Design Principles For Solid-State Magnetocaloric Refrigerators

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetocaloric Refrigeration Background and Objectives

Magnetocaloric refrigeration represents a revolutionary cooling technology that leverages the magnetocaloric effect (MCE) - a thermodynamic phenomenon where certain materials change temperature when exposed to varying magnetic fields. This technology has evolved significantly since its discovery by Emil Warburg in 1881, with major advancements occurring in the late 20th and early 21st centuries. The fundamental principle involves the alignment of magnetic moments in magnetocaloric materials when subjected to a magnetic field, resulting in heat release, followed by heat absorption when the field is removed.

The development trajectory of magnetocaloric refrigeration has been marked by several pivotal milestones. In 1997, the discovery of giant magnetocaloric effect in Gd5(Si2Ge2) by Pecharsky and Gschneidner at Ames Laboratory represented a watershed moment, demonstrating temperature changes significantly larger than previously observed. Subsequently, research has expanded to explore various material families including La(Fe,Si)13-based compounds, MnFe(P,As)-based materials, and Heusler alloys, each offering unique advantages in different temperature ranges and magnetic field conditions.

Current technological evolution is focused on transitioning from laboratory demonstrations to commercially viable solid-state refrigeration systems. This shift necessitates addressing challenges in material optimization, magnetic field generation efficiency, and thermal management system design. The field is moving toward more sustainable solutions, with emphasis on rare-earth-free materials and permanent magnet-based field sources to reduce energy consumption and environmental impact.

The primary objectives of solid-state magnetocaloric refrigeration research include developing materials with enhanced magnetocaloric properties (larger entropy change, minimal hysteresis), designing efficient heat exchange systems, and creating compact, cost-effective magnetic field generation mechanisms. These goals align with the broader aim of creating cooling technologies that surpass conventional vapor-compression systems in energy efficiency while eliminating environmentally harmful refrigerants.

Industry projections suggest that successful implementation of magnetocaloric refrigeration could reduce energy consumption in cooling applications by 20-30% compared to conventional technologies. This potential has attracted significant investment from major corporations and research institutions worldwide, with particular interest in applications ranging from household refrigeration to industrial cooling and air conditioning systems.

The technology's evolution is increasingly influenced by sustainability considerations, with researchers targeting materials composed of abundant, non-toxic elements and manufacturing processes with reduced environmental footprints. This aligns with global initiatives to reduce greenhouse gas emissions and transition to more sustainable energy systems.

The development trajectory of magnetocaloric refrigeration has been marked by several pivotal milestones. In 1997, the discovery of giant magnetocaloric effect in Gd5(Si2Ge2) by Pecharsky and Gschneidner at Ames Laboratory represented a watershed moment, demonstrating temperature changes significantly larger than previously observed. Subsequently, research has expanded to explore various material families including La(Fe,Si)13-based compounds, MnFe(P,As)-based materials, and Heusler alloys, each offering unique advantages in different temperature ranges and magnetic field conditions.

Current technological evolution is focused on transitioning from laboratory demonstrations to commercially viable solid-state refrigeration systems. This shift necessitates addressing challenges in material optimization, magnetic field generation efficiency, and thermal management system design. The field is moving toward more sustainable solutions, with emphasis on rare-earth-free materials and permanent magnet-based field sources to reduce energy consumption and environmental impact.

The primary objectives of solid-state magnetocaloric refrigeration research include developing materials with enhanced magnetocaloric properties (larger entropy change, minimal hysteresis), designing efficient heat exchange systems, and creating compact, cost-effective magnetic field generation mechanisms. These goals align with the broader aim of creating cooling technologies that surpass conventional vapor-compression systems in energy efficiency while eliminating environmentally harmful refrigerants.

Industry projections suggest that successful implementation of magnetocaloric refrigeration could reduce energy consumption in cooling applications by 20-30% compared to conventional technologies. This potential has attracted significant investment from major corporations and research institutions worldwide, with particular interest in applications ranging from household refrigeration to industrial cooling and air conditioning systems.

The technology's evolution is increasingly influenced by sustainability considerations, with researchers targeting materials composed of abundant, non-toxic elements and manufacturing processes with reduced environmental footprints. This aligns with global initiatives to reduce greenhouse gas emissions and transition to more sustainable energy systems.

