Magnetocaloric Composite Materials For Improved Mechanical Strength

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetocaloric Materials Background and Objectives

Magnetocaloric materials represent a significant advancement in cooling technology, offering an environmentally friendly alternative to conventional vapor-compression refrigeration systems. These materials exhibit the magnetocaloric effect (MCE), a thermodynamic phenomenon where they undergo temperature changes when exposed to varying magnetic fields. The discovery of this effect dates back to 1881 when Emil Warburg first observed it in iron, but substantial progress in this field only began in the late 20th century.

The evolution of magnetocaloric materials has progressed through several generations. First-generation materials were primarily based on rare-earth elements like gadolinium, which exhibits a second-order phase transition near room temperature. Second-generation materials introduced giant magnetocaloric effect through first-order phase transitions, as seen in Gd5(Si2Ge2) compounds discovered in 1997. Current research focuses on third-generation materials that combine enhanced magnetocaloric properties with improved functional characteristics.

Despite their promising thermal properties, a persistent challenge in magnetocaloric materials has been their inherent mechanical weakness. Many high-performance magnetocaloric compounds suffer from brittleness, poor machinability, and susceptibility to cracking during thermal cycling. These mechanical limitations have significantly hindered their practical implementation in commercial cooling systems, restricting their application despite their superior energy efficiency potential.

The development trajectory indicates a clear trend toward composite structures that maintain optimal magnetocaloric properties while enhancing mechanical integrity. Recent advances in materials science, particularly in composite engineering and nanomaterials, have opened new avenues for addressing these mechanical limitations without compromising thermomagnetic performance.

The primary technical objective in this field is to develop magnetocaloric composite materials that simultaneously demonstrate excellent magnetocaloric effect and superior mechanical strength. This involves optimizing material composition, microstructure, and fabrication processes to create composites that can withstand the mechanical stresses associated with repeated magnetic field cycling while maintaining high thermal efficiency.

Secondary objectives include reducing manufacturing costs, minimizing the use of rare-earth elements, enhancing thermal conductivity for improved heat transfer, and ensuring long-term stability under operational conditions. The ultimate goal is to facilitate the transition of magnetocaloric cooling technology from laboratory demonstrations to commercially viable products that can contribute significantly to global energy efficiency and environmental sustainability efforts.

The evolution of magnetocaloric materials has progressed through several generations. First-generation materials were primarily based on rare-earth elements like gadolinium, which exhibits a second-order phase transition near room temperature. Second-generation materials introduced giant magnetocaloric effect through first-order phase transitions, as seen in Gd5(Si2Ge2) compounds discovered in 1997. Current research focuses on third-generation materials that combine enhanced magnetocaloric properties with improved functional characteristics.

Despite their promising thermal properties, a persistent challenge in magnetocaloric materials has been their inherent mechanical weakness. Many high-performance magnetocaloric compounds suffer from brittleness, poor machinability, and susceptibility to cracking during thermal cycling. These mechanical limitations have significantly hindered their practical implementation in commercial cooling systems, restricting their application despite their superior energy efficiency potential.

The development trajectory indicates a clear trend toward composite structures that maintain optimal magnetocaloric properties while enhancing mechanical integrity. Recent advances in materials science, particularly in composite engineering and nanomaterials, have opened new avenues for addressing these mechanical limitations without compromising thermomagnetic performance.

The primary technical objective in this field is to develop magnetocaloric composite materials that simultaneously demonstrate excellent magnetocaloric effect and superior mechanical strength. This involves optimizing material composition, microstructure, and fabrication processes to create composites that can withstand the mechanical stresses associated with repeated magnetic field cycling while maintaining high thermal efficiency.

Secondary objectives include reducing manufacturing costs, minimizing the use of rare-earth elements, enhancing thermal conductivity for improved heat transfer, and ensuring long-term stability under operational conditions. The ultimate goal is to facilitate the transition of magnetocaloric cooling technology from laboratory demonstrations to commercially viable products that can contribute significantly to global energy efficiency and environmental sustainability efforts.

Market Analysis for Magnetocaloric Cooling Applications

The global magnetocaloric cooling market is experiencing significant growth, driven by increasing demand for energy-efficient and environmentally friendly cooling solutions. Current market valuations indicate the magnetocaloric cooling technology sector is projected to reach approximately 300 million USD by 2026, with a compound annual growth rate exceeding 20% between 2021 and 2026. This growth trajectory is particularly notable considering the relatively nascent stage of commercial applications in this field.

