High-Throughput Screening Methods For Magnetocaloric Alloys

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetocaloric Alloy Screening Background and Objectives

Magnetocaloric materials have emerged as a promising alternative for conventional vapor-compression refrigeration systems due to their potential for energy-efficient, environmentally friendly cooling technologies. The evolution of magnetocaloric research dates back to the early 20th century when the magnetocaloric effect (MCE) was first discovered by Emil Warburg in 1881. However, significant advancements in this field only began in the late 1990s with the discovery of giant magnetocaloric effect (GMCE) in Gd5(Si2Ge2) by Pecharsky and Gschneidner.

The technological trajectory has since shifted from single-element materials like gadolinium to more complex alloy systems, including La(Fe,Si)13-based, Heusler, and Fe2P-type compounds. These developments have been driven by the increasing demand for more efficient cooling solutions in various applications ranging from household refrigeration to industrial cooling systems and medical devices.

Current research focuses on identifying materials with enhanced magnetocaloric properties, including high magnetic entropy change, large adiabatic temperature change, minimal hysteresis, and appropriate Curie temperatures for specific applications. The challenge lies in systematically exploring the vast compositional space of potential magnetocaloric alloys to discover optimal materials.

High-throughput screening (HTS) methodologies represent a paradigm shift in magnetocaloric materials discovery, enabling rapid evaluation of numerous compositions simultaneously. These approaches combine experimental techniques such as combinatorial synthesis, automated characterization, and computational modeling to accelerate the identification of promising candidates.

The primary objective of this technical research is to comprehensively evaluate existing high-throughput screening methods for magnetocaloric alloys and identify the most effective strategies for future development. This includes assessing various synthesis techniques (thin-film deposition, bulk combinatorial methods), characterization tools (SQUID magnetometry, scanning Hall probe microscopy, infrared thermography), and computational approaches (density functional theory, machine learning algorithms).

Additionally, this research aims to establish standardized protocols for high-throughput evaluation of magnetocaloric materials, enabling more efficient comparison of results across different research groups. By systematically mapping the relationship between composition, structure, and magnetocaloric properties, we seek to develop predictive models that can guide the design of next-generation magnetocaloric alloys with optimized performance characteristics.

The ultimate goal is to accelerate the discovery and development of commercially viable magnetocaloric materials that can enable magnetic refrigeration technologies with superior energy efficiency compared to conventional cooling systems, contributing to global efforts in energy conservation and environmental protection.

The technological trajectory has since shifted from single-element materials like gadolinium to more complex alloy systems, including La(Fe,Si)13-based, Heusler, and Fe2P-type compounds. These developments have been driven by the increasing demand for more efficient cooling solutions in various applications ranging from household refrigeration to industrial cooling systems and medical devices.

Current research focuses on identifying materials with enhanced magnetocaloric properties, including high magnetic entropy change, large adiabatic temperature change, minimal hysteresis, and appropriate Curie temperatures for specific applications. The challenge lies in systematically exploring the vast compositional space of potential magnetocaloric alloys to discover optimal materials.

High-throughput screening (HTS) methodologies represent a paradigm shift in magnetocaloric materials discovery, enabling rapid evaluation of numerous compositions simultaneously. These approaches combine experimental techniques such as combinatorial synthesis, automated characterization, and computational modeling to accelerate the identification of promising candidates.

The primary objective of this technical research is to comprehensively evaluate existing high-throughput screening methods for magnetocaloric alloys and identify the most effective strategies for future development. This includes assessing various synthesis techniques (thin-film deposition, bulk combinatorial methods), characterization tools (SQUID magnetometry, scanning Hall probe microscopy, infrared thermography), and computational approaches (density functional theory, machine learning algorithms).

Additionally, this research aims to establish standardized protocols for high-throughput evaluation of magnetocaloric materials, enabling more efficient comparison of results across different research groups. By systematically mapping the relationship between composition, structure, and magnetocaloric properties, we seek to develop predictive models that can guide the design of next-generation magnetocaloric alloys with optimized performance characteristics.

