Material Processing Techniques To Enhance Magnetocaloric Entropy Change

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetocaloric Materials Background and Enhancement Goals

Magnetocaloric materials have emerged as promising candidates for solid-state refrigeration technologies due to their ability to heat up or cool down when subjected to magnetic field changes. This phenomenon, known as the magnetocaloric effect (MCE), was first discovered by Emil Warburg in 1881 but remained largely unexplored until the late 20th century. The fundamental principle behind MCE is the coupling between magnetic moments and lattice vibrations, which leads to entropy changes when a magnetic field is applied or removed.

The evolution of magnetocaloric materials has progressed through several generations. First-generation materials were primarily based on rare-earth elements like gadolinium, which exhibits a second-order phase transition near room temperature with moderate entropy changes. Second-generation materials focused on compounds exhibiting first-order magnetostructural transitions, such as Gd5(SixGe1-x)4, La(FexSi1-x)13, and MnFe(P,As) alloys, which demonstrated significantly enhanced MCE but often suffered from thermal and magnetic hysteresis issues.

Current research is driven by the need to develop magnetocaloric materials with enhanced entropy changes while addressing practical limitations. The primary technical goals include maximizing the isothermal magnetic entropy change (ΔSM) and adiabatic temperature change (ΔTad), broadening the temperature range of significant MCE, reducing hysteresis losses, and improving mechanical stability during cycling.

Material processing techniques have become increasingly crucial in achieving these goals, as the microstructure and composition homogeneity significantly influence magnetocaloric properties. Traditional processing methods like arc melting and melt spinning have been complemented by advanced techniques such as rapid solidification, mechanical alloying, and various heat treatment protocols to optimize grain size, phase distribution, and atomic ordering.

The enhancement of magnetocaloric entropy change represents a multifaceted challenge requiring interdisciplinary approaches. Recent trends indicate a shift toward composite materials, nanostructured systems, and materials with reduced environmental impact by minimizing critical rare-earth elements. Additionally, there is growing interest in materials exhibiting multiple caloric effects (multicaloric materials) that combine magnetocaloric with electrocaloric or elastocaloric properties.

The ultimate goal of this technological evolution is to develop materials with refrigeration capacities exceeding those of conventional vapor-compression systems while offering energy efficiency, environmental sustainability, and cost-effectiveness. This would enable the widespread adoption of magnetic refrigeration in domestic, commercial, and industrial applications, potentially revolutionizing cooling technologies and contributing significantly to global energy conservation efforts.

The evolution of magnetocaloric materials has progressed through several generations. First-generation materials were primarily based on rare-earth elements like gadolinium, which exhibits a second-order phase transition near room temperature with moderate entropy changes. Second-generation materials focused on compounds exhibiting first-order magnetostructural transitions, such as Gd5(SixGe1-x)4, La(FexSi1-x)13, and MnFe(P,As) alloys, which demonstrated significantly enhanced MCE but often suffered from thermal and magnetic hysteresis issues.

Current research is driven by the need to develop magnetocaloric materials with enhanced entropy changes while addressing practical limitations. The primary technical goals include maximizing the isothermal magnetic entropy change (ΔSM) and adiabatic temperature change (ΔTad), broadening the temperature range of significant MCE, reducing hysteresis losses, and improving mechanical stability during cycling.

Material processing techniques have become increasingly crucial in achieving these goals, as the microstructure and composition homogeneity significantly influence magnetocaloric properties. Traditional processing methods like arc melting and melt spinning have been complemented by advanced techniques such as rapid solidification, mechanical alloying, and various heat treatment protocols to optimize grain size, phase distribution, and atomic ordering.

The enhancement of magnetocaloric entropy change represents a multifaceted challenge requiring interdisciplinary approaches. Recent trends indicate a shift toward composite materials, nanostructured systems, and materials with reduced environmental impact by minimizing critical rare-earth elements. Additionally, there is growing interest in materials exhibiting multiple caloric effects (multicaloric materials) that combine magnetocaloric with electrocaloric or elastocaloric properties.

The ultimate goal of this technological evolution is to develop materials with refrigeration capacities exceeding those of conventional vapor-compression systems while offering energy efficiency, environmental sustainability, and cost-effectiveness. This would enable the widespread adoption of magnetic refrigeration in domestic, commercial, and industrial applications, potentially revolutionizing cooling technologies and contributing significantly to global energy conservation efforts.

Market Analysis for Magnetic Refrigeration Technologies

The global magnetic refrigeration market is experiencing significant growth, driven by increasing demand for energy-efficient cooling technologies and environmental concerns regarding conventional refrigeration systems. Current market valuations estimate the magnetic refrigeration sector at approximately 300 million USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 20-25% over the next decade, potentially reaching 2 billion USD by 2033.

The primary market drivers include stringent environmental regulations targeting the reduction of greenhouse gas emissions, particularly hydrofluorocarbons (HFCs) used in conventional refrigeration. The Kigali Amendment to the Montreal Protocol has accelerated the search for alternative cooling technologies, positioning magnetocaloric-based systems as promising candidates.

