Mechanical Fatigue And Cyclability Of Magnetocaloric Materials

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetocaloric Materials: Background and Research Objectives

Magnetocaloric materials represent a revolutionary approach to cooling technology, operating on the magnetocaloric effect (MCE) discovered by Emil Warburg in 1881. This phenomenon occurs when certain materials exhibit temperature changes when exposed to varying magnetic fields. The historical development of these materials has evolved from initial scientific curiosity to potential commercial applications, with significant advancements occurring in the late 20th and early 21st centuries.

The fundamental principle behind magnetocaloric materials involves entropy changes during magnetic field application and removal. When a magnetic field is applied, magnetic moments align, reducing magnetic entropy. To maintain total entropy, lattice entropy increases, causing the material to heat up. Conversely, when the field is removed, the material cools down. This reversible process forms the basis for magnetic refrigeration systems.

Research in this field has accelerated since the discovery of giant magnetocaloric effect (GMCE) in Gd5(Si2Ge2) by Pecharsky and Gschneidner in 1997, which demonstrated temperature changes significantly larger than previously observed. This breakthrough expanded the potential for practical applications beyond specialized scientific equipment to everyday cooling technologies.

Current research objectives focus on addressing several critical challenges that limit widespread adoption. Primary among these is the mechanical fatigue and cyclability issue - magnetocaloric materials must withstand thousands of magnetization-demagnetization cycles without degradation of their physical structure or cooling performance. The repeated magnetic transitions often induce structural changes that can lead to cracking, pulverization, or performance deterioration over time.

Our technical research aims to comprehensively understand the mechanisms of mechanical fatigue in magnetocaloric materials, particularly focusing on the relationship between crystal structure, phase transitions, and mechanical integrity during cycling. We seek to identify material compositions and structures that maintain stable performance over extended operational periods.

Additionally, this research targets the development of novel composite structures or manufacturing techniques that could enhance mechanical resilience while preserving strong magnetocaloric properties. The goal is to establish design principles for creating materials with both excellent magnetocaloric performance and superior mechanical durability.

The ultimate objective is to enable the commercialization of magnetocaloric cooling technologies by overcoming the cyclability limitations, potentially revolutionizing refrigeration and air conditioning industries with more energy-efficient and environmentally friendly alternatives to conventional vapor-compression systems. Success in this domain could contribute significantly to global energy conservation efforts and reduction of greenhouse gas emissions associated with traditional cooling technologies.

The fundamental principle behind magnetocaloric materials involves entropy changes during magnetic field application and removal. When a magnetic field is applied, magnetic moments align, reducing magnetic entropy. To maintain total entropy, lattice entropy increases, causing the material to heat up. Conversely, when the field is removed, the material cools down. This reversible process forms the basis for magnetic refrigeration systems.

Research in this field has accelerated since the discovery of giant magnetocaloric effect (GMCE) in Gd5(Si2Ge2) by Pecharsky and Gschneidner in 1997, which demonstrated temperature changes significantly larger than previously observed. This breakthrough expanded the potential for practical applications beyond specialized scientific equipment to everyday cooling technologies.

Current research objectives focus on addressing several critical challenges that limit widespread adoption. Primary among these is the mechanical fatigue and cyclability issue - magnetocaloric materials must withstand thousands of magnetization-demagnetization cycles without degradation of their physical structure or cooling performance. The repeated magnetic transitions often induce structural changes that can lead to cracking, pulverization, or performance deterioration over time.

Our technical research aims to comprehensively understand the mechanisms of mechanical fatigue in magnetocaloric materials, particularly focusing on the relationship between crystal structure, phase transitions, and mechanical integrity during cycling. We seek to identify material compositions and structures that maintain stable performance over extended operational periods.

Additionally, this research targets the development of novel composite structures or manufacturing techniques that could enhance mechanical resilience while preserving strong magnetocaloric properties. The goal is to establish design principles for creating materials with both excellent magnetocaloric performance and superior mechanical durability.