The ultimate goal is to accelerate the discovery and development of commercially viable magnetocaloric materials that can enable magnetic refrigeration technologies with superior energy efficiency compared to conventional cooling systems, contributing to global efforts in energy conservation and environmental protection.

Market Applications and Demand for Magnetocaloric Materials

The magnetocaloric materials market has experienced significant growth in recent years, driven primarily by the increasing demand for energy-efficient and environmentally friendly cooling technologies. The global market for magnetocaloric materials was valued at approximately $7.5 million in 2022 and is projected to reach $30 million by 2030, representing a compound annual growth rate of 18.9%. This growth trajectory is largely attributed to the rising concerns over greenhouse gas emissions from conventional vapor-compression refrigeration systems and the global push toward sustainable technologies.

The residential refrigeration sector represents the largest application segment for magnetocaloric materials, accounting for roughly 40% of the total market demand. This dominance stems from the increasing consumer preference for energy-efficient home appliances and the stringent energy efficiency regulations being implemented worldwide. Major appliance manufacturers like Whirlpool, Samsung, and Haier have already begun investing in magnetocaloric technology research to develop next-generation refrigerators with reduced environmental impact.

Commercial refrigeration follows as the second-largest application segment, with approximately 30% market share. This includes supermarkets, food processing facilities, and cold storage warehouses, where the potential energy savings from magnetocaloric cooling systems could significantly reduce operational costs. The healthcare sector, particularly for medical refrigeration and organ transportation, represents a growing niche market with premium pricing potential due to the precise temperature control capabilities of magnetocaloric systems.

Automotive air conditioning presents another promising application area, especially with the rapid growth of electric vehicles where energy efficiency is paramount. Leading automotive manufacturers have initiated research partnerships with material science companies to explore magnetocaloric cooling solutions that could extend EV range by reducing the energy consumption of climate control systems.

Geographically, North America and Europe currently lead the market demand for magnetocaloric materials, collectively accounting for over 65% of global consumption. This regional dominance is attributed to stricter environmental regulations, higher energy costs, and greater investment in clean technology research. However, the Asia-Pacific region is expected to witness the fastest growth rate in the coming years, driven by rapid industrialization, increasing disposable income, and growing environmental awareness in countries like China, Japan, and South Korea.

The residential refrigeration sector represents the largest application segment for magnetocaloric materials, accounting for roughly 40% of the total market demand. This dominance stems from the increasing consumer preference for energy-efficient home appliances and the stringent energy efficiency regulations being implemented worldwide. Major appliance manufacturers like Whirlpool, Samsung, and Haier have already begun investing in magnetocaloric technology research to develop next-generation refrigerators with reduced environmental impact.

Commercial refrigeration follows as the second-largest application segment, with approximately 30% market share. This includes supermarkets, food processing facilities, and cold storage warehouses, where the potential energy savings from magnetocaloric cooling systems could significantly reduce operational costs. The healthcare sector, particularly for medical refrigeration and organ transportation, represents a growing niche market with premium pricing potential due to the precise temperature control capabilities of magnetocaloric systems.

Automotive air conditioning presents another promising application area, especially with the rapid growth of electric vehicles where energy efficiency is paramount. Leading automotive manufacturers have initiated research partnerships with material science companies to explore magnetocaloric cooling solutions that could extend EV range by reducing the energy consumption of climate control systems.

Geographically, North America and Europe currently lead the market demand for magnetocaloric materials, collectively accounting for over 65% of global consumption. This regional dominance is attributed to stricter environmental regulations, higher energy costs, and greater investment in clean technology research. However, the Asia-Pacific region is expected to witness the fastest growth rate in the coming years, driven by rapid industrialization, increasing disposable income, and growing environmental awareness in countries like China, Japan, and South Korea.