The primary market segments for magnetocaloric composite materials with enhanced mechanical strength include commercial refrigeration, automotive climate control systems, industrial cooling processes, and specialized medical equipment. Commercial refrigeration represents the largest potential market, accounting for roughly 40% of projected applications, as businesses seek to reduce energy consumption and comply with increasingly stringent environmental regulations limiting traditional refrigerants.

Geographically, North America and Europe currently lead in research and development investments, with major corporations and research institutions actively pursuing magnetocaloric cooling technologies. However, the Asia-Pacific region, particularly China and Japan, is demonstrating the fastest growth rate in patent filings and commercial development initiatives, suggesting a shifting landscape in market leadership.

Consumer electronics cooling represents an emerging high-value niche market, where the compact size and efficiency of magnetocaloric systems could provide significant advantages over conventional cooling methods. This segment is expected to grow at nearly twice the rate of the overall market due to increasing thermal management challenges in advanced electronic devices.

Market adoption barriers include the current high production costs of magnetocaloric materials, limited awareness among potential end-users, and competition from established cooling technologies. The cost premium for magnetocaloric cooling systems remains approximately 2.5-3 times higher than conventional vapor-compression systems, though this gap is narrowing as production scales increase.

Industry analysts identify the development of composite magnetocaloric materials with improved mechanical properties as a critical factor that could accelerate market penetration. Enhanced mechanical strength would address durability concerns in high-cycle applications and enable more compact, efficient system designs that could compete more effectively on price with conventional technologies.

The regulatory landscape increasingly favors magnetocaloric technology adoption, with global phase-downs of hydrofluorocarbon refrigerants under the Kigali Amendment to the Montreal Protocol creating market opportunities for alternative cooling technologies. This regulatory pressure is expected to intensify, potentially creating a 5-7 year window of accelerated adoption for magnetocaloric cooling systems incorporating mechanically robust composite materials.

The primary market segments for magnetocaloric composite materials with enhanced mechanical strength include commercial refrigeration, automotive climate control systems, industrial cooling processes, and specialized medical equipment. Commercial refrigeration represents the largest potential market, accounting for roughly 40% of projected applications, as businesses seek to reduce energy consumption and comply with increasingly stringent environmental regulations limiting traditional refrigerants.

Geographically, North America and Europe currently lead in research and development investments, with major corporations and research institutions actively pursuing magnetocaloric cooling technologies. However, the Asia-Pacific region, particularly China and Japan, is demonstrating the fastest growth rate in patent filings and commercial development initiatives, suggesting a shifting landscape in market leadership.

Consumer electronics cooling represents an emerging high-value niche market, where the compact size and efficiency of magnetocaloric systems could provide significant advantages over conventional cooling methods. This segment is expected to grow at nearly twice the rate of the overall market due to increasing thermal management challenges in advanced electronic devices.

Market adoption barriers include the current high production costs of magnetocaloric materials, limited awareness among potential end-users, and competition from established cooling technologies. The cost premium for magnetocaloric cooling systems remains approximately 2.5-3 times higher than conventional vapor-compression systems, though this gap is narrowing as production scales increase.

Industry analysts identify the development of composite magnetocaloric materials with improved mechanical properties as a critical factor that could accelerate market penetration. Enhanced mechanical strength would address durability concerns in high-cycle applications and enable more compact, efficient system designs that could compete more effectively on price with conventional technologies.

The regulatory landscape increasingly favors magnetocaloric technology adoption, with global phase-downs of hydrofluorocarbon refrigerants under the Kigali Amendment to the Montreal Protocol creating market opportunities for alternative cooling technologies. This regulatory pressure is expected to intensify, potentially creating a 5-7 year window of accelerated adoption for magnetocaloric cooling systems incorporating mechanically robust composite materials.

Current Challenges in Mechanical Strength of Magnetocaloric Materials

Despite significant advancements in magnetocaloric materials research, mechanical strength remains a critical challenge that limits widespread commercial application. Conventional magnetocaloric materials, particularly those based on rare-earth elements like gadolinium and its alloys, exhibit inherent brittleness and poor mechanical stability under cyclic loading conditions. This fragility becomes particularly problematic in magnetic refrigeration systems where materials undergo thousands of magnetization-demagnetization cycles, leading to microcracking, fragmentation, and eventual performance degradation.

