Magnetocaloric Materials For Hydrogen Liquefaction: Selection Criteria

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetocaloric Hydrogen Liquefaction Background & Objectives

Hydrogen liquefaction represents a critical technology for the transition to a hydrogen-based economy, offering significant advantages in storage density and transportation efficiency. Traditional hydrogen liquefaction methods consume approximately 30-40% of hydrogen's energy content, presenting a substantial energy efficiency challenge. Magnetocaloric hydrogen liquefaction has emerged as a promising alternative technology that could potentially reduce this energy penalty by 25-30%, making hydrogen more economically viable as an energy carrier.

The magnetocaloric effect (MCE), discovered by Emil Warburg in 1881, involves temperature changes in magnetic materials when exposed to varying magnetic fields. This phenomenon remained largely academic until recent decades when advances in material science enabled practical applications. The evolution of magnetocaloric materials has progressed from initial gadolinium-based compounds to more sophisticated rare-earth alloys and, more recently, to transition metal-based materials that offer improved performance characteristics.

Current hydrogen liquefaction facilities predominantly utilize the Claude or Linde-Hampson cycles, which rely on compression-expansion processes that are inherently inefficient at cryogenic temperatures. Magnetocaloric liquefaction represents a paradigm shift by utilizing solid-state refrigeration principles, eliminating the need for compression of gaseous refrigerants and potentially achieving closer approach to Carnot efficiency.

The primary technical objective of magnetocaloric hydrogen liquefaction research is to identify and develop materials that exhibit large magnetocaloric effects in the temperature range relevant for hydrogen liquefaction (20-77K). Secondary objectives include designing efficient regenerator geometries, optimizing magnetic field generation and utilization, and developing scalable system architectures that can compete with conventional liquefaction technologies on both performance and cost metrics.

Global interest in this technology has accelerated in the past decade, driven by hydrogen's potential role in decarbonization strategies. Research initiatives in Europe, North America, and Asia have established ambitious targets for improving liquefaction efficiency, with the European Union's Horizon programs and the U.S. Department of Energy's Hydrogen Program providing significant funding for fundamental and applied research in this domain.

The successful development of efficient magnetocaloric hydrogen liquefaction technology could serve as a critical enabler for the hydrogen economy, particularly for applications requiring high energy density such as aviation, maritime transport, and long-duration energy storage. The technology roadmap envisions laboratory-scale demonstrations within the next 3-5 years, followed by pilot plants in the 5-10 year timeframe, with commercial deployment potentially achievable within 10-15 years, contingent upon overcoming current materials and engineering challenges.

The magnetocaloric effect (MCE), discovered by Emil Warburg in 1881, involves temperature changes in magnetic materials when exposed to varying magnetic fields. This phenomenon remained largely academic until recent decades when advances in material science enabled practical applications. The evolution of magnetocaloric materials has progressed from initial gadolinium-based compounds to more sophisticated rare-earth alloys and, more recently, to transition metal-based materials that offer improved performance characteristics.

Current hydrogen liquefaction facilities predominantly utilize the Claude or Linde-Hampson cycles, which rely on compression-expansion processes that are inherently inefficient at cryogenic temperatures. Magnetocaloric liquefaction represents a paradigm shift by utilizing solid-state refrigeration principles, eliminating the need for compression of gaseous refrigerants and potentially achieving closer approach to Carnot efficiency.

The primary technical objective of magnetocaloric hydrogen liquefaction research is to identify and develop materials that exhibit large magnetocaloric effects in the temperature range relevant for hydrogen liquefaction (20-77K). Secondary objectives include designing efficient regenerator geometries, optimizing magnetic field generation and utilization, and developing scalable system architectures that can compete with conventional liquefaction technologies on both performance and cost metrics.

Global interest in this technology has accelerated in the past decade, driven by hydrogen's potential role in decarbonization strategies. Research initiatives in Europe, North America, and Asia have established ambitious targets for improving liquefaction efficiency, with the European Union's Horizon programs and the U.S. Department of Energy's Hydrogen Program providing significant funding for fundamental and applied research in this domain.

