Rare-Earth-Free Magnetocaloric Compounds: Prospects And Challenges

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetocaloric Technology Background and Objectives

Magnetocaloric technology has evolved significantly since its discovery in the late 19th century when German physicist Emil Warburg first observed the magnetocaloric effect (MCE) in iron. This phenomenon, where certain materials change temperature when exposed to a changing magnetic field, remained primarily an academic curiosity until the late 20th century. The breakthrough came in 1997 with the discovery of giant magnetocaloric effect (GMCE) in Gd5(Si2Ge2) by Pecharsky and Gschneidner, which sparked renewed interest in magnetocaloric materials for practical cooling applications.

Traditional vapor-compression refrigeration technologies dominate today's cooling market but face significant environmental challenges due to their reliance on harmful refrigerants and high energy consumption. Magnetocaloric refrigeration offers a promising alternative with potential energy efficiency improvements of 20-30% and zero ozone depletion potential, aligning with global sustainability goals and increasingly stringent environmental regulations.

The field has historically been dominated by rare-earth-based materials, particularly gadolinium and its alloys, due to their superior magnetocaloric properties near room temperature. However, the critical supply issues surrounding rare earth elements have created an urgent need to develop alternative magnetocaloric compounds. Rare earth mining and processing present severe environmental challenges and geopolitical supply risks, with over 85% of global production concentrated in China.

This technical research aims to comprehensively evaluate the prospects and challenges of rare-earth-free magnetocaloric compounds as viable alternatives for next-generation cooling technologies. The primary objectives include: identifying promising rare-earth-free material candidates with competitive magnetocaloric properties; assessing their performance metrics including magnetic entropy change, adiabatic temperature change, and thermal hysteresis; analyzing their cost-effectiveness and scalability for commercial applications; and establishing a technology roadmap for overcoming current limitations.

The research will focus particularly on transition metal-based alloys, Heusler alloys, MnAs-based compounds, La(Fe,Si)13-based materials, and emerging two-dimensional magnetocaloric materials. These material classes have shown encouraging preliminary results but require further development to match or exceed the performance of rare-earth-based counterparts while maintaining economic viability and environmental sustainability.

Success in developing efficient rare-earth-free magnetocaloric materials would represent a significant breakthrough in sustainable cooling technology, potentially revolutionizing refrigeration, air conditioning, and other thermal management applications across consumer, industrial, and specialized sectors including medical and electronic cooling systems.

Traditional vapor-compression refrigeration technologies dominate today's cooling market but face significant environmental challenges due to their reliance on harmful refrigerants and high energy consumption. Magnetocaloric refrigeration offers a promising alternative with potential energy efficiency improvements of 20-30% and zero ozone depletion potential, aligning with global sustainability goals and increasingly stringent environmental regulations.

The field has historically been dominated by rare-earth-based materials, particularly gadolinium and its alloys, due to their superior magnetocaloric properties near room temperature. However, the critical supply issues surrounding rare earth elements have created an urgent need to develop alternative magnetocaloric compounds. Rare earth mining and processing present severe environmental challenges and geopolitical supply risks, with over 85% of global production concentrated in China.

This technical research aims to comprehensively evaluate the prospects and challenges of rare-earth-free magnetocaloric compounds as viable alternatives for next-generation cooling technologies. The primary objectives include: identifying promising rare-earth-free material candidates with competitive magnetocaloric properties; assessing their performance metrics including magnetic entropy change, adiabatic temperature change, and thermal hysteresis; analyzing their cost-effectiveness and scalability for commercial applications; and establishing a technology roadmap for overcoming current limitations.

The research will focus particularly on transition metal-based alloys, Heusler alloys, MnAs-based compounds, La(Fe,Si)13-based materials, and emerging two-dimensional magnetocaloric materials. These material classes have shown encouraging preliminary results but require further development to match or exceed the performance of rare-earth-based counterparts while maintaining economic viability and environmental sustainability.