Market Analysis for Solid-State Cooling Technologies

The global solid-state cooling technologies market is experiencing significant growth, driven by increasing demand for energy-efficient and environmentally friendly refrigeration solutions. The market size for solid-state cooling technologies was valued at approximately $500 million in 2022 and is projected to reach $2.3 billion by 2030, growing at a CAGR of 21.3% during the forecast period. This growth trajectory is primarily attributed to the rising concerns regarding greenhouse gas emissions from conventional vapor-compression refrigeration systems and stringent environmental regulations worldwide.

Magnetocaloric refrigeration represents one of the most promising segments within the solid-state cooling market, accounting for roughly 35% of the total market share. This technology leverages the magnetocaloric effect in materials like gadolinium alloys to achieve cooling without harmful refrigerants. The magnetocaloric refrigeration market is expected to grow at a faster rate than other solid-state cooling technologies due to its higher energy efficiency potential and recent breakthroughs in material science.

Geographically, North America and Europe currently dominate the solid-state magnetocaloric refrigeration market, collectively holding approximately 65% of the global market share. This dominance can be attributed to substantial R&D investments, presence of key technology developers, and favorable government policies promoting green technologies. However, the Asia-Pacific region is emerging as the fastest-growing market with a projected CAGR of 25.7% through 2030, driven by rapid industrialization, increasing disposable income, and growing environmental awareness in countries like China, Japan, and South Korea.

From an application perspective, the commercial refrigeration segment currently holds the largest market share at 42%, followed by domestic refrigeration (28%), automotive cooling systems (18%), and others (12%). The commercial refrigeration sector's dominance is due to early adoption by businesses seeking to reduce operational costs and comply with environmental regulations. However, the automotive cooling segment is expected to witness the highest growth rate in the coming years as electric vehicle manufacturers increasingly explore efficient cooling solutions for battery thermal management.

Key market drivers include increasing energy costs, growing environmental concerns, technological advancements in magnetocaloric materials, and supportive government policies. The market faces challenges such as high initial investment costs, technical limitations in scaling up the technology, and competition from improved conventional cooling systems. Nevertheless, ongoing research in advanced magnetocaloric materials and innovative system designs is expected to address these challenges and accelerate market penetration in the coming decade.

Magnetocaloric refrigeration represents one of the most promising segments within the solid-state cooling market, accounting for roughly 35% of the total market share. This technology leverages the magnetocaloric effect in materials like gadolinium alloys to achieve cooling without harmful refrigerants. The magnetocaloric refrigeration market is expected to grow at a faster rate than other solid-state cooling technologies due to its higher energy efficiency potential and recent breakthroughs in material science.

Geographically, North America and Europe currently dominate the solid-state magnetocaloric refrigeration market, collectively holding approximately 65% of the global market share. This dominance can be attributed to substantial R&D investments, presence of key technology developers, and favorable government policies promoting green technologies. However, the Asia-Pacific region is emerging as the fastest-growing market with a projected CAGR of 25.7% through 2030, driven by rapid industrialization, increasing disposable income, and growing environmental awareness in countries like China, Japan, and South Korea.

From an application perspective, the commercial refrigeration segment currently holds the largest market share at 42%, followed by domestic refrigeration (28%), automotive cooling systems (18%), and others (12%). The commercial refrigeration sector's dominance is due to early adoption by businesses seeking to reduce operational costs and comply with environmental regulations. However, the automotive cooling segment is expected to witness the highest growth rate in the coming years as electric vehicle manufacturers increasingly explore efficient cooling solutions for battery thermal management.

Key market drivers include increasing energy costs, growing environmental concerns, technological advancements in magnetocaloric materials, and supportive government policies. The market faces challenges such as high initial investment costs, technical limitations in scaling up the technology, and competition from improved conventional cooling systems. Nevertheless, ongoing research in advanced magnetocaloric materials and innovative system designs is expected to address these challenges and accelerate market penetration in the coming decade.

Current Challenges in Magnetocaloric Materials Development

Despite significant advancements in magnetocaloric materials research, several critical challenges continue to impede the widespread commercialization of solid-state magnetocaloric refrigeration systems. The primary obstacle remains the limited temperature span and cooling capacity of current magnetocaloric materials, particularly when operating in magnetic fields achievable with permanent magnets (typically below 2 Tesla). This limitation significantly restricts the practical application potential in consumer and industrial refrigeration.