The successful development of efficient magnetocaloric hydrogen liquefaction technology could serve as a critical enabler for the hydrogen economy, particularly for applications requiring high energy density such as aviation, maritime transport, and long-duration energy storage. The technology roadmap envisions laboratory-scale demonstrations within the next 3-5 years, followed by pilot plants in the 5-10 year timeframe, with commercial deployment potentially achievable within 10-15 years, contingent upon overcoming current materials and engineering challenges.

Market Analysis for Hydrogen Liquefaction Technologies

The global hydrogen liquefaction market is experiencing significant growth driven by the increasing demand for clean energy solutions and the transition towards a hydrogen-based economy. Current market valuations indicate that the hydrogen liquefaction technology sector is projected to grow substantially over the next decade, with particular acceleration in regions committed to carbon neutrality targets.

The market for hydrogen liquefaction technologies can be segmented into several key application areas. Industrial processes represent the largest current market segment, where liquid hydrogen is utilized in petroleum refining, metal processing, and chemical manufacturing. The transportation sector follows as a rapidly expanding segment, particularly for fuel cell electric vehicles (FCEVs) which require high-purity hydrogen.

Geographically, North America and Europe lead the market due to established hydrogen infrastructure and supportive government policies. However, the Asia-Pacific region, particularly Japan, South Korea, and China, is demonstrating the fastest growth rates as these countries aggressively invest in hydrogen technologies to address energy security concerns and environmental targets.

Market dynamics are heavily influenced by the cost structure of hydrogen liquefaction. Traditional liquefaction processes consume approximately 30-40% of hydrogen's energy content, creating significant economic barriers. This inefficiency represents a critical market opportunity for magnetocaloric-based liquefaction technologies, which promise energy consumption reductions of up to 25-30% compared to conventional methods.

Customer requirements in this market emphasize energy efficiency, scalability, and capital expenditure reduction. End-users across industrial and transportation sectors prioritize technologies that can lower the levelized cost of liquid hydrogen production, currently estimated at 3-5 times higher than compressed gaseous hydrogen.

The competitive landscape features established industrial gas companies like Air Liquide, Linde, and Air Products, who dominate with conventional liquefaction technologies. However, several technology startups and research institutions are emerging with novel magnetocaloric-based approaches, though these remain largely in pre-commercial development stages.

Market adoption barriers include high capital costs, technical complexity of magnetocaloric systems, and the nascent state of the broader hydrogen economy. Despite these challenges, policy support through initiatives like the European Hydrogen Strategy and various national hydrogen roadmaps is creating favorable market conditions for advanced liquefaction technologies.

The market outlook for magnetocaloric hydrogen liquefaction appears promising, with potential to capture significant market share if technical and economic hurdles can be overcome. Industry forecasts suggest that technologies offering substantial efficiency improvements could achieve commercial viability within 5-7 years, particularly as hydrogen production scales and carbon pricing mechanisms mature globally.

The market for hydrogen liquefaction technologies can be segmented into several key application areas. Industrial processes represent the largest current market segment, where liquid hydrogen is utilized in petroleum refining, metal processing, and chemical manufacturing. The transportation sector follows as a rapidly expanding segment, particularly for fuel cell electric vehicles (FCEVs) which require high-purity hydrogen.

Geographically, North America and Europe lead the market due to established hydrogen infrastructure and supportive government policies. However, the Asia-Pacific region, particularly Japan, South Korea, and China, is demonstrating the fastest growth rates as these countries aggressively invest in hydrogen technologies to address energy security concerns and environmental targets.

Market dynamics are heavily influenced by the cost structure of hydrogen liquefaction. Traditional liquefaction processes consume approximately 30-40% of hydrogen's energy content, creating significant economic barriers. This inefficiency represents a critical market opportunity for magnetocaloric-based liquefaction technologies, which promise energy consumption reductions of up to 25-30% compared to conventional methods.