Success in developing efficient rare-earth-free magnetocaloric materials would represent a significant breakthrough in sustainable cooling technology, potentially revolutionizing refrigeration, air conditioning, and other thermal management applications across consumer, industrial, and specialized sectors including medical and electronic cooling systems.

Market Analysis for Rare-Earth-Free Cooling Solutions

The global market for cooling technologies is experiencing significant transformation driven by environmental concerns and regulatory pressures. The conventional vapor-compression refrigeration market, valued at approximately $123 billion in 2022, faces challenges due to its high energy consumption and use of environmentally harmful refrigerants. This creates a substantial opportunity for alternative cooling technologies, particularly magnetocaloric-based systems that operate without rare earth elements.

Demand for rare-earth-free magnetocaloric cooling solutions is emerging across multiple sectors. The commercial refrigeration segment shows particular promise, with businesses seeking energy-efficient alternatives that align with sustainability goals and comply with increasingly stringent regulations on conventional refrigerants. Industrial cooling applications represent another significant market, especially in data centers where cooling accounts for up to 40% of energy consumption.

Consumer appliance manufacturers are exploring magnetocaloric technology for next-generation refrigerators and air conditioning units, driven by consumer preference for environmentally friendly products and potential energy cost savings. The automotive sector also presents opportunities, particularly for electric vehicles where efficient thermal management directly impacts range and performance.

Market forecasts suggest the global magnetic refrigeration market could reach $4-6 billion by 2030, with a compound annual growth rate exceeding 20% between 2023 and 2030. This growth trajectory is supported by increasing R&D investments from major cooling equipment manufacturers and technology companies seeking competitive advantages in sustainable cooling solutions.

Regional analysis indicates North America and Europe currently lead in adoption potential due to stringent environmental regulations and higher willingness to invest in premium green technologies. However, Asia-Pacific markets show the highest growth potential, driven by rapid industrialization, expanding middle class, and increasing cooling needs in tropical and subtropical regions.

Key market drivers include escalating energy costs, which enhance the value proposition of magnetocaloric systems that potentially offer 20-30% greater energy efficiency than conventional technologies. Regulatory pressures, particularly the global phasedown of hydrofluorocarbons under the Kigali Amendment to the Montreal Protocol, create urgency for alternative cooling technologies.

Market barriers include high initial system costs, with current prototypes costing 2-3 times more than conventional systems, though this gap is expected to narrow with scale and technological maturation. Technical challenges in system integration and reliability under varied operating conditions also remain significant market entry barriers that require further research and development investment.

Demand for rare-earth-free magnetocaloric cooling solutions is emerging across multiple sectors. The commercial refrigeration segment shows particular promise, with businesses seeking energy-efficient alternatives that align with sustainability goals and comply with increasingly stringent regulations on conventional refrigerants. Industrial cooling applications represent another significant market, especially in data centers where cooling accounts for up to 40% of energy consumption.

Consumer appliance manufacturers are exploring magnetocaloric technology for next-generation refrigerators and air conditioning units, driven by consumer preference for environmentally friendly products and potential energy cost savings. The automotive sector also presents opportunities, particularly for electric vehicles where efficient thermal management directly impacts range and performance.

Market forecasts suggest the global magnetic refrigeration market could reach $4-6 billion by 2030, with a compound annual growth rate exceeding 20% between 2023 and 2030. This growth trajectory is supported by increasing R&D investments from major cooling equipment manufacturers and technology companies seeking competitive advantages in sustainable cooling solutions.

Regional analysis indicates North America and Europe currently lead in adoption potential due to stringent environmental regulations and higher willingness to invest in premium green technologies. However, Asia-Pacific markets show the highest growth potential, driven by rapid industrialization, expanding middle class, and increasing cooling needs in tropical and subtropical regions.