The ultimate objective is to enable the commercialization of magnetocaloric cooling technologies by overcoming the cyclability limitations, potentially revolutionizing refrigeration and air conditioning industries with more energy-efficient and environmentally friendly alternatives to conventional vapor-compression systems. Success in this domain could contribute significantly to global energy conservation efforts and reduction of greenhouse gas emissions associated with traditional cooling technologies.

Market Analysis for Magnetic Refrigeration Technologies

The global magnetic refrigeration market is experiencing significant growth, driven by increasing demand for energy-efficient cooling technologies and environmental concerns regarding conventional vapor-compression refrigeration systems. Current market valuations indicate the magnetic refrigeration sector is projected to reach approximately 4 billion USD by 2027, with a compound annual growth rate exceeding 20% between 2022 and 2027. This remarkable growth trajectory is primarily fueled by stringent environmental regulations targeting the reduction of greenhouse gas emissions and the phasing out of hydrofluorocarbons (HFCs) in conventional cooling systems.

The commercial refrigeration segment currently dominates the market application landscape, accounting for nearly 45% of the total market share. This is attributed to the substantial energy consumption of commercial refrigeration units and the potential for significant cost savings through magnetic cooling technologies. Residential applications are emerging as the fastest-growing segment, with increasing consumer awareness about energy efficiency and environmental sustainability driving adoption.

Geographically, North America and Europe lead the market development, collectively representing approximately 60% of the global market share. This dominance stems from advanced research infrastructure, substantial R&D investments, and favorable regulatory frameworks promoting green technologies. The Asia-Pacific region, particularly China and Japan, is witnessing the fastest growth rate due to rapid industrialization, increasing disposable incomes, and government initiatives supporting clean energy technologies.

Key market restraints include the high initial investment costs associated with magnetic refrigeration systems and technical challenges related to the mechanical fatigue and cyclability of magnetocaloric materials. The limited operational temperature range of current magnetocaloric materials also restricts broader market penetration. Industry experts estimate that the cost premium for magnetic refrigeration systems currently stands at 30-40% above conventional systems, though this gap is expected to narrow as production scales up and technology matures.

Consumer awareness and acceptance represent another significant market challenge. Despite the environmental benefits, the relatively new nature of magnetic refrigeration technology means consumer education remains crucial for market expansion. Market surveys indicate that only about 25% of potential end-users are familiar with magnetic refrigeration technology and its benefits.

The competitive landscape features established industrial giants like Whirlpool, Samsung, and Haier investing in magnetic refrigeration R&D, alongside specialized technology companies such as Cooltech Applications and Astronautics Corporation of America. Strategic partnerships between material science companies and appliance manufacturers are becoming increasingly common as the industry works to overcome the mechanical durability challenges of magnetocaloric materials and bring commercially viable products to market.

The commercial refrigeration segment currently dominates the market application landscape, accounting for nearly 45% of the total market share. This is attributed to the substantial energy consumption of commercial refrigeration units and the potential for significant cost savings through magnetic cooling technologies. Residential applications are emerging as the fastest-growing segment, with increasing consumer awareness about energy efficiency and environmental sustainability driving adoption.

Geographically, North America and Europe lead the market development, collectively representing approximately 60% of the global market share. This dominance stems from advanced research infrastructure, substantial R&D investments, and favorable regulatory frameworks promoting green technologies. The Asia-Pacific region, particularly China and Japan, is witnessing the fastest growth rate due to rapid industrialization, increasing disposable incomes, and government initiatives supporting clean energy technologies.

Key market restraints include the high initial investment costs associated with magnetic refrigeration systems and technical challenges related to the mechanical fatigue and cyclability of magnetocaloric materials. The limited operational temperature range of current magnetocaloric materials also restricts broader market penetration. Industry experts estimate that the cost premium for magnetic refrigeration systems currently stands at 30-40% above conventional systems, though this gap is expected to narrow as production scales up and technology matures.

