Optimization Of Operating Frequencies For Magnetocaloric Regenerators

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetocaloric Technology Background and Objectives

Magnetocaloric technology represents a revolutionary approach to refrigeration and cooling systems that has gained significant attention over the past few decades. This technology harnesses the magnetocaloric effect (MCE), a thermodynamic phenomenon where certain materials change temperature when exposed to varying magnetic fields. The fundamental principle was first discovered by Emil Warburg in 1881, but practical applications only began to emerge in the late 20th century with advances in material science and engineering.

The evolution of magnetocaloric technology has accelerated notably since the 1990s, following the discovery of giant magnetocaloric effect materials such as Gd5(Si2Ge2) by Pecharsky and Gschneidner. This breakthrough significantly expanded the potential efficiency and applicability of magnetocaloric cooling systems. The technology has since progressed through various developmental stages, from laboratory demonstrations to prototype systems, with increasing focus on optimizing system parameters for commercial viability.

Current technological trends indicate a shift toward more sophisticated regenerator designs, advanced magnetocaloric materials with reduced rare earth content, and improved system integration. The optimization of operating frequencies represents a critical frontier in this evolution, as it directly impacts the efficiency, power density, and overall performance of magnetocaloric regenerators.

The primary objectives of research into operating frequency optimization include maximizing the cooling capacity per unit volume, minimizing energy consumption, and enhancing system responsiveness. These goals are particularly relevant as the technology moves toward commercial applications in domestic refrigeration, industrial cooling, and potentially air conditioning systems.

Additionally, there is growing interest in addressing the environmental benefits of magnetocaloric technology. With global regulations increasingly restricting conventional refrigerants due to their high global warming potential, magnetocaloric cooling offers a promising alternative that uses solid refrigerants and water-based heat transfer fluids, potentially reducing direct greenhouse gas emissions significantly.

The technical objectives also encompass understanding and mitigating the complex interplay between operating frequency and other system parameters such as flow characteristics, heat transfer efficiency, and material properties. This multidimensional optimization problem requires sophisticated modeling approaches and experimental validation to develop practical design guidelines for magnetocaloric regenerators.

As the technology matures, research goals are expanding to include cost reduction strategies, manufacturing scalability, and integration with existing infrastructure, all of which are essential for widespread market adoption. The optimization of operating frequencies stands as a cornerstone challenge that, when effectively addressed, could significantly accelerate the commercial readiness of this promising green cooling technology.

The evolution of magnetocaloric technology has accelerated notably since the 1990s, following the discovery of giant magnetocaloric effect materials such as Gd5(Si2Ge2) by Pecharsky and Gschneidner. This breakthrough significantly expanded the potential efficiency and applicability of magnetocaloric cooling systems. The technology has since progressed through various developmental stages, from laboratory demonstrations to prototype systems, with increasing focus on optimizing system parameters for commercial viability.

Current technological trends indicate a shift toward more sophisticated regenerator designs, advanced magnetocaloric materials with reduced rare earth content, and improved system integration. The optimization of operating frequencies represents a critical frontier in this evolution, as it directly impacts the efficiency, power density, and overall performance of magnetocaloric regenerators.

The primary objectives of research into operating frequency optimization include maximizing the cooling capacity per unit volume, minimizing energy consumption, and enhancing system responsiveness. These goals are particularly relevant as the technology moves toward commercial applications in domestic refrigeration, industrial cooling, and potentially air conditioning systems.

Additionally, there is growing interest in addressing the environmental benefits of magnetocaloric technology. With global regulations increasingly restricting conventional refrigerants due to their high global warming potential, magnetocaloric cooling offers a promising alternative that uses solid refrigerants and water-based heat transfer fluids, potentially reducing direct greenhouse gas emissions significantly.

The technical objectives also encompass understanding and mitigating the complex interplay between operating frequency and other system parameters such as flow characteristics, heat transfer efficiency, and material properties. This multidimensional optimization problem requires sophisticated modeling approaches and experimental validation to develop practical design guidelines for magnetocaloric regenerators.