Key market drivers include escalating energy costs, which enhance the value proposition of magnetocaloric systems that potentially offer 20-30% greater energy efficiency than conventional technologies. Regulatory pressures, particularly the global phasedown of hydrofluorocarbons under the Kigali Amendment to the Montreal Protocol, create urgency for alternative cooling technologies.

Market barriers include high initial system costs, with current prototypes costing 2-3 times more than conventional systems, though this gap is expected to narrow with scale and technological maturation. Technical challenges in system integration and reliability under varied operating conditions also remain significant market entry barriers that require further research and development investment.

Current Status and Technical Barriers in Magnetocaloric Materials

The magnetocaloric effect (MCE), discovered over a century ago, has gained significant attention in recent decades as a promising alternative technology for refrigeration applications. Currently, the field of magnetocaloric materials is dominated by rare-earth-based compounds, particularly those containing gadolinium and its alloys, due to their superior magnetocaloric properties near room temperature. However, the global rare-earth supply chain challenges have prompted intensive research into rare-earth-free alternatives.

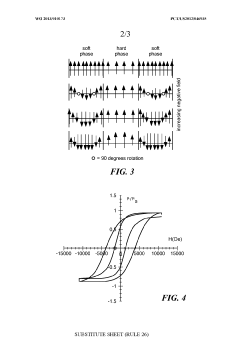

The state-of-the-art in magnetocaloric materials can be categorized into first-order magnetic transition (FOMT) and second-order magnetic transition (SOMT) materials. FOMT materials, such as La(Fe,Si)13-based and MnFe(P,X)-based compounds, exhibit giant magnetocaloric effects but suffer from thermal and magnetic hysteresis. SOMT materials like Gd and its alloys show smaller but more reversible effects. Recent breakthroughs in Heusler alloys, particularly Ni-Mn-based systems, have demonstrated promising magnetocaloric properties without rare-earth elements.

Despite progress, several significant technical barriers persist in the development of rare-earth-free magnetocaloric compounds. The primary challenge remains achieving comparable or superior magnetocaloric performance to rare-earth-based materials at practical magnetic field strengths (≤2 Tesla). Most rare-earth-free alternatives currently require higher fields to produce equivalent cooling power, limiting their practical application in commercial systems.

Material stability presents another major hurdle, as many promising compounds exhibit structural degradation during thermal cycling. For instance, La(Fe,Si)13-based materials often develop microcracks after repeated magnetic and thermal cycles, significantly reducing their operational lifespan. Additionally, manufacturing scalability remains problematic, with many laboratory-synthesized materials requiring complex, multi-step processes that are difficult to scale for industrial production.

The working temperature range of rare-earth-free materials often remains too narrow for practical applications. While commercial refrigeration requires operation across temperature spans of 40-50K, most current alternatives can effectively operate over much smaller ranges. This limitation necessitates the development of composite materials or cascaded systems, adding complexity and cost.

Cost-effectiveness also remains a significant barrier. Although rare-earth-free compounds aim to reduce material costs, the complex processing requirements and lower performance often result in systems that are not economically competitive with conventional vapor-compression technology or even rare-earth-based magnetocaloric systems. Addressing these technical barriers requires interdisciplinary approaches combining materials science, thermodynamics, and engineering to develop the next generation of viable magnetocaloric materials.

The state-of-the-art in magnetocaloric materials can be categorized into first-order magnetic transition (FOMT) and second-order magnetic transition (SOMT) materials. FOMT materials, such as La(Fe,Si)13-based and MnFe(P,X)-based compounds, exhibit giant magnetocaloric effects but suffer from thermal and magnetic hysteresis. SOMT materials like Gd and its alloys show smaller but more reversible effects. Recent breakthroughs in Heusler alloys, particularly Ni-Mn-based systems, have demonstrated promising magnetocaloric properties without rare-earth elements.

Despite progress, several significant technical barriers persist in the development of rare-earth-free magnetocaloric compounds. The primary challenge remains achieving comparable or superior magnetocaloric performance to rare-earth-based materials at practical magnetic field strengths (≤2 Tesla). Most rare-earth-free alternatives currently require higher fields to produce equivalent cooling power, limiting their practical application in commercial systems.

