Chiplet Applications in Cutting-Edge Control Interfaces

JUL 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Chiplet Tech Evolution

The evolution of chiplet technology in cutting-edge control interfaces represents a significant paradigm shift in semiconductor design and manufacturing. This approach, which involves breaking down complex systems into smaller, more manageable components, has gained traction due to its potential to overcome the limitations of traditional monolithic chip designs.

The chiplet concept emerged in the early 2010s as a response to the increasing challenges of scaling monolithic chips. As Moore's Law began to slow down, chipmakers sought alternative methods to improve performance and efficiency. The initial focus was on disaggregating large system-on-chip (SoC) designs into smaller, more specialized dies.

By 2015, the industry saw the first commercial applications of chiplets in high-performance computing. These early implementations demonstrated the feasibility of integrating multiple dies using advanced packaging technologies. The success of these initial efforts paved the way for broader adoption across various sectors, including control interfaces.

The period from 2016 to 2020 marked a crucial phase in chiplet technology development for control interfaces. During this time, researchers and engineers made significant strides in addressing key challenges such as inter-die communication, thermal management, and system integration. Advanced packaging technologies like 2.5D and 3D integration became more mature, enabling tighter coupling between chiplets.

From 2020 onwards, chiplet technology has seen accelerated adoption in cutting-edge control interfaces. This trend has been driven by the increasing demand for more sophisticated and efficient control systems in areas such as autonomous vehicles, industrial automation, and advanced robotics. The modular nature of chiplets allows for greater flexibility in designing control interfaces that can adapt to specific application requirements.

Recent developments have focused on standardizing chiplet interfaces and protocols to facilitate interoperability between different vendors' components. Initiatives like the Universal Chiplet Interconnect Express (UCIe) consortium aim to create an open ecosystem for chiplet-based designs, which is crucial for widespread adoption in control interface applications.

Looking ahead, the evolution of chiplet technology in control interfaces is expected to continue at a rapid pace. Future developments are likely to include more advanced 3D integration techniques, improved power management strategies, and the incorporation of artificial intelligence accelerators directly into chiplet-based control systems. These advancements will enable even more sophisticated and efficient control interfaces, pushing the boundaries of what is possible in fields like autonomous systems and smart manufacturing.

The chiplet concept emerged in the early 2010s as a response to the increasing challenges of scaling monolithic chips. As Moore's Law began to slow down, chipmakers sought alternative methods to improve performance and efficiency. The initial focus was on disaggregating large system-on-chip (SoC) designs into smaller, more specialized dies.

By 2015, the industry saw the first commercial applications of chiplets in high-performance computing. These early implementations demonstrated the feasibility of integrating multiple dies using advanced packaging technologies. The success of these initial efforts paved the way for broader adoption across various sectors, including control interfaces.

The period from 2016 to 2020 marked a crucial phase in chiplet technology development for control interfaces. During this time, researchers and engineers made significant strides in addressing key challenges such as inter-die communication, thermal management, and system integration. Advanced packaging technologies like 2.5D and 3D integration became more mature, enabling tighter coupling between chiplets.

From 2020 onwards, chiplet technology has seen accelerated adoption in cutting-edge control interfaces. This trend has been driven by the increasing demand for more sophisticated and efficient control systems in areas such as autonomous vehicles, industrial automation, and advanced robotics. The modular nature of chiplets allows for greater flexibility in designing control interfaces that can adapt to specific application requirements.

Recent developments have focused on standardizing chiplet interfaces and protocols to facilitate interoperability between different vendors' components. Initiatives like the Universal Chiplet Interconnect Express (UCIe) consortium aim to create an open ecosystem for chiplet-based designs, which is crucial for widespread adoption in control interface applications.

