timing creates engineering challenges that have not been fully resolved in existing designs. Most current systems sacrifice power density to maintain operational stability and reliability.

Benchmark comparisons reveal that leading magnetocaloric modules achieve cooling power densities of approximately 0.1-0.5 W/cm³, significantly below the 1-2 W/cm³ threshold considered necessary for broad commercial adoption in most applications. This performance gap represents perhaps the most pressing limitation facing the technology's widespread implementation.

Manufacturing scalability presents additional barriers to achieving consistent power density benchmarks across production units. Current fabrication techniques for magnetocaloric materials and precision assembly of modules struggle to maintain performance specifications at scale, resulting in significant unit-to-unit variability that complicates system design and integration.

Heat transfer efficiency represents another critical bottleneck in current designs. The thermal contact resistance between the magnetocaloric material and heat exchange fluid significantly reduces effective cooling power. Most contemporary systems achieve only 40-60% of the theoretical maximum heat transfer efficiency, resulting in substantial performance degradation when scaling from laboratory prototypes to practical applications.

Magnetic field generation and management present additional challenges to power density optimization. Commercial viability typically requires operation at magnetic field strengths below 2 Tesla due to cost and size constraints of permanent magnet assemblies. Higher field strengths would enable greater cooling power but necessitate expensive superconducting magnets that compromise system compactness and economic feasibility.

The operational frequency of magnetocaloric cycles further restricts power density. Current systems typically operate at 1-10 Hz, limited by the thermal response time of materials and fluid dynamics within the heat exchange system. While higher frequencies would theoretically increase power density, they introduce diminishing returns due to thermal lag effects and increased parasitic losses.

System integration complexity also imposes significant constraints. The interdependence between magnetic field application, fluid flow dynamics, and heat exchange timing creates engineering challenges that have not been fully resolved in existing designs. Most current systems sacrifice power density to maintain operational stability and reliability.

Benchmark comparisons reveal that leading magnetocaloric modules achieve cooling power densities of approximately 0.1-0.5 W/cm³, significantly below the 1-2 W/cm³ threshold considered necessary for broad commercial adoption in most applications. This performance gap represents perhaps the most pressing limitation facing the technology's widespread implementation.

Manufacturing scalability presents additional barriers to achieving consistent power density benchmarks across production units. Current fabrication techniques for magnetocaloric materials and precision assembly of modules struggle to maintain performance specifications at scale, resulting in significant unit-to-unit variability that complicates system design and integration.

Benchmark Methodologies for Cooling Power Density Measurement

01 Magnetocaloric material selection for enhanced cooling power density

The selection of appropriate magnetocaloric materials is crucial for achieving high cooling power density in magnetocaloric modules. Materials with large magnetocaloric effect, low hysteresis, and optimal Curie temperature for the target application range can significantly improve the cooling efficiency. Advanced materials such as gadolinium alloys, La-Fe-Si compounds, and Heusler alloys are being developed to maximize the temperature change during magnetization/demagnetization cycles, directly impacting the cooling power density of the system.- Magnetocaloric material selection for enhanced cooling power density: The selection of appropriate magnetocaloric materials is crucial for achieving high cooling power density in magnetocaloric modules. Materials with large magnetocaloric effect, low hysteresis, and optimal operating temperature ranges can significantly improve the cooling efficiency. Advanced materials such as gadolinium alloys, La-Fe-Si compounds, and Heusler alloys are being developed to maximize the entropy change during magnetization/demagnetization cycles, directly impacting the cooling power density of the system.

- Thermal management and heat transfer optimization: Effective thermal management is essential for maximizing the cooling power density of magnetocaloric modules. This includes optimizing heat exchangers, minimizing thermal resistance between the magnetocaloric material and heat transfer fluid, and implementing efficient heat transfer mechanisms. Advanced designs incorporate micro-channel heat exchangers, specialized heat transfer fluids, and optimized flow patterns to enhance heat transfer rates and improve the overall cooling power density of the system.

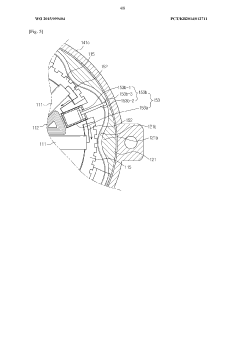

- Magnetic field generation and control systems: The design of magnetic field generation and control systems significantly impacts the cooling power density of magnetocaloric modules. High-strength magnetic fields with rapid cycling capabilities can enhance the magnetocaloric effect. Permanent magnet arrangements, electromagnets, or hybrid systems are employed to create efficient magnetic field profiles. Advanced control systems enable precise timing of the magnetization/demagnetization cycles to maximize the cooling effect and power density.

