Life Cycle Assessment Of Magnetic Refrigeration Versus Vapor Compression

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetic Refrigeration Technology Background and Objectives

Magnetic refrigeration technology represents a revolutionary approach to cooling systems that has been evolving since the discovery of the magnetocaloric effect by Emil Warburg in 1881. This phenomenon, where certain materials change temperature when exposed to changing magnetic fields, forms the foundation of magnetic refrigeration systems. The technology gained significant momentum in the late 20th century when materials with giant magnetocaloric effects were discovered, particularly gadolinium and its alloys.

The evolution of magnetic refrigeration has been driven by increasing environmental concerns associated with conventional vapor compression refrigeration systems. Traditional refrigerants such as chlorofluorocarbons (CFCs), hydrochlorofluorocarbons (HCFCs), and hydrofluorocarbons (HFCs) have been linked to ozone depletion and global warming, prompting international regulations like the Montreal Protocol and the Kigali Amendment to phase out these substances.

Magnetic refrigeration offers a promising alternative with potentially zero direct greenhouse gas emissions, as it uses solid refrigerants and water-based heat transfer fluids instead of gaseous refrigerants with high global warming potential. The technology aims to achieve comparable or superior cooling efficiency to conventional systems while significantly reducing environmental impact throughout its lifecycle.

The primary technical objective of magnetic refrigeration development is to create commercially viable systems that can compete with vapor compression technology in terms of cooling capacity, energy efficiency, and cost-effectiveness. Current research focuses on optimizing magnetocaloric materials to achieve larger temperature changes under practical magnetic field strengths, as well as designing efficient heat exchange systems to maximize the cooling effect.

Another critical objective is scaling the technology from laboratory demonstrations to commercial applications across various sectors including domestic refrigeration, commercial cooling, and industrial refrigeration. This requires addressing challenges related to system size, magnetic field generation efficiency, and overall system integration.

From a sustainability perspective, magnetic refrigeration aims to reduce the life cycle environmental impact of cooling technologies by eliminating harmful refrigerants, potentially improving energy efficiency, and utilizing materials with lower environmental footprints. The technology seeks to align with global sustainability goals and contribute to carbon neutrality targets by revolutionizing one of the most energy-intensive sectors worldwide.

As climate change concerns intensify and energy efficiency standards become more stringent, magnetic refrigeration represents a strategic technology with the potential to transform cooling systems across multiple industries while supporting environmental sustainability objectives.

The evolution of magnetic refrigeration has been driven by increasing environmental concerns associated with conventional vapor compression refrigeration systems. Traditional refrigerants such as chlorofluorocarbons (CFCs), hydrochlorofluorocarbons (HCFCs), and hydrofluorocarbons (HFCs) have been linked to ozone depletion and global warming, prompting international regulations like the Montreal Protocol and the Kigali Amendment to phase out these substances.

Magnetic refrigeration offers a promising alternative with potentially zero direct greenhouse gas emissions, as it uses solid refrigerants and water-based heat transfer fluids instead of gaseous refrigerants with high global warming potential. The technology aims to achieve comparable or superior cooling efficiency to conventional systems while significantly reducing environmental impact throughout its lifecycle.

The primary technical objective of magnetic refrigeration development is to create commercially viable systems that can compete with vapor compression technology in terms of cooling capacity, energy efficiency, and cost-effectiveness. Current research focuses on optimizing magnetocaloric materials to achieve larger temperature changes under practical magnetic field strengths, as well as designing efficient heat exchange systems to maximize the cooling effect.

Another critical objective is scaling the technology from laboratory demonstrations to commercial applications across various sectors including domestic refrigeration, commercial cooling, and industrial refrigeration. This requires addressing challenges related to system size, magnetic field generation efficiency, and overall system integration.

From a sustainability perspective, magnetic refrigeration aims to reduce the life cycle environmental impact of cooling technologies by eliminating harmful refrigerants, potentially improving energy efficiency, and utilizing materials with lower environmental footprints. The technology seeks to align with global sustainability goals and contribute to carbon neutrality targets by revolutionizing one of the most energy-intensive sectors worldwide.

As climate change concerns intensify and energy efficiency standards become more stringent, magnetic refrigeration represents a strategic technology with the potential to transform cooling systems across multiple industries while supporting environmental sustainability objectives.

Market Analysis for Sustainable Cooling Technologies

The global cooling technology market is experiencing a significant shift towards sustainable solutions, driven by increasing environmental concerns and stringent regulations on conventional refrigeration systems. The market for sustainable cooling technologies is projected to grow at a compound annual growth rate of 8.2% between 2023 and 2030, reaching a value of $38.4 billion by the end of the forecast period. This growth is primarily fueled by the phase-out of hydrofluorocarbons (HFCs) under the Kigali Amendment to the Montreal Protocol and the rising energy costs worldwide.

Magnetic refrigeration represents an emerging segment within this market, currently accounting for less than 1% of the total cooling technology market but showing promising growth potential. Industry analysts predict that magnetic refrigeration could capture up to 15% of the commercial refrigeration market by 2035, particularly in regions with advanced technological infrastructure and strong environmental policies.

