Thermal Regeneration Strategies In Magnetocaloric Heat Exchange Systems

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetocaloric Technology Background and Objectives

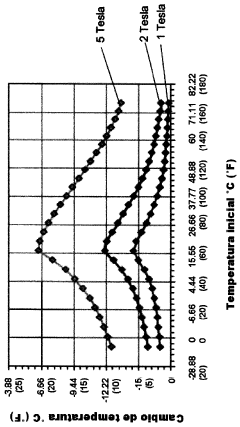

Magnetocaloric effect (MCE) represents a thermodynamic phenomenon where certain materials exhibit temperature changes when exposed to varying magnetic fields. This technology has evolved significantly since its discovery by Emil Warburg in 1881, with major advancements occurring in the late 20th century when materials with giant magnetocaloric effects were identified. The fundamental principle relies on the entropy change in magnetic materials, which can be harnessed for efficient cooling applications without conventional refrigerants.

The evolution of magnetocaloric technology has been marked by several key milestones, including the development of gadolinium-based materials in the 1970s, the discovery of giant magnetocaloric effect in Gd5(Si2Ge2) by Pecharsky and Gschneidner in 1997, and recent advancements in rare-earth-free magnetocaloric compounds. These developments have progressively enhanced the temperature span and efficiency of magnetocaloric systems, making them increasingly viable for commercial applications.

Current research in thermal regeneration strategies focuses on optimizing heat exchange processes within magnetocaloric systems to maximize energy efficiency and cooling capacity. The active magnetic regenerator (AMR) cycle has emerged as the predominant approach, where the magnetocaloric material serves dual functions as both the refrigerant and regenerator. This integration presents unique challenges in thermal management that conventional cooling technologies do not face.

The primary technical objectives in this field include developing magnetocaloric materials with enhanced thermal conductivity, designing efficient heat exchange geometries, minimizing thermal hysteresis, and creating effective regeneration cycles that maximize entropy transfer. Researchers aim to achieve temperature spans exceeding 50K with a coefficient of performance approaching theoretical limits, while using magnetic fields achievable with permanent magnets (<2 Tesla).

Long-term goals for magnetocaloric heat exchange systems include reducing dependency on rare earth elements, scaling systems for various applications from household refrigeration to industrial cooling, and integrating these systems with renewable energy sources. The technology aspires to surpass conventional vapor-compression cooling efficiency by 30-40%, potentially revolutionizing the refrigeration industry which accounts for approximately 17% of global electricity consumption.

The convergence of advanced materials science, thermal engineering, and computational modeling is driving innovation in this field, with particular emphasis on addressing the challenges of thermal regeneration—the critical process that determines overall system efficiency. As climate concerns intensify and energy efficiency standards become more stringent, magnetocaloric technology represents a promising pathway toward sustainable cooling solutions.

The evolution of magnetocaloric technology has been marked by several key milestones, including the development of gadolinium-based materials in the 1970s, the discovery of giant magnetocaloric effect in Gd5(Si2Ge2) by Pecharsky and Gschneidner in 1997, and recent advancements in rare-earth-free magnetocaloric compounds. These developments have progressively enhanced the temperature span and efficiency of magnetocaloric systems, making them increasingly viable for commercial applications.

Current research in thermal regeneration strategies focuses on optimizing heat exchange processes within magnetocaloric systems to maximize energy efficiency and cooling capacity. The active magnetic regenerator (AMR) cycle has emerged as the predominant approach, where the magnetocaloric material serves dual functions as both the refrigerant and regenerator. This integration presents unique challenges in thermal management that conventional cooling technologies do not face.

The primary technical objectives in this field include developing magnetocaloric materials with enhanced thermal conductivity, designing efficient heat exchange geometries, minimizing thermal hysteresis, and creating effective regeneration cycles that maximize entropy transfer. Researchers aim to achieve temperature spans exceeding 50K with a coefficient of performance approaching theoretical limits, while using magnetic fields achievable with permanent magnets (<2 Tesla).