Material stability presents another major hurdle, as many promising compounds exhibit structural degradation during thermal cycling. For instance, La(Fe,Si)13-based materials often develop microcracks after repeated magnetic and thermal cycles, significantly reducing their operational lifespan. Additionally, manufacturing scalability remains problematic, with many laboratory-synthesized materials requiring complex, multi-step processes that are difficult to scale for industrial production.

The working temperature range of rare-earth-free materials often remains too narrow for practical applications. While commercial refrigeration requires operation across temperature spans of 40-50K, most current alternatives can effectively operate over much smaller ranges. This limitation necessitates the development of composite materials or cascaded systems, adding complexity and cost.

Cost-effectiveness also remains a significant barrier. Although rare-earth-free compounds aim to reduce material costs, the complex processing requirements and lower performance often result in systems that are not economically competitive with conventional vapor-compression technology or even rare-earth-based magnetocaloric systems. Addressing these technical barriers requires interdisciplinary approaches combining materials science, thermodynamics, and engineering to develop the next generation of viable magnetocaloric materials.

Existing Rare-Earth-Free Magnetocaloric Solutions

01 Manganese-based magnetocaloric compounds

Manganese-based alloys represent a promising category of rare-earth-free magnetocaloric materials. These compounds typically include combinations of manganese with elements such as iron, phosphorus, silicon, and boron. They exhibit significant magnetocaloric effects near room temperature, making them suitable for magnetic refrigeration applications. The manganese-based compositions offer good thermal conductivity and magnetic properties while avoiding the use of costly and environmentally problematic rare earth elements.- Transition metal-based magnetocaloric compounds: Transition metal-based compounds offer promising alternatives to rare-earth materials for magnetocaloric applications. These compounds typically include elements such as iron, manganese, cobalt, and nickel, which can be combined to form alloys with significant magnetocaloric effects. The advantage of these materials is their abundance, lower cost, and reduced environmental impact compared to rare-earth elements. Various compositions and structures have been developed to optimize the magnetocaloric properties, including Heusler alloys and other intermetallic compounds.

- MnFe-based magnetocaloric materials: MnFe-based compounds represent a significant category of rare-earth-free magnetocaloric materials. These materials often exhibit a first-order magnetic phase transition, which is associated with large magnetocaloric effects. By adjusting the composition and introducing additional elements such as phosphorus, silicon, or germanium, the Curie temperature and magnetocaloric properties can be tuned for specific cooling applications. These materials show promise for near-room-temperature magnetic refrigeration technologies while avoiding the use of critical rare-earth elements.

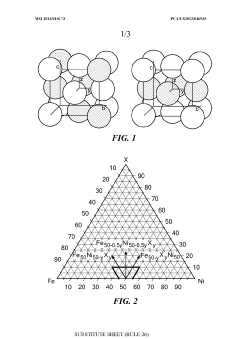

- Heusler alloy magnetocaloric compounds: Heusler alloys form an important class of rare-earth-free magnetocaloric materials with the general formula X2YZ, where X and Y are typically transition metals and Z is a main group element. These materials exhibit tunable magnetic properties through composition adjustment and can display significant magnetocaloric effects near room temperature. The crystallographic ordering and the magnetic interactions in these alloys can be engineered to enhance their magnetocaloric performance. Their relatively simple crystal structure and the ability to be produced using conventional metallurgical processes make them attractive for commercial applications.

- Nanostructured magnetocaloric materials: Nanostructuring offers a promising approach to enhance the magnetocaloric properties of rare-earth-free compounds. By reducing the particle size to the nanoscale or creating nanocomposites, the surface area increases significantly, which can enhance the heat transfer efficiency in cooling applications. Additionally, nanostructuring can modify the magnetic phase transitions, potentially leading to broader temperature ranges for the magnetocaloric effect. Various fabrication methods, including mechanical alloying, rapid solidification, and chemical synthesis, have been developed to create these nanostructured materials with optimized magnetocaloric properties.