Material hysteresis presents another substantial challenge, as it reduces energy efficiency and cooling capacity during cyclic operation. First-order phase transition materials, while offering larger magnetocaloric effects, often exhibit considerable thermal and magnetic hysteresis, diminishing their effectiveness in practical cooling cycles. Researchers are actively seeking ways to minimize hysteresis while maintaining strong magnetocaloric responses.

The mechanical stability of magnetocaloric materials under repeated thermal and magnetic cycling remains problematic. Many promising materials develop microcracks or undergo structural degradation after numerous operating cycles, severely limiting device longevity. This issue is particularly pronounced in materials with sharp first-order phase transitions, where volume and structural changes during transitions can lead to mechanical failure.

Cost-effectiveness and scalable production represent significant hurdles for commercial viability. Current high-performance magnetocaloric materials often contain expensive rare earth elements like gadolinium or rely on precisely controlled compositions that are challenging to manufacture consistently at scale. The development of rare-earth-free alternatives with comparable performance remains an active research area.

Environmental concerns and regulatory compliance also pose challenges. Some effective magnetocaloric materials contain toxic or environmentally problematic elements, limiting their acceptability in consumer applications. Researchers must balance performance requirements with environmental sustainability and safety considerations.

System integration issues further complicate development efforts. The optimal design of heat exchangers, magnetic field generators, and fluid flow systems for magnetocaloric devices requires interdisciplinary expertise and novel engineering approaches. Achieving efficient heat transfer between solid magnetocaloric materials and heat transfer fluids while maintaining minimal pressure drops presents particular difficulty.

Finally, the field faces a knowledge gap in understanding the fundamental physics of the magnetocaloric effect in complex material systems. More comprehensive theoretical models and advanced characterization techniques are needed to guide the rational design of next-generation materials with enhanced performance characteristics across broader temperature ranges and in lower magnetic fields.

Material hysteresis presents another substantial challenge, as it reduces energy efficiency and cooling capacity during cyclic operation. First-order phase transition materials, while offering larger magnetocaloric effects, often exhibit considerable thermal and magnetic hysteresis, diminishing their effectiveness in practical cooling cycles. Researchers are actively seeking ways to minimize hysteresis while maintaining strong magnetocaloric responses.

The mechanical stability of magnetocaloric materials under repeated thermal and magnetic cycling remains problematic. Many promising materials develop microcracks or undergo structural degradation after numerous operating cycles, severely limiting device longevity. This issue is particularly pronounced in materials with sharp first-order phase transitions, where volume and structural changes during transitions can lead to mechanical failure.

Cost-effectiveness and scalable production represent significant hurdles for commercial viability. Current high-performance magnetocaloric materials often contain expensive rare earth elements like gadolinium or rely on precisely controlled compositions that are challenging to manufacture consistently at scale. The development of rare-earth-free alternatives with comparable performance remains an active research area.

Environmental concerns and regulatory compliance also pose challenges. Some effective magnetocaloric materials contain toxic or environmentally problematic elements, limiting their acceptability in consumer applications. Researchers must balance performance requirements with environmental sustainability and safety considerations.

System integration issues further complicate development efforts. The optimal design of heat exchangers, magnetic field generators, and fluid flow systems for magnetocaloric devices requires interdisciplinary expertise and novel engineering approaches. Achieving efficient heat transfer between solid magnetocaloric materials and heat transfer fluids while maintaining minimal pressure drops presents particular difficulty.

Finally, the field faces a knowledge gap in understanding the fundamental physics of the magnetocaloric effect in complex material systems. More comprehensive theoretical models and advanced characterization techniques are needed to guide the rational design of next-generation materials with enhanced performance characteristics across broader temperature ranges and in lower magnetic fields.

Contemporary Design Solutions for Solid-State Magnetic Refrigerators

01 Magnetocaloric material selection and optimization

The selection and optimization of magnetocaloric materials is crucial for efficient solid-state refrigeration. Materials exhibiting large magnetocaloric effect near room temperature are preferred, such as gadolinium alloys, La-Fe-Si compounds, and Heusler alloys. Material composition, structure, and processing techniques can be optimized to enhance the magnetocaloric effect, reduce hysteresis, and improve thermal conductivity. Advanced manufacturing methods can create materials with tailored properties for specific temperature ranges and magnetic field strengths.- Magnetocaloric material selection and optimization: The selection and optimization of magnetocaloric materials is crucial for efficient solid-state refrigeration. Materials exhibiting large magnetocaloric effects near room temperature are particularly valuable. These include rare-earth alloys, Heusler alloys, and composite materials with enhanced thermal conductivity. Material optimization focuses on maximizing entropy change, reducing hysteresis, and ensuring mechanical stability during repeated magnetic cycling.