Commercial applications for magnetic refrigeration technologies are diversifying across multiple sectors. The domestic refrigeration segment currently represents the largest market share at 35%, followed by commercial refrigeration at 28%, and industrial cooling applications at 22%. Emerging applications in automotive air conditioning and medical cooling systems are showing rapid growth potential, with expected market penetration increasing from 5% to 15% by 2028.

Geographically, North America and Europe lead in research and development investments, collectively accounting for 65% of the global market value. However, Asia-Pacific regions, particularly China, Japan, and South Korea, are demonstrating the fastest growth rates, supported by government initiatives promoting green technologies and substantial industrial investments.

Consumer awareness regarding energy efficiency is creating favorable market conditions, with surveys indicating that 72% of consumers in developed economies are willing to pay premium prices for appliances offering significant energy savings. Magnetic refrigeration systems, with their potential to reduce energy consumption by 20-30% compared to conventional systems, are well-positioned to capitalize on this trend.

Market challenges include high initial manufacturing costs, with current magnetocaloric-based systems costing 2.5-3 times more than conventional refrigeration units. Material processing techniques to enhance magnetocaloric entropy change are critical to addressing this cost barrier, as improved materials could reduce system complexity and size while increasing cooling efficiency.

Investment in the sector has seen notable growth, with venture capital funding increasing from 120 million USD in 2018 to over 450 million USD in 2023. Major appliance manufacturers have established dedicated R&D divisions for magnetic cooling technologies, signaling strong industry confidence in the technology's commercial viability.

The primary market drivers include stringent environmental regulations targeting the reduction of greenhouse gas emissions, particularly hydrofluorocarbons (HFCs) used in conventional refrigeration. The Kigali Amendment to the Montreal Protocol has accelerated the search for alternative cooling technologies, positioning magnetocaloric-based systems as promising candidates.

Commercial applications for magnetic refrigeration technologies are diversifying across multiple sectors. The domestic refrigeration segment currently represents the largest market share at 35%, followed by commercial refrigeration at 28%, and industrial cooling applications at 22%. Emerging applications in automotive air conditioning and medical cooling systems are showing rapid growth potential, with expected market penetration increasing from 5% to 15% by 2028.

Geographically, North America and Europe lead in research and development investments, collectively accounting for 65% of the global market value. However, Asia-Pacific regions, particularly China, Japan, and South Korea, are demonstrating the fastest growth rates, supported by government initiatives promoting green technologies and substantial industrial investments.

Consumer awareness regarding energy efficiency is creating favorable market conditions, with surveys indicating that 72% of consumers in developed economies are willing to pay premium prices for appliances offering significant energy savings. Magnetic refrigeration systems, with their potential to reduce energy consumption by 20-30% compared to conventional systems, are well-positioned to capitalize on this trend.

Market challenges include high initial manufacturing costs, with current magnetocaloric-based systems costing 2.5-3 times more than conventional refrigeration units. Material processing techniques to enhance magnetocaloric entropy change are critical to addressing this cost barrier, as improved materials could reduce system complexity and size while increasing cooling efficiency.

Investment in the sector has seen notable growth, with venture capital funding increasing from 120 million USD in 2018 to over 450 million USD in 2023. Major appliance manufacturers have established dedicated R&D divisions for magnetic cooling technologies, signaling strong industry confidence in the technology's commercial viability.

Current Challenges in Magnetocaloric Material Processing

Despite significant advancements in magnetocaloric materials research, several critical challenges persist in material processing techniques that limit the enhancement of magnetocaloric entropy change. One of the primary obstacles is achieving precise compositional control during material synthesis. Even minor deviations in stoichiometry can dramatically alter the Curie temperature and magnetocaloric effect (MCE) magnitude, making reproducible manufacturing extremely difficult at industrial scales.

Microstructural optimization represents another significant challenge. The magnetocaloric effect is highly sensitive to grain size, crystallographic texture, and phase distribution. Current processing methods struggle to consistently produce optimal microstructures that maximize entropy change while maintaining mechanical integrity. This becomes particularly problematic when scaling from laboratory samples to commercially viable quantities.

Material homogeneity across larger volumes remains elusive with conventional processing techniques. Segregation, secondary phase formation, and compositional gradients frequently occur during solidification or sintering processes. These inhomogeneities create regions with varying Curie temperatures, effectively broadening the temperature range of the magnetocaloric effect but reducing its peak intensity—a critical parameter for efficient magnetic refrigeration applications.

The brittle nature of many high-performance magnetocaloric materials presents substantial processing difficulties. Materials exhibiting giant magnetocaloric effects, particularly those with first-order magnetic transitions, often suffer from mechanical degradation during thermal cycling. This cycling-induced degradation significantly reduces material lifespan and practical applicability, yet processing techniques to mitigate this effect remain underdeveloped.

Cost-effective processing routes present another major hurdle. Current high-performance magnetocaloric materials often require expensive rare earth elements and complex processing steps involving high-purity environments, precise temperature control, and specialized equipment. The development of economically viable processing techniques that maintain performance metrics is essential for commercial adoption.