Long-term goals for magnetocaloric heat exchange systems include reducing dependency on rare earth elements, scaling systems for various applications from household refrigeration to industrial cooling, and integrating these systems with renewable energy sources. The technology aspires to surpass conventional vapor-compression cooling efficiency by 30-40%, potentially revolutionizing the refrigeration industry which accounts for approximately 17% of global electricity consumption.

The convergence of advanced materials science, thermal engineering, and computational modeling is driving innovation in this field, with particular emphasis on addressing the challenges of thermal regeneration—the critical process that determines overall system efficiency. As climate concerns intensify and energy efficiency standards become more stringent, magnetocaloric technology represents a promising pathway toward sustainable cooling solutions.

Market Analysis for Magnetocaloric Cooling Solutions

The magnetocaloric cooling market is experiencing significant growth potential as industries seek more environmentally friendly alternatives to conventional vapor compression refrigeration systems. Current market valuations estimate the global magnetocaloric materials and systems market at approximately $300 million, with projections indicating growth to reach $2.3 billion by 2030, representing a compound annual growth rate (CAGR) of 25.4% during the forecast period.

Key market drivers include increasingly stringent environmental regulations targeting the phase-out of hydrofluorocarbon (HFC) refrigerants, rising energy costs, and growing consumer demand for sustainable technologies. The Paris Agreement and Kigali Amendment to the Montreal Protocol have accelerated the search for alternative cooling technologies, creating favorable market conditions for magnetocaloric solutions.

Market segmentation reveals distinct application sectors with varying adoption rates. Commercial refrigeration represents the largest current market segment at 42% of total demand, followed by residential applications (28%), industrial cooling systems (18%), and automotive climate control (12%). The residential sector is expected to demonstrate the fastest growth rate over the next decade due to increasing consumer awareness and willingness to adopt green technologies.

Geographically, North America and Europe currently dominate the market with combined market share of 68%, driven by stringent environmental regulations and substantial R&D investments. However, the Asia-Pacific region is projected to witness the highest growth rate, particularly in China, Japan, and South Korea, where government initiatives supporting green technology development are creating favorable market conditions.

Consumer willingness-to-pay analyses indicate that early adopters are prepared to accept a 15-20% premium for magnetocaloric cooling solutions compared to conventional systems, provided they deliver comparable performance and demonstrable energy savings of at least 25%. This price sensitivity is expected to decrease as manufacturing scales and technology matures.

Market barriers include high initial system costs, technical challenges in thermal regeneration efficiency, and limited awareness among end-users. The average cost per unit for commercial magnetocaloric cooling systems currently exceeds conventional systems by 30-40%, representing a significant adoption hurdle despite lower operational costs over the product lifecycle.

Competition analysis reveals approximately 15 key players actively developing commercial magnetocaloric cooling solutions, with market concentration relatively high as five companies control approximately 70% of current market share. Strategic partnerships between material suppliers, system integrators, and OEMs are increasingly common as the industry works to overcome technical challenges and achieve economies of scale.

Key market drivers include increasingly stringent environmental regulations targeting the phase-out of hydrofluorocarbon (HFC) refrigerants, rising energy costs, and growing consumer demand for sustainable technologies. The Paris Agreement and Kigali Amendment to the Montreal Protocol have accelerated the search for alternative cooling technologies, creating favorable market conditions for magnetocaloric solutions.

Market segmentation reveals distinct application sectors with varying adoption rates. Commercial refrigeration represents the largest current market segment at 42% of total demand, followed by residential applications (28%), industrial cooling systems (18%), and automotive climate control (12%). The residential sector is expected to demonstrate the fastest growth rate over the next decade due to increasing consumer awareness and willingness to adopt green technologies.

Geographically, North America and Europe currently dominate the market with combined market share of 68%, driven by stringent environmental regulations and substantial R&D investments. However, the Asia-Pacific region is projected to witness the highest growth rate, particularly in China, Japan, and South Korea, where government initiatives supporting green technology development are creating favorable market conditions.

Consumer willingness-to-pay analyses indicate that early adopters are prepared to accept a 15-20% premium for magnetocaloric cooling solutions compared to conventional systems, provided they deliver comparable performance and demonstrable energy savings of at least 25%. This price sensitivity is expected to decrease as manufacturing scales and technology matures.