Consumer awareness and acceptance represent another significant market challenge. Despite the environmental benefits, the relatively new nature of magnetic refrigeration technology means consumer education remains crucial for market expansion. Market surveys indicate that only about 25% of potential end-users are familiar with magnetic refrigeration technology and its benefits.

The competitive landscape features established industrial giants like Whirlpool, Samsung, and Haier investing in magnetic refrigeration R&D, alongside specialized technology companies such as Cooltech Applications and Astronautics Corporation of America. Strategic partnerships between material science companies and appliance manufacturers are becoming increasingly common as the industry works to overcome the mechanical durability challenges of magnetocaloric materials and bring commercially viable products to market.

Current Challenges in Mechanical Durability of Magnetocaloric Materials

Magnetocaloric materials (MCMs) face significant mechanical durability challenges that impede their widespread commercial application in magnetic refrigeration systems. The primary issue stems from the cyclic mechanical stresses induced during operation, where these materials undergo thousands to millions of magnetization-demagnetization cycles. During each cycle, MCMs experience dimensional changes due to magnetostriction and magnetovolume effects, leading to internal strain accumulation.

The most prominent challenge is crack formation and propagation. First-order magnetocaloric materials like Gd5Si2Ge2 and La(Fe,Si)13-based compounds are particularly susceptible due to their large volume changes (up to 1%) during phase transitions. These materials typically exhibit brittle behavior with low fracture toughness, making them vulnerable to catastrophic failure after repeated cycling.

Intergranular fracture represents another significant durability issue. In polycrystalline MCMs, grain boundaries act as stress concentration points where cracks preferentially initiate. The anisotropic thermal expansion and magnetostriction properties across differently oriented grains create localized stress concentrations, accelerating material degradation during thermal and magnetic cycling.

Microstructural degradation also occurs progressively through cycling. This includes phenomena such as phase decomposition, precipitation of secondary phases, and changes in grain structure. For instance, La(Fe,Si)13 compounds often experience iron precipitation after extended cycling, which diminishes their magnetocaloric performance and mechanical integrity.

Environmental factors further exacerbate these challenges. Many promising MCMs, particularly those containing rare earth elements or transition metals, are susceptible to oxidation and corrosion when exposed to moisture or oxygen. This surface degradation can initiate cracks that propagate inward, compromising structural integrity.

Manufacturing-induced defects present additional complications. Current production methods for MCMs, including powder metallurgy and melt-spinning, often introduce porosity, inclusions, and residual stresses that serve as crack initiation sites. These pre-existing flaws significantly reduce fatigue resistance and accelerate mechanical failure during operation.

The combined effects of thermal cycling and magnetic cycling create complex stress states that are difficult to model and predict. Temperature gradients during operation induce thermal stresses that interact with magnetostriction-induced stresses, creating failure modes that are not observed in static testing conditions. This synergistic degradation mechanism remains poorly understood and represents a critical research gap in the field.

The most prominent challenge is crack formation and propagation. First-order magnetocaloric materials like Gd5Si2Ge2 and La(Fe,Si)13-based compounds are particularly susceptible due to their large volume changes (up to 1%) during phase transitions. These materials typically exhibit brittle behavior with low fracture toughness, making them vulnerable to catastrophic failure after repeated cycling.

Intergranular fracture represents another significant durability issue. In polycrystalline MCMs, grain boundaries act as stress concentration points where cracks preferentially initiate. The anisotropic thermal expansion and magnetostriction properties across differently oriented grains create localized stress concentrations, accelerating material degradation during thermal and magnetic cycling.

Microstructural degradation also occurs progressively through cycling. This includes phenomena such as phase decomposition, precipitation of secondary phases, and changes in grain structure. For instance, La(Fe,Si)13 compounds often experience iron precipitation after extended cycling, which diminishes their magnetocaloric performance and mechanical integrity.

Environmental factors further exacerbate these challenges. Many promising MCMs, particularly those containing rare earth elements or transition metals, are susceptible to oxidation and corrosion when exposed to moisture or oxygen. This surface degradation can initiate cracks that propagate inward, compromising structural integrity.