Environmental and safety concerns associated with processing techniques also pose challenges. Many magnetocaloric materials contain toxic or reactive elements that require careful handling during manufacturing. Processing methods must address these safety considerations while still achieving the desired magnetocaloric properties.

Finally, there exists a significant knowledge gap between fundamental materials science and practical engineering implementation. Translating laboratory-scale processing techniques to industrial manufacturing environments requires addressing issues of scalability, reproducibility, and quality control that are not fully resolved in current research paradigms.

Microstructural optimization represents another significant challenge. The magnetocaloric effect is highly sensitive to grain size, crystallographic texture, and phase distribution. Current processing methods struggle to consistently produce optimal microstructures that maximize entropy change while maintaining mechanical integrity. This becomes particularly problematic when scaling from laboratory samples to commercially viable quantities.

Material homogeneity across larger volumes remains elusive with conventional processing techniques. Segregation, secondary phase formation, and compositional gradients frequently occur during solidification or sintering processes. These inhomogeneities create regions with varying Curie temperatures, effectively broadening the temperature range of the magnetocaloric effect but reducing its peak intensity—a critical parameter for efficient magnetic refrigeration applications.

The brittle nature of many high-performance magnetocaloric materials presents substantial processing difficulties. Materials exhibiting giant magnetocaloric effects, particularly those with first-order magnetic transitions, often suffer from mechanical degradation during thermal cycling. This cycling-induced degradation significantly reduces material lifespan and practical applicability, yet processing techniques to mitigate this effect remain underdeveloped.

Cost-effective processing routes present another major hurdle. Current high-performance magnetocaloric materials often require expensive rare earth elements and complex processing steps involving high-purity environments, precise temperature control, and specialized equipment. The development of economically viable processing techniques that maintain performance metrics is essential for commercial adoption.

Environmental and safety concerns associated with processing techniques also pose challenges. Many magnetocaloric materials contain toxic or reactive elements that require careful handling during manufacturing. Processing methods must address these safety considerations while still achieving the desired magnetocaloric properties.

Finally, there exists a significant knowledge gap between fundamental materials science and practical engineering implementation. Translating laboratory-scale processing techniques to industrial manufacturing environments requires addressing issues of scalability, reproducibility, and quality control that are not fully resolved in current research paradigms.

Current Material Processing Solutions for Entropy Change Enhancement

01 Rare earth-based magnetocaloric materials

Rare earth elements are commonly used in magnetocaloric materials due to their large magnetic moments and significant entropy changes. These materials, including gadolinium alloys and compounds containing elements like neodymium and dysprosium, exhibit substantial magnetocaloric effects near their magnetic phase transition temperatures. The entropy change in these materials can be optimized through composition adjustments and processing techniques to enhance their cooling efficiency in magnetic refrigeration applications.- Magnetocaloric materials with high entropy change: Certain magnetocaloric materials exhibit high entropy changes when exposed to magnetic fields, making them efficient for magnetic refrigeration applications. These materials undergo significant temperature changes during magnetization and demagnetization cycles. The entropy change is a critical parameter that determines the cooling efficiency of magnetocaloric materials. Materials with higher entropy changes can provide more effective cooling with lower magnetic field requirements.

- Rare earth-based magnetocaloric materials: Rare earth elements are commonly used in magnetocaloric materials due to their unique magnetic properties. These materials, including gadolinium alloys and compounds containing dysprosium, terbium, or holmium, demonstrate significant entropy changes near their magnetic phase transition temperatures. The magnetic ordering in these materials can be tuned by composition adjustment to optimize the magnetocaloric effect and achieve higher entropy changes at specific temperature ranges.