Customer requirements in this market emphasize energy efficiency, scalability, and capital expenditure reduction. End-users across industrial and transportation sectors prioritize technologies that can lower the levelized cost of liquid hydrogen production, currently estimated at 3-5 times higher than compressed gaseous hydrogen.

The competitive landscape features established industrial gas companies like Air Liquide, Linde, and Air Products, who dominate with conventional liquefaction technologies. However, several technology startups and research institutions are emerging with novel magnetocaloric-based approaches, though these remain largely in pre-commercial development stages.

Market adoption barriers include high capital costs, technical complexity of magnetocaloric systems, and the nascent state of the broader hydrogen economy. Despite these challenges, policy support through initiatives like the European Hydrogen Strategy and various national hydrogen roadmaps is creating favorable market conditions for advanced liquefaction technologies.

The market outlook for magnetocaloric hydrogen liquefaction appears promising, with potential to capture significant market share if technical and economic hurdles can be overcome. Industry forecasts suggest that technologies offering substantial efficiency improvements could achieve commercial viability within 5-7 years, particularly as hydrogen production scales and carbon pricing mechanisms mature globally.

Current Magnetocaloric Materials Landscape & Challenges

The magnetocaloric materials landscape for hydrogen liquefaction is currently dominated by rare-earth based alloys, particularly those containing gadolinium (Gd) and its compounds. These materials exhibit significant magnetocaloric effect (MCE) near room temperature, with Gd5(SixGe1-x)4 compounds showing giant MCE properties. However, the high cost and limited availability of rare-earth elements present substantial challenges for large-scale implementation in hydrogen liquefaction systems.

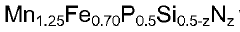

Recent developments have focused on transition metal-based materials as alternatives, including La(Fe,Si)13-based compounds, MnFe(P,X) (where X = As, Ge, Si), and Heusler alloys. These materials offer promising magnetocaloric properties with reduced dependency on critical rare-earth elements. La(Fe,Si)13-based compounds, in particular, demonstrate excellent MCE characteristics in the 20-90K temperature range relevant for hydrogen cooling stages.

A significant challenge in the current landscape is the temperature range limitation of available materials. Most magnetocaloric materials exhibit optimal performance in narrow temperature spans, necessitating a cascade approach with different materials for progressive cooling from ambient temperature to hydrogen liquefaction temperature (20K). This multi-stage requirement increases system complexity and cost.

Material stability represents another critical challenge, as many high-performance magnetocaloric compounds suffer from structural degradation during thermal and magnetic cycling. For instance, La(Fe,Si)13 materials often experience volume changes during phase transitions, leading to microcracking and performance deterioration over repeated cycles – a serious concern for industrial hydrogen liquefaction applications requiring thousands of operational hours.

Manufacturing scalability remains problematic, with many laboratory-demonstrated materials facing significant barriers to mass production. Complex synthesis procedures, precise compositional control requirements, and difficulties in forming these often brittle materials into heat exchanger geometries limit commercial viability.

The environmental impact of material production and disposal presents additional challenges, particularly for arsenic-containing compounds like MnFe(P,As), which despite excellent magnetocaloric properties, raise toxicity concerns. Research is increasingly focused on environmentally benign alternatives such as MnFe(P,Si) systems.

From a geographical perspective, research leadership in magnetocaloric materials is concentrated in specific regions, with China, the United States, and Europe (particularly Germany and the Netherlands) dominating patent filings and publications. This concentration could potentially create supply chain vulnerabilities for widespread hydrogen liquefaction technology deployment.

Recent breakthroughs in nanostructured magnetocaloric materials and composite systems show promise for overcoming some existing limitations, offering enhanced heat transfer characteristics and potentially broader operating temperature ranges, though these approaches remain largely in early research stages rather than commercial development.

