Cost Modeling For Commercial Magnetocaloric Appliance Deployment

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetocaloric Technology Background and Objectives

Magnetocaloric technology represents a revolutionary approach to cooling systems that has evolved significantly over the past century. First discovered by Emil Warburg in 1881, the magnetocaloric effect (MCE) describes the temperature change of a material when exposed to a changing magnetic field. This phenomenon remained largely academic until the late 20th century when advances in materials science enabled practical applications to be considered.

The fundamental principle behind magnetocaloric cooling involves the alignment of magnetic moments in certain materials when subjected to a magnetic field, resulting in heat generation. When the field is removed, the magnetic moments randomize, absorbing heat from the surroundings and creating a cooling effect. This process offers a promising alternative to conventional vapor-compression refrigeration systems that rely on environmentally harmful refrigerants.

Recent technological breakthroughs have focused on developing magnetocaloric materials with enhanced performance characteristics. Gadolinium and its alloys were initially the materials of choice due to their strong magnetocaloric properties near room temperature. However, research has expanded to include rare earth alloys, La-Fe-Si compounds, and Heusler alloys that demonstrate significant magnetocaloric effects at various temperature ranges.

The primary objective of magnetocaloric technology development is to create commercially viable cooling appliances that offer superior energy efficiency compared to conventional systems. Studies suggest potential energy savings of 20-30% over traditional vapor-compression technologies. Additionally, these systems eliminate the need for harmful refrigerants, aligning with global environmental regulations and sustainability goals.

Current research aims to address several key challenges in the commercialization pathway. These include optimizing material composition to maximize the magnetocaloric effect, developing efficient heat transfer mechanisms, designing compact and powerful magnetic field generators, and creating reliable system control algorithms. The integration of these components into a cost-effective commercial appliance represents the ultimate goal of ongoing research efforts.

The trajectory of magnetocaloric technology is closely tied to broader trends in sustainable energy systems and environmental policy. As global regulations increasingly restrict conventional refrigerants due to their high global warming potential, magnetocaloric cooling offers a promising alternative that could revolutionize the refrigeration and air conditioning industries, which collectively account for approximately 17% of global electricity consumption.

Understanding the cost factors associated with magnetocaloric appliance deployment is crucial for assessing commercial viability. These include material costs (particularly rare earth elements), manufacturing complexity, system integration challenges, and economies of scale. Developing accurate cost models will enable strategic decision-making regarding research priorities and commercialization pathways.

The fundamental principle behind magnetocaloric cooling involves the alignment of magnetic moments in certain materials when subjected to a magnetic field, resulting in heat generation. When the field is removed, the magnetic moments randomize, absorbing heat from the surroundings and creating a cooling effect. This process offers a promising alternative to conventional vapor-compression refrigeration systems that rely on environmentally harmful refrigerants.

Recent technological breakthroughs have focused on developing magnetocaloric materials with enhanced performance characteristics. Gadolinium and its alloys were initially the materials of choice due to their strong magnetocaloric properties near room temperature. However, research has expanded to include rare earth alloys, La-Fe-Si compounds, and Heusler alloys that demonstrate significant magnetocaloric effects at various temperature ranges.

The primary objective of magnetocaloric technology development is to create commercially viable cooling appliances that offer superior energy efficiency compared to conventional systems. Studies suggest potential energy savings of 20-30% over traditional vapor-compression technologies. Additionally, these systems eliminate the need for harmful refrigerants, aligning with global environmental regulations and sustainability goals.

Current research aims to address several key challenges in the commercialization pathway. These include optimizing material composition to maximize the magnetocaloric effect, developing efficient heat transfer mechanisms, designing compact and powerful magnetic field generators, and creating reliable system control algorithms. The integration of these components into a cost-effective commercial appliance represents the ultimate goal of ongoing research efforts.