The vapor compression refrigeration market, while still dominant with over 90% market share, is facing increasing challenges due to environmental concerns. However, it continues to benefit from established manufacturing infrastructure, lower initial costs, and widespread technical expertise. The transition from traditional vapor compression systems to more sustainable alternatives is expected to be gradual, with hybrid solutions gaining traction in the mid-term.

Regional analysis indicates that Europe leads in the adoption of sustainable cooling technologies, with stringent environmental regulations and substantial research funding. North America follows closely, driven by corporate sustainability initiatives and government incentives. The Asia-Pacific region, particularly China and Japan, is showing the fastest growth rate in research and development of magnetic refrigeration technologies.

Consumer and industrial demand patterns reveal a growing willingness to pay premium prices for environmentally friendly cooling solutions, especially in sectors where cooling represents a significant portion of operational costs. The healthcare, food retail, and data center industries are identified as early adopters of advanced cooling technologies, including magnetic refrigeration.

Economic analysis suggests that while magnetic refrigeration systems currently have higher upfront costs compared to conventional vapor compression systems, their total cost of ownership over a 15-year lifecycle could be 20-30% lower due to reduced energy consumption and maintenance requirements. This economic advantage is expected to improve as manufacturing scales up and technology matures.

Magnetic refrigeration represents an emerging segment within this market, currently accounting for less than 1% of the total cooling technology market but showing promising growth potential. Industry analysts predict that magnetic refrigeration could capture up to 15% of the commercial refrigeration market by 2035, particularly in regions with advanced technological infrastructure and strong environmental policies.

The vapor compression refrigeration market, while still dominant with over 90% market share, is facing increasing challenges due to environmental concerns. However, it continues to benefit from established manufacturing infrastructure, lower initial costs, and widespread technical expertise. The transition from traditional vapor compression systems to more sustainable alternatives is expected to be gradual, with hybrid solutions gaining traction in the mid-term.

Regional analysis indicates that Europe leads in the adoption of sustainable cooling technologies, with stringent environmental regulations and substantial research funding. North America follows closely, driven by corporate sustainability initiatives and government incentives. The Asia-Pacific region, particularly China and Japan, is showing the fastest growth rate in research and development of magnetic refrigeration technologies.

Consumer and industrial demand patterns reveal a growing willingness to pay premium prices for environmentally friendly cooling solutions, especially in sectors where cooling represents a significant portion of operational costs. The healthcare, food retail, and data center industries are identified as early adopters of advanced cooling technologies, including magnetic refrigeration.

Economic analysis suggests that while magnetic refrigeration systems currently have higher upfront costs compared to conventional vapor compression systems, their total cost of ownership over a 15-year lifecycle could be 20-30% lower due to reduced energy consumption and maintenance requirements. This economic advantage is expected to improve as manufacturing scales up and technology matures.

Current Status and Challenges in Magnetic Cooling Systems

Magnetic refrigeration technology has evolved significantly over the past decades, emerging as a promising alternative to conventional vapor compression cooling systems. Currently, magnetic cooling systems operate based on the magnetocaloric effect (MCE), where certain materials exhibit temperature changes when exposed to varying magnetic fields. The most advanced prototypes have achieved temperature spans of 20-25K, with cooling capacities ranging from a few watts to several kilowatts, demonstrating the technology's potential for practical applications.

Despite these advancements, magnetic cooling systems face several critical challenges that hinder widespread commercial adoption. The primary limitation remains the relatively low temperature span compared to vapor compression systems, which typically achieve spans of 40-50K. This restricts magnetic refrigeration's applicability in conventional refrigeration and air conditioning applications that require larger temperature differences.

Material constraints represent another significant hurdle. Current magnetocaloric materials, predominantly rare-earth-based alloys like gadolinium and its compounds, face issues of high cost, limited availability, and environmental concerns related to mining and processing. The search for alternative materials with comparable or superior magnetocaloric properties, but lower environmental impact and cost, remains an active research area.

System efficiency presents additional challenges. While theoretical analyses suggest magnetic refrigeration could achieve 30-40% higher efficiency than vapor compression systems, practical implementations have yet to consistently demonstrate this advantage. Current prototypes typically operate at comparable or slightly better coefficients of performance (COP) than conventional systems, ranging from 2-5 depending on operating conditions.

From a life cycle assessment perspective, magnetic cooling systems currently show mixed results. The production phase of magnetocaloric materials often has higher environmental impacts than conventional refrigerants due to energy-intensive rare earth element extraction and processing. However, these systems eliminate the need for harmful refrigerants with high global warming potential, potentially offering significant environmental benefits during operation and disposal phases.

Manufacturing scalability and system integration pose further challenges. The precise engineering required for magnetic field generation, fluid distribution systems, and heat exchangers increases complexity and cost. Current magnetic field generators, typically permanent magnets or electromagnets, are either too expensive, too bulky, or too energy-intensive for cost-effective mass production.

Globally, research efforts are concentrated in Europe, North America, and East Asia, with significant advancements coming from research institutions in Denmark, France, China, Japan, and the United States. Commercial development remains primarily at the prototype and demonstration stage, with few systems approaching market readiness. The technology readiness level (TRL) for magnetic refrigeration systems generally ranges between 4-6, indicating progress beyond basic research but still requiring significant development before full commercialization.