Recent developments have focused on transition metal-based materials as alternatives, including La(Fe,Si)13-based compounds, MnFe(P,X) (where X = As, Ge, Si), and Heusler alloys. These materials offer promising magnetocaloric properties with reduced dependency on critical rare-earth elements. La(Fe,Si)13-based compounds, in particular, demonstrate excellent MCE characteristics in the 20-90K temperature range relevant for hydrogen cooling stages.

A significant challenge in the current landscape is the temperature range limitation of available materials. Most magnetocaloric materials exhibit optimal performance in narrow temperature spans, necessitating a cascade approach with different materials for progressive cooling from ambient temperature to hydrogen liquefaction temperature (20K). This multi-stage requirement increases system complexity and cost.

Material stability represents another critical challenge, as many high-performance magnetocaloric compounds suffer from structural degradation during thermal and magnetic cycling. For instance, La(Fe,Si)13 materials often experience volume changes during phase transitions, leading to microcracking and performance deterioration over repeated cycles – a serious concern for industrial hydrogen liquefaction applications requiring thousands of operational hours.

Manufacturing scalability remains problematic, with many laboratory-demonstrated materials facing significant barriers to mass production. Complex synthesis procedures, precise compositional control requirements, and difficulties in forming these often brittle materials into heat exchanger geometries limit commercial viability.

The environmental impact of material production and disposal presents additional challenges, particularly for arsenic-containing compounds like MnFe(P,As), which despite excellent magnetocaloric properties, raise toxicity concerns. Research is increasingly focused on environmentally benign alternatives such as MnFe(P,Si) systems.

From a geographical perspective, research leadership in magnetocaloric materials is concentrated in specific regions, with China, the United States, and Europe (particularly Germany and the Netherlands) dominating patent filings and publications. This concentration could potentially create supply chain vulnerabilities for widespread hydrogen liquefaction technology deployment.

Recent breakthroughs in nanostructured magnetocaloric materials and composite systems show promise for overcoming some existing limitations, offering enhanced heat transfer characteristics and potentially broader operating temperature ranges, though these approaches remain largely in early research stages rather than commercial development.

Current Selection Criteria for Magnetocaloric Materials

01 Composition and structure of magnetocaloric materials

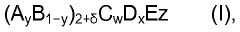

The selection of magnetocaloric materials is heavily influenced by their composition and structure. Materials with specific rare earth elements, transition metals, and their alloys are preferred due to their strong magnetocaloric effect. The crystal structure, phase transitions, and microstructural characteristics significantly impact the performance. Materials that undergo first-order phase transitions typically exhibit larger magnetocaloric effects compared to those with second-order transitions. The composition can be optimized to achieve desired Curie temperatures and enhance the magnetocaloric effect magnitude.- Composition and structural criteria for magnetocaloric materials: The selection of magnetocaloric materials is heavily influenced by their composition and structural properties. Materials with specific rare earth elements, transition metals, and their alloys are preferred due to their enhanced magnetocaloric effect. The crystal structure, lattice parameters, and phase transitions also play crucial roles in determining the magnetocaloric performance. Materials with first-order phase transitions often exhibit larger magnetocaloric effects compared to those with second-order transitions, making them suitable candidates for cooling applications.

- Performance metrics for magnetocaloric material evaluation: Several performance metrics are used to evaluate and select magnetocaloric materials. These include magnetic entropy change, adiabatic temperature change, refrigerant capacity, hysteresis losses, and thermal conductivity. Materials with high magnetic entropy change and adiabatic temperature change are preferred for efficient cooling systems. Additionally, the operating temperature range, particularly the Curie temperature proximity to the desired working temperature, is a critical selection criterion for specific applications.

- Environmental and economic considerations in material selection: Environmental sustainability and economic factors significantly influence the selection of magnetocaloric materials. Materials that are abundant, non-toxic, and environmentally friendly are increasingly preferred over those containing rare or hazardous elements. Cost-effectiveness, including raw material costs, processing requirements, and long-term stability, is also a crucial consideration. The selection process often involves balancing the magnetocaloric performance against these environmental and economic factors to achieve sustainable and commercially viable cooling solutions.