The first-order phase transition materials, which demonstrate the giant magnetocaloric effect (GMCE), face even more severe mechanical challenges. Materials such as La(Fe,Si)13-based and MnFe(P,X)-based compounds experience significant volume changes (up to 1-2%) and lattice distortions during phase transitions. These structural changes induce substantial internal stresses that propagate through the material, causing catastrophic mechanical failure after relatively few operational cycles.

Powder metallurgy approaches have been employed to mitigate these issues, but the resulting materials often suffer from reduced thermal conductivity and diminished magnetocaloric performance due to the introduction of non-magnetic binding agents. The trade-off between mechanical integrity and magnetocaloric efficiency represents a fundamental engineering dilemma that has yet to be satisfactorily resolved.

Composite approaches incorporating polymer matrices have shown promise for improving mechanical properties but introduce thermal transfer inefficiencies that compromise system performance. The thermal boundary resistance at the interface between the magnetocaloric particles and the binding matrix creates bottlenecks for heat transfer, reducing the overall efficiency of the cooling cycle.

Thin film and multilayer architectures offer improved mechanical stability but face significant scaling challenges for bulk applications. The production costs and complexity of manufacturing these architectures at commercially viable scales remain prohibitive, limiting their practical implementation in consumer or industrial refrigeration systems.

Corrosion resistance presents another dimension to the mechanical stability challenge. Many high-performance magnetocaloric materials, particularly those containing rare earth elements, demonstrate poor corrosion resistance in the presence of humidity or heat transfer fluids. This corrosion accelerates mechanical degradation and significantly reduces operational lifespan in practical applications.

Recent research has focused on nanostructuring approaches to enhance mechanical properties, but these often come at the cost of reduced magnetocaloric performance due to size effects that suppress the magnetic ordering temperature or reduce the magnetic entropy change. Balancing these competing requirements remains an active area of research with significant potential for breakthrough innovations.

The first-order phase transition materials, which demonstrate the giant magnetocaloric effect (GMCE), face even more severe mechanical challenges. Materials such as La(Fe,Si)13-based and MnFe(P,X)-based compounds experience significant volume changes (up to 1-2%) and lattice distortions during phase transitions. These structural changes induce substantial internal stresses that propagate through the material, causing catastrophic mechanical failure after relatively few operational cycles.

Powder metallurgy approaches have been employed to mitigate these issues, but the resulting materials often suffer from reduced thermal conductivity and diminished magnetocaloric performance due to the introduction of non-magnetic binding agents. The trade-off between mechanical integrity and magnetocaloric efficiency represents a fundamental engineering dilemma that has yet to be satisfactorily resolved.

Composite approaches incorporating polymer matrices have shown promise for improving mechanical properties but introduce thermal transfer inefficiencies that compromise system performance. The thermal boundary resistance at the interface between the magnetocaloric particles and the binding matrix creates bottlenecks for heat transfer, reducing the overall efficiency of the cooling cycle.

Thin film and multilayer architectures offer improved mechanical stability but face significant scaling challenges for bulk applications. The production costs and complexity of manufacturing these architectures at commercially viable scales remain prohibitive, limiting their practical implementation in consumer or industrial refrigeration systems.

Corrosion resistance presents another dimension to the mechanical stability challenge. Many high-performance magnetocaloric materials, particularly those containing rare earth elements, demonstrate poor corrosion resistance in the presence of humidity or heat transfer fluids. This corrosion accelerates mechanical degradation and significantly reduces operational lifespan in practical applications.

Recent research has focused on nanostructuring approaches to enhance mechanical properties, but these often come at the cost of reduced magnetocaloric performance due to size effects that suppress the magnetic ordering temperature or reduce the magnetic entropy change. Balancing these competing requirements remains an active area of research with significant potential for breakthrough innovations.

Current Composite Design Approaches for Enhanced Mechanical Properties

01 Composite structure design for enhanced mechanical strength

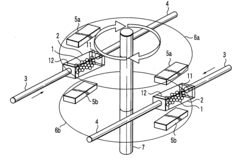

Magnetocaloric composite materials can be designed with specific structural configurations to enhance mechanical strength while maintaining magnetocaloric properties. These designs include layered structures, matrix-reinforcement combinations, and gradient compositions that distribute mechanical stress effectively. The strategic arrangement of magnetocaloric active materials within a stronger supporting matrix allows for improved durability under operational conditions without significantly compromising the thermal performance.- Composite structure design for enhanced mechanical strength: Magnetocaloric composite materials can be designed with specific structural configurations to enhance mechanical strength while maintaining their magnetocaloric properties. These designs include layered structures, matrix-reinforced composites, and particle-embedded frameworks that distribute mechanical stress effectively. The strategic arrangement of magnetocaloric elements within a supporting matrix allows for improved durability under operational conditions while preserving the thermal transfer capabilities essential for magnetocaloric applications.