The trajectory of magnetocaloric technology is closely tied to broader trends in sustainable energy systems and environmental policy. As global regulations increasingly restrict conventional refrigerants due to their high global warming potential, magnetocaloric cooling offers a promising alternative that could revolutionize the refrigeration and air conditioning industries, which collectively account for approximately 17% of global electricity consumption.

Understanding the cost factors associated with magnetocaloric appliance deployment is crucial for assessing commercial viability. These include material costs (particularly rare earth elements), manufacturing complexity, system integration challenges, and economies of scale. Developing accurate cost models will enable strategic decision-making regarding research priorities and commercialization pathways.

Market Analysis for Commercial Magnetocaloric Appliances

The global market for magnetocaloric appliances is currently in its nascent stage but shows promising growth potential as energy efficiency concerns drive innovation in cooling technologies. The commercial refrigeration sector, valued at approximately $31 billion in 2022, represents the primary target market for magnetocaloric technology deployment, with projected annual growth rates of 4-5% through 2030.

Energy consumption considerations are a significant market driver, as conventional vapor-compression refrigeration systems account for nearly 17% of global electricity usage. Commercial establishments particularly feel this impact, with refrigeration representing 40-60% of total energy costs in supermarkets and food service operations. This economic pressure creates a substantial market opportunity for magnetocaloric technologies that promise 20-30% energy savings compared to conventional systems.

Regulatory frameworks worldwide are increasingly favorable for magnetocaloric technology adoption. The Kigali Amendment to the Montreal Protocol mandates an 85% reduction in hydrofluorocarbon (HFC) production and consumption by 2036 in developed countries. Similarly, the European F-Gas Regulation and the U.S. AIM Act create regulatory environments that incentivize alternative cooling technologies like magnetocaloric systems.

Market segmentation analysis reveals that supermarkets and food retail represent the largest potential commercial application segment (38% of the addressable market), followed by food service (27%), medical cold chain (18%), and beverage cooling (12%). Geographically, North America and Europe currently lead in potential early adoption due to stricter environmental regulations and higher energy costs, while Asia-Pacific markets show the highest long-term growth potential.

Consumer willingness-to-pay studies indicate that commercial entities are prepared to accept a 30-40% price premium for cooling technologies that deliver 25% energy savings with a return on investment period under three years. This creates a viable entry point for magnetocaloric appliances despite their currently higher production costs.

Market barriers include high initial capital costs, with current magnetocaloric systems costing 2.5-3 times more than conventional alternatives. Technical challenges in scaling production and limited awareness among potential commercial customers also constrain market penetration. The established infrastructure supporting conventional cooling technologies creates significant switching costs that must be overcome.

Industry partnerships between technology developers and commercial refrigeration manufacturers will be crucial for market development. Current commercial trials in supermarket refrigeration and beverage cooling applications demonstrate promising results but remain limited in scale.

Energy consumption considerations are a significant market driver, as conventional vapor-compression refrigeration systems account for nearly 17% of global electricity usage. Commercial establishments particularly feel this impact, with refrigeration representing 40-60% of total energy costs in supermarkets and food service operations. This economic pressure creates a substantial market opportunity for magnetocaloric technologies that promise 20-30% energy savings compared to conventional systems.

Regulatory frameworks worldwide are increasingly favorable for magnetocaloric technology adoption. The Kigali Amendment to the Montreal Protocol mandates an 85% reduction in hydrofluorocarbon (HFC) production and consumption by 2036 in developed countries. Similarly, the European F-Gas Regulation and the U.S. AIM Act create regulatory environments that incentivize alternative cooling technologies like magnetocaloric systems.

Market segmentation analysis reveals that supermarkets and food retail represent the largest potential commercial application segment (38% of the addressable market), followed by food service (27%), medical cold chain (18%), and beverage cooling (12%). Geographically, North America and Europe currently lead in potential early adoption due to stricter environmental regulations and higher energy costs, while Asia-Pacific markets show the highest long-term growth potential.