- Heat transfer system design and thermal management: Effective heat transfer systems are essential in magnetocaloric refrigerators to efficiently move heat between the magnetocaloric material, heat exchangers, and the environment. This includes the design of heat exchangers with optimized surface area, selection of appropriate heat transfer fluids or solid-state thermal conductors, and implementation of thermal switches to control heat flow direction. Proper thermal management ensures maximum temperature span and cooling capacity.

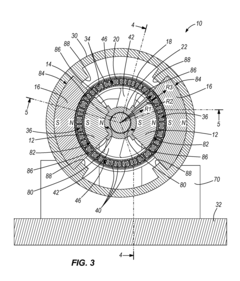

- Magnetic field generation and control systems: The design of magnetic field generation and control systems is critical for magnetocaloric refrigerators. This includes permanent magnet arrangements that maximize field strength while minimizing volume and weight, electromagnet designs for variable field control, and magnetic field concentration techniques. Advanced systems incorporate precise timing control for field application and removal to optimize the thermodynamic cycle and energy efficiency.

- Regenerator bed configuration and flow dynamics: The configuration of the regenerator bed, where the magnetocaloric material is housed, significantly impacts system performance. Design considerations include the geometry of the bed, packing density of magnetocaloric materials, flow channel design for heat transfer fluids, and layering of different materials to create a temperature gradient. Optimized flow dynamics reduce pressure drop while maximizing heat transfer efficiency throughout the thermodynamic cycle.

- System integration and control strategies: Successful solid-state magnetocaloric refrigerators require sophisticated system integration and control strategies. This includes electronic control systems that synchronize magnetic field application with heat transfer processes, sensors for temperature and field strength monitoring, and adaptive algorithms that optimize performance under varying load conditions. Advanced designs incorporate energy recovery mechanisms and cascaded systems to achieve larger temperature spans for practical applications.

02 Heat transfer system design

Effective heat transfer systems are essential for solid-state magnetocaloric refrigerators. These systems typically include heat exchangers, regenerators, and thermal switches that facilitate heat flow between the magnetocaloric material and the environment. The design must minimize thermal resistance while maximizing surface area contact with the magnetocaloric material. Advanced heat transfer fluids, microchannel heat exchangers, and thermally conductive interfaces can significantly improve system efficiency. Proper thermal management ensures rapid heat extraction during the magnetocaloric cycle.Expand Specific Solutions03 Magnetic field generation and control

The magnetic field generation system is a critical component that directly affects the performance of magnetocaloric refrigerators. Permanent magnets, electromagnets, or superconducting magnets can be used to create the required magnetic field. The design must consider field strength, uniformity, and the ability to rapidly change the field experienced by the magnetocaloric material. Advanced configurations like Halbach arrays or rotating permanent magnet assemblies can provide efficient field generation while minimizing size and energy consumption. Precise control of magnetic field timing and strength is essential for optimizing the refrigeration cycle.Expand Specific Solutions04 Thermodynamic cycle optimization

Optimizing the thermodynamic cycle is fundamental to achieving high efficiency in solid-state magnetocaloric refrigerators. This involves careful timing and sequencing of magnetization, demagnetization, heat absorption, and heat rejection processes. Advanced cycle designs like multi-stage cascades, regenerative cycles, or hybrid cycles can enhance performance. Computational modeling and simulation tools help predict and optimize cycle parameters such as frequency, dwell time, and phase relationships. The cycle design must balance cooling power, temperature span, and energy efficiency based on the specific application requirements.Expand Specific Solutions05 System integration and control strategies

Effective integration of components and sophisticated control strategies are essential for practical magnetocaloric refrigeration systems. This includes the mechanical design of moving parts, flow control systems, and electronic controllers that coordinate the operation of all subsystems. Advanced sensors monitor temperature, magnetic field, and fluid flow to enable real-time adjustments. Adaptive control algorithms can optimize performance under varying load conditions and ambient temperatures. The overall system design must consider size constraints, noise reduction, reliability, and manufacturability while maintaining high energy efficiency and cooling performance.Expand Specific Solutions