Market barriers include high initial system costs, technical challenges in thermal regeneration efficiency, and limited awareness among end-users. The average cost per unit for commercial magnetocaloric cooling systems currently exceeds conventional systems by 30-40%, representing a significant adoption hurdle despite lower operational costs over the product lifecycle.

Competition analysis reveals approximately 15 key players actively developing commercial magnetocaloric cooling solutions, with market concentration relatively high as five companies control approximately 70% of current market share. Strategic partnerships between material suppliers, system integrators, and OEMs are increasingly common as the industry works to overcome technical challenges and achieve economies of scale.

Current Thermal Regeneration Challenges

Magnetocaloric heat exchange systems face several critical thermal regeneration challenges that impede their widespread commercial adoption. The primary obstacle remains the thermal hysteresis phenomenon, where the temperature change during magnetization and demagnetization cycles exhibits path-dependent behavior. This creates inefficiencies in the regeneration process, reducing the overall coefficient of performance (COP) by approximately 15-30% compared to theoretical maximums.

Material limitations constitute another significant challenge. Current magnetocaloric materials, predominantly rare-earth alloys like Gd5(Si2Ge2) and La(Fe,Si)13, demonstrate optimal performance only within narrow temperature ranges. This restricts the temperature span achievable in a single-stage regenerator to typically 20-40K, insufficient for many practical applications requiring temperature differentials of 50K or greater.

Heat transfer inefficiencies within regenerator beds represent a persistent technical hurdle. The inherent trade-off between pressure drop and heat transfer effectiveness creates design constraints that are difficult to overcome. Current regenerator geometries struggle to maintain uniform flow distribution, with computational fluid dynamics (CFD) models revealing flow channeling effects that reduce thermal exchange efficiency by up to 25% in practical systems.

Thermal parasitic losses through regenerator walls and supporting structures continue to undermine system performance. Recent experimental studies indicate that these losses can account for 10-35% of the total cooling capacity, depending on system size and operating conditions. As systems are miniaturized for specific applications, the surface-to-volume ratio increases, exacerbating this challenge.

Temporal and spatial temperature fluctuations within regenerator beds create additional complications. The cyclic nature of magnetocaloric systems produces temperature oscillations that can reach ±3K at typical operating frequencies (1-10 Hz). These fluctuations reduce effective temperature spans and complicate control systems designed to maintain stable output temperatures.

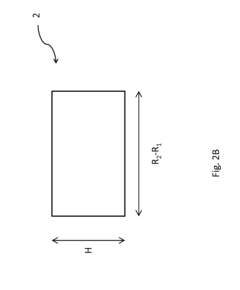

Manufacturing constraints further limit regenerator performance. Current production methods struggle to create regenerator geometries with optimal porosity (typically 30-40%) while maintaining structural integrity and uniform flow channels. Advanced manufacturing techniques like selective laser melting show promise but remain cost-prohibitive for mass production.

System integration challenges persist when incorporating regenerators into complete heat pump systems. The synchronization of fluid flow with magnetization cycles requires precise timing control, with studies showing that phase misalignments of even 5-10° can reduce system efficiency by up to 12%. This necessitates sophisticated control algorithms that add complexity and cost to practical implementations.

Material limitations constitute another significant challenge. Current magnetocaloric materials, predominantly rare-earth alloys like Gd5(Si2Ge2) and La(Fe,Si)13, demonstrate optimal performance only within narrow temperature ranges. This restricts the temperature span achievable in a single-stage regenerator to typically 20-40K, insufficient for many practical applications requiring temperature differentials of 50K or greater.

Heat transfer inefficiencies within regenerator beds represent a persistent technical hurdle. The inherent trade-off between pressure drop and heat transfer effectiveness creates design constraints that are difficult to overcome. Current regenerator geometries struggle to maintain uniform flow distribution, with computational fluid dynamics (CFD) models revealing flow channeling effects that reduce thermal exchange efficiency by up to 25% in practical systems.

Thermal parasitic losses through regenerator walls and supporting structures continue to undermine system performance. Recent experimental studies indicate that these losses can account for 10-35% of the total cooling capacity, depending on system size and operating conditions. As systems are miniaturized for specific applications, the surface-to-volume ratio increases, exacerbating this challenge.