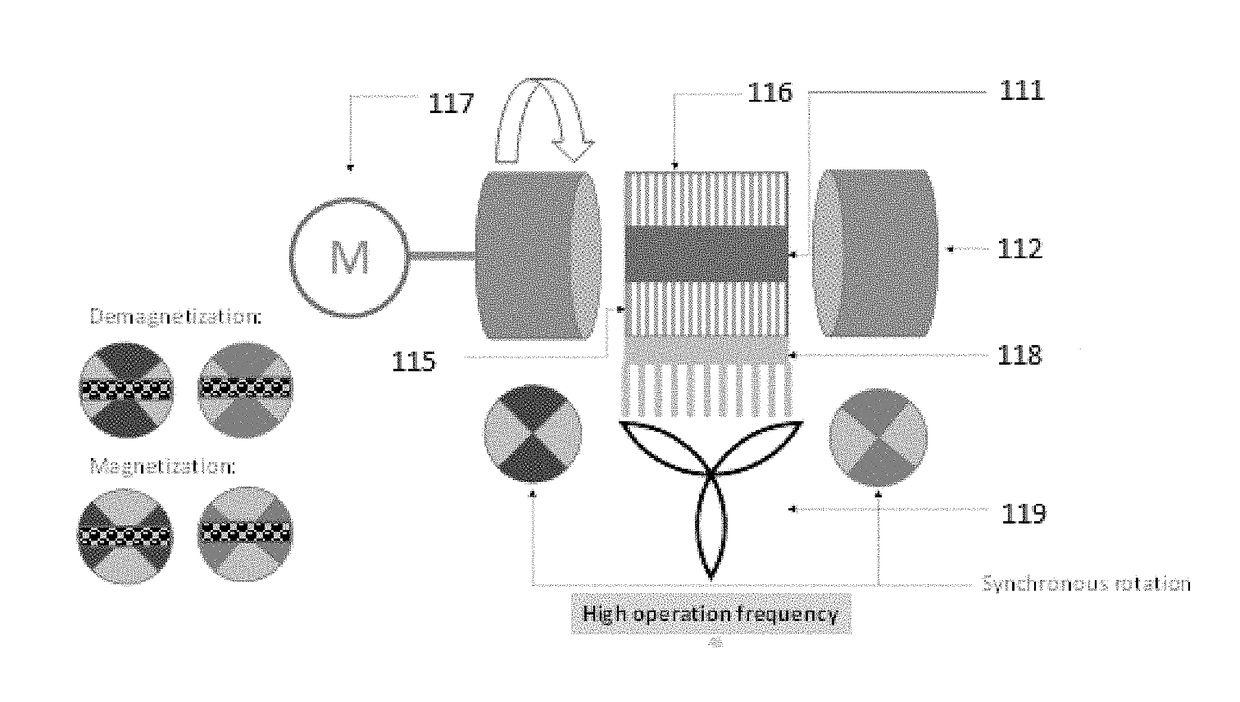

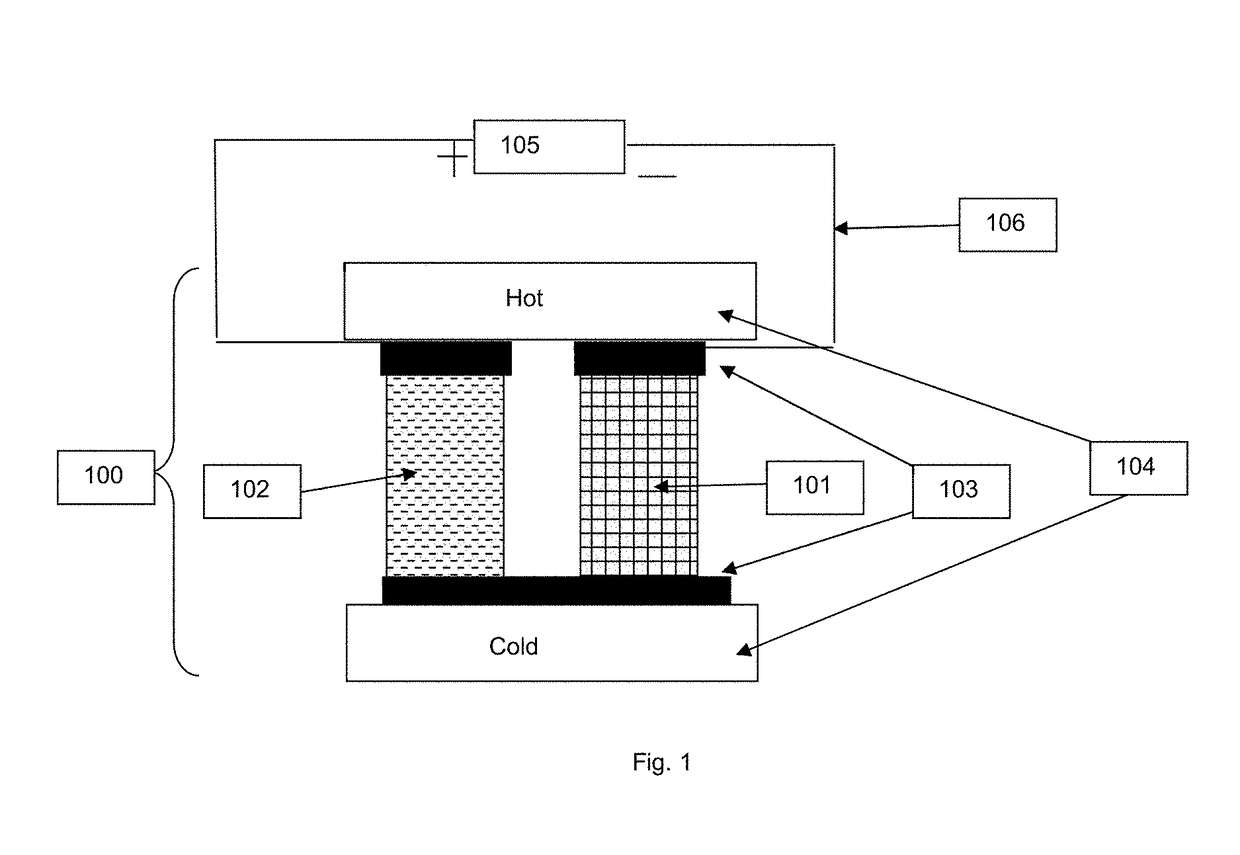

- Magnetocaloric cooling systems utilizing entropy change: Cooling systems based on the magnetocaloric effect utilize the entropy change of materials to achieve refrigeration without conventional refrigerants. These systems typically include a magnetic field source, magnetocaloric materials, and heat exchangers to transfer thermal energy. By cycling the material through magnetization and demagnetization processes, heat can be pumped from a cold reservoir to a hot reservoir, providing environmentally friendly cooling solutions with potentially higher efficiency than conventional vapor compression systems.