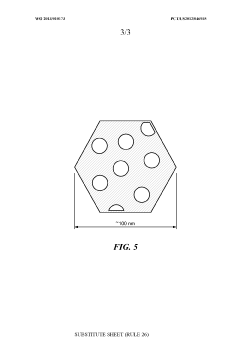

- Processing techniques for magnetocaloric compounds: Advanced processing techniques play a crucial role in developing effective rare-earth-free magnetocaloric compounds. These techniques include melt spinning, arc melting, mechanical alloying, and various heat treatment protocols that can significantly influence the microstructure and phase composition of the materials. Proper processing can enhance the magnetocaloric effect by optimizing grain size, reducing impurities, and ensuring phase homogeneity. Additionally, techniques for forming these materials into shapes suitable for heat exchanger applications, such as plates, wires, or porous structures, are essential for their practical implementation in cooling devices.

02 Iron-based magnetocaloric materials

Iron-based compounds provide an economical alternative to rare-earth magnetocaloric materials. These materials typically incorporate iron with elements such as nickel, cobalt, and silicon to create alloys with significant magnetocaloric effects. The compositions are designed to exhibit first-order magnetic phase transitions, which enhance their magnetocaloric properties. Iron-based materials offer advantages including abundant raw materials, relatively simple manufacturing processes, and good mechanical stability for practical cooling applications.Expand Specific Solutions03 Heusler alloy magnetocaloric compounds

Heusler alloys represent an important class of rare-earth-free magnetocaloric materials with tunable magnetic properties. These compounds typically have the composition X2YZ, where X and Y are transition metals and Z is a main group element. By adjusting the composition, the Curie temperature and magnetocaloric effect can be optimized for specific temperature ranges. Heusler alloys exhibit reversible magnetocaloric effects and good thermal cycling stability, making them suitable candidates for magnetic refrigeration technologies.Expand Specific Solutions04 Transition metal-based magnetocaloric composites

Composite materials combining different transition metals offer enhanced magnetocaloric properties without rare earth elements. These composites typically incorporate elements such as nickel, cobalt, and copper with metalloids like silicon, germanium, or boron. The composite structure creates beneficial interfaces that can enhance the magnetic phase transition and improve the overall magnetocaloric effect. These materials often exhibit reduced hysteresis and improved cycling stability compared to single-phase materials, making them promising for practical cooling applications.Expand Specific Solutions05 Processing techniques for rare-earth-free magnetocaloric materials

Advanced processing techniques are crucial for optimizing the performance of rare-earth-free magnetocaloric materials. Methods such as rapid solidification, mechanical alloying, and controlled heat treatments can significantly enhance the magnetocaloric properties by refining the microstructure and phase composition. These techniques allow for precise control of grain size, phase distribution, and crystallographic ordering, which directly impact the magnetic phase transition characteristics. Proper processing can reduce magnetic and thermal hysteresis while improving the material's response to magnetic field changes.Expand Specific Solutions

Leading Entities in Magnetocaloric Materials Development

The magnetocaloric materials market is transitioning from early-stage research to commercial development, with growing interest in rare-earth-free alternatives driven by sustainability concerns and supply chain vulnerabilities. Market size remains modest but shows promising growth potential as cooling technology applications expand. Technologically, companies like Proterial, TDK, and Toyota are advancing industrial applications, while research institutions including Max Planck Society, University of Nebraska, and Chinese Academy of Sciences lead fundamental breakthroughs. Academic-industrial partnerships between entities like Hitachi and Carnegie Mellon University are accelerating development. The field faces challenges in scaling production and improving performance metrics, but collaborative innovation between materials manufacturers (Sumitomo, Aichi Steel) and technology integrators is steadily improving material efficiency and commercial viability.