Despite these advancements, magnetic cooling systems face several critical challenges that hinder widespread commercial adoption. The primary limitation remains the relatively low temperature span compared to vapor compression systems, which typically achieve spans of 40-50K. This restricts magnetic refrigeration's applicability in conventional refrigeration and air conditioning applications that require larger temperature differences.

Material constraints represent another significant hurdle. Current magnetocaloric materials, predominantly rare-earth-based alloys like gadolinium and its compounds, face issues of high cost, limited availability, and environmental concerns related to mining and processing. The search for alternative materials with comparable or superior magnetocaloric properties, but lower environmental impact and cost, remains an active research area.

System efficiency presents additional challenges. While theoretical analyses suggest magnetic refrigeration could achieve 30-40% higher efficiency than vapor compression systems, practical implementations have yet to consistently demonstrate this advantage. Current prototypes typically operate at comparable or slightly better coefficients of performance (COP) than conventional systems, ranging from 2-5 depending on operating conditions.

From a life cycle assessment perspective, magnetic cooling systems currently show mixed results. The production phase of magnetocaloric materials often has higher environmental impacts than conventional refrigerants due to energy-intensive rare earth element extraction and processing. However, these systems eliminate the need for harmful refrigerants with high global warming potential, potentially offering significant environmental benefits during operation and disposal phases.

Manufacturing scalability and system integration pose further challenges. The precise engineering required for magnetic field generation, fluid distribution systems, and heat exchangers increases complexity and cost. Current magnetic field generators, typically permanent magnets or electromagnets, are either too expensive, too bulky, or too energy-intensive for cost-effective mass production.

Globally, research efforts are concentrated in Europe, North America, and East Asia, with significant advancements coming from research institutions in Denmark, France, China, Japan, and the United States. Commercial development remains primarily at the prototype and demonstration stage, with few systems approaching market readiness. The technology readiness level (TRL) for magnetic refrigeration systems generally ranges between 4-6, indicating progress beyond basic research but still requiring significant development before full commercialization.

Comparative Technical Solutions: Magnetic vs Vapor Compression

01 Comparative life cycle assessment of magnetic refrigeration and vapor compression systems

Life cycle assessment methodologies are used to compare the environmental impact of magnetic refrigeration systems with conventional vapor compression systems. These assessments evaluate factors such as energy consumption, greenhouse gas emissions, and resource utilization throughout the entire lifecycle of both technologies. The analysis typically shows that magnetic refrigeration can offer environmental advantages due to the absence of refrigerants with high global warming potential, though manufacturing impacts must be considered.- Comparative life cycle assessment of magnetic refrigeration and vapor compression systems: Life cycle assessment methodologies are used to compare the environmental impacts of magnetic refrigeration systems versus conventional vapor compression systems. These assessments evaluate factors such as energy consumption, greenhouse gas emissions, and resource utilization throughout the entire lifecycle of both technologies. The analysis typically shows that magnetic refrigeration can offer environmental advantages due to the absence of refrigerants with high global warming potential, though manufacturing impacts must be considered.

- Energy efficiency analysis of magnetic refrigeration technology: Magnetic refrigeration systems are evaluated for their energy efficiency compared to conventional vapor compression systems. These analyses consider the coefficient of performance, power consumption, and thermal efficiency under various operating conditions. Studies indicate that magnetic refrigeration can potentially achieve higher energy efficiency, particularly in specific temperature ranges, which contributes to reduced lifecycle environmental impacts and operational costs.

- Environmental impact of refrigerant-free cooling technologies: Magnetic refrigeration eliminates the need for conventional refrigerants that contribute to global warming and ozone depletion. Life cycle assessments evaluate the environmental benefits of these refrigerant-free cooling technologies, including reduced risk of refrigerant leakage and end-of-life disposal issues. The analyses quantify the potential reduction in direct greenhouse gas emissions and other environmental impacts throughout the system lifecycle.

- Material considerations in magnetic refrigeration lifecycle: The environmental impact of materials used in magnetic refrigeration systems is a critical aspect of lifecycle assessment. This includes the extraction and processing of rare earth elements and other materials used in magnetocaloric components, as well as their recyclability and disposal. Assessments compare these impacts against the material footprint of conventional vapor compression systems, considering factors such as resource depletion, toxicity, and waste generation.

- Economic lifecycle analysis and market adoption factors: Economic aspects of the lifecycle assessment compare the total cost of ownership between magnetic refrigeration and vapor compression systems. This includes initial investment, operational costs, maintenance requirements, and end-of-life considerations. The analyses evaluate market adoption barriers and opportunities, considering factors such as technological maturity, manufacturing scalability, and regulatory frameworks that may influence the commercial viability of magnetic refrigeration technology.