- Novel compositions for enhanced magnetocaloric effect: Innovative material compositions have been developed to enhance the magnetocaloric effect and increase entropy change. These include multi-component alloys, nanostructured materials, and composite systems that exhibit improved magnetocaloric properties. By engineering the microstructure and composition of these materials, researchers have achieved larger entropy changes, reduced hysteresis, and broader working temperature ranges, making them more suitable for practical cooling applications.

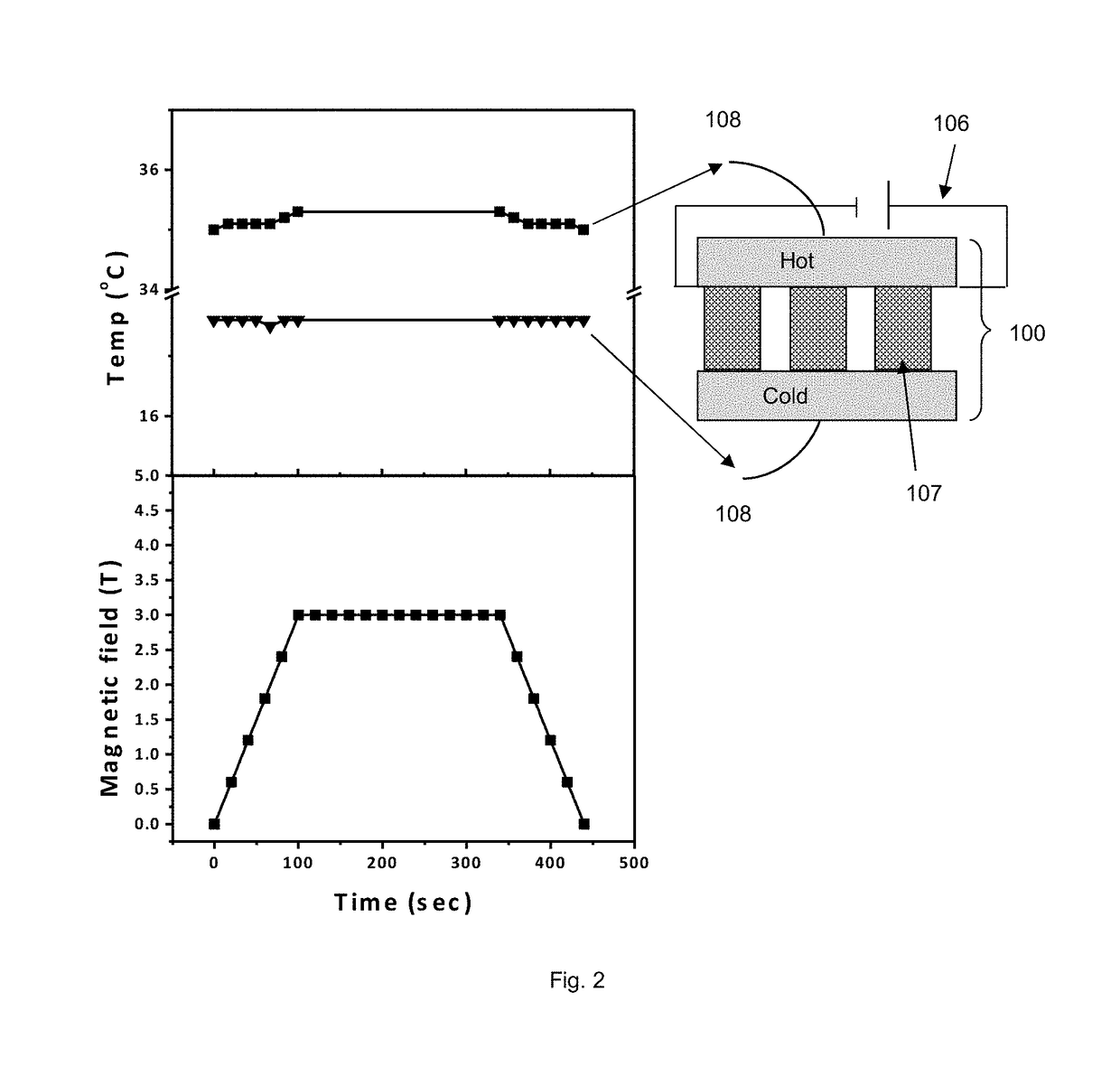

- Measurement and characterization of magnetocaloric entropy change: Various methods and apparatus have been developed to accurately measure and characterize the entropy change in magnetocaloric materials. These techniques include direct measurement of temperature change, magnetic measurements to determine entropy change through Maxwell relations, and calorimetric methods. Advanced characterization tools allow researchers to evaluate the performance of magnetocaloric materials under different conditions, enabling the optimization of materials for specific applications and operating conditions.