Current HTS Challenges in Magnetocaloric Alloy Discovery

The discovery of novel magnetocaloric alloys through High-Throughput Screening (HTS) faces several significant challenges that impede rapid progress in this field. These challenges span across methodological, technical, and analytical domains, creating bottlenecks in the efficient identification of promising magnetocaloric materials.

Sample preparation represents a primary obstacle in HTS for magnetocaloric alloys. The creation of compositionally diverse sample libraries with precise stoichiometry control remains difficult, particularly when dealing with multi-component systems. Conventional methods often struggle to maintain homogeneity across gradient samples, leading to unreliable magnetocaloric property measurements and potentially overlooking promising compositions.

Measurement throughput constitutes another major limitation. Traditional characterization techniques for magnetocaloric properties—such as direct adiabatic temperature change measurements and magnetic entropy change calculations—are inherently time-consuming. These methods typically require temperature stabilization periods and multiple field cycles, resulting in characterization rates that fail to match the pace at which compositional libraries can be fabricated.

Data quality and consistency issues further complicate the HTS process. Magnetocaloric measurements are sensitive to sample geometry, thermal contact, and environmental conditions. Maintaining uniform measurement conditions across hundreds or thousands of samples presents significant technical difficulties, often leading to systematic errors that can mask subtle but potentially valuable magnetocaloric effects.

The correlation between easily measured proxy properties and actual magnetocaloric performance remains inadequately established. While magnetic susceptibility or saturation magnetization can be measured more rapidly, their relationship to entropy change or refrigerant capacity is not always straightforward, particularly in complex alloy systems exhibiting competing magnetic interactions.

Computational challenges also persist in the HTS workflow. The integration of experimental data with theoretical predictions remains suboptimal, with current models struggling to accurately predict magnetocaloric properties from first principles for novel compositions. This gap limits the effectiveness of theory-guided experimental design that could otherwise significantly accelerate discovery.

Infrastructure limitations present practical barriers as well. Few research facilities possess the integrated capabilities necessary for seamless HTS implementation—from combinatorial synthesis to automated characterization and data analysis. The substantial capital investment required for such facilities restricts widespread adoption of comprehensive HTS approaches in magnetocaloric research.

Finally, the multi-parameter optimization problem inherent in magnetocaloric alloy development complicates the HTS process. Researchers must simultaneously optimize for maximum entropy change, appropriate transition temperature, minimal hysteresis, mechanical stability, and cost-effectiveness—a complex challenge that current HTS methodologies struggle to address comprehensively.

Sample preparation represents a primary obstacle in HTS for magnetocaloric alloys. The creation of compositionally diverse sample libraries with precise stoichiometry control remains difficult, particularly when dealing with multi-component systems. Conventional methods often struggle to maintain homogeneity across gradient samples, leading to unreliable magnetocaloric property measurements and potentially overlooking promising compositions.

Measurement throughput constitutes another major limitation. Traditional characterization techniques for magnetocaloric properties—such as direct adiabatic temperature change measurements and magnetic entropy change calculations—are inherently time-consuming. These methods typically require temperature stabilization periods and multiple field cycles, resulting in characterization rates that fail to match the pace at which compositional libraries can be fabricated.

Data quality and consistency issues further complicate the HTS process. Magnetocaloric measurements are sensitive to sample geometry, thermal contact, and environmental conditions. Maintaining uniform measurement conditions across hundreds or thousands of samples presents significant technical difficulties, often leading to systematic errors that can mask subtle but potentially valuable magnetocaloric effects.

The correlation between easily measured proxy properties and actual magnetocaloric performance remains inadequately established. While magnetic susceptibility or saturation magnetization can be measured more rapidly, their relationship to entropy change or refrigerant capacity is not always straightforward, particularly in complex alloy systems exhibiting competing magnetic interactions.

Computational challenges also persist in the HTS workflow. The integration of experimental data with theoretical predictions remains suboptimal, with current models struggling to accurately predict magnetocaloric properties from first principles for novel compositions. This gap limits the effectiveness of theory-guided experimental design that could otherwise significantly accelerate discovery.