02 Energy efficiency analysis of magnetic refrigeration technology

Magnetic refrigeration systems are evaluated for their energy efficiency compared to conventional vapor compression systems. These analyses consider the coefficient of performance, power consumption, and thermal efficiency under various operating conditions. Studies indicate that magnetic refrigeration can potentially achieve higher energy efficiency, particularly in specific temperature ranges, which contributes to reduced lifecycle environmental impact and operational costs.Expand Specific Solutions03 Environmental impact of refrigerant-free cooling technologies

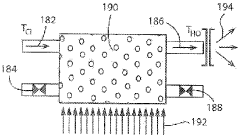

Magnetic refrigeration offers environmental benefits as a refrigerant-free cooling technology. Unlike vapor compression systems that use refrigerants with high global warming potential, magnetic refrigeration utilizes solid refrigerants and water-based heat transfer fluids. This eliminates refrigerant leakage concerns and end-of-life disposal issues, potentially reducing the overall environmental footprint throughout the product lifecycle.Expand Specific Solutions04 Material considerations in magnetic refrigeration lifecycle

The lifecycle assessment of magnetic refrigeration systems must consider the environmental impact of materials used, particularly rare earth elements in magnetocaloric materials. The extraction, processing, and eventual recycling or disposal of these materials significantly affect the overall sustainability of magnetic refrigeration technology. Research focuses on developing alternative materials with reduced environmental impact while maintaining performance efficiency.Expand Specific Solutions05 Economic lifecycle comparison between cooling technologies

Economic analyses compare the total lifecycle costs of magnetic refrigeration systems versus conventional vapor compression systems. These assessments include initial investment, operational costs, maintenance requirements, and end-of-life considerations. While magnetic refrigeration systems often have higher upfront costs due to specialized materials and components, they may offer long-term economic advantages through energy savings and reduced maintenance, depending on application and scale.Expand Specific Solutions

Key Industry Players in Advanced Refrigeration

The magnetic refrigeration market is in an early growth phase, with increasing interest due to its potential environmental advantages over traditional vapor compression systems. The global market size remains relatively small but is expected to expand significantly as the technology matures. From a technical maturity perspective, magnetic refrigeration is transitioning from research to commercialization, with key players at different development stages. Academic institutions like Technical University of Denmark and University of Porto are advancing fundamental research, while companies such as Astronautics Corporation of America and Toshiba have developed working prototypes. Established HVAC manufacturers including Danfoss, Carrier, and DENSO are investing in the technology, while materials specialists like Baotou Rare Earth Research Institute and DuPont are focusing on improving the magnetic refrigerants essential for system efficiency and cost-effectiveness.

Technical University of Denmark

Technical Solution: Technical University of Denmark (DTU) has conducted extensive research on magnetic refrigeration life cycle assessment compared to vapor compression systems. Their approach focuses on developing and optimizing magnetocaloric materials with reduced rare earth content while maintaining high performance. DTU has created comprehensive life cycle models that account for material extraction, manufacturing, use phase, and end-of-life scenarios for both technologies. Their research demonstrates that magnetic refrigeration systems can achieve 20-30% lower global warming potential over the full life cycle compared to vapor compression systems when optimized properly. DTU has developed novel magnetocaloric materials based on lanthanum-iron-silicon compounds that exhibit strong magnetocaloric effects near room temperature with reduced rare earth content. Their life cycle assessments incorporate detailed energy modeling across different climate zones and usage patterns, showing that magnetic refrigeration offers the greatest environmental benefits in regions with clean electricity generation. DTU has also pioneered advanced regenerator designs that maximize heat transfer efficiency while minimizing pressure drops in the heat transfer fluid.

Strengths: Comprehensive scientific approach to life cycle assessment; development of materials with reduced environmental impact; consideration of full cradle-to-grave environmental effects. Weaknesses: Research remains primarily academic rather than commercial implementation; some proposed materials still face durability and manufacturing challenges; economic viability not fully demonstrated at commercial scale.