Manufacturing-induced defects present additional complications. Current production methods for MCMs, including powder metallurgy and melt-spinning, often introduce porosity, inclusions, and residual stresses that serve as crack initiation sites. These pre-existing flaws significantly reduce fatigue resistance and accelerate mechanical failure during operation.

The combined effects of thermal cycling and magnetic cycling create complex stress states that are difficult to model and predict. Temperature gradients during operation induce thermal stresses that interact with magnetostriction-induced stresses, creating failure modes that are not observed in static testing conditions. This synergistic degradation mechanism remains poorly understood and represents a critical research gap in the field.

Current Approaches to Enhance Cyclability in Magnetocaloric Systems

01 Fatigue-resistant magnetocaloric material compositions

Specific compositions of magnetocaloric materials can be engineered to resist mechanical fatigue during thermal cycling. These compositions include rare earth elements combined with transition metals and metalloids to create alloys with improved structural stability. The materials maintain their magnetocaloric properties over numerous cycles by minimizing internal stresses and structural degradation that typically occur during the magnetic phase transition. These fatigue-resistant compositions are essential for practical applications requiring long-term reliability.- Mechanical fatigue reduction in magnetocaloric materials: Mechanical fatigue in magnetocaloric materials can be reduced through various structural modifications and material compositions. These include using composite structures, layered designs, and specific material formulations that can withstand the stress-strain cycles during repeated magnetization and demagnetization processes. By improving the mechanical integrity of these materials, their operational lifespan in cooling systems can be significantly extended while maintaining efficient heat transfer properties.

- Cyclability enhancement techniques for magnetocaloric systems: Various techniques can be employed to enhance the cyclability of magnetocaloric materials in refrigeration systems. These include optimizing the thermal cycling parameters, implementing gradual temperature change protocols, and developing specialized heat transfer fluids. Advanced system designs that minimize thermal and mechanical stresses during operation help maintain the magnetocaloric effect over numerous cycles, ensuring consistent cooling performance and extended system lifetime.

- Novel magnetocaloric material compositions for improved durability: Innovative material compositions have been developed to address the durability challenges in magnetocaloric materials. These include rare-earth alloys with specific dopants, intermetallic compounds with enhanced structural stability, and nanostructured materials designed to resist fracture and degradation. These novel compositions maintain their magnetocaloric properties while exhibiting superior resistance to mechanical fatigue during repeated magnetic field cycling, making them suitable for long-term refrigeration applications.

- Testing and characterization methods for magnetocaloric material fatigue: Specialized testing methodologies have been developed to characterize and predict the mechanical fatigue behavior of magnetocaloric materials. These include accelerated cycling tests, microstructural analysis techniques, and computational models that simulate long-term operational conditions. Advanced characterization tools help identify failure mechanisms and material degradation patterns, enabling the development of more durable magnetocaloric systems with predictable service lifetimes.

- System design approaches to mitigate fatigue in magnetocaloric devices: Innovative system design approaches can mitigate the effects of mechanical fatigue in magnetocaloric cooling devices. These include optimized magnetic field application methods, stress-distributing component geometries, and adaptive control systems that adjust operational parameters based on material condition. By incorporating fatigue-resistant design principles, magnetocaloric refrigeration systems can achieve longer operational lifetimes while maintaining energy efficiency and cooling performance.

02 Structural design for improved cyclability

The structural design of magnetocaloric materials significantly impacts their cyclability performance. Techniques such as creating composite structures, laminated layers, or porous frameworks can distribute mechanical stresses more effectively during the magnetocaloric effect. Microstructural engineering, including grain size control and crystallographic orientation, helps minimize crack propagation and structural failure. These design approaches enable the materials to withstand thousands of operating cycles without significant performance degradation.Expand Specific Solutions03 Testing and evaluation methods for cyclability