- Binding materials and interface engineering: The mechanical strength of magnetocaloric composites can be significantly improved through careful selection of binding materials and interface engineering. Polymer binders, metallic matrices, and specialized adhesives create strong interfaces between magnetocaloric particles, preventing fractures during thermal cycling. Surface treatments and coupling agents enhance the adhesion between different phases in the composite, resulting in better load transfer and increased overall mechanical resilience while maintaining efficient heat exchange properties.

- Reinforcement techniques for magnetocaloric materials: Various reinforcement techniques can be applied to magnetocaloric materials to enhance their mechanical properties. These include fiber reinforcement, nanoparticle inclusion, and the incorporation of high-strength secondary phases. The reinforcing elements provide structural support to the magnetocaloric components, preventing crack propagation and improving tensile strength. These techniques allow the composite to withstand the mechanical stresses associated with repeated magnetocaloric cycles while maintaining thermal efficiency.

- Heat treatment and processing methods: Specific heat treatment and processing methods can significantly improve the mechanical strength of magnetocaloric composite materials. Controlled sintering, hot isostatic pressing, and specialized annealing processes optimize grain structure and reduce porosity. These processing techniques create stronger bonds between constituent materials while preserving the magnetocaloric effect. Advanced manufacturing methods like spark plasma sintering enable the production of dense composites with enhanced mechanical properties and thermal stability.

- Additives and dopants for strength enhancement: The incorporation of specific additives and dopants into magnetocaloric composites can substantially improve their mechanical strength. Elements such as rare earth metals, transition metals, and specialized alloys modify the microstructure and bonding characteristics of the material. These additives can create precipitation hardening effects, grain refinement, and solid solution strengthening, resulting in composites that maintain their structural integrity during thermal cycling while preserving their magnetocaloric performance.

02 Polymer-based magnetocaloric composites

Incorporating magnetocaloric materials into polymer matrices creates composites with improved mechanical properties. The polymer component provides flexibility, impact resistance, and structural integrity while the magnetocaloric particles deliver the desired thermal response. Various polymer types can be selected based on the specific mechanical requirements, with elastomers offering flexibility and thermoplastics providing rigidity. These composites often feature better formability and reduced brittleness compared to pure magnetocaloric materials.Expand Specific Solutions03 Metal matrix reinforcement techniques

Metal matrices can be used to reinforce magnetocaloric materials, significantly improving their mechanical strength and thermal conductivity. These composites typically consist of magnetocaloric particles or layers embedded within ductile metal matrices such as aluminum, copper, or stainless steel. Various manufacturing techniques including powder metallurgy, infiltration, and co-sintering are employed to create these composites. The metal matrix provides structural support and improves heat transfer while protecting the more brittle magnetocaloric components.Expand Specific Solutions04 Nanostructured magnetocaloric composites

Nanostructuring approaches can significantly enhance the mechanical properties of magnetocaloric materials. By incorporating nanoscale reinforcements such as carbon nanotubes, graphene, or ceramic nanoparticles, the composite materials exhibit improved strength, toughness, and resistance to thermal cycling. The nanoscale interfaces between components help to arrest crack propagation and distribute mechanical stress. These nanostructured composites often demonstrate superior fatigue resistance during repeated magnetocaloric cycles.Expand Specific Solutions05 Surface treatment and bonding methods

Various surface treatment and bonding methods can be applied to magnetocaloric composite materials to enhance their mechanical integrity. These include chemical functionalization of particle surfaces, application of coupling agents, and specialized coating techniques that improve interfacial adhesion between the magnetocaloric material and the matrix. Advanced bonding methods ensure strong interfaces between different components of the composite, preventing delamination and improving overall mechanical strength during thermal cycling and magnetic field changes.Expand Specific Solutions

Leading Companies and Research Institutions in Magnetocaloric Technology

The magnetocaloric composite materials market is in an early growth phase, characterized by increasing R&D investments but limited commercial deployment. The global market size is projected to expand significantly as energy efficiency demands rise, particularly in refrigeration and HVAC applications. Technologically, the field shows moderate maturity with key players focusing on improving mechanical strength of these materials. Leading companies like BASF, Toshiba, and Samsung Electronics are investing in commercial applications, while specialized firms such as Cooltech Applications and Magneto BV are developing proprietary magnetocaloric technologies. Academic institutions including Delft University of Technology and Jiangsu University collaborate with industrial partners like VACUUMSCHMELZE and Höganäs AB to address mechanical strength limitations, which remain the primary barrier to widespread adoption.