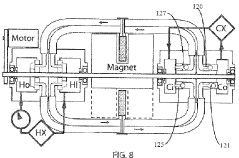

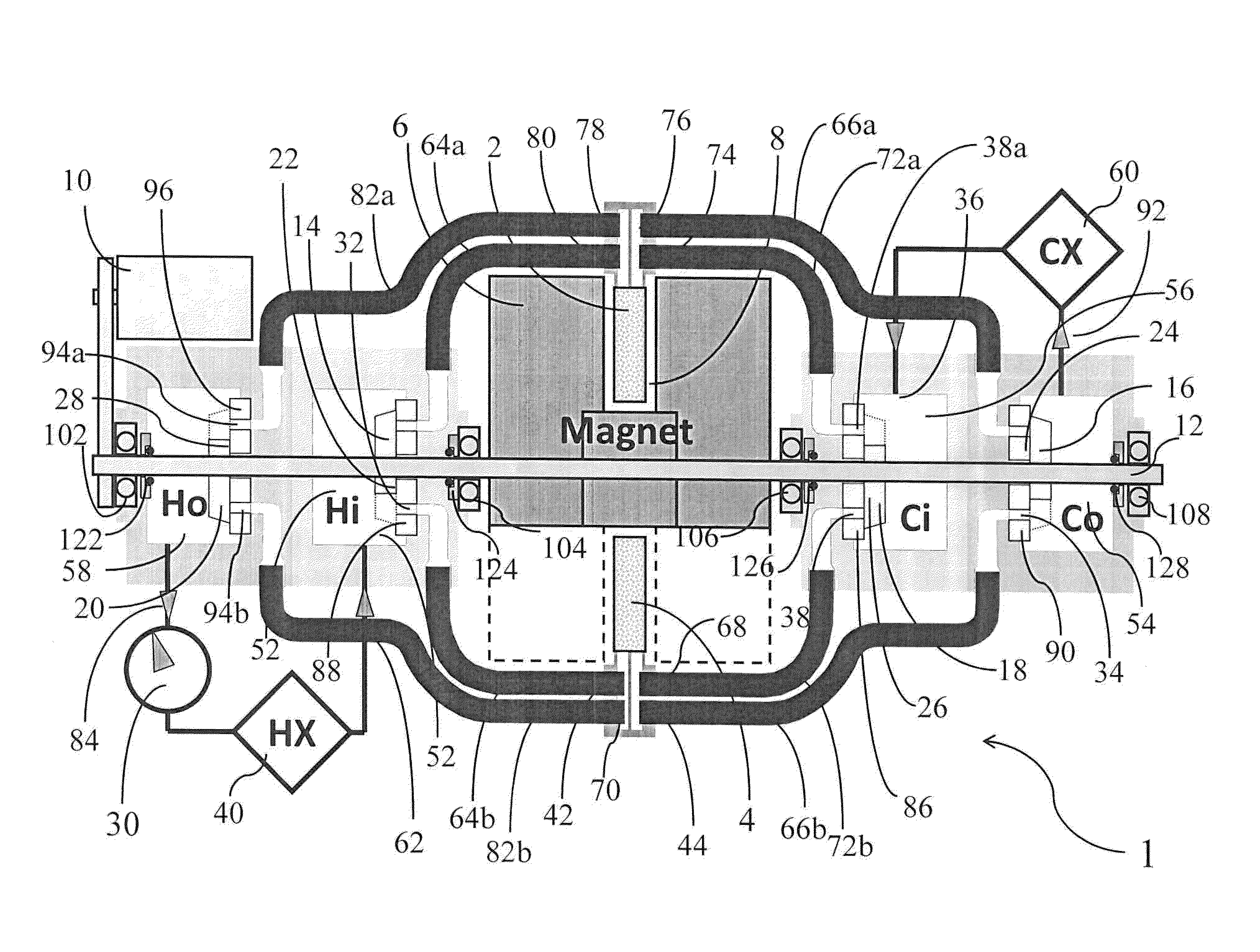

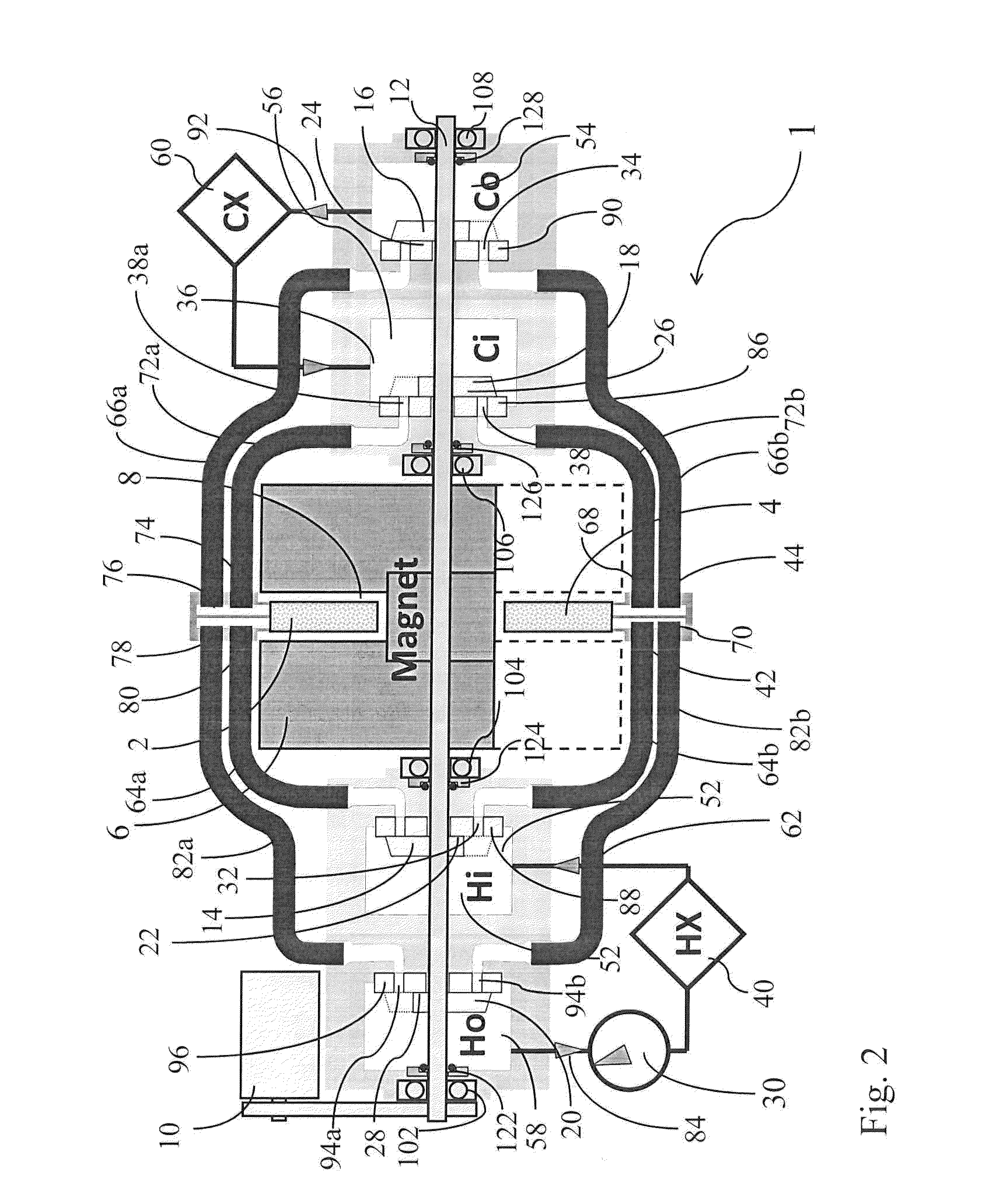

Astronautics Corporation of America

Technical Solution: Astronautics Corporation of America has developed advanced magnetic refrigeration systems based on the magnetocaloric effect (MCE). Their technology utilizes rotating permanent magnets and specialized magnetocaloric materials to create temperature gradients without traditional refrigerants. Their approach features a rotary magnetic refrigerator design with high-performance gadolinium alloys as the active magnetic regenerator (AMR) material. The system achieves cooling through cyclical magnetization and demagnetization processes, creating an environmentally friendly alternative to vapor compression. Life cycle assessment studies of their systems have demonstrated potential energy savings of 20-30% compared to conventional vapor compression systems, with significantly reduced global warming potential due to the elimination of refrigerants with high GWP values. Their technology has progressed from laboratory prototypes to near-commercial demonstration units capable of producing temperature spans exceeding 20°C with cooling capacities suitable for residential refrigeration applications.

Strengths: Zero direct greenhouse gas emissions due to elimination of refrigerants; potential for higher energy efficiency than vapor compression systems; reduced noise levels due to fewer moving parts. Weaknesses: Higher initial manufacturing costs due to expensive rare earth materials; limited temperature spans compared to mature vapor compression systems; challenges in scaling to higher cooling capacities.