As the technology matures, research goals are expanding to include cost reduction strategies, manufacturing scalability, and integration with existing infrastructure, all of which are essential for widespread market adoption. The optimization of operating frequencies stands as a cornerstone challenge that, when effectively addressed, could significantly accelerate the commercial readiness of this promising green cooling technology.

Market Analysis for Magnetocaloric Cooling Systems

The global magnetocaloric cooling systems market is experiencing significant growth, driven by increasing environmental concerns and the search for energy-efficient alternatives to conventional vapor-compression refrigeration. Current market valuations indicate that the magnetocaloric cooling industry is projected to grow at a compound annual growth rate of 20-25% between 2023 and 2030, with the market expected to reach several billion dollars by the end of the decade.

The primary market segments for magnetocaloric cooling systems include commercial refrigeration, domestic refrigeration, automotive air conditioning, and industrial cooling applications. Commercial refrigeration represents the largest current market opportunity, with supermarkets and food processing facilities showing particular interest in energy-efficient cooling technologies that can reduce operational costs and environmental impact.

Consumer demand for environmentally friendly cooling solutions is creating a favorable market environment for magnetocaloric technology. With global regulations increasingly restricting the use of hydrofluorocarbons (HFCs) and other refrigerants with high global warming potential, magnetocaloric cooling offers a compelling alternative with zero direct greenhouse gas emissions.

Regional market analysis reveals that North America and Europe are leading in terms of research, development, and early commercial adoption of magnetocaloric cooling systems. This is largely due to stringent environmental regulations and higher energy costs in these regions. Asia-Pacific, particularly China and Japan, is expected to witness the fastest growth rate in the coming years due to rapid industrialization and increasing environmental awareness.

Key market drivers include the potential for 20-30% energy savings compared to conventional cooling systems, elimination of environmentally harmful refrigerants, reduced noise levels, and longer system lifespans. However, market penetration faces challenges related to high initial system costs, which are currently 2-3 times higher than conventional cooling systems.

The optimization of operating frequencies for magnetocaloric regenerators directly impacts market viability by affecting system efficiency, size, and cost. Market research indicates that achieving optimal frequency operation could reduce system costs by up to 40% and increase energy efficiency by 15-25%, significantly improving market competitiveness.

Consumer willingness to pay premiums for environmentally friendly cooling solutions varies by segment, with commercial and industrial users showing greater acceptance of higher upfront costs when offset by operational savings. The residential market remains more price-sensitive, suggesting that initial market penetration should focus on commercial applications while economies of scale develop.

The primary market segments for magnetocaloric cooling systems include commercial refrigeration, domestic refrigeration, automotive air conditioning, and industrial cooling applications. Commercial refrigeration represents the largest current market opportunity, with supermarkets and food processing facilities showing particular interest in energy-efficient cooling technologies that can reduce operational costs and environmental impact.

Consumer demand for environmentally friendly cooling solutions is creating a favorable market environment for magnetocaloric technology. With global regulations increasingly restricting the use of hydrofluorocarbons (HFCs) and other refrigerants with high global warming potential, magnetocaloric cooling offers a compelling alternative with zero direct greenhouse gas emissions.

Regional market analysis reveals that North America and Europe are leading in terms of research, development, and early commercial adoption of magnetocaloric cooling systems. This is largely due to stringent environmental regulations and higher energy costs in these regions. Asia-Pacific, particularly China and Japan, is expected to witness the fastest growth rate in the coming years due to rapid industrialization and increasing environmental awareness.

Key market drivers include the potential for 20-30% energy savings compared to conventional cooling systems, elimination of environmentally harmful refrigerants, reduced noise levels, and longer system lifespans. However, market penetration faces challenges related to high initial system costs, which are currently 2-3 times higher than conventional cooling systems.