Leading Entities in Magnetocaloric Cooling Research

The magnetocaloric refrigeration market is currently in an early growth phase, characterized by increasing research intensity and emerging commercial applications. Market size remains modest but is projected to expand significantly as the technology matures, driven by environmental regulations and energy efficiency demands. Technical University of Denmark leads academic research, while commercial development is pursued by major corporations including Toshiba, BASF, IBM, and appliance manufacturers Gree and Haier. Chinese institutions, particularly the Chinese Academy of Sciences and various rare earth research institutes, are making significant contributions due to China's dominance in rare earth materials essential for magnetocaloric materials. The technology is approaching commercial viability with companies like Camfridge developing prototype systems, though challenges in material optimization and system design remain.

Technical University of Denmark

Technical Solution: Technical University of Denmark has developed advanced solid-state magnetocaloric refrigeration systems based on their patented active magnetic regenerator (AMR) technology. Their approach utilizes carefully engineered regenerator geometries with optimized flow channels and heat transfer surfaces to maximize the magnetocaloric effect. The university has pioneered layered regenerator designs that incorporate multiple magnetocaloric materials with varying Curie temperatures to broaden the operating temperature span[1]. Their systems typically employ permanent magnet assemblies in Halbach array configurations to generate the required magnetic field changes while minimizing system size. Recent developments include novel heat transfer fluids with improved thermal properties and reduced pumping power requirements, as well as advanced control algorithms that optimize the timing of magnetization/demagnetization cycles relative to fluid flow[2]. The university has demonstrated working prototypes achieving temperature spans exceeding 25K and cooling capacities suitable for domestic refrigeration applications.

Strengths: Industry-leading expertise in AMR design and optimization; extensive experimental validation capabilities; strong focus on system integration and practical implementation. Weaknesses: Higher manufacturing complexity of layered regenerator designs; reliance on relatively expensive rare earth materials for optimal performance; challenges in scaling to commercial production volumes.

Chinese Academy of Sciences Institute of Physics

Technical Solution: The Chinese Academy of Sciences Institute of Physics has developed comprehensive design principles for solid-state magnetocaloric refrigerators focusing on novel material compositions and structures. Their approach centers on first-principles calculations to predict and optimize magnetocaloric properties in rare earth-transition metal compounds, particularly La(Fe,Si)13-based materials with reduced hysteresis and enhanced thermal conductivity[1]. The institute has pioneered composite magnetocaloric materials that combine multiple phases to achieve broader working temperature ranges while maintaining high magnetic entropy changes. Their refrigerator designs incorporate innovative heat exchanger geometries that maximize surface contact between the magnetocaloric material and heat transfer fluid while minimizing pressure drops. The institute has also developed specialized manufacturing techniques for producing magnetocaloric materials with precisely controlled microstructures, including melt-spinning and hydrogen-disproportionation-desorption-recombination (HDDR) processes that enhance material performance and stability[2]. Recent work has focused on reducing rare earth content while maintaining performance through partial substitution with more abundant elements.

Strengths: World-class materials science expertise; comprehensive approach from fundamental physics to practical implementation; strong capabilities in computational materials design and characterization. Weaknesses: Some materials still require expensive rare earth elements; challenges in scaling up specialized manufacturing processes; thermal management issues in high-performance materials with first-order transitions.

Key Technical Innovations in Magnetocaloric Effect Utilization

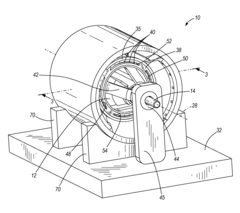

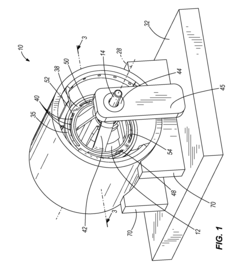

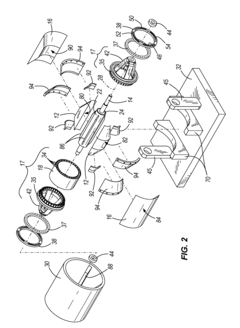

Magnetic refrigeration device

PatentActiveUS20100071383A1

Innovation

- A magnetic refrigeration device comprising a rotatable shaft with inner and outer magnets creating a magnetic gap, where magnetocaloric material alternates between magnetized and demagnetized positions, coupled with a heat transfer fluid circuit to optimize heat absorption and release through multiple channels, enhancing the temperature gradient and efficiency.