Temporal and spatial temperature fluctuations within regenerator beds create additional complications. The cyclic nature of magnetocaloric systems produces temperature oscillations that can reach ±3K at typical operating frequencies (1-10 Hz). These fluctuations reduce effective temperature spans and complicate control systems designed to maintain stable output temperatures.

Manufacturing constraints further limit regenerator performance. Current production methods struggle to create regenerator geometries with optimal porosity (typically 30-40%) while maintaining structural integrity and uniform flow channels. Advanced manufacturing techniques like selective laser melting show promise but remain cost-prohibitive for mass production.

System integration challenges persist when incorporating regenerators into complete heat pump systems. The synchronization of fluid flow with magnetization cycles requires precise timing control, with studies showing that phase misalignments of even 5-10° can reduce system efficiency by up to 12%. This necessitates sophisticated control algorithms that add complexity and cost to practical implementations.

Current Thermal Regeneration Methodologies

01 Active Magnetic Regenerator (AMR) System Design

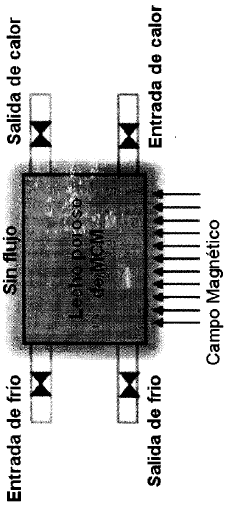

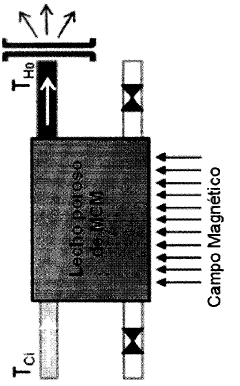

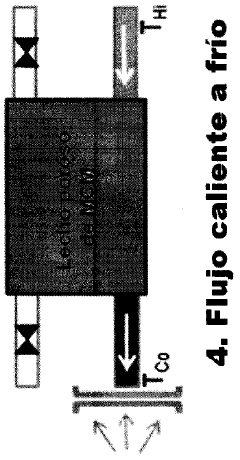

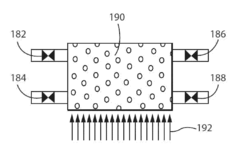

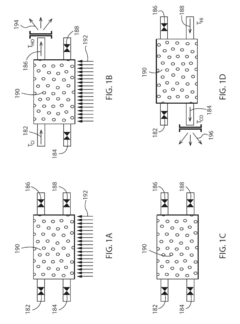

Active Magnetic Regenerator systems are core components of magnetocaloric heat exchange technology. These systems utilize beds of magnetocaloric materials that heat up when magnetized and cool down when demagnetized. The design of these regenerators focuses on optimizing flow patterns, bed geometry, and material distribution to maximize thermal efficiency. Advanced AMR designs incorporate multiple beds working in sequence to create continuous cooling or heating cycles, with careful consideration of fluid flow dynamics through the magnetocaloric material matrix.- Active Magnetic Regenerator (AMR) System Design: Active Magnetic Regenerator systems are core components of magnetocaloric heat exchange technology. These systems utilize magnetocaloric materials that heat up when exposed to a magnetic field and cool down when the field is removed. The AMR design typically includes a regenerator bed containing magnetocaloric material, a magnet assembly for field application and removal, and a heat transfer fluid circulation system. Optimized designs focus on fluid flow patterns, regenerator geometry, and cycle timing to maximize thermal efficiency and cooling capacity.

- Magnetocaloric Materials for Thermal Regeneration: The selection and composition of magnetocaloric materials significantly impact the performance of heat exchange systems. Materials exhibiting the magnetocaloric effect, such as gadolinium alloys, lanthanum-iron-silicon compounds, and manganese-based alloys, are engineered to optimize their thermal response to magnetic field changes. Advanced materials development focuses on creating compounds with high thermal conductivity, appropriate Curie temperatures, reduced hysteresis, and enhanced temperature span capabilities to improve overall system efficiency and performance across various operating conditions.