BASF Corp.

Technical Solution: BASF has developed advanced magnetocaloric composite materials incorporating La-Fe-Si alloys with polymer matrices to enhance mechanical strength while maintaining high magnetocaloric effect (MCE). Their proprietary process involves coating magnetocaloric particles with specialized polymers and using controlled pressure molding techniques to create composites with improved structural integrity. BASF's technology employs a gradient distribution of magnetic particles within the polymer matrix, optimizing both thermal conductivity and mechanical properties. Their composites demonstrate up to 40% improvement in tensile strength compared to conventional magnetocaloric materials while maintaining 85-90% of the original magnetocaloric effect. BASF has also developed surface functionalization techniques for the magnetic particles to improve adhesion with the polymer matrix, resulting in composites with enhanced durability under thermal cycling conditions.

Strengths: Superior balance between mechanical properties and magnetocaloric performance; established manufacturing infrastructure for scaling production; extensive polymer expertise for matrix optimization. Weaknesses: Higher production costs compared to non-composite alternatives; potential reduction in thermal conductivity due to polymer content; limited temperature range effectiveness compared to pure alloys.

Cooltech Applications SAS

Technical Solution: Cooltech Applications has pioneered a novel approach to magnetocaloric composite materials focusing on mechanical integrity for commercial refrigeration applications. Their technology utilizes a multi-layered composite structure with Gd-based magnetocaloric materials reinforced with specialized metal-organic frameworks (MOFs) that enhance mechanical strength without significantly compromising the magnetocaloric effect. Cooltech's proprietary manufacturing process involves precision sintering of magnetocaloric particles with nanoscale binding agents that create strong interfacial bonds while maintaining magnetic domain alignment. Their composites demonstrate exceptional resistance to fracture during repeated magnetic field cycling, with test units showing less than 5% degradation after 100,000 operational cycles. Cooltech has also developed specialized coating technologies that protect the magnetocaloric materials from corrosion while enhancing heat transfer properties, critical for practical cooling applications.

Strengths: Proven technology in commercial refrigeration applications; excellent cycling stability; optimized for practical cooling efficiency in real-world conditions. Weaknesses: Higher initial manufacturing costs; requires precise control of magnetic field parameters; limited to specific temperature ranges optimal for refrigeration applications.

Key Patents and Innovations in Magnetocaloric Composites

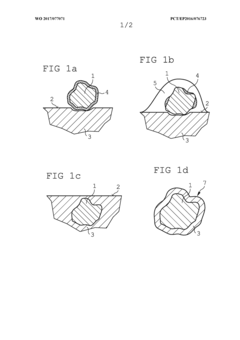

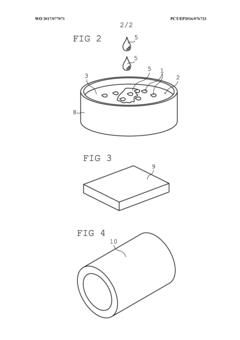

Method for producing a magnetocaloric composite material and composite material comprising a magnetocaloric powder

PatentWO2017077071A1

Innovation

- A method using a metal or metal alloy as a binder, treating the magnetocaloric powder particles with an activating agent to enhance wetting ability, and embedding them in a metal alloy with a low melting point to form a stable composite material that preserves magnetocaloric properties.