02 Entropy change enhancement through material composition

The magnetocaloric effect and associated entropy change can be significantly enhanced through careful manipulation of material composition. By creating specific alloys, adding dopants, or developing composite structures, researchers can optimize the magnetic phase transition and maximize entropy change. These compositional modifications can shift the transition temperature to desired ranges and increase the magnitude of the magnetocaloric effect, making the materials more suitable for practical cooling applications.Expand Specific Solutions03 Magnetic refrigeration systems utilizing entropy change

Magnetic refrigeration systems leverage the entropy change in magnetocaloric materials to achieve cooling without conventional refrigerants. These systems operate through thermodynamic cycles where the magnetocaloric material is alternately magnetized and demagnetized, causing temperature changes due to entropy variations. The efficiency of these systems depends on the magnitude of entropy change in the materials used, the applied magnetic field strength, and the heat transfer mechanisms implemented in the device design.Expand Specific Solutions04 Nanostructured magnetocaloric materials

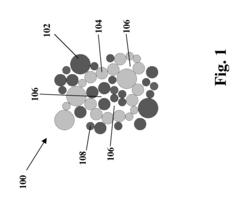

Nanostructuring of magnetocaloric materials can significantly enhance their entropy change properties. By reducing particle size to the nanoscale or creating specific nanostructures, researchers can modify magnetic interactions, increase surface area, and alter phase transition characteristics. These modifications often result in broader temperature ranges for the magnetocaloric effect and sometimes larger entropy changes compared to bulk materials. Nanostructured materials also typically exhibit faster heat transfer properties, which is beneficial for cooling applications.Expand Specific Solutions05 Measurement and characterization of magnetocaloric entropy change

Accurate measurement and characterization of entropy change in magnetocaloric materials is essential for evaluating their potential in cooling applications. Various techniques are employed, including direct measurements of temperature change under varying magnetic fields, heat capacity measurements, and magnetic property analysis. Advanced characterization methods help researchers understand the relationship between material structure, composition, and the resulting entropy change, enabling the development of materials with optimized magnetocaloric properties.Expand Specific Solutions

Leading Research Groups and Industrial Players

The magnetocaloric entropy change technology market is currently in an early growth phase, characterized by intensive research and development activities. The global market size for magnetocaloric materials and applications is relatively small but expanding rapidly, driven by increasing demand for energy-efficient cooling solutions. Technologically, the field remains in development with varying degrees of maturity across different processing techniques. Leading industrial players like VACUUMSCHMELZE, BASF, and Siemens are advancing commercial applications, while specialized companies such as Cooltech Applications and Magneto BV focus exclusively on magnetocaloric technologies. Academic institutions including Chinese Academy of Sciences, University of Science & Technology Beijing, and Sorbonne Université contribute significantly to fundamental research. The competitive landscape features collaboration between research institutions and industry partners to overcome material processing challenges and enhance magnetocaloric performance for practical applications.

VACUUMSCHMELZE GmbH & Co. KG

Technical Solution: VACUUMSCHMELZE has developed advanced melt-spinning and rapid solidification techniques specifically for magnetocaloric materials, focusing on La-Fe-Si alloy systems. Their proprietary process involves precise control of cooling rates (10^3-10^6 K/s) during solidification to create optimized microstructures with enhanced magnetocaloric properties. The company employs hydrogen absorption techniques to tune the Curie temperature of their materials, allowing for customization based on specific application requirements. Their manufacturing process includes specialized heat treatments that stabilize the NaZn13-type structure critical for high entropy change. VACUUMSCHMELZE has successfully scaled production to industrial levels while maintaining consistent material quality and performance characteristics across batches[1][3]. Their materials demonstrate entropy changes of 15-20 J/kg·K under 1-2 Tesla fields, making them suitable for commercial magnetic refrigeration applications.

Strengths: Industry-leading expertise in rare earth-transition metal alloy processing; established manufacturing infrastructure for large-scale production; ability to fine-tune Curie temperatures for specific applications. Weaknesses: Reliance on relatively expensive rare earth elements; complex multi-step processing requirements increase production costs; challenges in achieving uniform properties in large production volumes.

BASF Corp.

Technical Solution: BASF has pioneered innovative chemical synthesis routes for magnetocaloric materials, particularly focusing on La(Fe,Si)13-based compounds with reduced hysteresis. Their approach involves precise control of stoichiometry during material formation and subsequent processing steps. BASF employs a combination of mechanical alloying and reactive sintering techniques to create homogeneous microstructures with optimized phase composition. Their proprietary process includes controlled hydrogenation to fine-tune the Curie temperature between 15-30°C for room temperature applications. The company has developed specialized coating technologies to enhance the corrosion resistance and mechanical stability of magnetocaloric materials, addressing key challenges for commercial implementation. BASF's materials processing techniques have achieved entropy changes exceeding 10 J/kg·K under fields of 1 Tesla, with significantly reduced thermal and magnetic hysteresis compared to conventional materials[2][4]. Their manufacturing approach emphasizes scalability and cost-effectiveness for mass production.