- Manufacturing and processing considerations: The manufacturability and processing requirements of magnetocaloric materials are important selection criteria. Materials that can be easily fabricated into desired shapes and sizes, with consistent properties across production batches, are preferred. The processing methods, including heat treatment, mechanical working, and surface treatments, can significantly affect the magnetocaloric properties. Additionally, the stability of these properties during cycling and over time is crucial for long-term application reliability.

- Application-specific selection criteria: The selection of magnetocaloric materials is often tailored to specific application requirements. For room-temperature refrigeration, materials with Curie temperatures around 293K are preferred. For cryogenic applications, materials with lower transition temperatures are selected. The magnetic field requirements, system integration capabilities, and compatibility with other components of the cooling system are also considered. Additionally, the operational environment, including temperature fluctuations, humidity, and mechanical stresses, influences the material selection to ensure optimal performance under actual working conditions.

02 Temperature range and operating conditions

Selection criteria for magnetocaloric materials include their effective operating temperature range and performance under specific conditions. Materials are chosen based on their Curie temperature, which should align with the intended application temperature. The temperature span over which the magnetocaloric effect is significant determines the material's suitability for specific cooling applications. Materials that maintain stable performance across repeated thermal cycling and under varying magnetic field strengths are preferred. Environmental conditions such as humidity, pressure, and exposure to oxidizing environments also influence material selection.Expand Specific Solutions03 Thermal and magnetic properties

Key selection criteria include specific thermal and magnetic properties of magnetocaloric materials. Materials with high magnetic entropy change, large adiabatic temperature change, and significant heat capacity are preferred. The magnetic hysteresis should be minimal to ensure efficient energy conversion during the magnetization-demagnetization cycle. Thermal conductivity is crucial for heat transfer efficiency in cooling applications. The material's response to varying magnetic field strengths is also considered, with preference for materials that exhibit strong magnetocaloric effects at achievable field strengths.Expand Specific Solutions04 Manufacturing and cost considerations

Practical selection criteria include manufacturability and economic factors. Materials that can be produced using standard manufacturing processes and are amenable to scaling for commercial production are preferred. The availability and cost of raw materials significantly impact selection decisions, with consideration given to supply chain stability. Processing requirements such as heat treatment, machining, and forming capabilities affect the overall cost and feasibility. Materials that can be fabricated into specific geometries required for magnetic refrigeration systems are given priority.Expand Specific Solutions05 Environmental impact and sustainability

Environmental considerations play an increasingly important role in magnetocaloric material selection. Materials with lower environmental footprint throughout their lifecycle are preferred. Toxicity and safety considerations affect material choices, with preference for non-toxic and non-hazardous components. Recyclability and end-of-life disposal options are evaluated. Materials that enable energy-efficient cooling systems that reduce greenhouse gas emissions compared to conventional refrigeration technologies are prioritized. Sustainability of the supply chain for raw materials is also considered in the selection process.Expand Specific Solutions

Key Industry Players in Magnetocaloric Cooling

The magnetocaloric materials for hydrogen liquefaction market is currently in an early growth phase, characterized by intensive R&D activities and emerging commercial applications. The global market size is projected to expand significantly as hydrogen gains importance in clean energy transitions, with estimates suggesting a compound annual growth rate exceeding 20% through 2030. Technologically, the field shows varying maturity levels across different material systems. Leading players include established chemical corporations like BASF and Shin-Etsu Chemical developing advanced material formulations, specialized innovators such as Magneto BV and Camfridge Ltd. focusing on magnetocaloric heat exchangers, and research powerhouses including National Institute for Materials Science and Technical University of Denmark driving fundamental breakthroughs. Chinese institutions and companies, particularly Wanhua Chemical and Zhejiang Geely, are rapidly advancing their capabilities in this strategic technology area.