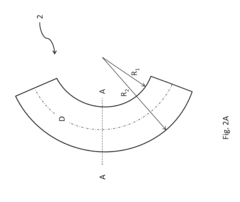

- Cascaded Regenerator Systems for Enhanced Temperature Span: Cascaded regenerator systems employ multiple stages of magnetocaloric materials with different Curie temperatures to achieve wider temperature spans than single-material systems. By arranging materials in sequence according to their transition temperatures, these systems can maintain efficient heat transfer across larger temperature gradients. This approach enables applications requiring significant temperature differences between hot and cold reservoirs, improving the practical utility of magnetocaloric cooling for commercial and industrial applications.

- Heat Transfer Fluid Dynamics and Flow Control: The management of heat transfer fluid dynamics is crucial for efficient thermal regeneration in magnetocaloric systems. Innovative flow control mechanisms, including reciprocating, rotary, and continuous flow designs, optimize the heat exchange between the fluid and magnetocaloric material. Advanced systems incorporate precise timing of fluid displacement relative to magnetic field changes, flow distribution techniques to minimize channeling effects, and reduced pressure drop designs to lower pumping power requirements while maintaining effective heat transfer characteristics.

- System Integration and Efficiency Optimization: Comprehensive system integration approaches focus on optimizing the overall efficiency of magnetocaloric heat exchange systems. This includes reducing parasitic losses from pumping power and magnetic field generation, thermal insulation strategies to minimize unwanted heat transfer, and advanced control algorithms that adapt to varying load conditions. Additional innovations include energy recovery mechanisms, hybrid systems combining magnetocaloric cooling with conventional technologies, and compact designs that maximize cooling power density while minimizing system footprint and material usage.

02 Magnetocaloric Material Composition and Selection

The selection and composition of magnetocaloric materials are crucial for effective thermal regeneration. Materials exhibiting strong magnetocaloric effects near the desired operating temperature are preferred. Common materials include gadolinium alloys, lanthanum-iron-silicon compounds, and manganese-based alloys. These materials are engineered to optimize their thermal conductivity, specific heat capacity, and magnetic response. Advanced systems may use layered or graded materials with different Curie temperatures to broaden the operating temperature range and improve efficiency across varying thermal conditions.Expand Specific Solutions03 Thermal Regeneration Cycle Optimization

Optimizing the thermal regeneration cycle is essential for efficient magnetocaloric heat exchange. This involves precise timing of magnetization/demagnetization processes, fluid flow control, and heat transfer management. Advanced systems implement variable cycle frequencies, adaptive control algorithms, and optimized phase relationships between multiple regenerator beds. The cycle optimization considers factors such as fluid residence time, magnetic field strength variation, and thermal gradients within the regenerator to maximize the coefficient of performance and minimize energy consumption during operation.Expand Specific Solutions04 Heat Transfer Fluid Selection and Flow Management

The selection of appropriate heat transfer fluids and management of their flow patterns significantly impacts the efficiency of magnetocaloric heat exchange systems. Water-based solutions, specialized oils, and gas-based heat transfer media are commonly used depending on the operating temperature range. Flow management techniques include pulsed flow, counter-flow arrangements, and variable flow rates synchronized with the magnetization cycle. Advanced systems incorporate flow distributors, specialized channels, and optimized regenerator geometries to ensure uniform fluid distribution and maximize heat transfer between the fluid and magnetocaloric materials.Expand Specific Solutions05 System Integration and Cascaded Magnetocaloric Devices

Integration of magnetocaloric heat exchange systems into practical applications requires careful consideration of overall system design. Cascaded arrangements of multiple magnetocaloric stages can achieve larger temperature spans and improved efficiency. These integrated systems often incorporate auxiliary components such as heat exchangers, pumps, and control systems optimized for the specific application. Advanced designs focus on reducing parasitic losses, improving compactness, and enhancing reliability through innovative mechanical designs and control strategies that coordinate the operation of multiple subsystems for optimal performance.Expand Specific Solutions