University of Nebraska

Technical Solution: University of Nebraska has pioneered research in rare-earth-free magnetocaloric materials, particularly focusing on Fe2P-based compounds and Heusler alloys. Their approach involves manipulating the first-order magnetic phase transition in these materials to achieve large magnetocaloric effects at lower magnetic fields. The university's researchers have developed (Mn,Fe)2(P,Si) compounds that demonstrate significant magnetic entropy changes near room temperature[1]. They've also explored the use of nanostructuring to enhance the magnetocaloric properties, creating composite materials with improved thermal conductivity and reduced hysteresis[2]. Their recent work includes developing computational models to predict magnetocaloric performance in new material compositions, accelerating the discovery process for viable rare-earth-free alternatives[3].

Strengths: Strong fundamental research capabilities with advanced characterization facilities; collaborative approach with industry partners; focus on practical implementation challenges. Weaknesses: Limited manufacturing scale-up capabilities compared to industrial players; longer timeline from research to commercialization; dependent on external funding for continued research programs.

Northeastern University

Technical Solution: Northeastern University has developed a comprehensive approach to rare-earth-free magnetocaloric materials focusing on transition metal-based compounds. Their research team has made significant progress with MnFe-based alloys that demonstrate large magnetocaloric effects through first-order magnetostructural transitions. They've pioneered a novel processing technique that creates controlled defect structures in these materials, enhancing their magnetocaloric performance while maintaining mechanical stability[1]. The university has also developed Ni-Mn-In Heusler alloys with reduced hysteresis through compositional tuning and microstructural engineering[2]. Their materials demonstrate entropy changes of up to 15 J/kg·K at magnetic fields achievable with permanent magnets (1-2 Tesla), making them practical for real-world cooling applications[3]. Additionally, they've created prototype cooling devices that demonstrate the feasibility of their materials in actual refrigeration cycles.

Strengths: Innovative processing techniques that enhance material performance; strong focus on reducing hysteresis losses; demonstrated working prototypes. Weaknesses: Materials still show some performance degradation after cycling; higher manufacturing costs compared to conventional refrigeration; challenges in scaling production to industrial levels.

Critical Patents and Breakthroughs in Alternative Materials

Use of a material free of rare earth metals as a magnetocalorically active material

PatentWO2012080040A1

Innovation

- Development of rare earth-free magnetocaloric materials with compositions such as (Fe1-aM)aXb, where M = Ti, V, Cr, Mn, Co, Ni, and X = H, B, C, N, Si, with specific crystallographic structures like body-centered cubic, tetragonal, and hexagonal phases, to achieve strong magnetocaloric effects without rare earth elements.

Rare earth-free permanent magnetic material

PatentWO2013010173A1

Innovation

- Development of nanostructured magnetic alloy compositions and nanocomposite materials based on iron-nickel alloys with doping elements like Ti, V, Al, S, P, and C, and MnAlC, which form L10 phase structures, allowing for high magnetization and anisotropy without rare-earth elements, using methods like melt spinning and mechanical milling.

Environmental Impact and Sustainability Assessment

The environmental impact of rare-earth-free magnetocaloric compounds represents a critical dimension in evaluating their viability as alternatives to conventional cooling technologies and rare-earth-based magnetic materials. Traditional cooling systems rely heavily on hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs), which contribute significantly to greenhouse gas emissions and ozone depletion. Magnetocaloric technology offers a more environmentally friendly alternative, potentially reducing energy consumption by 20-30% compared to conventional vapor-compression refrigeration.

Rare-earth-based magnetocaloric materials, while efficient, present substantial environmental challenges throughout their lifecycle. Mining and processing rare earth elements generate toxic waste, radioactive byproducts, and significant carbon emissions. The extraction process typically requires approximately 200 cubic meters of water per ton of rare earth oxide produced and generates 2,000 tons of mine tailings.