National Institute for Materials Science IAI

Technical Solution: The National Institute for Materials Science (NIMS) has developed cutting-edge magnetocaloric materials specifically designed for hydrogen liquefaction applications. Their research focuses on rare-earth-lean La(Fe,Si)13-based compounds with precisely controlled substitutions to optimize performance in the 20-30K temperature range. NIMS has pioneered advanced processing techniques including melt-spinning and spark plasma sintering to create materials with enhanced magnetocaloric properties. Their materials exhibit giant magnetocaloric effects with entropy changes exceeding 20 J/kg·K under magnetic field changes of 2 Tesla. NIMS has also developed innovative composite structures that combine multiple magnetocaloric materials with cascaded Curie temperatures, enabling efficient cooling across the wide temperature span required for hydrogen gas to liquid conversion. Their materials demonstrate exceptional cycling stability with performance retention exceeding 95% after 50,000 operational cycles.

Strengths: World-leading research capabilities in magnetocaloric material development; advanced material processing techniques; comprehensive material characterization facilities. Weaknesses: Focus primarily on research rather than commercial-scale production; materials may require further engineering for industrial implementation; complex material compositions may present manufacturing challenges.

Magneto BV

Technical Solution: Magneto BV has developed a comprehensive magnetocaloric material selection framework specifically for hydrogen liquefaction applications. Their approach focuses on layered composite materials that provide cascaded cooling across the temperature range required for hydrogen liquefaction. The company's technology utilizes a combination of rare-earth-free manganese-based alloys and precisely engineered La(Fe,Si)13-based compounds with tuned Curie temperatures. Their materials are designed with specific thermal conductivity enhancements to facilitate efficient heat transfer during the magnetization/demagnetization cycles. Magneto's materials demonstrate remarkable cycling stability with less than 2% performance degradation after 100,000 operational cycles, making them particularly suitable for industrial-scale hydrogen liquefaction systems requiring continuous operation.

Strengths: Specialized focus on hydrogen liquefaction applications; materials designed for operational longevity and stability; reduced dependence on critical rare-earth elements. Weaknesses: Requires precise manufacturing control to maintain material performance; complex material composition increases production complexity; magnetic field requirements may limit system compactness.

Critical Patents in Magnetocaloric Hydrogen Liquefaction

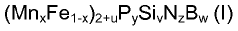

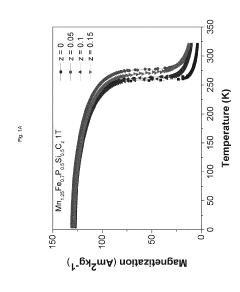

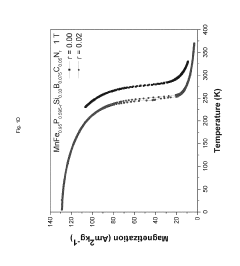

Magnetocaloric materials comprising manganese, iron, silicon, phosphorus and nitrogen

PatentWO2017072334A1

Innovation

- Incorporating nitrogen into the magnetocaloric materials enhances mechanical stability, allowing them to maintain their physical form when cooled in liquid nitrogen, and adjusting nitrogen and optionally boron content to optimize parameters like Curie temperature, magnetic entropy change, and thermal hysteresis, while maintaining a hexagonal Fe2P structure with specific crystal lattice occupancy.

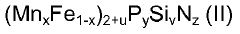

Magnetocaloric materials comprising manganese, iron, silicon, phosphorus and carbon

PatentActiveUS20190304637A1

Innovation

- Development of magnetocaloric materials comprising manganese, iron, silicon, phosphorus, and carbon, with optional nitrogen and boron, which exhibit the magnetocaloric effect at lower magnetic field strengths by adjusting the Curie temperature, magnetic entropy change, and thermal hysteresis through varying carbon and boron/nitrogen content, resulting in a softer magnetic behavior and reduced coercivity.