Leading Companies in Magnetocaloric Technology

The magnetocaloric heat exchange systems market is currently in a growth phase, with increasing interest in this energy-efficient cooling technology. The global market size is projected to expand significantly as environmental regulations drive demand for alternatives to conventional vapor-compression refrigeration. Technologically, the field shows moderate maturity with several key players advancing thermal regeneration strategies. Cooltech Applications SAS and Astronautics Corporation lead with commercial prototypes, while major appliance manufacturers like Samsung, Haier, and Gree are investing in R&D. Research institutions including Tsinghua University and IFW Dresden contribute fundamental advancements. VACUUMSCHMELZE and Baotou Rare Earth Research Institute focus on developing specialized magnetic materials essential for system efficiency. The industry is witnessing increased patent activity and collaborative research efforts to overcome thermal regeneration challenges.

Cooltech Applications SAS

Technical Solution: Cooltech Applications has developed advanced magnetic refrigeration systems utilizing active magnetic regeneration (AMR) cycles. Their technology employs a sophisticated thermal regeneration strategy where magnetocaloric materials are arranged in layered beds with carefully engineered porosity and fluid flow channels. The system operates by cyclically magnetizing and demagnetizing these materials while a heat transfer fluid flows through the regenerator beds. This creates a temperature gradient that enables efficient heat pumping. Cooltech's proprietary regenerator design incorporates multiple stages of gadolinium-based and rare earth alloys with varying Curie temperatures, allowing for operation across wider temperature spans than conventional single-material systems. Their thermal regeneration approach includes precise timing control of fluid flow relative to the magnetization cycle, optimizing heat transfer and minimizing entropy generation during the process.

Strengths: Industry-leading temperature spans (>30K) in their regenerators; commercialized systems with proven reliability; advanced fluid flow management reducing parasitic losses. Weaknesses: Higher initial system costs compared to conventional cooling; regenerator efficiency still limited by available magnetocaloric materials; system complexity requiring sophisticated control systems.

VACUUMSCHMELZE GmbH & Co. KG

Technical Solution: VACUUMSCHMELZE has pioneered specialized magnetocaloric materials optimized specifically for thermal regeneration applications. Their approach focuses on developing high-performance La-Fe-Si-based compounds with precisely tuned Curie temperatures and minimal thermal and magnetic hysteresis. These materials are incorporated into advanced regenerator designs that maximize thermal exchange efficiency. Their thermal regeneration strategy involves sophisticated material processing techniques that create optimized porosity structures within the regenerator beds, enhancing fluid-solid heat transfer while minimizing pressure drop. VACUUMSCHMELZE has developed proprietary methods for shaping these materials into geometries specifically designed for regenerator applications, including thin plates, microchannel structures, and honeycombs that maximize surface area while maintaining structural integrity during thermal cycling. Their regenerators incorporate gradient material compositions that enable efficient operation across temperature spans of 20-40K.

Strengths: World-leading expertise in magnetocaloric material development and processing; materials with exceptionally low hysteresis reducing energy losses during cycling; advanced manufacturing capabilities for complex regenerator geometries. Weaknesses: Higher material costs compared to conventional refrigerants; challenges in scaling production of specialized materials; sensitivity of material performance to precise composition control.

Key Patents in Magnetocaloric Regeneration

System and method for reverse degradation of a magnetocaloric material.

PatentInactiveMX2014000602A

Innovation

- Maintain magnetocaloric materials at temperatures significantly different from their Curie temperature to reverse the degradation process, using a modified magnetic refrigeration system with heating elements or dual subsystems to regenerate the materials.

Magnetic refrigeration system with unequal blows

PatentActiveUS20160076797A1

Innovation

- Implementing unequal hot and cold blow durations and flow rates, along with a reduction in the angular extent of the high-field region, to minimize the gap volume and magnet mass while maintaining cooling performance.

Environmental Impact Assessment

The environmental impact of magnetocaloric heat exchange systems represents a critical dimension in evaluating their sustainability and long-term viability. These systems offer significant potential for reducing greenhouse gas emissions compared to conventional vapor-compression refrigeration technologies. Quantitative assessments indicate that magnetocaloric cooling systems can achieve 20-30% higher energy efficiency, potentially reducing electricity consumption and associated carbon emissions substantially when implemented at scale.