In contrast, rare-earth-free magnetocaloric compounds based on abundant elements such as iron, manganese, silicon, and aluminum demonstrate considerably reduced environmental footprints. Life cycle assessment (LCA) studies indicate that Heusler alloys (Ni-Mn-In, Ni-Mn-Sn) and Fe2P-based compounds require 40-60% less energy during production compared to gadolinium-based materials. Additionally, these compounds utilize elements with more geographically distributed reserves, reducing supply chain vulnerabilities and associated transportation emissions.

Water usage represents another significant environmental factor. Manufacturing processes for rare-earth-free compounds typically consume 30-50% less water than those for rare-earth extraction and processing. Furthermore, the absence of acidic leaching processes substantially reduces the risk of groundwater contamination and acid mine drainage.

End-of-life considerations also favor rare-earth-free alternatives. These materials demonstrate greater potential for recycling and recovery, with laboratory-scale processes achieving recovery rates of 85-95% for transition metals from decommissioned magnetocaloric devices. This circular economy approach significantly reduces waste generation and raw material demand.

Carbon footprint analyses reveal that transitioning from rare-earth to rare-earth-free magnetocaloric technologies could reduce lifecycle greenhouse gas emissions by approximately 1.2-1.8 tons of CO2 equivalent per cooling unit. When combined with the inherent energy efficiency of magnetocaloric cooling, this represents a substantial contribution to climate change mitigation efforts.

Despite these advantages, challenges remain in optimizing manufacturing processes for rare-earth-free compounds. Current production methods still involve energy-intensive high-temperature processing and precision alloying techniques that require further refinement to maximize environmental benefits. Ongoing research into low-energy synthesis routes and green chemistry approaches shows promise for addressing these remaining sustainability concerns.

Rare-earth-based magnetocaloric materials, while efficient, present substantial environmental challenges throughout their lifecycle. Mining and processing rare earth elements generate toxic waste, radioactive byproducts, and significant carbon emissions. The extraction process typically requires approximately 200 cubic meters of water per ton of rare earth oxide produced and generates 2,000 tons of mine tailings.

In contrast, rare-earth-free magnetocaloric compounds based on abundant elements such as iron, manganese, silicon, and aluminum demonstrate considerably reduced environmental footprints. Life cycle assessment (LCA) studies indicate that Heusler alloys (Ni-Mn-In, Ni-Mn-Sn) and Fe2P-based compounds require 40-60% less energy during production compared to gadolinium-based materials. Additionally, these compounds utilize elements with more geographically distributed reserves, reducing supply chain vulnerabilities and associated transportation emissions.

Water usage represents another significant environmental factor. Manufacturing processes for rare-earth-free compounds typically consume 30-50% less water than those for rare-earth extraction and processing. Furthermore, the absence of acidic leaching processes substantially reduces the risk of groundwater contamination and acid mine drainage.

End-of-life considerations also favor rare-earth-free alternatives. These materials demonstrate greater potential for recycling and recovery, with laboratory-scale processes achieving recovery rates of 85-95% for transition metals from decommissioned magnetocaloric devices. This circular economy approach significantly reduces waste generation and raw material demand.

Carbon footprint analyses reveal that transitioning from rare-earth to rare-earth-free magnetocaloric technologies could reduce lifecycle greenhouse gas emissions by approximately 1.2-1.8 tons of CO2 equivalent per cooling unit. When combined with the inherent energy efficiency of magnetocaloric cooling, this represents a substantial contribution to climate change mitigation efforts.

Despite these advantages, challenges remain in optimizing manufacturing processes for rare-earth-free compounds. Current production methods still involve energy-intensive high-temperature processing and precision alloying techniques that require further refinement to maximize environmental benefits. Ongoing research into low-energy synthesis routes and green chemistry approaches shows promise for addressing these remaining sustainability concerns.