The optimization of operating frequencies for magnetocaloric regenerators directly impacts market viability by affecting system efficiency, size, and cost. Market research indicates that achieving optimal frequency operation could reduce system costs by up to 40% and increase energy efficiency by 15-25%, significantly improving market competitiveness.

Consumer willingness to pay premiums for environmentally friendly cooling solutions varies by segment, with commercial and industrial users showing greater acceptance of higher upfront costs when offset by operational savings. The residential market remains more price-sensitive, suggesting that initial market penetration should focus on commercial applications while economies of scale develop.

Current Challenges in Magnetocaloric Regenerator Operation

Magnetocaloric regenerators face several significant operational challenges that impede their widespread commercial adoption. One primary issue is the optimization of operating frequencies, which directly impacts system efficiency and cooling capacity. Current regenerators typically operate at frequencies between 1-10 Hz, but this range represents a compromise rather than an optimized solution for most applications.

The thermal exchange dynamics within magnetocaloric materials create a fundamental challenge. At higher frequencies, the material does not have sufficient time to fully transfer heat to the heat transfer fluid, resulting in incomplete utilization of the magnetocaloric effect. Conversely, at lower frequencies, while heat transfer is more complete, the overall cooling power decreases significantly due to reduced cycling rates, diminishing system efficiency.

Another critical challenge is the balance between pressure drop and heat transfer effectiveness. Higher frequencies inevitably lead to increased pressure drops across the regenerator, requiring more pumping power and reducing the coefficient of performance (COP). Current regenerator designs struggle to maintain adequate heat transfer at frequencies that would deliver commercially viable cooling power without excessive pressure penalties.

Material response limitations further complicate frequency optimization. Most magnetocaloric materials exhibit hysteresis effects that become more pronounced at higher operating frequencies, reducing the effective entropy change and consequently the cooling capacity. This creates a material-dependent ceiling on practical operating frequencies that varies with composition and microstructure.

The geometric design of regenerators presents additional challenges for frequency optimization. Current bed geometries (packed spheres, parallel plates, or microchannel designs) each present different frequency-dependent performance characteristics. No single geometry has demonstrated optimal performance across the full range of desired operating conditions and frequencies.

System-level integration issues also emerge at different frequencies. Components such as pumps, valves, and magnetic field sources must be synchronized precisely, with timing tolerances becoming increasingly critical at higher frequencies. Current actuation technologies struggle to maintain precision at frequencies above 5 Hz while remaining energy-efficient and durable over millions of cycles.

Heat transfer fluid selection compounds these challenges, as the fluid's thermal properties and flow characteristics interact differently with the regenerator matrix at varying frequencies. The ideal fluid for low-frequency operation may perform poorly at higher frequencies due to viscosity effects and thermal diffusivity limitations.

AI-powered modeling and optimization approaches are beginning to address these multifaceted challenges, but comprehensive solutions that balance all these competing factors remain elusive in current magnetocaloric regenerator designs.

The thermal exchange dynamics within magnetocaloric materials create a fundamental challenge. At higher frequencies, the material does not have sufficient time to fully transfer heat to the heat transfer fluid, resulting in incomplete utilization of the magnetocaloric effect. Conversely, at lower frequencies, while heat transfer is more complete, the overall cooling power decreases significantly due to reduced cycling rates, diminishing system efficiency.

Another critical challenge is the balance between pressure drop and heat transfer effectiveness. Higher frequencies inevitably lead to increased pressure drops across the regenerator, requiring more pumping power and reducing the coefficient of performance (COP). Current regenerator designs struggle to maintain adequate heat transfer at frequencies that would deliver commercially viable cooling power without excessive pressure penalties.

Material response limitations further complicate frequency optimization. Most magnetocaloric materials exhibit hysteresis effects that become more pronounced at higher operating frequencies, reducing the effective entropy change and consequently the cooling capacity. This creates a material-dependent ceiling on practical operating frequencies that varies with composition and microstructure.