Consumer willingness-to-pay studies indicate that commercial entities are prepared to accept a 30-40% price premium for cooling technologies that deliver 25% energy savings with a return on investment period under three years. This creates a viable entry point for magnetocaloric appliances despite their currently higher production costs.

Market barriers include high initial capital costs, with current magnetocaloric systems costing 2.5-3 times more than conventional alternatives. Technical challenges in scaling production and limited awareness among potential commercial customers also constrain market penetration. The established infrastructure supporting conventional cooling technologies creates significant switching costs that must be overcome.

Industry partnerships between technology developers and commercial refrigeration manufacturers will be crucial for market development. Current commercial trials in supermarket refrigeration and beverage cooling applications demonstrate promising results but remain limited in scale.

Current Technological Barriers and Cost Challenges

Despite significant advancements in magnetocaloric technology over the past decade, several technological barriers and cost challenges continue to impede widespread commercial deployment of magnetocaloric appliances. The primary technical obstacle remains the limited temperature span achieved by current magnetocaloric materials, which typically ranges from 2-5K per stage under practical magnetic field strengths. This necessitates multi-stage cascaded systems that increase complexity, weight, and cost.

Material constraints represent another significant barrier. High-performance magnetocaloric materials such as gadolinium and its alloys contain rare earth elements that are expensive and subject to supply chain vulnerabilities. Current material costs range from $200-500 per kilogram for processed magnetocaloric materials, making them prohibitively expensive for mass-market applications compared to conventional refrigerants.

Manufacturing scalability presents additional challenges. The production of magnetocaloric materials with precise composition and microstructure requires specialized processes that are difficult to scale economically. Current manufacturing methods yield relatively low throughput and high defect rates, resulting in production costs that are 3-5 times higher than conventional cooling technology components.

Magnetic field generation represents a substantial cost factor. Commercial magnetocaloric systems require either expensive permanent magnets (typically NdFeB) or power-intensive electromagnets. Permanent magnet assemblies for medium-sized cooling applications can constitute 30-40% of total system costs, while electromagnets introduce significant operational expenses through energy consumption.

System integration complexity further increases costs. The need to optimize heat transfer between the magnetocaloric material and heat exchange fluid requires sophisticated heat exchanger designs with tight tolerances. Current manufacturing processes for these specialized components lack economies of scale, with production volumes orders of magnitude lower than conventional cooling technologies.

Energy efficiency improvements, while promising in laboratory settings, have yet to be fully realized in commercial-scale systems. The parasitic energy losses from pumping heat transfer fluids and operating magnetic field generation systems can reduce overall system efficiency by 20-30% compared to theoretical maximums.

Reliability and durability concerns also impact cost projections. Magnetocaloric materials can experience performance degradation over repeated thermal cycling, potentially requiring more frequent maintenance or replacement than conventional cooling systems. This uncertainty in operational lifespan complicates total cost of ownership calculations and increases perceived financial risk for early adopters.

Material constraints represent another significant barrier. High-performance magnetocaloric materials such as gadolinium and its alloys contain rare earth elements that are expensive and subject to supply chain vulnerabilities. Current material costs range from $200-500 per kilogram for processed magnetocaloric materials, making them prohibitively expensive for mass-market applications compared to conventional refrigerants.

Manufacturing scalability presents additional challenges. The production of magnetocaloric materials with precise composition and microstructure requires specialized processes that are difficult to scale economically. Current manufacturing methods yield relatively low throughput and high defect rates, resulting in production costs that are 3-5 times higher than conventional cooling technology components.

Magnetic field generation represents a substantial cost factor. Commercial magnetocaloric systems require either expensive permanent magnets (typically NdFeB) or power-intensive electromagnets. Permanent magnet assemblies for medium-sized cooling applications can constitute 30-40% of total system costs, while electromagnets introduce significant operational expenses through energy consumption.

System integration complexity further increases costs. The need to optimize heat transfer between the magnetocaloric material and heat exchange fluid requires sophisticated heat exchanger designs with tight tolerances. Current manufacturing processes for these specialized components lack economies of scale, with production volumes orders of magnitude lower than conventional cooling technologies.