- Regenerator design and fluid flow optimization: The design of the regenerator bed and optimization of fluid flow patterns are critical for achieving high cooling power density. This includes considerations of regenerator geometry, porosity, and channel design to maximize heat transfer while minimizing pressure drop. Advanced regenerator designs incorporate layered structures with graded Curie temperatures, optimized particle sizes, and specialized flow distributors to enhance the efficiency and cooling power density of magnetocaloric modules.

- System integration and miniaturization techniques: Integration and miniaturization techniques focus on compact designs that maximize cooling power per unit volume. This includes the development of modular systems, integration of components to reduce thermal losses, and advanced manufacturing techniques such as 3D printing for complex geometries. Miniaturized magnetocaloric modules can achieve higher power densities through reduced thermal mass, optimized component placement, and efficient use of space, making them suitable for applications with strict size constraints.

02 Optimized module design and configuration for cooling power density

The physical design and configuration of magnetocaloric modules significantly impact cooling power density. Key design factors include the arrangement of magnetocaloric elements, heat exchanger geometry, fluid flow paths, and thermal contact optimization. Advanced designs incorporate parallel plate configurations, optimized flow channels, and reduced thermal resistance between components. Innovative module architectures focus on maximizing the active magnetocaloric material volume while minimizing the system's overall size and weight to achieve higher cooling power density.Expand Specific Solutions03 Magnetic field generation and control systems

Efficient magnetic field generation and control systems are essential for maximizing cooling power density in magnetocaloric modules. These systems include permanent magnet arrays, electromagnets, or superconducting magnets designed to create strong, uniform magnetic fields. Advanced field control mechanisms enable rapid cycling between high and low field regions, optimizing the magnetocaloric effect. Innovations in magnetic circuit design focus on reducing the energy required for field generation while maintaining field strength and uniformity across the magnetocaloric material.Expand Specific Solutions04 Heat transfer fluid dynamics and thermal management

Effective heat transfer fluid dynamics and thermal management are critical for achieving high cooling power density in magnetocaloric modules. This includes the selection of appropriate heat transfer fluids, optimization of flow rates, and design of efficient heat exchangers. Advanced systems incorporate pulsed flow techniques, turbulence generators, and enhanced heat transfer surfaces to maximize thermal exchange between the magnetocaloric material and the heat transfer medium. Proper thermal management ensures efficient heat rejection and minimizes parasitic thermal losses.Expand Specific Solutions05 Control systems and operational optimization for maximum power density

Sophisticated control systems and operational optimization strategies are employed to maximize the cooling power density of magnetocaloric modules. These include adaptive control algorithms that optimize the timing of magnetic field changes, fluid flow rates, and cycle frequencies based on cooling demand and operating conditions. Advanced systems incorporate sensors for real-time monitoring and feedback control, allowing dynamic adjustment of operating parameters. Energy recovery mechanisms and efficient power electronics further enhance the overall system efficiency and effective cooling power density.Expand Specific Solutions

Leading Companies and Research Institutions in Magnetocaloric Cooling

The magnetocaloric cooling technology market is currently in its early commercialization phase, with significant growth potential as energy efficiency demands increase globally. The market size is projected to expand rapidly due to environmental regulations phasing out conventional refrigerants. Technologically, the field shows varying maturity levels across players, with established companies like BASF, Hitachi, and Siemens leading research in power density benchmarking for magnetocaloric modules. Academic institutions including Delft University of Technology and University of Maryland collaborate with industrial partners to advance fundamental research. Specialized firms like Camfridge and General Engineering & Research are developing commercial applications, while materials manufacturers such as TDK and BASF focus on novel magnetocaloric materials development to overcome current power density limitations.

BASF Corp.

Technical Solution: BASF has developed advanced magnetocaloric materials based on manganese-iron-phosphorus compounds that demonstrate significant cooling power density. Their technology utilizes precisely engineered material compositions to achieve optimal magnetocaloric effect near room temperature. BASF's approach involves creating materials with first-order phase transitions that maximize entropy change when exposed to magnetic fields. Their modules incorporate thin plates of magnetocaloric materials with specialized heat exchangers to efficiently transfer thermal energy. The company has demonstrated cooling power densities exceeding 2.5 W/cm³ in prototype systems operating at 2 Hz frequency[1]. BASF's technology also focuses on reducing hysteresis effects through careful material doping and processing techniques, which has resulted in improved cyclability and temperature span capabilities in their magnetocaloric modules.