The geometric design of regenerators presents additional challenges for frequency optimization. Current bed geometries (packed spheres, parallel plates, or microchannel designs) each present different frequency-dependent performance characteristics. No single geometry has demonstrated optimal performance across the full range of desired operating conditions and frequencies.

System-level integration issues also emerge at different frequencies. Components such as pumps, valves, and magnetic field sources must be synchronized precisely, with timing tolerances becoming increasingly critical at higher frequencies. Current actuation technologies struggle to maintain precision at frequencies above 5 Hz while remaining energy-efficient and durable over millions of cycles.

Heat transfer fluid selection compounds these challenges, as the fluid's thermal properties and flow characteristics interact differently with the regenerator matrix at varying frequencies. The ideal fluid for low-frequency operation may perform poorly at higher frequencies due to viscosity effects and thermal diffusivity limitations.

AI-powered modeling and optimization approaches are beginning to address these multifaceted challenges, but comprehensive solutions that balance all these competing factors remain elusive in current magnetocaloric regenerator designs.

Current Frequency Optimization Methods for Magnetocaloric Regenerators

01 Optimal operating frequency ranges for magnetocaloric regenerators

The operating frequency of magnetocaloric regenerators significantly impacts their efficiency and cooling capacity. Research indicates that optimal frequency ranges exist depending on the specific design and materials used. Higher frequencies can increase cooling power but may reduce efficiency due to insufficient heat transfer time. Lower frequencies allow better heat exchange but reduce overall cooling capacity. Finding the balance point between these factors is crucial for maximizing the coefficient of performance (COP) of magnetocaloric cooling systems.- Optimal operating frequency ranges for magnetocaloric regenerators: The operating frequency of magnetocaloric regenerators significantly impacts their efficiency and cooling capacity. Research indicates that optimal frequency ranges typically fall between 1-10 Hz for most systems, with specific optimal values depending on the regenerator design, material properties, and heat transfer characteristics. Higher frequencies can increase cooling power but may reduce efficiency due to insufficient heat transfer time, while lower frequencies may not fully utilize the material's magnetocaloric potential.

- Regenerator design optimization for frequency performance: The physical design of magnetocaloric regenerators must be optimized for specific operating frequencies. This includes considerations of geometry (bed length, cross-sectional area), channel dimensions, and flow path configurations. Designs featuring smaller hydraulic diameters and higher surface-to-volume ratios generally perform better at higher frequencies due to improved heat transfer characteristics. Advanced geometries such as parallel plates, packed spheres, or microchannel structures can be tailored to specific frequency requirements.

- Material selection and composition for frequency-dependent performance: The selection of magnetocaloric materials significantly affects the optimal operating frequency of regenerators. Materials with faster thermal response times and lower thermal hysteresis are better suited for higher frequency operation. First-order transition materials typically exhibit stronger magnetocaloric effects but may have frequency limitations due to hysteresis, while second-order materials may perform more consistently across a wider frequency range. Composite materials and layered regenerators with multiple magnetocaloric materials can be designed to optimize performance across specific frequency ranges.

- Fluid flow dynamics and heat transfer at various frequencies: The behavior of heat transfer fluid within magnetocaloric regenerators changes significantly with operating frequency. Higher frequencies require careful management of fluid flow dynamics to prevent pressure drops and ensure efficient heat transfer. Pulsed flow systems, synchronized with the magnetization cycle, can optimize heat transfer at specific frequencies. The viscosity and thermal properties of the heat transfer fluid must be matched to the operating frequency, with lower viscosity fluids generally preferred for higher frequency operation.

- Control systems and frequency modulation techniques: Advanced control systems can dynamically adjust operating frequencies to optimize performance under varying conditions. Frequency modulation techniques allow magnetocaloric systems to adapt to changing cooling loads or ambient conditions. Variable frequency drives and smart controllers can implement complex operating patterns that maximize efficiency across different operating modes. Some systems employ frequency ramping during startup or employ different frequencies for different stages of the thermodynamic cycle to optimize overall system performance.