Energy efficiency improvements, while promising in laboratory settings, have yet to be fully realized in commercial-scale systems. The parasitic energy losses from pumping heat transfer fluids and operating magnetic field generation systems can reduce overall system efficiency by 20-30% compared to theoretical maximums.

Reliability and durability concerns also impact cost projections. Magnetocaloric materials can experience performance degradation over repeated thermal cycling, potentially requiring more frequent maintenance or replacement than conventional cooling systems. This uncertainty in operational lifespan complicates total cost of ownership calculations and increases perceived financial risk for early adopters.

Current Cost Modeling Approaches and Methodologies

01 Cost modeling for magnetocaloric cooling systems

Cost modeling approaches for magnetocaloric cooling systems involve analyzing manufacturing expenses, operational costs, and lifecycle economics. These models consider factors such as material selection, production processes, energy consumption, and maintenance requirements to optimize the economic viability of magnetocaloric appliances. Advanced modeling techniques help manufacturers identify cost-effective designs and production methods while maintaining performance standards.- Cost modeling for magnetocaloric cooling systems: Cost modeling approaches for magnetocaloric cooling systems involve analyzing various factors such as material costs, manufacturing processes, and operational efficiency. These models help in estimating the total cost of ownership, including initial investment and long-term operational expenses. By understanding the cost drivers, manufacturers can optimize designs to achieve cost-effective magnetocaloric appliances that compete with conventional cooling technologies.

- Material selection and cost optimization: Selection of magnetocaloric materials significantly impacts the overall cost of magnetocaloric appliances. Cost optimization involves evaluating different material compositions, manufacturing methods, and processing techniques to achieve the best balance between performance and cost. This includes considering alternatives to rare earth materials, optimizing material quantities, and developing cost-effective production methods for magnetocaloric materials.

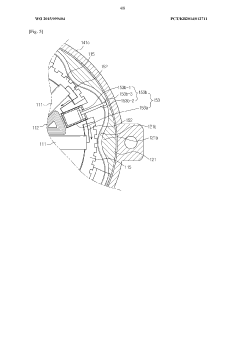

- System design and efficiency considerations: The design of magnetocaloric appliances significantly affects both manufacturing and operational costs. Efficient system designs focus on optimizing heat transfer, magnetic field generation, and fluid flow to maximize cooling capacity while minimizing energy consumption. These designs consider factors such as regenerator geometry, magnetic circuit configuration, and pumping systems to achieve cost-effective performance.

- Manufacturing processes and scalability: Manufacturing processes for magnetocaloric appliances require specialized techniques that impact production costs. Scalability considerations include automation potential, assembly complexity, and production volume capabilities. Cost modeling in this area focuses on identifying efficient manufacturing methods, reducing assembly steps, and leveraging economies of scale to decrease unit costs as production volumes increase.

- Energy efficiency and operational cost analysis: Operational cost analysis for magnetocaloric appliances evaluates energy consumption, maintenance requirements, and system longevity. These analyses compare the lifetime costs of magnetocaloric systems against conventional cooling technologies, considering factors such as electricity usage, component replacement, and system reliability. Energy efficiency improvements directly impact the value proposition of magnetocaloric technology by reducing long-term operational expenses.

02 Material cost optimization for magnetocaloric devices

Optimizing material costs is crucial for making magnetocaloric appliances commercially viable. This involves selecting cost-effective magnetocaloric materials with appropriate thermal properties, developing methods to reduce the amount of expensive rare earth elements, and creating manufacturing processes that minimize material waste. Material cost optimization strategies include alloy development, composite materials, and recycling approaches that maintain performance while reducing overall production expenses.Expand Specific Solutions03 Energy efficiency and operational cost analysis