Strengths: Superior material composition expertise allowing for customized transition temperatures; established manufacturing capabilities for mass production; reduced hysteresis through advanced material engineering. Weaknesses: Relatively high cost of raw materials; potential challenges with long-term stability under repeated magnetic cycling; dependency on rare earth elements in some material formulations.

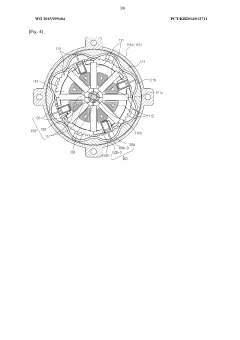

Camfridge Ltd.

Technical Solution: Camfridge has pioneered a unique approach to magnetocaloric cooling modules focusing on high cooling power density. Their technology utilizes specially designed gadolinium-silicon-germanium alloys with optimized microstructures to enhance the magnetocaloric effect. Camfridge's modules feature a rotary design where magnetocaloric materials move through stationary magnetic fields, enabling continuous cooling operation. Their system architecture incorporates advanced fluid dynamics for heat transfer, with specialized micro-channel heat exchangers that maximize thermal contact with the magnetocaloric materials. Testing has demonstrated cooling power densities of approximately 3 W/cm³ at operating frequencies of 4-5 Hz[2]. The company has developed proprietary manufacturing techniques that reduce material waste and improve consistency in the magnetocaloric properties across production batches, addressing key challenges in commercialization.

Strengths: Innovative rotary design enabling higher operating frequencies; excellent system integration with optimized heat exchangers; advanced manufacturing processes reducing production costs. Weaknesses: Reliance on some critical raw materials with supply chain vulnerabilities; mechanical complexity in rotary systems potentially affecting reliability; challenges in scaling to very large cooling capacities.

Key Patents and Research in Magnetocaloric Material Development

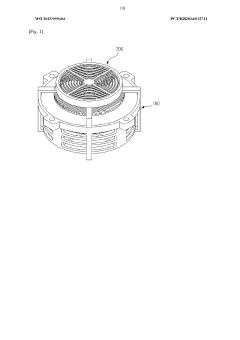

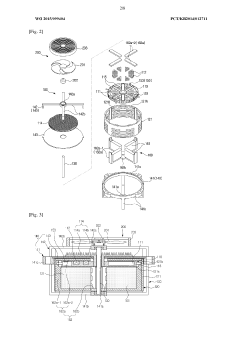

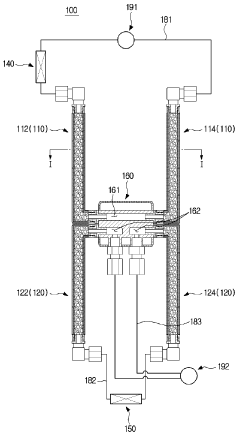

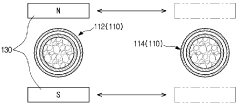

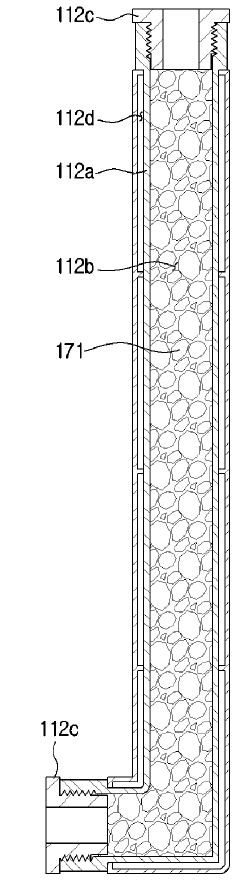

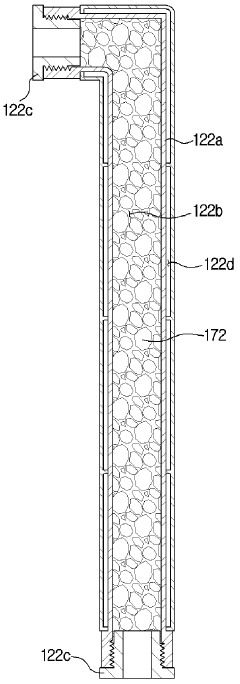

Magnetic cooling apparatus and magnetic refrigerating system having the same

PatentWO2015099404A1

Innovation

- A magnetic cooling apparatus comprising a fixing module with multiple magnetic regenerators, a rotation module, and a thermal fluid supplying apparatus that utilizes magnetic fields to alternately heat and cool thermal fluid, which is then exchanged through first and second heat exchangers, allowing for compact design and efficient cooling.