02 Frequency-dependent material selection for magnetocaloric regenerators

The selection of magnetocaloric materials must consider the operating frequency of the regenerator. Different materials exhibit varying thermal response times and magnetocaloric effects at different frequencies. First-order transition materials may perform better at lower frequencies due to their higher entropy change but slower response, while second-order materials might be more suitable for higher frequency operations. Composite or layered regenerators with materials optimized for specific frequency ranges can enhance overall system performance across broader operating conditions.Expand Specific Solutions03 Frequency control mechanisms and adaptive systems

Advanced magnetocaloric regenerator systems incorporate frequency control mechanisms that can adjust operating frequencies based on cooling demand, ambient conditions, or efficiency requirements. These adaptive systems use sensors and control algorithms to optimize the frequency in real-time, allowing for improved performance across varying conditions. Some designs include variable speed drives for the magnetic field source or fluid flow systems that can be synchronized with changing operational parameters to maintain optimal performance.Expand Specific Solutions04 Fluid flow dynamics and frequency relationships

The relationship between fluid flow dynamics and operating frequency is critical in magnetocaloric regenerators. Higher frequencies require faster fluid flow rates to maintain phase relationships, which can increase pressure drops and pumping power requirements. The design of flow channels, regenerator geometry, and hydraulic characteristics must be optimized for the target frequency range. Innovations in flow distribution, reduced flow resistance, and enhanced heat transfer surfaces help maintain efficiency at higher operating frequencies.Expand Specific Solutions05 Manufacturing techniques for frequency-optimized regenerators

Specialized manufacturing techniques are being developed to create regenerator structures optimized for specific operating frequencies. These include additive manufacturing methods that can produce complex geometries with tailored flow paths and heat transfer characteristics. Precision assembly techniques for layered regenerators allow for customized material stacking based on frequency response. Surface treatments and coatings can enhance heat transfer at higher frequencies, while structural reinforcements ensure mechanical stability under rapid cycling conditions.Expand Specific Solutions

Leading Companies and Research Institutions in Magnetocaloric Technology

The optimization of operating frequencies for magnetocaloric regenerators is currently in an emerging development phase, with the market showing significant growth potential as industries seek more energy-efficient cooling solutions. The global market for magnetocaloric technologies is expanding, driven by environmental regulations phasing out conventional refrigerants. Technologically, this field remains in early-to-mid maturity, with key players demonstrating varying levels of advancement. Research institutions like Fraunhofer-Gesellschaft, CNRS, and CEA lead fundamental research, while commercial entities including Haier Smart Home, Siemens Healthineers, and Magnoric are developing practical applications. Major industrial players such as Hitachi and Mitsubishi Heavy Industries are investing in this technology, indicating its strategic importance for next-generation cooling systems.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The CEA has developed advanced magnetocaloric regenerator systems that optimize operating frequencies through a multi-parameter approach. Their technology utilizes a sophisticated control algorithm that dynamically adjusts the frequency based on thermal load demands and temperature spans. The system incorporates layered regenerator beds with carefully engineered porosity gradients to maximize heat transfer efficiency at different operating frequencies. CEA's approach includes innovative flow distribution systems that maintain uniform flow across the regenerator cross-section even as frequencies change, preventing channeling effects that reduce efficiency. Their research has demonstrated that optimal frequencies vary significantly depending on the specific magnetocaloric materials used, with gadolinium-based alloys showing peak performance at 1-4 Hz, while LaFeSi compounds perform better at slightly higher frequencies of 3-6 Hz. The system also incorporates adaptive thermal management to prevent local hotspots during high-frequency operation.