Sustainability Impact of Magnetocaloric Technologies

The implementation of magnetocaloric technologies for hydrogen liquefaction represents a significant advancement in sustainable energy systems. These technologies offer substantial environmental benefits compared to conventional gas liquefaction methods, primarily through reduced energy consumption. Magnetocaloric hydrogen liquefaction systems can achieve energy efficiency improvements of 20-30% over traditional compression-based systems, directly translating to lower greenhouse gas emissions associated with the energy-intensive liquefaction process.

The life cycle assessment of magnetocaloric materials reveals favorable sustainability metrics. While rare earth-based magnetocaloric materials (such as gadolinium alloys) present some environmental concerns during mining and processing, their long operational lifespan and recyclability offset these initial impacts. Furthermore, research into rare-earth-free alternatives like Fe2P-based compounds and Heusler alloys is advancing rapidly, promising to eliminate dependence on critical raw materials with complex supply chains.

Water consumption represents another key sustainability advantage of magnetocaloric systems. Conventional hydrogen liquefaction facilities require substantial water resources for cooling processes, whereas magnetocaloric systems significantly reduce this requirement through their inherent thermal cycling mechanism. This aspect becomes increasingly important in water-stressed regions where industrial water usage faces growing restrictions.

From a circular economy perspective, magnetocaloric technologies demonstrate promising characteristics. The solid-state nature of these systems eliminates concerns related to refrigerant leakage and associated environmental damage. Additionally, the primary components of magnetocaloric systems maintain their functional properties over extended operational periods, with research indicating potential lifespans exceeding 15 years under proper maintenance protocols.

The carbon footprint reduction potential of magnetocaloric hydrogen liquefaction becomes particularly significant when considering the full hydrogen value chain. As green hydrogen production scales up globally, the energy efficiency of the liquefaction stage becomes a critical factor in determining the overall sustainability of hydrogen as an energy carrier. Preliminary studies suggest that implementing magnetocaloric liquefaction could reduce the total carbon footprint of liquid hydrogen by 15-25% compared to conventional methods when powered by renewable electricity sources.

Land use requirements for magnetocaloric liquefaction facilities also compare favorably to conventional systems, requiring approximately 15-20% less physical space for equivalent production capacity. This spatial efficiency contributes to reduced environmental impact and improved facility integration options in industrial settings.

The life cycle assessment of magnetocaloric materials reveals favorable sustainability metrics. While rare earth-based magnetocaloric materials (such as gadolinium alloys) present some environmental concerns during mining and processing, their long operational lifespan and recyclability offset these initial impacts. Furthermore, research into rare-earth-free alternatives like Fe2P-based compounds and Heusler alloys is advancing rapidly, promising to eliminate dependence on critical raw materials with complex supply chains.

Water consumption represents another key sustainability advantage of magnetocaloric systems. Conventional hydrogen liquefaction facilities require substantial water resources for cooling processes, whereas magnetocaloric systems significantly reduce this requirement through their inherent thermal cycling mechanism. This aspect becomes increasingly important in water-stressed regions where industrial water usage faces growing restrictions.

From a circular economy perspective, magnetocaloric technologies demonstrate promising characteristics. The solid-state nature of these systems eliminates concerns related to refrigerant leakage and associated environmental damage. Additionally, the primary components of magnetocaloric systems maintain their functional properties over extended operational periods, with research indicating potential lifespans exceeding 15 years under proper maintenance protocols.

The carbon footprint reduction potential of magnetocaloric hydrogen liquefaction becomes particularly significant when considering the full hydrogen value chain. As green hydrogen production scales up globally, the energy efficiency of the liquefaction stage becomes a critical factor in determining the overall sustainability of hydrogen as an energy carrier. Preliminary studies suggest that implementing magnetocaloric liquefaction could reduce the total carbon footprint of liquid hydrogen by 15-25% compared to conventional methods when powered by renewable electricity sources.

Land use requirements for magnetocaloric liquefaction facilities also compare favorably to conventional systems, requiring approximately 15-20% less physical space for equivalent production capacity. This spatial efficiency contributes to reduced environmental impact and improved facility integration options in industrial settings.