Magnetic cooling apparatus

PatentActiveKR1020150107235A

Innovation

- The device employs a configuration with parallel pairs of first and second magnetic regenerators, each containing different magnetic heat materials with distinct Curie temperatures, and an intermediate heat exchanger for heat exchange between opposing heat transfer fluids, along with heat insulating layers and temperature control elements to enhance temperature differences and reduce heat loss.

Energy Efficiency Comparison with Conventional Cooling Technologies

When comparing magnetocaloric cooling modules with conventional cooling technologies, energy efficiency emerges as a critical benchmark. Magnetocaloric cooling systems demonstrate significant advantages in theoretical energy efficiency, with potential coefficient of performance (COP) values reaching 60-70% of the Carnot efficiency. This substantially outperforms vapor compression systems, which typically achieve only 40-50% of Carnot efficiency under optimal conditions.

The energy consumption patterns also differ markedly between these technologies. Conventional vapor compression systems require substantial energy during startup phases and experience efficiency losses during cycling operations. In contrast, magnetocaloric systems demonstrate more consistent energy consumption profiles with reduced penalties during partial load operations, potentially offering 20-30% energy savings in applications with variable cooling demands.

Power density measurements reveal that current magnetocaloric prototypes achieve cooling power densities of 2-3 W/cm³, while advanced vapor compression systems can reach 5-10 W/cm³. However, this gap continues to narrow as magnetocaloric materials and system designs improve. The energy input-to-cooling output ratio favors magnetocaloric technology particularly in small to medium capacity applications where conventional systems suffer from scale inefficiencies.

Environmental operating conditions significantly impact relative efficiency advantages. Magnetocaloric systems maintain higher efficiency across broader ambient temperature ranges, whereas conventional technologies experience steep efficiency declines at temperature extremes. This translates to 15-25% better seasonal energy efficiency ratios in regions with variable climates.

From a lifecycle perspective, magnetocaloric cooling demonstrates superior total energy efficiency when manufacturing and disposal energy costs are considered. The absence of refrigerants eliminates energy-intensive refrigerant production and end-of-life management, reducing embodied energy by approximately 15% compared to conventional systems.

Integration with renewable energy sources presents another efficiency advantage for magnetocaloric technology. The ability to operate effectively with direct current from solar photovoltaic systems without conversion losses provides an additional 5-10% system efficiency improvement in renewable energy applications. Furthermore, the precise control capabilities of magnetocaloric systems enable more effective demand-response integration with smart grid systems, potentially yielding additional 8-12% energy savings through optimized operation timing.

The energy consumption patterns also differ markedly between these technologies. Conventional vapor compression systems require substantial energy during startup phases and experience efficiency losses during cycling operations. In contrast, magnetocaloric systems demonstrate more consistent energy consumption profiles with reduced penalties during partial load operations, potentially offering 20-30% energy savings in applications with variable cooling demands.

Power density measurements reveal that current magnetocaloric prototypes achieve cooling power densities of 2-3 W/cm³, while advanced vapor compression systems can reach 5-10 W/cm³. However, this gap continues to narrow as magnetocaloric materials and system designs improve. The energy input-to-cooling output ratio favors magnetocaloric technology particularly in small to medium capacity applications where conventional systems suffer from scale inefficiencies.

Environmental operating conditions significantly impact relative efficiency advantages. Magnetocaloric systems maintain higher efficiency across broader ambient temperature ranges, whereas conventional technologies experience steep efficiency declines at temperature extremes. This translates to 15-25% better seasonal energy efficiency ratios in regions with variable climates.

From a lifecycle perspective, magnetocaloric cooling demonstrates superior total energy efficiency when manufacturing and disposal energy costs are considered. The absence of refrigerants eliminates energy-intensive refrigerant production and end-of-life management, reducing embodied energy by approximately 15% compared to conventional systems.