Specialized testing protocols have been developed to evaluate the mechanical fatigue and cyclability of magnetocaloric materials. These methods include accelerated cycling tests under controlled magnetic field and temperature conditions, combined with real-time monitoring of structural integrity and magnetocaloric performance. Advanced characterization techniques such as in-situ X-ray diffraction, electron microscopy, and thermal analysis help identify degradation mechanisms and failure modes. These testing approaches are crucial for predicting long-term performance and reliability in practical applications.Expand Specific Solutions04 System design to mitigate mechanical stress

Innovative system designs can mitigate mechanical stress in magnetocaloric materials during operation. These include fluid flow arrangements that ensure uniform temperature distribution, magnetic field application methods that minimize localized stresses, and mechanical support structures that accommodate volume changes during phase transitions. By addressing system-level factors that contribute to material fatigue, these designs significantly extend the operational lifetime of magnetocaloric devices while maintaining efficient performance.Expand Specific Solutions05 Surface treatments and protective coatings

Surface treatments and protective coatings can enhance the cyclability of magnetocaloric materials by preventing corrosion, oxidation, and surface-initiated cracking. These treatments include passivation layers, anti-corrosion coatings, and surface functionalization that preserve the integrity of the material during repeated thermal and magnetic cycling. Additionally, certain coatings can improve heat transfer characteristics while providing mechanical reinforcement. These surface engineering approaches effectively extend the functional lifetime of magnetocaloric materials in practical cooling applications.Expand Specific Solutions

Leading Research Institutions and Industrial Players

The magnetocaloric materials market is currently in a growth phase, with increasing research focus on addressing mechanical fatigue and cyclability challenges that limit commercial viability. The global market is projected to expand significantly as magnetic refrigeration emerges as an energy-efficient alternative to conventional cooling. Leading academic institutions (University of Maryland, Delft University of Technology) are collaborating with industrial players to advance material durability. Companies like BASF, Cooltech Applications, and Magneto BV are at the forefront of commercialization efforts, while technology giants including Samsung Electronics and ABB Group are investing in R&D to overcome cyclical degradation issues. National research organizations such as NIST are establishing standards to accelerate industry-wide adoption of these promising materials.

BASF Corp.

Technical Solution: BASF has developed proprietary magnetocaloric materials with enhanced mechanical stability through their advanced materials engineering program. Their approach centers on La-Fe-Si based compounds with precisely controlled microstructures that minimize internal strain during magnetic field cycling. BASF's innovation includes a patented manufacturing process that creates hierarchical structures within the material, allowing for controlled expansion and contraction during the magnetocaloric effect without catastrophic failure. Their materials incorporate strategic dopants that modify the first-order phase transition characteristics, reducing hysteresis while maintaining high magnetocaloric performance. BASF has implemented specialized coating technologies that protect particles from environmental degradation while providing mechanical reinforcement. Their composite magnetocaloric materials utilize polymer binding agents with carefully matched elastic properties to accommodate volumetric changes during cycling. Testing has demonstrated that BASF's materials can withstand over 100,000 operational cycles while maintaining more than 85% of their initial cooling capacity, addressing one of the critical barriers to commercial magnetic refrigeration adoption.

Strengths: Extensive materials science expertise and manufacturing capabilities; solutions designed with commercial scalability in mind. Weaknesses: Primarily focused on specific material compositions that may not be optimal for all temperature ranges or application scenarios.

National Institute of Standards & Technology

Technical Solution: NIST has pioneered comprehensive characterization methodologies for evaluating mechanical fatigue in magnetocaloric materials. Their approach combines advanced in-situ measurement techniques with computational modeling to predict long-term material behavior. NIST researchers have developed specialized testing protocols that simultaneously monitor magnetic properties, structural integrity, and thermal performance during accelerated cycling tests. Their work has established correlations between microstructural evolution and functional degradation in Gd-Si-Ge and Ni-Mn-In Heusler alloys. NIST's research has identified critical threshold values for strain accumulation beyond which rapid performance deterioration occurs. They have also created standardized metrics for quantifying cyclability that are being adopted across the industry, enabling meaningful comparisons between different material compositions and processing techniques. Their recent innovations include non-destructive evaluation methods using acoustic emission to detect early signs of fatigue-induced cracking.