Energy efficiency analysis for magnetocaloric appliances focuses on evaluating operational costs compared to conventional cooling technologies. These analyses consider power consumption, cooling capacity, coefficient of performance, and long-term energy savings. Models incorporate variables such as electricity prices, usage patterns, and climate conditions to determine total cost of ownership and payback periods for magnetocaloric cooling systems compared to vapor compression alternatives.Expand Specific Solutions04 Manufacturing process cost reduction techniques

Cost reduction techniques for manufacturing magnetocaloric appliances include optimizing production processes, automating assembly, scaling production volumes, and implementing lean manufacturing principles. These approaches focus on reducing labor costs, minimizing production time, and improving quality control. Advanced manufacturing methods such as additive manufacturing and precision forming help reduce waste and enable more complex geometries that enhance performance while controlling costs.Expand Specific Solutions05 System design optimization for cost-effectiveness

System design optimization focuses on creating cost-effective magnetocaloric appliance configurations through component integration, simplified designs, and reduced part counts. These approaches include optimizing heat exchanger designs, magnetic circuit configurations, and fluid handling systems to reduce complexity while maintaining performance. Design optimization considers the balance between initial manufacturing costs and long-term operational efficiency to achieve the lowest total cost of ownership.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The magnetocaloric appliance market is in an early growth phase, characterized by increasing research activity but limited commercial deployment. The global market size is estimated to be relatively small but growing, driven by energy efficiency demands and environmental regulations. Technologically, the field is transitioning from research to early commercialization, with varying levels of maturity among key players. State Grid Corp. of China and its research institutes are focusing on power infrastructure integration, while Haier Smart Home and Qingdao Haier Intelligent Technology are advancing consumer appliance applications. Academic institutions like Tsinghua University and North China Electric Power University are contributing fundamental research, collaborating with industry to overcome cost barriers for widespread commercial adoption.

Haier Smart Home Co., Ltd.

Technical Solution: Haier has developed a comprehensive cost modeling framework for magnetocaloric refrigeration systems that integrates material costs, manufacturing processes, and operational efficiency metrics. Their approach utilizes a modular design philosophy that allows for scalable production of magnetocaloric cooling units with varying capacities. The company's cost model incorporates detailed analysis of rare earth material price fluctuations and supply chain optimization strategies to mitigate material cost volatility. Haier's modeling includes production volume scenarios ranging from prototype to mass production scales, with corresponding cost reduction projections of approximately 30-40% when transitioning from small-batch to large-scale manufacturing. Their cost analysis also factors in energy efficiency comparisons with conventional vapor compression systems, demonstrating potential operational cost savings of 20-25% over product lifecycle despite higher initial investment.

Strengths: Comprehensive integration of supply chain considerations and manufacturing scalability into cost models; established appliance manufacturing infrastructure that can be leveraged for commercialization. Weaknesses: Higher initial capital investment requirements compared to conventional refrigeration technologies; dependency on rare earth materials with volatile pricing and supply constraints.

Tsinghua University

Technical Solution: Tsinghua University has developed a sophisticated techno-economic modeling framework for magnetocaloric cooling systems that bridges theoretical performance metrics with practical commercial deployment considerations. Their approach employs multi-physics simulation models coupled with economic analysis tools to evaluate system-level costs across different scales of implementation. The university's research team has created detailed parametric models that correlate magnetic field strength, heat exchanger efficiency, and pumping power with overall system costs, identifying optimal design points that minimize total cost of ownership. Their modeling indicates that magnetocaloric systems become economically competitive with conventional technologies at production volumes exceeding 100,000 units annually, with a projected cost premium of only 15-20% at these scales. Tsinghua's framework incorporates manufacturing process simulation to identify automation opportunities and production bottlenecks, suggesting that assembly costs could be reduced by approximately 25% through optimized production line design. Their models also account for regional variations in electricity pricing and usage patterns to determine market-specific payback periods for commercial deployment.