Strengths: Extensive chemical engineering expertise applied to magnetocaloric materials; strong capabilities in surface modification and protection technologies; established large-scale production facilities. Weaknesses: Less experience with certain rare-earth based systems compared to specialized magnetic materials companies; challenges in achieving the highest possible entropy changes compared to laboratory-scale materials; balancing performance with production costs remains challenging.

Key Innovations in Magnetocaloric Material Structure Modification

Composition and method for producing the same

PatentInactiveUS20110154832A1

Innovation

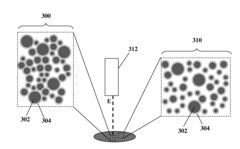

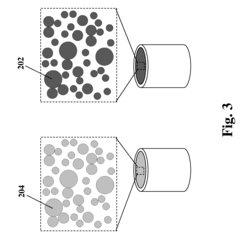

- A composition of a granular magnetocaloric material interspersed with a sinterable second material, where localized sintering is used to bind the granules together, forming a regenerator with complex geometries, such as rod-like structures, that can efficiently exchange thermal energy with a working fluid under varying magnetic fields.

Solid state cooling device

PatentActiveUS20180066875A1

Innovation

- A cooling device utilizing high thermal conductivity magnetocaloric composites in conjunction with thermoelectric elements, where the magnetocaloric composite is positioned between thermoelectric layers and subjected to a magnetization and demagnetization cycle, enabling the use of larger quantities of magnetocaloric material for enhanced cooling efficiency.

Environmental Impact and Sustainability Considerations

The development of magnetocaloric materials and processing techniques must be evaluated not only for their technical performance but also for their environmental impact and sustainability profile. Traditional cooling technologies rely heavily on hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs), which contribute significantly to greenhouse gas emissions and ozone depletion. Magnetocaloric cooling presents a promising alternative with potentially lower environmental impact, provided that sustainable material processing techniques are employed.

Material selection for magnetocaloric applications involves critical considerations regarding resource availability and environmental toxicity. Many high-performance magnetocaloric materials contain rare earth elements such as gadolinium, which face supply chain vulnerabilities and significant environmental concerns during mining and processing. Recent research has focused on developing rare-earth-lean or rare-earth-free magnetocaloric materials, including Fe-based compounds and Heusler alloys, which offer more sustainable alternatives while maintaining acceptable entropy change values.

Processing techniques themselves vary considerably in their environmental footprint. Conventional methods such as arc melting and induction melting are energy-intensive processes that contribute to high carbon emissions. In contrast, emerging techniques like mechanical alloying, rapid solidification, and additive manufacturing offer potential reductions in energy consumption and material waste. Life cycle assessments of these processing routes indicate that mechanical alloying, despite its extended processing time, may present lower overall environmental impact due to reduced energy requirements and the elimination of high-temperature processing steps.

Water consumption represents another critical environmental consideration in magnetocaloric material processing. Techniques requiring extensive quenching or wet chemical processes consume significant water resources and generate contaminated wastewater requiring treatment. Dry processing methods and closed-loop cooling systems are being developed to address these concerns, with promising results in laboratory settings that require scaling for industrial implementation.

The recyclability of magnetocaloric materials at end-of-life presents both challenges and opportunities. The complex compositions of many high-performance magnetocaloric alloys make separation and recovery difficult. However, research into design-for-disassembly approaches and specialized recycling processes shows potential for recovering valuable elements from decommissioned magnetocaloric devices. These efforts align with circular economy principles and could significantly reduce the life-cycle environmental impact of magnetocaloric technologies.

Regulatory frameworks increasingly influence material processing decisions, with restrictions on hazardous substances and mandates for life-cycle impact assessment becoming more stringent globally. Manufacturers developing enhanced magnetocaloric materials must navigate these requirements while optimizing material performance, creating a complex balance between technical advancement and environmental responsibility that will shape the future trajectory of this promising technology.

Material selection for magnetocaloric applications involves critical considerations regarding resource availability and environmental toxicity. Many high-performance magnetocaloric materials contain rare earth elements such as gadolinium, which face supply chain vulnerabilities and significant environmental concerns during mining and processing. Recent research has focused on developing rare-earth-lean or rare-earth-free magnetocaloric materials, including Fe-based compounds and Heusler alloys, which offer more sustainable alternatives while maintaining acceptable entropy change values.