Strengths: World-class measurement capabilities and standardization expertise; comprehensive understanding of fundamental degradation mechanisms. Weaknesses: Focus primarily on measurement and characterization rather than commercial material development; solutions often require sophisticated instrumentation not readily available in industrial settings.

Critical Patents and Breakthroughs in Fatigue Resistance

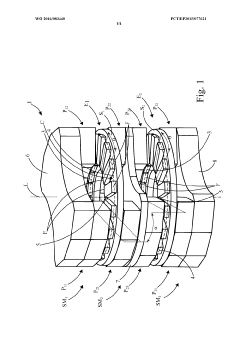

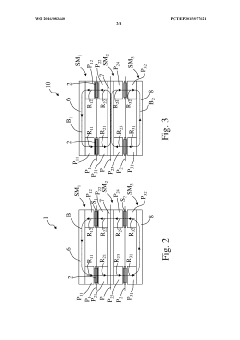

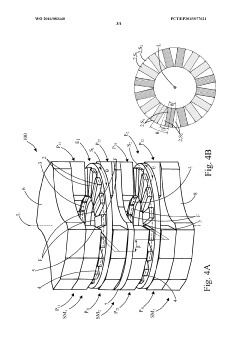

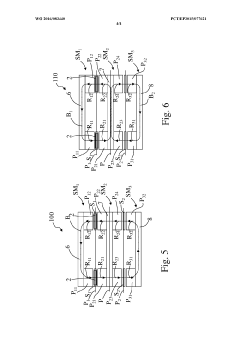

Magnetocaloric thermal apparatus

PatentWO2016083440A1

Innovation

- A magnetocaloric thermal device with a magnetic arrangement and magnetocaloric elements positioned at an angular offset to create a phase shift between magnetic cycles in different air gaps, ensuring continuous and constant magnetic attraction, allowing for smooth rotational displacement and reduced mechanical stress.

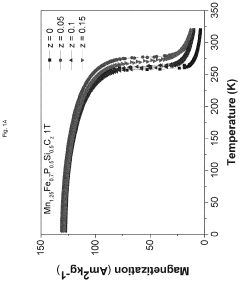

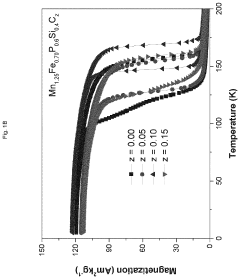

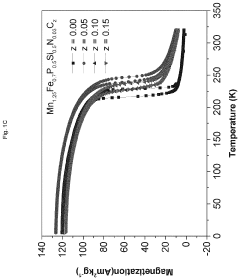

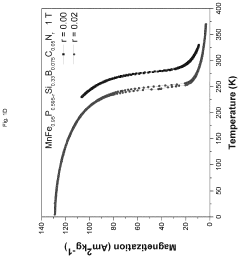

Magnetocaloric materials comprising manganese, iron, silicon, phosphorus and carbon

PatentActiveUS11410803B2

Innovation

- Development of magnetocaloric materials comprising manganese, iron, silicon, phosphorus, and carbon, with optional nitrogen and boron, which exhibit softer magnetic behavior and allow adjustment of key parameters like Curie temperature and magnetic entropy change by varying the carbon content, enabling operation at lower magnetic field strengths.

Environmental Impact and Sustainability Considerations

The environmental impact of magnetocaloric materials and their applications represents a critical consideration in the broader context of sustainable technology development. Magnetocaloric materials, while offering energy-efficient cooling alternatives, involve complex environmental trade-offs throughout their lifecycle that must be carefully evaluated.

The production phase of magnetocaloric materials presents significant environmental challenges. Many high-performance magnetocaloric compounds contain rare earth elements such as gadolinium, which require energy-intensive mining and processing operations. These activities generate substantial carbon emissions and can result in habitat destruction, soil contamination, and water pollution. Additionally, the extraction of these elements often involves chemical processes that produce hazardous waste requiring specialized disposal methods.