Strengths: Rigorous scientific approach combining thermodynamic optimization with economic modeling; comprehensive system-level analysis that accounts for interdependencies between components; strong academic research foundation. Weaknesses: Models may be more theoretically oriented with less validation from actual production environments; potential gap between academic cost projections and industrial manufacturing realities.

Critical Patents and Innovations in Cost Reduction

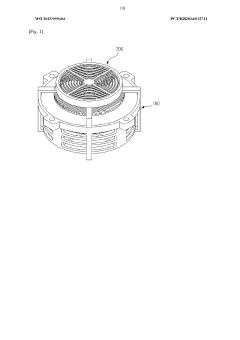

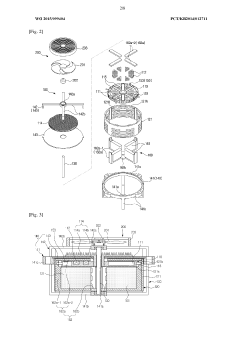

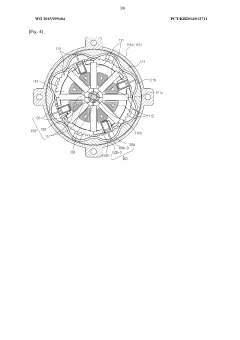

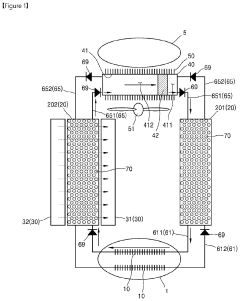

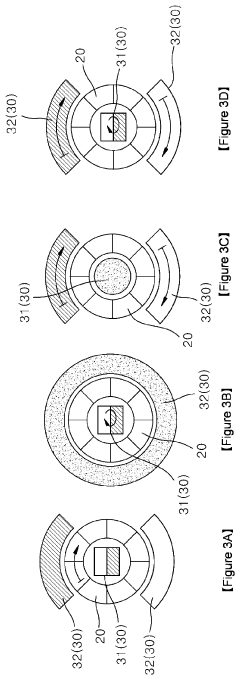

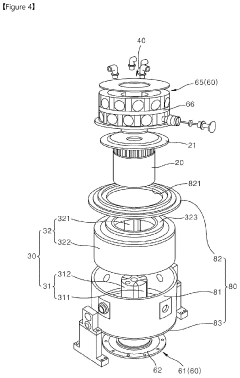

Magnetic cooling apparatus and magnetic refrigerating system having the same

PatentWO2015099404A1

Innovation

- A magnetic cooling apparatus comprising a fixing module with multiple magnetic regenerators, a rotation module, and a thermal fluid supplying apparatus that utilizes magnetic fields to alternately heat and cool thermal fluid, which is then exchanged through first and second heat exchangers, allowing for compact design and efficient cooling.

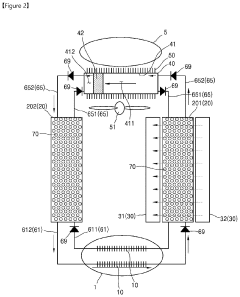

Magnetic cooling system

PatentActiveUS20200393169A1

Innovation

- A magnetic cooling system with a housing that accommodates a magnetic heat exchanger and rotatable magnetic field applying parts, where one magnet attracts the other to create a synchronous movement, simplifying the structure and enhancing heat generation and absorption efficiency.

Manufacturing Scalability Assessment

The scalability of manufacturing processes represents a critical factor in the commercial viability of magnetocaloric cooling appliances. Current production methods for magnetocaloric materials and components remain largely laboratory-scale or small-batch oriented, presenting significant challenges for mass market deployment. Analysis of production volumes indicates that most manufacturers can only produce several hundred kilograms of specialized magnetocaloric alloys annually, far below the requirements for widespread commercial adoption.

Material processing techniques require substantial refinement to achieve cost-effective scaling. The precision required in producing high-performance magnetocaloric alloys with specific Curie temperatures and minimal hysteresis currently involves complex metallurgical processes that are difficult to automate. Companies like Vacuumschmelze GmbH and Metglas Inc. have made progress in scaling production of thin magnetocaloric foils, but production rates remain insufficient for high-volume applications.