Infrastructure limitations present practical barriers as well. Few research facilities possess the integrated capabilities necessary for seamless HTS implementation—from combinatorial synthesis to automated characterization and data analysis. The substantial capital investment required for such facilities restricts widespread adoption of comprehensive HTS approaches in magnetocaloric research.

Finally, the multi-parameter optimization problem inherent in magnetocaloric alloy development complicates the HTS process. Researchers must simultaneously optimize for maximum entropy change, appropriate transition temperature, minimal hysteresis, mechanical stability, and cost-effectiveness—a complex challenge that current HTS methodologies struggle to address comprehensively.

Current High-Throughput Screening Approaches for Magnetic Materials

01 High-throughput screening methods for magnetocaloric materials

High-throughput screening methods involve systematic testing of multiple alloy compositions to identify those with optimal magnetocaloric properties. These methods typically use combinatorial synthesis approaches to create material libraries with varying compositions, followed by automated characterization techniques to measure magnetocaloric effect (MCE) parameters such as magnetic entropy change and adiabatic temperature change. This approach significantly accelerates the discovery of new magnetocaloric alloys by enabling the evaluation of numerous compositions simultaneously.- Computational screening methods for magnetocaloric materials: Computational methods are employed to screen and identify potential magnetocaloric alloys with desirable properties. These methods include density functional theory calculations, machine learning algorithms, and high-throughput computational screening to predict magnetocaloric effect (MCE) in various alloy compositions. This approach allows researchers to efficiently explore a vast compositional space and identify promising candidates before experimental validation, significantly reducing development time and costs.

- Experimental characterization techniques for magnetocaloric alloys: Various experimental techniques are used to characterize and screen magnetocaloric alloys, including direct measurement of adiabatic temperature change, isothermal magnetic entropy change, and heat capacity measurements under applied magnetic fields. Advanced characterization methods such as magnetometry, calorimetry, and thermal analysis are employed to evaluate the magnetocaloric performance of different alloy compositions and structures, enabling the identification of materials with optimal refrigeration capacity.

- Compositional optimization and alloying strategies: Systematic approaches to optimize the composition of magnetocaloric alloys involve exploring various elemental combinations and their proportions. Methods include substitutional alloying, where certain elements are partially replaced to tune the Curie temperature and enhance the magnetocaloric effect. Gradient and combinatorial synthesis techniques allow for rapid screening of multiple compositions simultaneously, while precise control of stoichiometry helps in achieving desired phase transitions and magnetic properties.

- Microstructural analysis and processing techniques: Screening methods focused on microstructural analysis examine how processing conditions affect the magnetocaloric properties of alloys. Techniques such as heat treatment, rapid solidification, mechanical alloying, and severe plastic deformation are used to modify grain size, phase distribution, and crystallographic texture. Advanced microscopy and diffraction methods help correlate microstructural features with magnetocaloric performance, enabling the development of optimized processing routes for enhanced refrigeration efficiency.

- Performance evaluation and system integration testing: Methods to evaluate the practical performance of magnetocaloric alloys in actual cooling systems involve testing their durability, cycling stability, and efficiency under operating conditions. This includes assessing factors such as thermal hysteresis, mechanical integrity during repeated magnetic cycling, and compatibility with heat transfer fluids. Prototype testing in active magnetic regenerator systems provides valuable data on the real-world cooling capacity and energy efficiency of different alloy compositions.