Looking ahead, the evolution of chiplet technology in control interfaces is expected to continue at a rapid pace. Future developments are likely to include more advanced 3D integration techniques, improved power management strategies, and the incorporation of artificial intelligence accelerators directly into chiplet-based control systems. These advancements will enable even more sophisticated and efficient control interfaces, pushing the boundaries of what is possible in fields like autonomous systems and smart manufacturing.

Market Demand Analysis

The market demand for Chiplet applications in cutting-edge control interfaces has been experiencing significant growth in recent years. This surge is primarily driven by the increasing complexity of modern electronic systems and the need for more efficient, scalable, and cost-effective solutions in various industries.

In the semiconductor industry, the demand for Chiplet-based control interfaces is particularly strong. As traditional monolithic chip designs reach their physical and economic limits, Chiplet technology offers a viable alternative for continued performance improvements and cost reduction. Major semiconductor companies are investing heavily in Chiplet-based solutions to meet the growing demand for high-performance computing, artificial intelligence, and data center applications.

The automotive sector represents another key market for Chiplet applications in control interfaces. As vehicles become more autonomous and connected, there is a growing need for advanced control systems that can handle complex sensor data and make real-time decisions. Chiplet-based solutions offer the flexibility and performance required for these next-generation automotive control interfaces.

In the industrial automation sector, the demand for Chiplet applications is driven by the need for more sophisticated control systems in smart factories and Industry 4.0 initiatives. Chiplet-based control interfaces can provide the necessary processing power and flexibility to manage complex manufacturing processes and enable real-time data analysis for improved efficiency and productivity.

The telecommunications industry is also showing increased interest in Chiplet applications for control interfaces, particularly in the context of 5G and future 6G networks. These advanced networks require high-performance, low-latency control systems that can manage complex network configurations and optimize data transmission. Chiplet technology offers a scalable solution to meet these demanding requirements.

Market analysts predict that the global market for Chiplet-based solutions, including applications in control interfaces, will grow at a compound annual growth rate (CAGR) of over 40% in the next five years. This rapid growth is expected to be fueled by advancements in Chiplet integration technologies, standardization efforts, and increasing adoption across various industries.

However, challenges remain in terms of interoperability, testing, and packaging technologies. Addressing these challenges will be crucial for realizing the full market potential of Chiplet applications in cutting-edge control interfaces. Industry collaborations and standardization efforts, such as those led by the Open Compute Project and CHIPS Alliance, are expected to play a significant role in overcoming these hurdles and driving further market growth.

In the semiconductor industry, the demand for Chiplet-based control interfaces is particularly strong. As traditional monolithic chip designs reach their physical and economic limits, Chiplet technology offers a viable alternative for continued performance improvements and cost reduction. Major semiconductor companies are investing heavily in Chiplet-based solutions to meet the growing demand for high-performance computing, artificial intelligence, and data center applications.

The automotive sector represents another key market for Chiplet applications in control interfaces. As vehicles become more autonomous and connected, there is a growing need for advanced control systems that can handle complex sensor data and make real-time decisions. Chiplet-based solutions offer the flexibility and performance required for these next-generation automotive control interfaces.

In the industrial automation sector, the demand for Chiplet applications is driven by the need for more sophisticated control systems in smart factories and Industry 4.0 initiatives. Chiplet-based control interfaces can provide the necessary processing power and flexibility to manage complex manufacturing processes and enable real-time data analysis for improved efficiency and productivity.

The telecommunications industry is also showing increased interest in Chiplet applications for control interfaces, particularly in the context of 5G and future 6G networks. These advanced networks require high-performance, low-latency control systems that can manage complex network configurations and optimize data transmission. Chiplet technology offers a scalable solution to meet these demanding requirements.

Market analysts predict that the global market for Chiplet-based solutions, including applications in control interfaces, will grow at a compound annual growth rate (CAGR) of over 40% in the next five years. This rapid growth is expected to be fueled by advancements in Chiplet integration technologies, standardization efforts, and increasing adoption across various industries.