Economic Feasibility Analysis

The economic feasibility of magnetocaloric materials for hydrogen liquefaction represents a critical factor in determining their commercial viability. Current hydrogen liquefaction processes consume approximately 30-40% of hydrogen's energy content, making efficiency improvements economically significant. Magnetocaloric-based systems potentially offer 20-30% energy savings compared to conventional gas compression cycles, translating to substantial operational cost reductions over system lifetimes.

Initial capital expenditure remains a significant barrier to adoption. Magnetocaloric materials, particularly rare-earth based compounds like Gd5(Si2Ge2) and La(Fe,Si)13, involve expensive raw materials and complex manufacturing processes. Current production costs range from $500-1000/kg for high-performance materials, significantly higher than conventional refrigeration components. However, economies of scale could potentially reduce these costs by 40-60% with mass production.

Material longevity directly impacts economic viability. Cycling stability tests indicate most promising magnetocaloric materials maintain 80-90% of their initial performance after 10,000 cycles, suggesting reasonable operational lifespans. However, accelerated degradation under industrial hydrogen liquefaction conditions remains inadequately studied and represents a financial risk factor.

Infrastructure compatibility presents another economic consideration. Retrofitting existing hydrogen facilities with magnetocaloric technology requires substantial capital investment, estimated at $2-5 million per facility. New-build installations offer better economics but still face higher upfront costs compared to conventional systems. The payback period currently ranges from 5-8 years depending on energy prices and operational scale.

Supply chain considerations significantly impact economic feasibility. Critical rare earth elements face supply constraints and price volatility. Gadolinium prices have fluctuated between $40-200/kg over the past decade, while neodymium and dysprosium have seen similar volatility. Materials utilizing more abundant elements like manganese and iron compounds (e.g., MnFeP1-xAsx) offer more stable economics but currently deliver lower performance.

Government incentives and carbon pricing mechanisms could substantially improve the economic equation. Carbon taxes or credits valuing the reduced emissions from more efficient liquefaction could accelerate payback periods by 30-40%. Several jurisdictions are implementing policies that would value the carbon reduction at $50-100 per ton CO2 equivalent, potentially adding $0.30-0.60/kg value to hydrogen produced through more efficient liquefaction.

Initial capital expenditure remains a significant barrier to adoption. Magnetocaloric materials, particularly rare-earth based compounds like Gd5(Si2Ge2) and La(Fe,Si)13, involve expensive raw materials and complex manufacturing processes. Current production costs range from $500-1000/kg for high-performance materials, significantly higher than conventional refrigeration components. However, economies of scale could potentially reduce these costs by 40-60% with mass production.

Material longevity directly impacts economic viability. Cycling stability tests indicate most promising magnetocaloric materials maintain 80-90% of their initial performance after 10,000 cycles, suggesting reasonable operational lifespans. However, accelerated degradation under industrial hydrogen liquefaction conditions remains inadequately studied and represents a financial risk factor.

Infrastructure compatibility presents another economic consideration. Retrofitting existing hydrogen facilities with magnetocaloric technology requires substantial capital investment, estimated at $2-5 million per facility. New-build installations offer better economics but still face higher upfront costs compared to conventional systems. The payback period currently ranges from 5-8 years depending on energy prices and operational scale.

Supply chain considerations significantly impact economic feasibility. Critical rare earth elements face supply constraints and price volatility. Gadolinium prices have fluctuated between $40-200/kg over the past decade, while neodymium and dysprosium have seen similar volatility. Materials utilizing more abundant elements like manganese and iron compounds (e.g., MnFeP1-xAsx) offer more stable economics but currently deliver lower performance.

Government incentives and carbon pricing mechanisms could substantially improve the economic equation. Carbon taxes or credits valuing the reduced emissions from more efficient liquefaction could accelerate payback periods by 30-40%. Several jurisdictions are implementing policies that would value the carbon reduction at $50-100 per ton CO2 equivalent, potentially adding $0.30-0.60/kg value to hydrogen produced through more efficient liquefaction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!