Critical Patents and Research in Magnetocaloric Materials

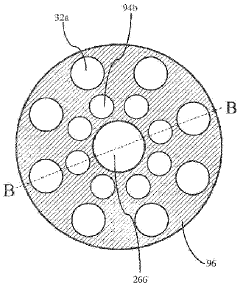

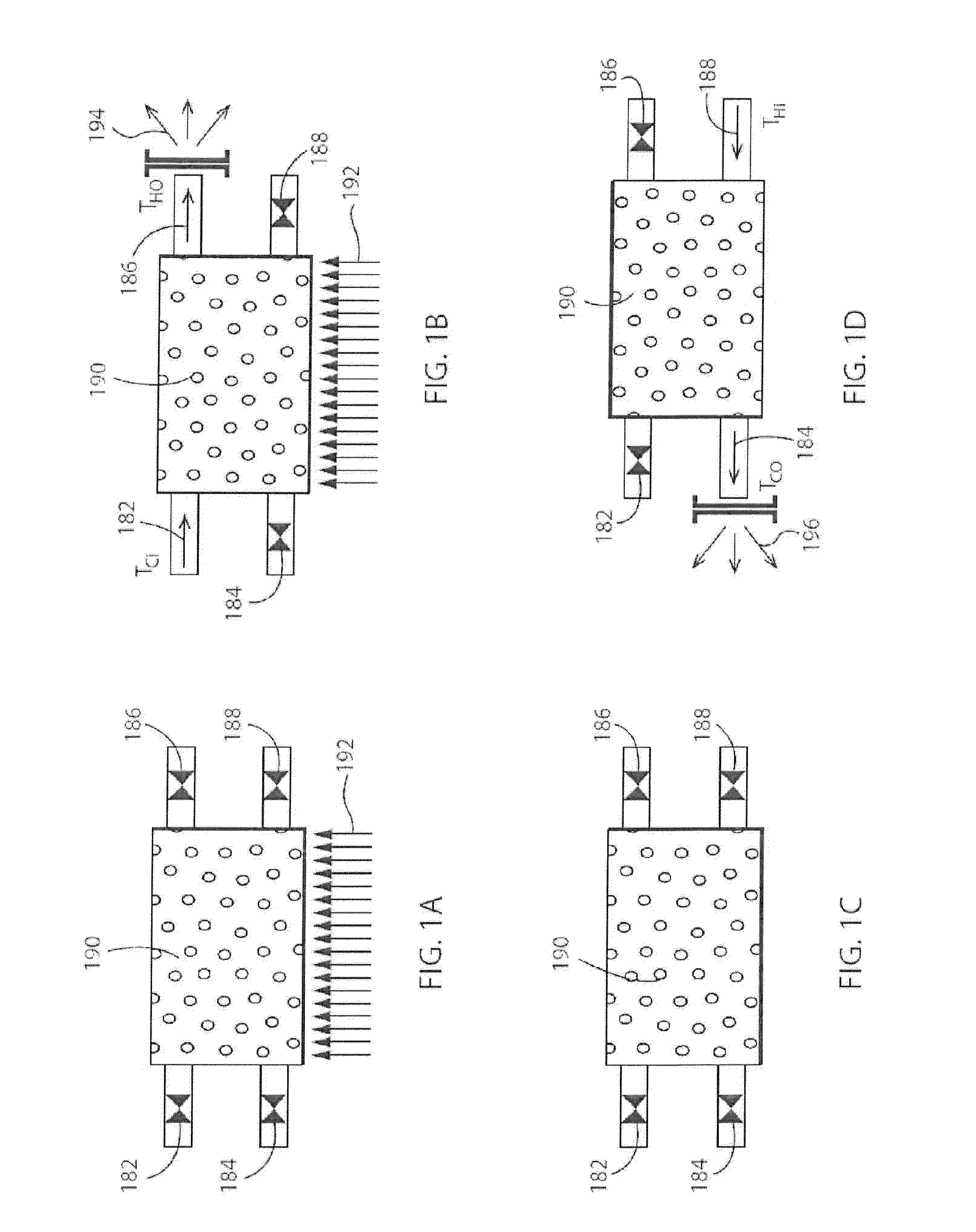

Magnetic refrigeration system with improved coaxial valve

PatentInactiveIN201717018041A

Innovation

- The implementation of a magnetic refrigeration system with balanced conduits, utilizing a rotary valve design with concentric positioning and adjustable compression mechanisms to ensure equal fluid flow through the valve system, addressing both steady-state and dynamic flow imbalances, and incorporating check valves for unidirectional flow to prevent backflow.

Magnetic Refrigeration System With Improved Flow Efficiency

PatentActiveUS20150168030A1

Innovation

- A magnetic refrigeration system with balanced conduits and a rotary valve design that synchronizes fluid flow with the magnet assembly, ensuring equal flow resistance and minimizing backflow by using concentric positioning of valves and a positive displacement pump for efficient fluid circulation.

Environmental Impact Assessment Methodologies

Environmental impact assessment methodologies for comparing magnetic refrigeration and vapor compression systems require comprehensive frameworks that capture the full spectrum of environmental effects throughout their life cycles. The Life Cycle Assessment (LCA) methodology stands as the primary analytical tool, following ISO 14040 and 14044 standards which establish a structured approach including goal and scope definition, inventory analysis, impact assessment, and interpretation phases.

For refrigeration technologies, specialized methodologies have been developed to address their unique environmental challenges. The TEWI (Total Equivalent Warming Impact) methodology combines direct emissions from refrigerant leakage with indirect emissions from energy consumption, providing a holistic view of climate impact. Similarly, the LCCP (Life Cycle Climate Performance) extends this approach by incorporating manufacturing and end-of-life emissions, offering a more comprehensive assessment framework.

Material flow analysis (MFA) plays a crucial role in evaluating magnetic refrigeration systems, particularly regarding rare earth elements used in magnetocaloric materials. This methodology tracks material inputs, outputs, and stocks throughout the product life cycle, highlighting potential resource constraints and environmental hotspots associated with mining and processing these critical materials.

Environmental impact categories typically assessed include global warming potential, ozone depletion potential, acidification, eutrophication, and resource depletion. For magnetic refrigeration specifically, additional metrics related to rare earth element extraction impacts, such as land use change and toxicity potentials, require careful consideration due to their significant environmental footprint.

Uncertainty analysis methodologies, including Monte Carlo simulation and sensitivity analysis, are essential when comparing emerging technologies like magnetic refrigeration with established vapor compression systems. These approaches help quantify confidence levels in comparative assessments where data quality may vary significantly between mature and developing technologies.

Consequential LCA methodologies are particularly relevant when evaluating market-wide transitions from conventional vapor compression to magnetic refrigeration technologies. Unlike attributional approaches that focus on direct impacts, consequential methodologies account for market-mediated effects and technological substitutions across broader economic systems.

Harmonization of methodological approaches remains challenging due to varying system boundaries, functional units, and allocation procedures across studies. Recent efforts have focused on developing standardized comparative frameworks specifically for cooling technologies that ensure fair comparison between conventional and emerging refrigeration systems while accounting for regional variations in electricity generation profiles and usage patterns.

For refrigeration technologies, specialized methodologies have been developed to address their unique environmental challenges. The TEWI (Total Equivalent Warming Impact) methodology combines direct emissions from refrigerant leakage with indirect emissions from energy consumption, providing a holistic view of climate impact. Similarly, the LCCP (Life Cycle Climate Performance) extends this approach by incorporating manufacturing and end-of-life emissions, offering a more comprehensive assessment framework.

Material flow analysis (MFA) plays a crucial role in evaluating magnetic refrigeration systems, particularly regarding rare earth elements used in magnetocaloric materials. This methodology tracks material inputs, outputs, and stocks throughout the product life cycle, highlighting potential resource constraints and environmental hotspots associated with mining and processing these critical materials.