02 Computational modeling and simulation techniques

Computational methods are employed to predict magnetocaloric properties of alloys before physical synthesis. These techniques include density functional theory (DFT), Monte Carlo simulations, and machine learning algorithms that can predict phase transitions, Curie temperatures, and magnetic entropy changes based on alloy composition and structure. By screening thousands of potential compositions virtually, researchers can identify promising candidates for experimental validation, reducing the time and resources required for materials discovery.Expand Specific Solutions03 Characterization methods for magnetocaloric properties

Various characterization techniques are used to evaluate the magnetocaloric properties of alloys. These include direct measurements of adiabatic temperature change, magnetic property measurements using vibrating sample magnetometers, differential scanning calorimetry for thermal analysis, and X-ray diffraction for structural characterization. Advanced techniques such as neutron diffraction and synchrotron radiation are also employed to understand the relationship between crystal structure, magnetic ordering, and magnetocaloric effect, enabling more effective screening of potential materials.Expand Specific Solutions04 Composition optimization and doping strategies

Systematic approaches to optimize alloy compositions involve studying the effects of elemental substitutions and doping on magnetocaloric properties. Researchers investigate how varying the ratios of constituent elements or introducing small amounts of dopants can enhance the magnetocaloric effect, tune the Curie temperature, reduce hysteresis, or improve mechanical properties. This method helps identify composition ranges that yield the best combination of properties for specific cooling applications and temperature ranges.Expand Specific Solutions05 Prototype testing and performance evaluation systems

Specialized testing systems are developed to evaluate the performance of magnetocaloric alloys in actual cooling devices. These systems measure parameters such as cooling capacity, efficiency, and cycling stability under conditions that simulate real-world applications. Test beds may incorporate magnetic field generators, heat exchangers, and fluid circulation systems to assess how materials perform in active magnetic regenerator cycles. This practical evaluation helps bridge the gap between material discovery and application development by identifying alloys that not only show promising magnetocaloric properties but also perform well in functional cooling systems.Expand Specific Solutions

Leading Research Groups and Industrial Players in Magnetocalorics

The high-throughput screening methods for magnetocaloric alloys market is currently in its growth phase, with increasing adoption driven by the need for more efficient cooling technologies. The global market is expanding as research institutions and companies seek sustainable alternatives to conventional refrigeration. Key players demonstrate varying levels of technological maturity: Wildcat Discovery Technologies and LG Chem lead with advanced high-throughput capabilities, while research institutions like National Institute for Materials Science and universities (Zhejiang, Huazhong) contribute significant academic innovations. Industrial players such as DENSO, Hitachi, and IHI are integrating these technologies into practical applications. The competitive landscape shows a blend of specialized materials companies, large industrial conglomerates, and academic institutions collaborating to advance this emerging field.

Zhejiang University

Technical Solution: Zhejiang University has developed a comprehensive high-throughput screening methodology for magnetocaloric alloys that combines computational materials science with advanced experimental techniques. Their approach begins with first-principles calculations and CALPHAD (CALculation of PHAse Diagrams) modeling to predict promising compositional regions with potentially high magnetocaloric effect. The university has established an automated materials synthesis platform capable of producing compositionally graded bulk samples using techniques such as melt spinning and spark plasma sintering. These samples are then characterized through a custom-built array of measurement devices that simultaneously evaluate magnetic properties, thermal conductivity, and structural stability. Zhejiang's system incorporates a unique high-throughput X-ray diffraction setup that can rapidly identify phase transitions critical to magnetocaloric performance. Their researchers have developed machine learning algorithms that correlate structural and compositional features with magnetocaloric properties, enabling accelerated discovery of new materials. This integrated approach has led to the identification of several novel Fe-based and Mn-based magnetocaloric alloys with reduced hysteresis and enhanced refrigeration capacity compared to conventional materials.

Strengths: Their integrated computational-experimental approach provides both fundamental understanding and practical materials discovery. The focus on bulk material synthesis rather than thin films offers more direct translation to practical applications. Weaknesses: Their system requires coordination across multiple specialized research teams and equipment sets, making it challenging to implement in smaller research environments. The emphasis on reduced rare earth content may sometimes compromise maximum performance metrics.

Wildcat Discovery Technologies, Inc.