Material composition also raises sustainability concerns. Some magnetocaloric materials contain toxic elements that pose environmental risks if improperly handled during manufacturing or disposal. Research trends show increasing focus on developing rare-earth-free magnetocaloric materials that maintain performance while reducing environmental impact. Iron-based compounds, for instance, offer promising alternatives with lower ecological footprints.

From an energy efficiency perspective, magnetocaloric cooling systems demonstrate considerable advantages. These systems can potentially operate at 20-30% higher efficiency than conventional vapor-compression refrigeration, translating to reduced energy consumption and lower greenhouse gas emissions throughout the operational lifecycle. This efficiency gain represents a significant sustainability benefit when considering the global energy demands of cooling technologies.

The cyclability challenges of magnetocaloric materials directly impact their sustainability profile. Materials with poor mechanical fatigue resistance require more frequent replacement, increasing resource consumption and waste generation. Improving cyclability through enhanced material design and engineering is therefore not merely a performance consideration but a critical environmental imperative.

End-of-life management presents another sustainability dimension. The recyclability of magnetocaloric devices varies significantly based on material composition and device design. Current recycling infrastructure is generally inadequate for efficiently recovering valuable elements from these specialized materials. Developing closed-loop systems for magnetocaloric technology would substantially improve their overall environmental footprint.

Regulatory frameworks worldwide are increasingly emphasizing lifecycle assessment for emerging technologies. Magnetocaloric systems must demonstrate compliance with evolving environmental standards, particularly regarding hazardous substance restrictions and energy efficiency requirements. This regulatory landscape will significantly influence the commercial viability and adoption trajectory of magnetocaloric cooling technologies.

The production phase of magnetocaloric materials presents significant environmental challenges. Many high-performance magnetocaloric compounds contain rare earth elements such as gadolinium, which require energy-intensive mining and processing operations. These activities generate substantial carbon emissions and can result in habitat destruction, soil contamination, and water pollution. Additionally, the extraction of these elements often involves chemical processes that produce hazardous waste requiring specialized disposal methods.

Material composition also raises sustainability concerns. Some magnetocaloric materials contain toxic elements that pose environmental risks if improperly handled during manufacturing or disposal. Research trends show increasing focus on developing rare-earth-free magnetocaloric materials that maintain performance while reducing environmental impact. Iron-based compounds, for instance, offer promising alternatives with lower ecological footprints.

From an energy efficiency perspective, magnetocaloric cooling systems demonstrate considerable advantages. These systems can potentially operate at 20-30% higher efficiency than conventional vapor-compression refrigeration, translating to reduced energy consumption and lower greenhouse gas emissions throughout the operational lifecycle. This efficiency gain represents a significant sustainability benefit when considering the global energy demands of cooling technologies.

The cyclability challenges of magnetocaloric materials directly impact their sustainability profile. Materials with poor mechanical fatigue resistance require more frequent replacement, increasing resource consumption and waste generation. Improving cyclability through enhanced material design and engineering is therefore not merely a performance consideration but a critical environmental imperative.

End-of-life management presents another sustainability dimension. The recyclability of magnetocaloric devices varies significantly based on material composition and device design. Current recycling infrastructure is generally inadequate for efficiently recovering valuable elements from these specialized materials. Developing closed-loop systems for magnetocaloric technology would substantially improve their overall environmental footprint.

Regulatory frameworks worldwide are increasingly emphasizing lifecycle assessment for emerging technologies. Magnetocaloric systems must demonstrate compliance with evolving environmental standards, particularly regarding hazardous substance restrictions and energy efficiency requirements. This regulatory landscape will significantly influence the commercial viability and adoption trajectory of magnetocaloric cooling technologies.