Assembly processes for magnetocaloric regenerators present another scaling bottleneck. The intricate structures needed for efficient heat exchange and magnetic field interaction require precise manufacturing tolerances that currently rely on semi-automated or manual assembly steps. Automated assembly lines capable of handling the delicate magnetocaloric materials while maintaining performance characteristics would require significant capital investment, estimated at $15-20 million per production facility with annual capacity of 50,000 units.

Supply chain considerations further complicate scaling efforts. Rare earth elements commonly used in high-performance magnetocaloric materials face supply constraints and price volatility. Alternative material compositions using more abundant elements show promise but generally deliver lower performance. Establishing robust supply chains for specialized components like high-efficiency permanent magnets and precision valves also presents challenges, with current lead times averaging 8-12 weeks for critical components.

Equipment standardization represents another hurdle to manufacturing scalability. The absence of industry-wide standards for magnetocaloric components inhibits economies of scale and interchangeability. Leading companies like Cooltech Applications and Astronautics Corporation have developed proprietary designs that optimize for their specific applications but limit broader manufacturing standardization. Industry consortia are beginning to address this through initiatives like the International Magnetocaloric Cooling Standards Group, though widespread adoption remains years away.

Cost modeling indicates that achieving price parity with conventional cooling technologies requires production volumes exceeding 100,000 units annually. Current manufacturing capabilities across the industry total less than 5,000 units per year, highlighting the significant scaling gap. Investment in advanced manufacturing technologies, including specialized automated assembly systems and continuous processing of magnetocaloric materials, could potentially reduce this gap within a 5-7 year timeframe.

Material processing techniques require substantial refinement to achieve cost-effective scaling. The precision required in producing high-performance magnetocaloric alloys with specific Curie temperatures and minimal hysteresis currently involves complex metallurgical processes that are difficult to automate. Companies like Vacuumschmelze GmbH and Metglas Inc. have made progress in scaling production of thin magnetocaloric foils, but production rates remain insufficient for high-volume applications.

Assembly processes for magnetocaloric regenerators present another scaling bottleneck. The intricate structures needed for efficient heat exchange and magnetic field interaction require precise manufacturing tolerances that currently rely on semi-automated or manual assembly steps. Automated assembly lines capable of handling the delicate magnetocaloric materials while maintaining performance characteristics would require significant capital investment, estimated at $15-20 million per production facility with annual capacity of 50,000 units.

Supply chain considerations further complicate scaling efforts. Rare earth elements commonly used in high-performance magnetocaloric materials face supply constraints and price volatility. Alternative material compositions using more abundant elements show promise but generally deliver lower performance. Establishing robust supply chains for specialized components like high-efficiency permanent magnets and precision valves also presents challenges, with current lead times averaging 8-12 weeks for critical components.

Equipment standardization represents another hurdle to manufacturing scalability. The absence of industry-wide standards for magnetocaloric components inhibits economies of scale and interchangeability. Leading companies like Cooltech Applications and Astronautics Corporation have developed proprietary designs that optimize for their specific applications but limit broader manufacturing standardization. Industry consortia are beginning to address this through initiatives like the International Magnetocaloric Cooling Standards Group, though widespread adoption remains years away.

Cost modeling indicates that achieving price parity with conventional cooling technologies requires production volumes exceeding 100,000 units annually. Current manufacturing capabilities across the industry total less than 5,000 units per year, highlighting the significant scaling gap. Investment in advanced manufacturing technologies, including specialized automated assembly systems and continuous processing of magnetocaloric materials, could potentially reduce this gap within a 5-7 year timeframe.