Technical Solution: Wildcat Discovery Technologies has pioneered a proprietary high-throughput screening platform specifically adapted for magnetocaloric materials discovery. Their system can synthesize and test up to 1,000 unique material compositions per week, dramatically accelerating the traditional materials development timeline. Wildcat's approach combines robotic synthesis of bulk magnetocaloric alloys in small quantities (typically 1-5 grams) with parallel characterization using custom-designed arrays of magnetometers and calorimeters. Their technology incorporates precise thermal control systems that can measure magnetic entropy changes across temperature ranges relevant for refrigeration applications (250-350K). The company has developed specialized software that integrates experimental data with predictive models to guide the iterative optimization of alloy compositions. This closed-loop system continuously refines the search space based on measured performance metrics, including magnetic entropy change (ΔSM), adiabatic temperature change (ΔTad), and hysteresis properties. Wildcat has successfully applied this methodology to develop several promising magnetocaloric alloy systems with reduced rare earth content.

Strengths: Extremely high testing throughput allows rapid exploration of complex compositional spaces. Their closed-loop optimization approach efficiently converges on promising material candidates. Weaknesses: As a commercial entity, much of their specific methodological details remain proprietary, limiting broader scientific impact. Their focus on commercial applications may prioritize near-term practical materials over fundamental scientific discoveries.

Key Innovations in Magnetocaloric Characterization Techniques

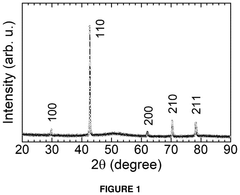

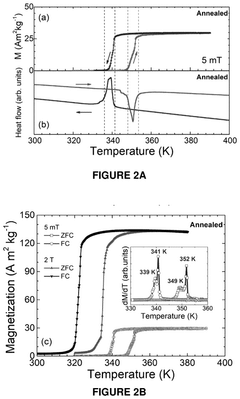

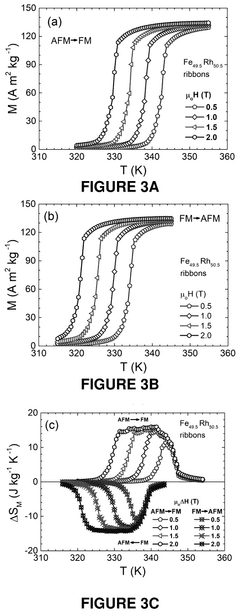

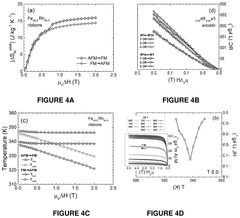

Iron-Rhodium magnetocaloric alloy ribbons for high performance cooling-heating applications and process for manufacturing the same

PatentPendingUS20250029757A1

Innovation

- The development of polycrystalline Fe100-xRhx magnetocaloric materials with a chemically ordered bcc CsCl-type crystalline structure, produced through rapid solidification using the melt spinning technique, which enhances the magnetocaloric properties at low magnetic field changes.

Magnetocaloric materials containing b

PatentInactiveEP3031058A1

Innovation

- The development of magnetocaloric materials with the general formula (MnxFe1-x)2+uPi-y-zSiyBz, where 0.25 < x < 0.55, 0.25 < y < 0.65, 0 < z < 0.2, and y + z < 0.7, which are non-toxic and have a hexagonal crystalline structure, allowing for high saturation magnetization and minimal cell volume change during magnetic phase transitions.

Environmental Impact and Sustainability of Magnetocaloric Technologies

The environmental impact of magnetocaloric technologies represents a critical dimension in evaluating their viability as alternatives to conventional cooling systems. Magnetocaloric materials, particularly those identified through high-throughput screening methods, offer significant sustainability advantages over traditional vapor-compression refrigeration technologies that rely on hydrofluorocarbons (HFCs) and other environmentally harmful refrigerants.

When examining the life cycle assessment of magnetocaloric cooling systems, the environmental footprint begins with raw material extraction. Many magnetocaloric alloys contain rare earth elements such as gadolinium, which present sustainability challenges due to energy-intensive mining and processing operations. However, high-throughput screening methods are increasingly identifying rare-earth-free alternatives based on transition metals like Fe, Mn, and Ni, substantially reducing the environmental burden associated with material sourcing.