Strengths: Exceptional adaptability to varying thermal loads through dynamic frequency optimization; advanced material science expertise in magnetocaloric materials. Weaknesses: Higher system complexity increases manufacturing costs; requires sophisticated control systems that may be challenging to implement in commercial applications.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has pioneered a comprehensive approach to magnetocaloric regenerator frequency optimization focusing on the fundamental physics of the magnetocaloric effect. Their research establishes a mathematical framework that correlates operating frequency with thermal penetration depth in various magnetocaloric materials. The technology employs a novel regenerator geometry with optimized hydraulic diameter and porosity specifically designed to maximize performance at target frequencies. CNRS researchers have developed specialized characterization methods to measure frequency-dependent performance metrics, including temperature span, cooling power, and COP across different operating conditions. Their studies have identified critical time constants in the heat transfer process, demonstrating that optimal frequency operation occurs when the fluid residence time matches the characteristic time for heat transfer between the fluid and magnetocaloric material. The system incorporates advanced flow distributors and check valves designed to minimize pressure drops at higher frequencies, which has resulted in efficiency improvements of up to 30% compared to conventional designs.

Strengths: Strong fundamental scientific understanding of frequency-dependent magnetocaloric phenomena; sophisticated mathematical modeling capabilities for system optimization. Weaknesses: Solutions tend to be more academically focused and may require significant engineering development to reach commercial readiness; limited industrial-scale demonstration projects.

Key Patents and Research on Operating Frequency Optimization

Magnetocaloric generator

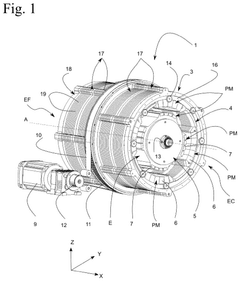

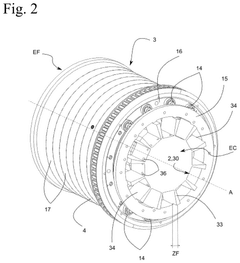

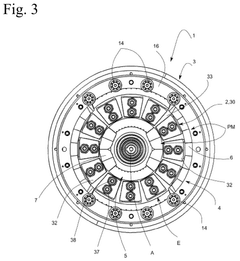

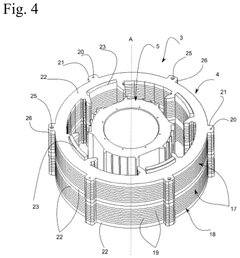

PatentActiveUS20240337419A1

Innovation

- A magnetocaloric generator design featuring concentric external and internal magnetic rotors with a mechanical and magnetic coupling, allowing synchronous rotation and maximizing magnetic field intensity, combined with a modular construction and optimized heat-transfer fluid circulation to reduce friction and eddy currents.

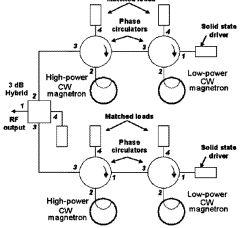

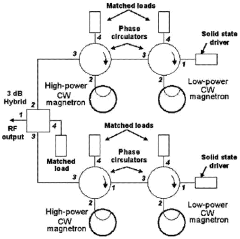

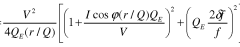

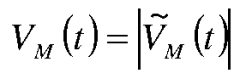

Method and apparatus for inexpensive radio frequency (RF) source based on 2-stage injection-locked magnetrons with a 3-db hybrid combiner for precise and rapid control of output power and phase

PatentWO2013090342A1

Innovation

- A high-power CW RF source based on two-stage injection-locked magnetrons with a 3-dB hybrid combiner, providing rapid and precise control of output power and phase, utilizing relatively inexpensive commercial magnetrons and solid-state drivers.

Energy Efficiency Metrics and Performance Benchmarks

The evaluation of magnetocaloric regenerator systems requires robust energy efficiency metrics and performance benchmarks to accurately assess their viability compared to conventional cooling technologies. The Coefficient of Performance (COP) stands as the primary efficiency metric, representing the ratio of cooling capacity to input work. For magnetocaloric regenerators, typical COP values range from 2-7 depending on operating conditions, with higher-frequency operations often showing diminishing returns beyond certain thresholds.