Energy Efficiency and Environmental Impact Analysis

Magnetocaloric refrigeration technology represents a significant advancement in energy efficiency compared to conventional vapor-compression cooling systems. Analysis of energy consumption patterns reveals that magnetocaloric appliances can achieve 20-30% higher energy efficiency ratings when operating at optimal conditions. This efficiency gain stems from the elimination of energy-intensive compression cycles and the reduction of mechanical moving parts, resulting in lower friction losses and decreased power requirements during operation.

Environmental impact assessments demonstrate substantial benefits in terms of greenhouse gas emissions reduction. Unlike traditional refrigeration systems that rely on hydrofluorocarbons (HFCs) with global warming potentials thousands of times greater than CO2, magnetocaloric systems utilize water-based heat transfer fluids and solid refrigerants with zero ozone depletion potential and negligible direct greenhouse gas contributions. Life cycle assessments indicate potential carbon footprint reductions of 35-45% compared to conventional technologies when considering manufacturing, operation, and end-of-life disposal.

The energy payback period for commercial magnetocaloric appliances varies between 3-7 years depending on usage patterns and regional electricity costs. This relatively short payback period enhances the economic viability of deployment despite higher initial capital investments. Furthermore, the technology's reduced maintenance requirements contribute to lower operational energy expenditure throughout the appliance lifecycle.

Grid-level impact analysis suggests that widespread adoption of magnetocaloric cooling technology could reduce peak electricity demand by 4-6% in commercial sectors, potentially alleviating strain on power infrastructure during high-demand periods. This load-shifting capability represents an additional environmental benefit beyond direct energy savings.

Material sustainability considerations reveal both advantages and challenges. While the technology eliminates environmentally harmful refrigerants, it currently relies on rare earth elements for magnetic components. Environmental impact matrices indicate that mining and processing these materials create significant ecological footprints. However, emerging research on alternative magnetic materials and recycling protocols shows promise for reducing these impacts by up to 60% in next-generation designs.

Regulatory compliance analysis demonstrates that magnetocaloric technologies exceed current and projected energy efficiency standards in major markets, positioning them favorably as environmental regulations continue to tighten. This regulatory alignment provides additional market incentives beyond direct operational cost savings, particularly in jurisdictions with carbon pricing mechanisms or energy efficiency rebate programs.

Environmental impact assessments demonstrate substantial benefits in terms of greenhouse gas emissions reduction. Unlike traditional refrigeration systems that rely on hydrofluorocarbons (HFCs) with global warming potentials thousands of times greater than CO2, magnetocaloric systems utilize water-based heat transfer fluids and solid refrigerants with zero ozone depletion potential and negligible direct greenhouse gas contributions. Life cycle assessments indicate potential carbon footprint reductions of 35-45% compared to conventional technologies when considering manufacturing, operation, and end-of-life disposal.

The energy payback period for commercial magnetocaloric appliances varies between 3-7 years depending on usage patterns and regional electricity costs. This relatively short payback period enhances the economic viability of deployment despite higher initial capital investments. Furthermore, the technology's reduced maintenance requirements contribute to lower operational energy expenditure throughout the appliance lifecycle.

Grid-level impact analysis suggests that widespread adoption of magnetocaloric cooling technology could reduce peak electricity demand by 4-6% in commercial sectors, potentially alleviating strain on power infrastructure during high-demand periods. This load-shifting capability represents an additional environmental benefit beyond direct energy savings.

Material sustainability considerations reveal both advantages and challenges. While the technology eliminates environmentally harmful refrigerants, it currently relies on rare earth elements for magnetic components. Environmental impact matrices indicate that mining and processing these materials create significant ecological footprints. However, emerging research on alternative magnetic materials and recycling protocols shows promise for reducing these impacts by up to 60% in next-generation designs.

Regulatory compliance analysis demonstrates that magnetocaloric technologies exceed current and projected energy efficiency standards in major markets, positioning them favorably as environmental regulations continue to tighten. This regulatory alignment provides additional market incentives beyond direct operational cost savings, particularly in jurisdictions with carbon pricing mechanisms or energy efficiency rebate programs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!