Manufacturing processes for magnetocaloric alloys typically require precise composition control and heat treatments. While these processes consume energy, they generally produce fewer direct emissions compared to the production of conventional refrigerants. The operational phase of magnetocaloric technologies demonstrates their most significant environmental advantage – the absence of greenhouse gas emissions and ozone-depleting substances that characterize conventional cooling systems.

Energy efficiency represents another crucial sustainability metric. Current magnetocaloric prototypes demonstrate potential energy savings of 20-30% compared to conventional systems, though this varies with operating conditions and system design. As high-throughput screening identifies materials with larger magnetocaloric effects and optimized working temperatures, these efficiency gains are expected to increase further.

End-of-life considerations also favor magnetocaloric technologies. The metallic alloys used in these systems are highly recyclable, with potential recovery rates exceeding 90% for many compositions. This circular economy potential stands in stark contrast to conventional refrigerants, which require specialized disposal procedures to prevent atmospheric release.

Water consumption presents a mixed sustainability profile. While magnetocaloric systems eliminate water pollution risks associated with refrigerant leakage, some designs employ water as a heat transfer medium, potentially increasing water consumption compared to air-cooled conventional systems. This trade-off requires careful evaluation in water-stressed regions.

Regulatory frameworks increasingly favor technologies with reduced environmental impact. The Kigali Amendment to the Montreal Protocol mandates the phase-down of HFCs, creating policy incentives for alternative cooling technologies like magnetocaloric systems. This regulatory landscape enhances the long-term sustainability proposition of magnetocaloric technologies identified through high-throughput screening methods.

When examining the life cycle assessment of magnetocaloric cooling systems, the environmental footprint begins with raw material extraction. Many magnetocaloric alloys contain rare earth elements such as gadolinium, which present sustainability challenges due to energy-intensive mining and processing operations. However, high-throughput screening methods are increasingly identifying rare-earth-free alternatives based on transition metals like Fe, Mn, and Ni, substantially reducing the environmental burden associated with material sourcing.

Manufacturing processes for magnetocaloric alloys typically require precise composition control and heat treatments. While these processes consume energy, they generally produce fewer direct emissions compared to the production of conventional refrigerants. The operational phase of magnetocaloric technologies demonstrates their most significant environmental advantage – the absence of greenhouse gas emissions and ozone-depleting substances that characterize conventional cooling systems.

Energy efficiency represents another crucial sustainability metric. Current magnetocaloric prototypes demonstrate potential energy savings of 20-30% compared to conventional systems, though this varies with operating conditions and system design. As high-throughput screening identifies materials with larger magnetocaloric effects and optimized working temperatures, these efficiency gains are expected to increase further.

End-of-life considerations also favor magnetocaloric technologies. The metallic alloys used in these systems are highly recyclable, with potential recovery rates exceeding 90% for many compositions. This circular economy potential stands in stark contrast to conventional refrigerants, which require specialized disposal procedures to prevent atmospheric release.

Water consumption presents a mixed sustainability profile. While magnetocaloric systems eliminate water pollution risks associated with refrigerant leakage, some designs employ water as a heat transfer medium, potentially increasing water consumption compared to air-cooled conventional systems. This trade-off requires careful evaluation in water-stressed regions.

Regulatory frameworks increasingly favor technologies with reduced environmental impact. The Kigali Amendment to the Montreal Protocol mandates the phase-down of HFCs, creating policy incentives for alternative cooling technologies like magnetocaloric systems. This regulatory landscape enhances the long-term sustainability proposition of magnetocaloric technologies identified through high-throughput screening methods.

Materials Informatics Integration for Accelerated Discovery

The integration of materials informatics represents a transformative approach to magnetocaloric materials discovery, combining computational methods, data science, and machine learning to accelerate the identification of promising magnetocaloric alloys. This paradigm shift moves beyond traditional trial-and-error experimentation toward data-driven discovery frameworks that can process vast compositional and structural spaces efficiently.