Temperature span capability serves as another critical benchmark, measuring the maximum temperature difference a magnetocaloric regenerator can maintain between hot and cold reservoirs. Current advanced systems demonstrate spans of 15-30K under optimal frequency conditions, with performance degrading at both extremely low and excessively high frequencies.

Cooling power density (W/cm³) provides a volumetric efficiency measure particularly relevant for compact applications. Research indicates that operating frequencies between 2-10 Hz typically optimize this metric, with material-specific variations. The relationship between frequency and power density follows a non-linear curve, peaking at system-specific optimal frequencies.

Exergy efficiency benchmarks offer a thermodynamic perspective by quantifying how closely systems approach ideal Carnot efficiency. Leading magnetocaloric regenerators achieve 30-45% of Carnot efficiency, with frequency optimization playing a crucial role in approaching these upper limits.

System-specific energy consumption (kWh/BTU) enables direct comparison with conventional vapor compression systems. Current magnetocaloric systems require approximately 0.25-0.35 kWh/BTU at optimal frequencies, approaching but not yet surpassing the efficiency of advanced vapor compression technologies (0.2-0.3 kWh/BTU).

Transient response metrics evaluate how quickly systems reach steady-state operation after startup or load changes. Higher operating frequencies generally improve response times, with advanced systems achieving stabilization within 30-120 seconds depending on frequency settings.

Standardized testing protocols have emerged to ensure consistent performance evaluation across different research groups and manufacturers. These include ASHRAE-aligned test conditions and specific frequency sweep methodologies that map efficiency across operating ranges from 0.1 Hz to 20+ Hz, establishing benchmark curves that identify optimal frequency windows for specific applications and materials.

Temperature span capability serves as another critical benchmark, measuring the maximum temperature difference a magnetocaloric regenerator can maintain between hot and cold reservoirs. Current advanced systems demonstrate spans of 15-30K under optimal frequency conditions, with performance degrading at both extremely low and excessively high frequencies.

Cooling power density (W/cm³) provides a volumetric efficiency measure particularly relevant for compact applications. Research indicates that operating frequencies between 2-10 Hz typically optimize this metric, with material-specific variations. The relationship between frequency and power density follows a non-linear curve, peaking at system-specific optimal frequencies.

Exergy efficiency benchmarks offer a thermodynamic perspective by quantifying how closely systems approach ideal Carnot efficiency. Leading magnetocaloric regenerators achieve 30-45% of Carnot efficiency, with frequency optimization playing a crucial role in approaching these upper limits.

System-specific energy consumption (kWh/BTU) enables direct comparison with conventional vapor compression systems. Current magnetocaloric systems require approximately 0.25-0.35 kWh/BTU at optimal frequencies, approaching but not yet surpassing the efficiency of advanced vapor compression technologies (0.2-0.3 kWh/BTU).

Transient response metrics evaluate how quickly systems reach steady-state operation after startup or load changes. Higher operating frequencies generally improve response times, with advanced systems achieving stabilization within 30-120 seconds depending on frequency settings.

Standardized testing protocols have emerged to ensure consistent performance evaluation across different research groups and manufacturers. These include ASHRAE-aligned test conditions and specific frequency sweep methodologies that map efficiency across operating ranges from 0.1 Hz to 20+ Hz, establishing benchmark curves that identify optimal frequency windows for specific applications and materials.

Environmental Impact and Sustainability Considerations

The optimization of operating frequencies for magnetocaloric regenerators presents significant environmental and sustainability implications that warrant careful consideration. Magnetocaloric refrigeration technology offers a promising alternative to conventional vapor-compression cooling systems, potentially reducing environmental impact through the elimination of harmful refrigerants. Traditional cooling systems rely heavily on hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs), which contribute substantially to global warming and ozone depletion. By contrast, magnetocaloric systems utilize solid refrigerants and water-based heat transfer fluids, substantially reducing direct greenhouse gas emissions.