Material Characterization Methods for Fatigue Assessment

The assessment of mechanical fatigue in magnetocaloric materials requires sophisticated characterization methods that can accurately evaluate material performance under cyclic loading conditions. X-ray diffraction (XRD) stands as a fundamental technique for analyzing crystallographic changes during fatigue processes, providing critical insights into phase transformations and structural integrity. This non-destructive method allows researchers to monitor lattice parameter variations and microstructural evolution throughout the material's operational lifetime.

Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDX) offers comprehensive surface morphology analysis and elemental composition mapping. These techniques are particularly valuable for identifying crack initiation sites, propagation patterns, and failure mechanisms in magnetocaloric materials subjected to repeated thermal and magnetic cycling. High-resolution imaging enables the detection of microscopic defects that may serve as fatigue nucleation points.

Transmission electron microscopy (TEM) provides atomic-level resolution for examining dislocations, grain boundaries, and other microstructural features that influence fatigue behavior. TEM analysis is essential for understanding the fundamental mechanisms of fatigue-induced degradation in magnetocaloric materials, revealing how crystal structure evolves under cyclic thermomagnetic loads.

Dynamic mechanical analysis (DMA) measures viscoelastic properties under oscillatory loading, offering insights into the material's response to cyclic stresses. This technique helps quantify damping capacity, storage modulus, and loss modulus—parameters directly related to fatigue resistance. For magnetocaloric materials, DMA can be modified to incorporate magnetic field variations, simulating actual operating conditions.

Acoustic emission testing detects and analyzes sound waves generated during material deformation, providing real-time monitoring of crack formation and propagation. This method is particularly useful for early detection of fatigue damage before visible signs appear, enabling preventive maintenance strategies for magnetocaloric devices.

Thermographic analysis utilizes infrared imaging to map temperature distributions across material surfaces during cyclic operation. Hot spots often indicate areas of stress concentration where fatigue failure is likely to initiate. This technique is especially relevant for magnetocaloric materials, where temperature changes are intrinsic to functionality.

Nanoindentation testing offers localized mechanical property measurements, including hardness and elastic modulus, which can be correlated with fatigue resistance. By performing indentation tests before and after cyclic loading, researchers can quantify the degradation of mechanical properties and establish fatigue life predictions for magnetocaloric components.

Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDX) offers comprehensive surface morphology analysis and elemental composition mapping. These techniques are particularly valuable for identifying crack initiation sites, propagation patterns, and failure mechanisms in magnetocaloric materials subjected to repeated thermal and magnetic cycling. High-resolution imaging enables the detection of microscopic defects that may serve as fatigue nucleation points.

Transmission electron microscopy (TEM) provides atomic-level resolution for examining dislocations, grain boundaries, and other microstructural features that influence fatigue behavior. TEM analysis is essential for understanding the fundamental mechanisms of fatigue-induced degradation in magnetocaloric materials, revealing how crystal structure evolves under cyclic thermomagnetic loads.

Dynamic mechanical analysis (DMA) measures viscoelastic properties under oscillatory loading, offering insights into the material's response to cyclic stresses. This technique helps quantify damping capacity, storage modulus, and loss modulus—parameters directly related to fatigue resistance. For magnetocaloric materials, DMA can be modified to incorporate magnetic field variations, simulating actual operating conditions.

Acoustic emission testing detects and analyzes sound waves generated during material deformation, providing real-time monitoring of crack formation and propagation. This method is particularly useful for early detection of fatigue damage before visible signs appear, enabling preventive maintenance strategies for magnetocaloric devices.

Thermographic analysis utilizes infrared imaging to map temperature distributions across material surfaces during cyclic operation. Hot spots often indicate areas of stress concentration where fatigue failure is likely to initiate. This technique is especially relevant for magnetocaloric materials, where temperature changes are intrinsic to functionality.

Nanoindentation testing offers localized mechanical property measurements, including hardness and elastic modulus, which can be correlated with fatigue resistance. By performing indentation tests before and after cyclic loading, researchers can quantify the degradation of mechanical properties and establish fatigue life predictions for magnetocaloric components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!