Materials informatics platforms specifically designed for magnetocaloric research typically incorporate multiple data sources, including experimental measurements, theoretical calculations, and literature-derived information. These systems enable researchers to establish correlations between composition, structure, and magnetocaloric properties through sophisticated data mining techniques. The implementation of machine learning algorithms, particularly those utilizing artificial neural networks and genetic algorithms, has demonstrated remarkable success in predicting magnetocaloric effect (MCE) magnitudes across unexplored compositional regions.

Recent advances in this field include the development of automated workflows that integrate high-throughput computational screening with targeted experimental validation. These systems employ physics-based models alongside data-driven approaches to generate comprehensive property predictions. For instance, density functional theory (DFT) calculations combined with phase diagram information can be used to predict structural stability and magnetic transition temperatures, which are then incorporated into machine learning models to estimate entropy changes and refrigeration capacities.

Several research groups have successfully implemented materials informatics approaches for magnetocaloric materials discovery. The Materials Project and AFLOW consortiums have expanded their databases to include magnetic properties relevant to MCE screening. Additionally, specialized platforms like CaloriCool have developed integrated computational tools specifically optimized for caloric materials exploration, incorporating both first-principles calculations and experimental validation protocols.

The effectiveness of these integrated approaches has been demonstrated through the accelerated discovery of several promising magnetocaloric compounds. For example, informatics-guided screening recently identified novel quaternary Heusler alloys with enhanced MCE properties that conventional experimental approaches might have overlooked due to the vast compositional space. Similarly, machine learning models trained on existing magnetocaloric data have successfully predicted composition regions with low hysteresis and tunable transition temperatures.

Future developments in this area will likely focus on incorporating uncertainty quantification into prediction models and developing autonomous research systems capable of designing, executing, and analyzing experiments with minimal human intervention. The continued refinement of these integrated informatics approaches promises to dramatically reduce the time and resources required to discover and optimize next-generation magnetocaloric materials for practical cooling applications.

Materials informatics platforms specifically designed for magnetocaloric research typically incorporate multiple data sources, including experimental measurements, theoretical calculations, and literature-derived information. These systems enable researchers to establish correlations between composition, structure, and magnetocaloric properties through sophisticated data mining techniques. The implementation of machine learning algorithms, particularly those utilizing artificial neural networks and genetic algorithms, has demonstrated remarkable success in predicting magnetocaloric effect (MCE) magnitudes across unexplored compositional regions.

Recent advances in this field include the development of automated workflows that integrate high-throughput computational screening with targeted experimental validation. These systems employ physics-based models alongside data-driven approaches to generate comprehensive property predictions. For instance, density functional theory (DFT) calculations combined with phase diagram information can be used to predict structural stability and magnetic transition temperatures, which are then incorporated into machine learning models to estimate entropy changes and refrigeration capacities.

Several research groups have successfully implemented materials informatics approaches for magnetocaloric materials discovery. The Materials Project and AFLOW consortiums have expanded their databases to include magnetic properties relevant to MCE screening. Additionally, specialized platforms like CaloriCool have developed integrated computational tools specifically optimized for caloric materials exploration, incorporating both first-principles calculations and experimental validation protocols.

The effectiveness of these integrated approaches has been demonstrated through the accelerated discovery of several promising magnetocaloric compounds. For example, informatics-guided screening recently identified novel quaternary Heusler alloys with enhanced MCE properties that conventional experimental approaches might have overlooked due to the vast compositional space. Similarly, machine learning models trained on existing magnetocaloric data have successfully predicted composition regions with low hysteresis and tunable transition temperatures.

Future developments in this area will likely focus on incorporating uncertainty quantification into prediction models and developing autonomous research systems capable of designing, executing, and analyzing experiments with minimal human intervention. The continued refinement of these integrated informatics approaches promises to dramatically reduce the time and resources required to discover and optimize next-generation magnetocaloric materials for practical cooling applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!