Environmental impact categories typically assessed include global warming potential, ozone depletion potential, acidification, eutrophication, and resource depletion. For magnetic refrigeration specifically, additional metrics related to rare earth element extraction impacts, such as land use change and toxicity potentials, require careful consideration due to their significant environmental footprint.

Uncertainty analysis methodologies, including Monte Carlo simulation and sensitivity analysis, are essential when comparing emerging technologies like magnetic refrigeration with established vapor compression systems. These approaches help quantify confidence levels in comparative assessments where data quality may vary significantly between mature and developing technologies.

Consequential LCA methodologies are particularly relevant when evaluating market-wide transitions from conventional vapor compression to magnetic refrigeration technologies. Unlike attributional approaches that focus on direct impacts, consequential methodologies account for market-mediated effects and technological substitutions across broader economic systems.

Harmonization of methodological approaches remains challenging due to varying system boundaries, functional units, and allocation procedures across studies. Recent efforts have focused on developing standardized comparative frameworks specifically for cooling technologies that ensure fair comparison between conventional and emerging refrigeration systems while accounting for regional variations in electricity generation profiles and usage patterns.

Energy Efficiency and Performance Metrics

When comparing magnetic refrigeration with conventional vapor compression systems, energy efficiency metrics serve as critical evaluation parameters. The Coefficient of Performance (COP) stands as the primary indicator, with magnetic refrigeration systems demonstrating theoretical COPs ranging from 6-10 under laboratory conditions, significantly higher than the typical 3-5 range for advanced vapor compression systems. This efficiency advantage stems from the absence of compression work and the reversible nature of the magnetocaloric effect.

Energy consumption patterns reveal that magnetic refrigeration can potentially reduce electricity usage by 20-30% compared to conventional systems when operating under similar cooling loads. This reduction translates to substantial energy savings over the operational lifetime, particularly in commercial and industrial applications where cooling demands are continuous and intensive.

Performance stability represents another crucial metric, with magnetic refrigeration systems exhibiting more consistent efficiency across varying ambient temperatures. Unlike vapor compression systems that experience significant COP degradation at extreme ambient conditions, magnetic systems maintain relatively stable performance profiles within a broader operating range, offering particular advantages in regions with highly variable climates.

Exergy analysis further highlights the thermodynamic advantages of magnetic refrigeration, with exergy destruction rates approximately 15-25% lower than comparable vapor compression systems. This indicates more effective utilization of available energy resources and reduced irreversibilities in the cooling process, contributing to overall system efficiency.

Part-load performance metrics demonstrate that magnetic refrigeration systems maintain higher relative efficiency at reduced cooling loads compared to conventional systems. While vapor compression units typically experience efficiency penalties during cycling or partial loading, magnetic systems can be more precisely controlled through magnetic field modulation, maintaining near-optimal efficiency across varying demand profiles.

Temperature lift capabilities currently favor conventional systems, with commercial vapor compression units achieving temperature differentials of 40-50°C, while current magnetic refrigeration prototypes typically demonstrate 5-15°C. This limitation represents a significant technical challenge for magnetic refrigeration in applications requiring substantial temperature differences between heat source and sink.

System response dynamics also differ significantly, with magnetic refrigeration offering faster thermal response times due to the near-instantaneous nature of the magnetocaloric effect, compared to the thermodynamic delays inherent in vapor compression cycles. This characteristic enables more precise temperature control and potentially reduces energy waste during transient operational states.

Energy consumption patterns reveal that magnetic refrigeration can potentially reduce electricity usage by 20-30% compared to conventional systems when operating under similar cooling loads. This reduction translates to substantial energy savings over the operational lifetime, particularly in commercial and industrial applications where cooling demands are continuous and intensive.

Performance stability represents another crucial metric, with magnetic refrigeration systems exhibiting more consistent efficiency across varying ambient temperatures. Unlike vapor compression systems that experience significant COP degradation at extreme ambient conditions, magnetic systems maintain relatively stable performance profiles within a broader operating range, offering particular advantages in regions with highly variable climates.

Exergy analysis further highlights the thermodynamic advantages of magnetic refrigeration, with exergy destruction rates approximately 15-25% lower than comparable vapor compression systems. This indicates more effective utilization of available energy resources and reduced irreversibilities in the cooling process, contributing to overall system efficiency.

Part-load performance metrics demonstrate that magnetic refrigeration systems maintain higher relative efficiency at reduced cooling loads compared to conventional systems. While vapor compression units typically experience efficiency penalties during cycling or partial loading, magnetic systems can be more precisely controlled through magnetic field modulation, maintaining near-optimal efficiency across varying demand profiles.

Temperature lift capabilities currently favor conventional systems, with commercial vapor compression units achieving temperature differentials of 40-50°C, while current magnetic refrigeration prototypes typically demonstrate 5-15°C. This limitation represents a significant technical challenge for magnetic refrigeration in applications requiring substantial temperature differences between heat source and sink.

System response dynamics also differ significantly, with magnetic refrigeration offering faster thermal response times due to the near-instantaneous nature of the magnetocaloric effect, compared to the thermodynamic delays inherent in vapor compression cycles. This characteristic enables more precise temperature control and potentially reduces energy waste during transient operational states.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!