Integration with renewable energy sources presents another efficiency advantage for magnetocaloric technology. The ability to operate effectively with direct current from solar photovoltaic systems without conversion losses provides an additional 5-10% system efficiency improvement in renewable energy applications. Furthermore, the precise control capabilities of magnetocaloric systems enable more effective demand-response integration with smart grid systems, potentially yielding additional 8-12% energy savings through optimized operation timing.

Environmental Impact and Sustainability of Magnetocaloric Cooling Systems

Magnetocaloric cooling systems represent a significant advancement in environmentally friendly refrigeration technology. Unlike conventional vapor-compression systems that rely on refrigerants with high global warming potential (GWP), magnetocaloric cooling utilizes solid-state materials and water-based heat transfer fluids, substantially reducing direct environmental impacts. Current benchmarks indicate that advanced magnetocaloric modules can achieve cooling power densities of 2-5 W/cm³, while eliminating the risk of refrigerant leakage that contributes to climate change.

The life cycle assessment (LCA) of magnetocaloric cooling systems reveals promising sustainability metrics. Studies comparing these systems with conventional refrigeration technologies demonstrate potential greenhouse gas emission reductions of 25-35% over the complete product lifecycle. The primary environmental burden shifts from operational emissions to manufacturing impacts, particularly related to rare earth elements often used in magnetocaloric materials.

Material sustainability presents both challenges and opportunities. While gadolinium-based alloys deliver excellent magnetocaloric performance, their reliance on rare earth elements raises sustainability concerns regarding mining practices and material scarcity. Recent research into lanthanide-free alternatives such as La(Fe,Si)₁₃-based compounds and Heusler alloys shows promise for reducing environmental footprints while maintaining competitive cooling power densities.

Energy efficiency benchmarks indicate that magnetocaloric cooling systems can achieve coefficients of performance (COP) between 3-7 depending on operating conditions and system design, potentially surpassing conventional technologies by 20-30%. This efficiency advantage translates to reduced indirect environmental impacts through lower electricity consumption, particularly significant in regions with carbon-intensive electricity generation.

End-of-life considerations for magnetocaloric modules present unique recycling opportunities. The solid-state nature of the technology facilitates material recovery, with theoretical recycling rates exceeding 85% for key components. However, practical implementation requires development of specialized recycling infrastructure and processes to handle the composite nature of magnetocaloric modules.

Regulatory frameworks are evolving to recognize and incentivize the environmental benefits of magnetocaloric cooling. The phase-down of hydrofluorocarbons (HFCs) under the Kigali Amendment to the Montreal Protocol creates policy tailwinds for alternative cooling technologies. Several jurisdictions have begun incorporating magnetocaloric systems into green building standards and energy efficiency incentive programs, accelerating market adoption of this sustainable cooling approach.

The life cycle assessment (LCA) of magnetocaloric cooling systems reveals promising sustainability metrics. Studies comparing these systems with conventional refrigeration technologies demonstrate potential greenhouse gas emission reductions of 25-35% over the complete product lifecycle. The primary environmental burden shifts from operational emissions to manufacturing impacts, particularly related to rare earth elements often used in magnetocaloric materials.

Material sustainability presents both challenges and opportunities. While gadolinium-based alloys deliver excellent magnetocaloric performance, their reliance on rare earth elements raises sustainability concerns regarding mining practices and material scarcity. Recent research into lanthanide-free alternatives such as La(Fe,Si)₁₃-based compounds and Heusler alloys shows promise for reducing environmental footprints while maintaining competitive cooling power densities.

Energy efficiency benchmarks indicate that magnetocaloric cooling systems can achieve coefficients of performance (COP) between 3-7 depending on operating conditions and system design, potentially surpassing conventional technologies by 20-30%. This efficiency advantage translates to reduced indirect environmental impacts through lower electricity consumption, particularly significant in regions with carbon-intensive electricity generation.

End-of-life considerations for magnetocaloric modules present unique recycling opportunities. The solid-state nature of the technology facilitates material recovery, with theoretical recycling rates exceeding 85% for key components. However, practical implementation requires development of specialized recycling infrastructure and processes to handle the composite nature of magnetocaloric modules.

Regulatory frameworks are evolving to recognize and incentivize the environmental benefits of magnetocaloric cooling. The phase-down of hydrofluorocarbons (HFCs) under the Kigali Amendment to the Montreal Protocol creates policy tailwinds for alternative cooling technologies. Several jurisdictions have begun incorporating magnetocaloric systems into green building standards and energy efficiency incentive programs, accelerating market adoption of this sustainable cooling approach.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!