Material considerations form a crucial aspect of environmental impact analysis. Current magnetocaloric materials often contain rare earth elements such as gadolinium, which present environmental challenges in mining, processing, and disposal phases. The extraction of these materials involves energy-intensive processes and can result in habitat disruption, water pollution, and toxic waste generation. Recent research has focused on developing rare-earth-free alternatives using transition metal alloys that demonstrate promising magnetocaloric properties while reducing environmental burden.

Life cycle assessment (LCA) studies of magnetocaloric systems reveal complex environmental trade-offs. While operational efficiency provides clear benefits, the manufacturing phase currently shows higher environmental impacts compared to conventional technologies due to specialized material requirements and precision engineering needs. A comprehensive LCA conducted by the University of Denmark demonstrated that the break-even point for environmental advantage occurs after approximately 3-5 years of operation, depending on usage patterns and energy sources.

Thermal regeneration strategies significantly influence the environmental profile of these systems. Efficient regeneration cycles minimize energy losses and maximize the coefficient of performance, directly reducing the carbon footprint during operation. Advanced regeneration techniques utilizing cascaded materials and optimized flow patterns have demonstrated potential to reduce energy consumption by an additional 15-20% compared to first-generation magnetocaloric systems.

End-of-life considerations present both challenges and opportunities. The high value of rare earth materials in magnetocaloric systems creates economic incentives for recycling, though specialized separation processes are required. Current recycling technologies can recover approximately 70-85% of rare earth content, though research aims to improve these rates. Designing systems with modular components and easily separable materials can significantly enhance recyclability and reduce waste.

Water consumption represents another important environmental consideration, particularly in cooling tower configurations. Magnetocaloric systems typically require less water for heat rejection compared to conventional refrigeration, potentially reducing water footprint by 25-40% in commercial applications. This advantage becomes particularly significant in water-stressed regions where cooling demands and water scarcity intersect.

Material considerations form a crucial aspect of environmental impact analysis. Current magnetocaloric materials often contain rare earth elements such as gadolinium, which present environmental challenges in mining, processing, and disposal phases. The extraction of these materials involves energy-intensive processes and can result in habitat disruption, water pollution, and toxic waste generation. Recent research has focused on developing rare-earth-free alternatives using transition metal alloys that demonstrate promising magnetocaloric properties while reducing environmental burden.

Life cycle assessment (LCA) studies of magnetocaloric systems reveal complex environmental trade-offs. While operational efficiency provides clear benefits, the manufacturing phase currently shows higher environmental impacts compared to conventional technologies due to specialized material requirements and precision engineering needs. A comprehensive LCA conducted by the University of Denmark demonstrated that the break-even point for environmental advantage occurs after approximately 3-5 years of operation, depending on usage patterns and energy sources.

Thermal regeneration strategies significantly influence the environmental profile of these systems. Efficient regeneration cycles minimize energy losses and maximize the coefficient of performance, directly reducing the carbon footprint during operation. Advanced regeneration techniques utilizing cascaded materials and optimized flow patterns have demonstrated potential to reduce energy consumption by an additional 15-20% compared to first-generation magnetocaloric systems.

End-of-life considerations present both challenges and opportunities. The high value of rare earth materials in magnetocaloric systems creates economic incentives for recycling, though specialized separation processes are required. Current recycling technologies can recover approximately 70-85% of rare earth content, though research aims to improve these rates. Designing systems with modular components and easily separable materials can significantly enhance recyclability and reduce waste.

Water consumption represents another important environmental consideration, particularly in cooling tower configurations. Magnetocaloric systems typically require less water for heat rejection compared to conventional refrigeration, potentially reducing water footprint by 25-40% in commercial applications. This advantage becomes particularly significant in water-stressed regions where cooling demands and water scarcity intersect.

Material Science Advancements

Recent advancements in material science have significantly propelled the development of magnetocaloric materials, which form the cornerstone of magnetocaloric heat exchange systems. These materials exhibit the magnetocaloric effect (MCE), characterized by temperature changes when exposed to varying magnetic fields. The efficiency of thermal regeneration strategies in these systems heavily depends on the intrinsic properties of these materials.