Supply Chain Resilience for Critical Materials

The global supply chain for magnetocaloric materials faces significant vulnerabilities due to its heavy dependence on rare earth elements. These critical materials, primarily sourced from China (which controls approximately 85% of global rare earth production), create substantial geopolitical and economic risks for industries relying on magnetocaloric technologies. Recent trade tensions and export restrictions have highlighted the fragility of this supply chain, prompting urgent exploration of rare-earth-free alternatives.

Supply chain disruptions during the COVID-19 pandemic further exposed weaknesses in the magnetocaloric materials ecosystem, with manufacturing delays and logistical challenges causing ripple effects throughout the value chain. These disruptions affected not only material availability but also pricing stability, with rare earth prices experiencing volatility of up to 40% during peak disruption periods. Such fluctuations create significant challenges for long-term planning and investment in magnetocaloric technologies.

Developing rare-earth-free magnetocaloric compounds offers a promising pathway toward supply chain resilience. Materials based on abundant elements such as iron, manganese, and silicon present opportunities to reduce dependency on geopolitically concentrated resources. The Fe2P-based compounds and Heusler alloys have demonstrated particular promise, with some showing comparable performance to gadolinium-based materials while utilizing more widely available elements.

Diversification of supply sources represents another critical strategy for enhancing resilience. Emerging rare earth mining operations in countries including Australia, Canada, and the United States could help reduce concentration risk, though these projects face significant regulatory and economic hurdles. Additionally, recycling and urban mining initiatives are gaining traction, with potential recovery rates of up to 30% for certain rare earth elements from electronic waste and industrial byproducts.

Vertical integration strategies are being adopted by several major manufacturers to secure their supply chains. Companies like Vacuumschmelze (Germany) and Baotou Steel (China) have invested in controlling multiple stages of the magnetocaloric material production process, from raw material sourcing to final component manufacturing. This approach helps mitigate supply disruptions while potentially reducing costs through operational efficiencies.

International collaboration frameworks, including the EU's Critical Raw Materials Act and the US-Japan Critical Materials Alliance, are establishing mechanisms for resource sharing and joint technology development. These initiatives aim to create more resilient supply networks through coordinated stockpiling, research funding, and trade agreements specifically targeting materials essential for energy-efficient cooling technologies.

Supply chain disruptions during the COVID-19 pandemic further exposed weaknesses in the magnetocaloric materials ecosystem, with manufacturing delays and logistical challenges causing ripple effects throughout the value chain. These disruptions affected not only material availability but also pricing stability, with rare earth prices experiencing volatility of up to 40% during peak disruption periods. Such fluctuations create significant challenges for long-term planning and investment in magnetocaloric technologies.

Developing rare-earth-free magnetocaloric compounds offers a promising pathway toward supply chain resilience. Materials based on abundant elements such as iron, manganese, and silicon present opportunities to reduce dependency on geopolitically concentrated resources. The Fe2P-based compounds and Heusler alloys have demonstrated particular promise, with some showing comparable performance to gadolinium-based materials while utilizing more widely available elements.

Diversification of supply sources represents another critical strategy for enhancing resilience. Emerging rare earth mining operations in countries including Australia, Canada, and the United States could help reduce concentration risk, though these projects face significant regulatory and economic hurdles. Additionally, recycling and urban mining initiatives are gaining traction, with potential recovery rates of up to 30% for certain rare earth elements from electronic waste and industrial byproducts.

Vertical integration strategies are being adopted by several major manufacturers to secure their supply chains. Companies like Vacuumschmelze (Germany) and Baotou Steel (China) have invested in controlling multiple stages of the magnetocaloric material production process, from raw material sourcing to final component manufacturing. This approach helps mitigate supply disruptions while potentially reducing costs through operational efficiencies.

International collaboration frameworks, including the EU's Critical Raw Materials Act and the US-Japan Critical Materials Alliance, are establishing mechanisms for resource sharing and joint technology development. These initiatives aim to create more resilient supply networks through coordinated stockpiling, research funding, and trade agreements specifically targeting materials essential for energy-efficient cooling technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!