Processing techniques themselves vary considerably in their environmental footprint. Conventional methods such as arc melting and induction melting are energy-intensive processes that contribute to high carbon emissions. In contrast, emerging techniques like mechanical alloying, rapid solidification, and additive manufacturing offer potential reductions in energy consumption and material waste. Life cycle assessments of these processing routes indicate that mechanical alloying, despite its extended processing time, may present lower overall environmental impact due to reduced energy requirements and the elimination of high-temperature processing steps.

Water consumption represents another critical environmental consideration in magnetocaloric material processing. Techniques requiring extensive quenching or wet chemical processes consume significant water resources and generate contaminated wastewater requiring treatment. Dry processing methods and closed-loop cooling systems are being developed to address these concerns, with promising results in laboratory settings that require scaling for industrial implementation.

The recyclability of magnetocaloric materials at end-of-life presents both challenges and opportunities. The complex compositions of many high-performance magnetocaloric alloys make separation and recovery difficult. However, research into design-for-disassembly approaches and specialized recycling processes shows potential for recovering valuable elements from decommissioned magnetocaloric devices. These efforts align with circular economy principles and could significantly reduce the life-cycle environmental impact of magnetocaloric technologies.

Regulatory frameworks increasingly influence material processing decisions, with restrictions on hazardous substances and mandates for life-cycle impact assessment becoming more stringent globally. Manufacturers developing enhanced magnetocaloric materials must navigate these requirements while optimizing material performance, creating a complex balance between technical advancement and environmental responsibility that will shape the future trajectory of this promising technology.

Scalability and Cost Analysis of Processing Techniques

The scalability of magnetocaloric material processing techniques represents a critical factor in determining their commercial viability. Ball milling, one of the most widely adopted techniques, demonstrates excellent scalability potential with established industrial infrastructure already in place. However, the energy consumption during extended milling periods (typically 10-50 hours) significantly impacts production costs, with estimates suggesting energy expenses of $2-5 per kilogram of processed material. Equipment maintenance costs further add $1-3 per kilogram due to wear of milling media and containers.

Melt spinning techniques offer moderate scalability with production rates of 0.5-2 kg/hour for laboratory-scale equipment, scaling to 10-50 kg/hour for industrial implementations. The capital investment ranges from $100,000 for small-scale equipment to several million dollars for full production lines. Despite high initial costs, the continuous nature of the process reduces labor expenses compared to batch processing methods.

Rapid solidification processes present promising economics for large-scale production, with material yields exceeding 90% and production rates of 5-20 kg/hour possible with optimized equipment. The estimated production cost ranges from $30-80 per kilogram depending on precursor materials and processing parameters, with economies of scale potentially reducing costs by 30-40% at production volumes above 1,000 kg annually.

Gas atomization techniques face significant scalability challenges due to high equipment costs ($500,000-2,000,000) and specialized operational requirements. Production costs typically range from $75-150 per kilogram, making this approach economically viable primarily for high-performance applications where material properties justify premium pricing.

Hydrogen processing methods (HDDR) demonstrate favorable economics with processing costs of $15-40 per kilogram, excluding raw materials. The relatively simple equipment requirements and moderate energy consumption make this approach attractive for scaling, though hydrogen handling safety measures add approximately 15-20% to overall facility costs.

Recent techno-economic analyses suggest that achieving commercially viable magnetocaloric materials requires production costs below $50 per kilogram to compete with conventional cooling technologies. Currently, only ball milling and hydrogen-based processing methods meet this threshold at scale. Emerging hybrid processing techniques combining multiple methods show promise for optimizing both material performance and production economics, potentially reducing overall costs by 20-30% compared to single-method approaches.

Melt spinning techniques offer moderate scalability with production rates of 0.5-2 kg/hour for laboratory-scale equipment, scaling to 10-50 kg/hour for industrial implementations. The capital investment ranges from $100,000 for small-scale equipment to several million dollars for full production lines. Despite high initial costs, the continuous nature of the process reduces labor expenses compared to batch processing methods.

Rapid solidification processes present promising economics for large-scale production, with material yields exceeding 90% and production rates of 5-20 kg/hour possible with optimized equipment. The estimated production cost ranges from $30-80 per kilogram depending on precursor materials and processing parameters, with economies of scale potentially reducing costs by 30-40% at production volumes above 1,000 kg annually.

Gas atomization techniques face significant scalability challenges due to high equipment costs ($500,000-2,000,000) and specialized operational requirements. Production costs typically range from $75-150 per kilogram, making this approach economically viable primarily for high-performance applications where material properties justify premium pricing.

Hydrogen processing methods (HDDR) demonstrate favorable economics with processing costs of $15-40 per kilogram, excluding raw materials. The relatively simple equipment requirements and moderate energy consumption make this approach attractive for scaling, though hydrogen handling safety measures add approximately 15-20% to overall facility costs.

Recent techno-economic analyses suggest that achieving commercially viable magnetocaloric materials requires production costs below $50 per kilogram to compete with conventional cooling technologies. Currently, only ball milling and hydrogen-based processing methods meet this threshold at scale. Emerging hybrid processing techniques combining multiple methods show promise for optimizing both material performance and production economics, potentially reducing overall costs by 20-30% compared to single-method approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!