The discovery of giant magnetocaloric effect (GMCE) in Gd5(Si2Ge2) by Pecharsky and Gschneidner in 1997 marked a pivotal moment in this field. This breakthrough expanded the potential for practical applications of magnetocaloric cooling technologies. Subsequently, research has focused on developing materials with enhanced magnetocaloric properties, reduced hysteresis, and improved thermal conductivity.

Rare-earth-based alloys, particularly those containing gadolinium, have been extensively studied due to their significant magnetocaloric effect near room temperature. However, the high cost and limited availability of rare earth elements have driven research toward alternative materials. Heusler alloys, La(Fe,Si)13-based compounds, and MnFe(P,X) (where X represents As, Ge, Si) materials have emerged as promising candidates, offering comparable performance with more abundant elements.

Nanostructuring approaches have revolutionized material design for magnetocaloric applications. By controlling grain size, interface properties, and compositional gradients at the nanoscale, researchers have achieved enhanced magnetocaloric responses and reduced thermal hysteresis. Composite materials combining different magnetocaloric substances have demonstrated improved heat transfer characteristics and mechanical stability, addressing key challenges in regenerator design.

Advanced manufacturing techniques, including additive manufacturing and precision casting, have enabled the production of complex geometries optimized for heat exchange efficiency. These techniques allow for the creation of intricate flow channels and maximized surface area, enhancing the thermal regeneration process in magnetocaloric systems.

Computational materials science has accelerated the discovery and optimization of new magnetocaloric materials. Machine learning algorithms and high-throughput screening methods have identified promising compositions with tailored Curie temperatures and magnetocaloric responses. These computational approaches have significantly reduced the time and resources required for experimental testing.

The development of materials with first-order magnetic phase transitions has been particularly significant, as these materials typically exhibit larger entropy changes compared to those with second-order transitions. However, challenges related to thermal hysteresis and mechanical stability during cycling remain areas of active research, driving the exploration of composite and layered material structures designed specifically for thermal regeneration applications.

The discovery of giant magnetocaloric effect (GMCE) in Gd5(Si2Ge2) by Pecharsky and Gschneidner in 1997 marked a pivotal moment in this field. This breakthrough expanded the potential for practical applications of magnetocaloric cooling technologies. Subsequently, research has focused on developing materials with enhanced magnetocaloric properties, reduced hysteresis, and improved thermal conductivity.

Rare-earth-based alloys, particularly those containing gadolinium, have been extensively studied due to their significant magnetocaloric effect near room temperature. However, the high cost and limited availability of rare earth elements have driven research toward alternative materials. Heusler alloys, La(Fe,Si)13-based compounds, and MnFe(P,X) (where X represents As, Ge, Si) materials have emerged as promising candidates, offering comparable performance with more abundant elements.

Nanostructuring approaches have revolutionized material design for magnetocaloric applications. By controlling grain size, interface properties, and compositional gradients at the nanoscale, researchers have achieved enhanced magnetocaloric responses and reduced thermal hysteresis. Composite materials combining different magnetocaloric substances have demonstrated improved heat transfer characteristics and mechanical stability, addressing key challenges in regenerator design.

Advanced manufacturing techniques, including additive manufacturing and precision casting, have enabled the production of complex geometries optimized for heat exchange efficiency. These techniques allow for the creation of intricate flow channels and maximized surface area, enhancing the thermal regeneration process in magnetocaloric systems.

Computational materials science has accelerated the discovery and optimization of new magnetocaloric materials. Machine learning algorithms and high-throughput screening methods have identified promising compositions with tailored Curie temperatures and magnetocaloric responses. These computational approaches have significantly reduced the time and resources required for experimental testing.

The development of materials with first-order magnetic phase transitions has been particularly significant, as these materials typically exhibit larger entropy changes compared to those with second-order transitions. However, challenges related to thermal hysteresis and mechanical stability during cycling remain areas of active research, driving the exploration of composite and layered material structures designed specifically for thermal regeneration applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!