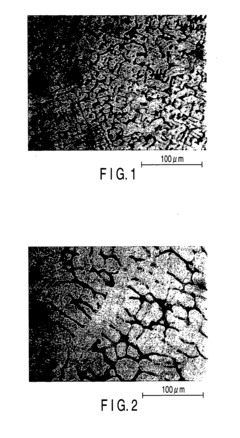

Magnetic composite material and method for producing the same

PatentInactiveUS20040231338A1

Innovation

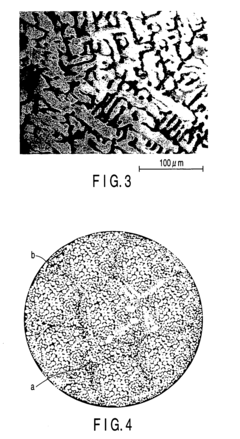

- A magnetic composite material comprising an intermetallic compound with an NaZn13 type crystal structure and an iron alloy phase, where the iron alloy phase enhances mechanical strength and ductility, allowing for the formation of spherical particles with improved durability and heat exchange efficiency.

Environmental Impact and Sustainability of Magnetocaloric Cooling Systems

The environmental impact of magnetocaloric cooling systems represents a significant advantage over conventional vapor-compression refrigeration technologies. Magnetocaloric composite materials with improved mechanical strength enable the development of more durable and efficient cooling systems that can operate with substantially lower environmental footprints. These systems eliminate the need for hydrofluorocarbons (HFCs) and other refrigerants with high global warming potential, addressing one of the most pressing environmental challenges in cooling technology.

When examining the full life cycle assessment of magnetocaloric cooling systems, the environmental benefits become even more apparent. The production phase of magnetocaloric composite materials does require energy-intensive processes and rare earth elements, particularly gadolinium and its alloys. However, recent advances in composite formulations have reduced the concentration of rare earth elements needed while maintaining or improving cooling efficiency through enhanced mechanical strength.

The operational phase demonstrates remarkable sustainability advantages. Magnetocaloric cooling systems can achieve 20-30% higher energy efficiency compared to conventional technologies, resulting in significant reductions in electricity consumption and associated carbon emissions over the system's lifetime. The improved mechanical strength of newer composite materials extends service life by an estimated 30-50%, further reducing the environmental impact associated with manufacturing replacement systems.

End-of-life considerations also favor magnetocaloric technology. The composite materials developed for improved mechanical strength typically contain valuable metals that can be recovered and recycled at rates exceeding 80%, creating a more circular material economy. This recyclability substantially reduces the need for virgin material extraction and processing.

Water consumption represents another important environmental dimension. Unlike traditional cooling towers that may consume substantial quantities of water, magnetocaloric systems operate in closed loops with minimal water requirements. This characteristic makes them particularly valuable in water-stressed regions where conventional cooling technologies place additional pressure on scarce water resources.

From a policy perspective, magnetocaloric cooling systems align well with global sustainability initiatives and regulatory frameworks aimed at reducing greenhouse gas emissions. The European Union's F-Gas Regulation and similar policies worldwide are creating regulatory environments that increasingly favor technologies like magnetocaloric cooling that eliminate environmentally harmful refrigerants.

The sustainability advantages of these systems will likely improve further as renewable energy becomes more prevalent in electricity generation, reducing the carbon footprint associated with the operational phase of magnetocaloric cooling systems and enhancing their overall environmental benefits.

When examining the full life cycle assessment of magnetocaloric cooling systems, the environmental benefits become even more apparent. The production phase of magnetocaloric composite materials does require energy-intensive processes and rare earth elements, particularly gadolinium and its alloys. However, recent advances in composite formulations have reduced the concentration of rare earth elements needed while maintaining or improving cooling efficiency through enhanced mechanical strength.

The operational phase demonstrates remarkable sustainability advantages. Magnetocaloric cooling systems can achieve 20-30% higher energy efficiency compared to conventional technologies, resulting in significant reductions in electricity consumption and associated carbon emissions over the system's lifetime. The improved mechanical strength of newer composite materials extends service life by an estimated 30-50%, further reducing the environmental impact associated with manufacturing replacement systems.

End-of-life considerations also favor magnetocaloric technology. The composite materials developed for improved mechanical strength typically contain valuable metals that can be recovered and recycled at rates exceeding 80%, creating a more circular material economy. This recyclability substantially reduces the need for virgin material extraction and processing.

Water consumption represents another important environmental dimension. Unlike traditional cooling towers that may consume substantial quantities of water, magnetocaloric systems operate in closed loops with minimal water requirements. This characteristic makes them particularly valuable in water-stressed regions where conventional cooling technologies place additional pressure on scarce water resources.