Magnetocaloric refrigeration regenerator using the demagnetizing

PatentWO2024257002A1

Innovation

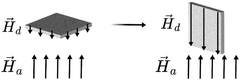

- A magnetocaloric refrigeration apparatus utilizing anisotropic-shaped magnetocaloric materials and a rotating magnetic field to induce the magnetocaloric effect, reducing the need for intense magnetic fields and enabling the use of less expensive magnets, with a system comprising a magnetic field source, regenerator bed, tubing circuit, and flow control device.

Environmental Impact and Sustainability Advantages

Magnetocaloric refrigeration technology represents a significant advancement in sustainable cooling solutions, offering substantial environmental benefits compared to conventional vapor-compression systems. The environmental impact of solid-state magnetocaloric refrigerators is markedly reduced due to the elimination of harmful refrigerants that contribute to ozone depletion and global warming. Traditional cooling systems rely heavily on hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs), which have global warming potentials hundreds to thousands of times greater than CO2. In contrast, magnetocaloric systems utilize solid refrigerants and water-based heat transfer fluids, effectively eliminating these harmful emissions.

Energy efficiency constitutes another critical sustainability advantage of magnetocaloric refrigeration. These systems can theoretically achieve 30-60% higher efficiency than conventional vapor-compression technologies when optimally designed. This efficiency derives from the reversible nature of the magnetocaloric effect and the reduction of energy losses associated with gas compression cycles. The improved coefficient of performance (COP) directly translates to reduced electricity consumption and lower indirect carbon emissions throughout the operational lifecycle.

From a lifecycle perspective, solid-state magnetocaloric refrigerators offer additional sustainability benefits through their material composition and longevity. The primary materials used—rare earth elements and transition metals—while requiring energy-intensive mining and processing, can be fully recovered and recycled at end-of-life. This closed-loop potential significantly reduces the environmental footprint compared to conventional refrigeration systems, where refrigerant leakage and disposal present persistent environmental challenges.

The noise pollution reduction represents an often-overlooked environmental advantage of magnetocaloric systems. The absence of compressors eliminates a significant source of mechanical noise, contributing to healthier living and working environments, particularly in densely populated urban settings where noise pollution is increasingly recognized as an environmental and public health concern.

When considering manufacturing sustainability, magnetocaloric refrigeration technologies present both challenges and opportunities. While the production of rare earth materials for magnetocaloric alloys currently involves environmentally intensive processes, ongoing research into alternative materials and more sustainable extraction methods shows promise for reducing this impact. Additionally, the simplified mechanical design of these systems potentially reduces manufacturing complexity and associated environmental costs.

The transition to magnetocaloric refrigeration aligns with global sustainability initiatives and regulatory frameworks aimed at phasing out environmentally harmful refrigerants. As countries implement stricter regulations on traditional refrigerants under the Kigali Amendment to the Montreal Protocol, magnetocaloric technology offers a compliance pathway that simultaneously advances technological innovation and environmental protection.

Energy efficiency constitutes another critical sustainability advantage of magnetocaloric refrigeration. These systems can theoretically achieve 30-60% higher efficiency than conventional vapor-compression technologies when optimally designed. This efficiency derives from the reversible nature of the magnetocaloric effect and the reduction of energy losses associated with gas compression cycles. The improved coefficient of performance (COP) directly translates to reduced electricity consumption and lower indirect carbon emissions throughout the operational lifecycle.

From a lifecycle perspective, solid-state magnetocaloric refrigerators offer additional sustainability benefits through their material composition and longevity. The primary materials used—rare earth elements and transition metals—while requiring energy-intensive mining and processing, can be fully recovered and recycled at end-of-life. This closed-loop potential significantly reduces the environmental footprint compared to conventional refrigeration systems, where refrigerant leakage and disposal present persistent environmental challenges.

The noise pollution reduction represents an often-overlooked environmental advantage of magnetocaloric systems. The absence of compressors eliminates a significant source of mechanical noise, contributing to healthier living and working environments, particularly in densely populated urban settings where noise pollution is increasingly recognized as an environmental and public health concern.

When considering manufacturing sustainability, magnetocaloric refrigeration technologies present both challenges and opportunities. While the production of rare earth materials for magnetocaloric alloys currently involves environmentally intensive processes, ongoing research into alternative materials and more sustainable extraction methods shows promise for reducing this impact. Additionally, the simplified mechanical design of these systems potentially reduces manufacturing complexity and associated environmental costs.