Energy efficiency gains from optimized operating frequencies directly translate to reduced carbon footprints. Research indicates that properly tuned magnetocaloric regenerators can achieve coefficient of performance (COP) values 20-30% higher than conventional refrigeration systems. This efficiency improvement could significantly decrease global energy consumption, considering that refrigeration and air conditioning currently account for approximately 17% of worldwide electricity usage. Each percentage point of efficiency gained through frequency optimization represents substantial carbon emission reductions at scale.

Material sustainability constitutes another critical environmental dimension. Current magnetocaloric materials often contain rare earth elements such as gadolinium, which present sustainability challenges due to environmentally destructive mining practices and geopolitical supply constraints. Frequency optimization research increasingly focuses on maximizing cooling performance with reduced rare earth content or alternative material compositions. Recent advances have demonstrated promising results with manganese-based compounds and iron-silicon alloys that offer improved environmental profiles while maintaining performance when operated at their optimal frequencies.

Life cycle assessment studies of magnetocaloric systems with optimized operating parameters reveal potential reductions in environmental impact across manufacturing, operation, and end-of-life phases. The extended operational lifespan resulting from reduced mechanical wear at optimal frequencies further enhances sustainability metrics. Additionally, the absence of pressurized gases eliminates leakage concerns that plague conventional systems, reducing maintenance requirements and associated resource consumption.

Water consumption represents an often overlooked environmental consideration. Optimized magnetocaloric systems typically employ water-based heat transfer fluids, potentially increasing water usage compared to conventional systems. However, frequency optimization research increasingly addresses this concern by developing regenerator designs that minimize fluid requirements while maintaining thermal performance. Advanced regenerator geometries operating at precisely tuned frequencies have demonstrated water consumption reductions of up to 40% compared to early prototype systems.

AI-driven optimization of operating frequencies may further enhance sustainability through predictive maintenance and adaptive control systems that continuously adjust parameters based on environmental conditions and usage patterns, maximizing efficiency throughout the system's operational life.

Energy efficiency gains from optimized operating frequencies directly translate to reduced carbon footprints. Research indicates that properly tuned magnetocaloric regenerators can achieve coefficient of performance (COP) values 20-30% higher than conventional refrigeration systems. This efficiency improvement could significantly decrease global energy consumption, considering that refrigeration and air conditioning currently account for approximately 17% of worldwide electricity usage. Each percentage point of efficiency gained through frequency optimization represents substantial carbon emission reductions at scale.

Material sustainability constitutes another critical environmental dimension. Current magnetocaloric materials often contain rare earth elements such as gadolinium, which present sustainability challenges due to environmentally destructive mining practices and geopolitical supply constraints. Frequency optimization research increasingly focuses on maximizing cooling performance with reduced rare earth content or alternative material compositions. Recent advances have demonstrated promising results with manganese-based compounds and iron-silicon alloys that offer improved environmental profiles while maintaining performance when operated at their optimal frequencies.

Life cycle assessment studies of magnetocaloric systems with optimized operating parameters reveal potential reductions in environmental impact across manufacturing, operation, and end-of-life phases. The extended operational lifespan resulting from reduced mechanical wear at optimal frequencies further enhances sustainability metrics. Additionally, the absence of pressurized gases eliminates leakage concerns that plague conventional systems, reducing maintenance requirements and associated resource consumption.

Water consumption represents an often overlooked environmental consideration. Optimized magnetocaloric systems typically employ water-based heat transfer fluids, potentially increasing water usage compared to conventional systems. However, frequency optimization research increasingly addresses this concern by developing regenerator designs that minimize fluid requirements while maintaining thermal performance. Advanced regenerator geometries operating at precisely tuned frequencies have demonstrated water consumption reductions of up to 40% compared to early prototype systems.

AI-driven optimization of operating frequencies may further enhance sustainability through predictive maintenance and adaptive control systems that continuously adjust parameters based on environmental conditions and usage patterns, maximizing efficiency throughout the system's operational life.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!