From a policy perspective, magnetocaloric cooling systems align well with global sustainability initiatives and regulatory frameworks aimed at reducing greenhouse gas emissions. The European Union's F-Gas Regulation and similar policies worldwide are creating regulatory environments that increasingly favor technologies like magnetocaloric cooling that eliminate environmentally harmful refrigerants.

The sustainability advantages of these systems will likely improve further as renewable energy becomes more prevalent in electricity generation, reducing the carbon footprint associated with the operational phase of magnetocaloric cooling systems and enhancing their overall environmental benefits.

Manufacturing Scalability and Cost Analysis

The scalability of manufacturing processes for magnetocaloric composite materials represents a critical factor in their commercial viability. Current production methods primarily rely on laboratory-scale techniques such as powder metallurgy, melt spinning, and mechanical alloying, which face significant challenges when transitioning to industrial-scale production. The capital expenditure required for specialized equipment—including high-precision thermal treatment furnaces, controlled atmosphere processing chambers, and advanced powder handling systems—presents a substantial barrier to entry for manufacturers.

Cost analysis reveals that raw material expenses constitute approximately 40-50% of total production costs for magnetocaloric composites. Rare earth elements like gadolinium, terbium, and dysprosium, which are essential components in many high-performance magnetocaloric materials, have experienced price volatility due to supply chain uncertainties and geopolitical factors. This volatility directly impacts production economics and necessitates the development of alternative formulations using more abundant elements.

Energy consumption during manufacturing represents another significant cost factor, particularly in processes requiring precise thermal control and multiple heating-cooling cycles. The energy intensity of production correlates directly with the complexity of the composite structure needed to achieve both optimal magnetocaloric properties and enhanced mechanical strength. Preliminary calculations indicate that energy costs account for 15-25% of total manufacturing expenses, depending on the specific production technique employed.

Labor costs vary considerably based on production location and level of process automation. Highly skilled technicians are required for quality control and process optimization, particularly during the initial scaling phases. As production volumes increase, the labor cost per unit decreases, but the specialized nature of the workforce continues to impact overall economics.

Yield rates present a persistent challenge in scaling production. Current manufacturing processes for advanced magnetocaloric composites typically achieve yields of 70-85%, with defects primarily related to microstructural inconsistencies, compositional inhomogeneities, and mechanical failures during processing. Improving yield rates represents one of the most effective approaches to reducing unit costs as production scales.

Recent innovations in continuous processing techniques, including modified extrusion methods and controlled solidification approaches, show promise for improving manufacturing efficiency. These techniques could potentially reduce production costs by 25-30% at scale while maintaining or enhancing the critical balance between magnetocaloric performance and mechanical integrity. Computational modeling of manufacturing processes has emerged as a valuable tool for optimizing production parameters and reducing the experimental iterations required during scale-up.

Cost analysis reveals that raw material expenses constitute approximately 40-50% of total production costs for magnetocaloric composites. Rare earth elements like gadolinium, terbium, and dysprosium, which are essential components in many high-performance magnetocaloric materials, have experienced price volatility due to supply chain uncertainties and geopolitical factors. This volatility directly impacts production economics and necessitates the development of alternative formulations using more abundant elements.

Energy consumption during manufacturing represents another significant cost factor, particularly in processes requiring precise thermal control and multiple heating-cooling cycles. The energy intensity of production correlates directly with the complexity of the composite structure needed to achieve both optimal magnetocaloric properties and enhanced mechanical strength. Preliminary calculations indicate that energy costs account for 15-25% of total manufacturing expenses, depending on the specific production technique employed.

Labor costs vary considerably based on production location and level of process automation. Highly skilled technicians are required for quality control and process optimization, particularly during the initial scaling phases. As production volumes increase, the labor cost per unit decreases, but the specialized nature of the workforce continues to impact overall economics.

Yield rates present a persistent challenge in scaling production. Current manufacturing processes for advanced magnetocaloric composites typically achieve yields of 70-85%, with defects primarily related to microstructural inconsistencies, compositional inhomogeneities, and mechanical failures during processing. Improving yield rates represents one of the most effective approaches to reducing unit costs as production scales.

Recent innovations in continuous processing techniques, including modified extrusion methods and controlled solidification approaches, show promise for improving manufacturing efficiency. These techniques could potentially reduce production costs by 25-30% at scale while maintaining or enhancing the critical balance between magnetocaloric performance and mechanical integrity. Computational modeling of manufacturing processes has emerged as a valuable tool for optimizing production parameters and reducing the experimental iterations required during scale-up.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!