The transition to magnetocaloric refrigeration aligns with global sustainability initiatives and regulatory frameworks aimed at phasing out environmentally harmful refrigerants. As countries implement stricter regulations on traditional refrigerants under the Kigali Amendment to the Montreal Protocol, magnetocaloric technology offers a compliance pathway that simultaneously advances technological innovation and environmental protection.

Thermal Management System Integration Strategies

The integration of thermal management systems in solid-state magnetocaloric refrigerators requires careful consideration of multiple engineering aspects to maximize efficiency and performance. Heat transfer mechanisms must be optimized across the entire refrigeration cycle, with particular attention to the interfaces between the magnetocaloric material and heat exchange fluids or surfaces. Effective thermal management begins with proper material selection for heat exchangers, typically utilizing high thermal conductivity metals like copper or aluminum, often enhanced with specialized coatings to improve thermal contact.

System-level integration strategies frequently employ parallel plate configurations where magnetocaloric materials are arranged in thin layers alternating with heat exchange channels. This arrangement maximizes the surface area for heat transfer while minimizing the thermal resistance pathway. The heat transfer fluid selection is equally critical, with water-based solutions dominating in applications above freezing temperatures, while specialized heat transfer fluids are necessary for sub-zero operations.

Active thermal management techniques include precisely controlled pumping systems that synchronize fluid flow rates with the magnetocaloric cycle. Advanced designs incorporate variable flow control to match the thermal load requirements at different stages of the cycle, reducing parasitic energy losses. Thermal bridging between hot and cold sides must be minimized through strategic insulation placement and careful component layout to prevent efficiency degradation.

Regenerator design represents a cornerstone of thermal management integration, with active magnetic regenerator (AMR) configurations being the most widely implemented. These systems require careful balancing of fluid channel dimensions, flow characteristics, and thermal mass ratios to achieve optimal performance across the desired temperature span. Computational fluid dynamics modeling has become an essential tool for optimizing these parameters before physical prototyping.

Thermal management must also address transient operating conditions, as magnetocaloric refrigeration systems rarely operate at steady state in practical applications. This necessitates adaptive control strategies that can respond to varying thermal loads while maintaining temperature stability. Some advanced systems incorporate thermal energy storage components to buffer load variations and improve overall system efficiency.

Manufacturing considerations significantly impact thermal management integration, with techniques like additive manufacturing enabling complex heat exchanger geometries previously impossible with conventional fabrication methods. These advanced manufacturing approaches allow for optimized fluid channels and improved thermal contact between components, directly enhancing system performance through better thermal management.

System-level integration strategies frequently employ parallel plate configurations where magnetocaloric materials are arranged in thin layers alternating with heat exchange channels. This arrangement maximizes the surface area for heat transfer while minimizing the thermal resistance pathway. The heat transfer fluid selection is equally critical, with water-based solutions dominating in applications above freezing temperatures, while specialized heat transfer fluids are necessary for sub-zero operations.

Active thermal management techniques include precisely controlled pumping systems that synchronize fluid flow rates with the magnetocaloric cycle. Advanced designs incorporate variable flow control to match the thermal load requirements at different stages of the cycle, reducing parasitic energy losses. Thermal bridging between hot and cold sides must be minimized through strategic insulation placement and careful component layout to prevent efficiency degradation.

Regenerator design represents a cornerstone of thermal management integration, with active magnetic regenerator (AMR) configurations being the most widely implemented. These systems require careful balancing of fluid channel dimensions, flow characteristics, and thermal mass ratios to achieve optimal performance across the desired temperature span. Computational fluid dynamics modeling has become an essential tool for optimizing these parameters before physical prototyping.

Thermal management must also address transient operating conditions, as magnetocaloric refrigeration systems rarely operate at steady state in practical applications. This necessitates adaptive control strategies that can respond to varying thermal loads while maintaining temperature stability. Some advanced systems incorporate thermal energy storage components to buffer load variations and improve overall system efficiency.

Manufacturing considerations significantly impact thermal management integration, with techniques like additive manufacturing enabling complex heat exchanger geometries previously impossible with conventional fabrication methods. These advanced manufacturing approaches allow for optimized fluid channels and improved thermal contact between components, directly enhancing system performance through better thermal management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!