However, challenges remain in terms of interoperability, testing, and packaging technologies. Addressing these challenges will be crucial for realizing the full market potential of Chiplet applications in cutting-edge control interfaces. Industry collaborations and standardization efforts, such as those led by the Open Compute Project and CHIPS Alliance, are expected to play a significant role in overcoming these hurdles and driving further market growth.

Chiplet Challenges

The adoption of chiplet technology in cutting-edge control interfaces presents several significant challenges that need to be addressed for successful implementation. One of the primary obstacles is the integration complexity associated with combining multiple chiplets into a single package. This requires advanced packaging technologies and precise interconnect solutions to ensure seamless communication between different chiplets.

Thermal management poses another critical challenge in chiplet-based control interfaces. As multiple chiplets are packed closely together, heat dissipation becomes a crucial concern. Efficient cooling solutions and thermal design considerations are necessary to maintain optimal performance and reliability of the control interface system.

Signal integrity and power delivery are additional hurdles that engineers must overcome when implementing chiplet technology in control interfaces. The high-speed communication between chiplets and the need for low-latency data transfer demand sophisticated signal routing and power distribution networks. Ensuring clean signal transmission and stable power supply across the chiplet-based system is essential for maintaining the accuracy and responsiveness of control interfaces.

Standardization and interoperability present ongoing challenges in the chiplet ecosystem. The lack of universal standards for chiplet interfaces and protocols can hinder the widespread adoption of this technology in control interface applications. Efforts to establish industry-wide standards and promote interoperability between chiplets from different manufacturers are crucial for the long-term success of chiplet-based solutions.

Testing and validation of chiplet-based control interfaces introduce new complexities in the development process. Traditional testing methodologies may not be sufficient to address the unique characteristics of chiplet architectures. Developing comprehensive test strategies that can effectively verify the functionality and performance of individual chiplets, as well as the integrated system, is essential for ensuring the reliability of control interface solutions.

Cost considerations also play a significant role in the adoption of chiplet technology for control interfaces. While chiplets offer potential cost benefits through improved yield and flexibility, the initial investment in chiplet-specific design tools, manufacturing processes, and testing equipment can be substantial. Balancing the long-term advantages with the upfront costs remains a challenge for many organizations considering chiplet-based solutions.

Lastly, the design and optimization of chiplet-based control interfaces require new approaches and methodologies. Traditional monolithic design practices may not be directly applicable to chiplet architectures. Developing efficient design flows, optimization techniques, and simulation tools tailored for chiplet-based systems is crucial for maximizing the potential of this technology in control interface applications.

Thermal management poses another critical challenge in chiplet-based control interfaces. As multiple chiplets are packed closely together, heat dissipation becomes a crucial concern. Efficient cooling solutions and thermal design considerations are necessary to maintain optimal performance and reliability of the control interface system.

Signal integrity and power delivery are additional hurdles that engineers must overcome when implementing chiplet technology in control interfaces. The high-speed communication between chiplets and the need for low-latency data transfer demand sophisticated signal routing and power distribution networks. Ensuring clean signal transmission and stable power supply across the chiplet-based system is essential for maintaining the accuracy and responsiveness of control interfaces.

Standardization and interoperability present ongoing challenges in the chiplet ecosystem. The lack of universal standards for chiplet interfaces and protocols can hinder the widespread adoption of this technology in control interface applications. Efforts to establish industry-wide standards and promote interoperability between chiplets from different manufacturers are crucial for the long-term success of chiplet-based solutions.

Testing and validation of chiplet-based control interfaces introduce new complexities in the development process. Traditional testing methodologies may not be sufficient to address the unique characteristics of chiplet architectures. Developing comprehensive test strategies that can effectively verify the functionality and performance of individual chiplets, as well as the integrated system, is essential for ensuring the reliability of control interface solutions.

Cost considerations also play a significant role in the adoption of chiplet technology for control interfaces. While chiplets offer potential cost benefits through improved yield and flexibility, the initial investment in chiplet-specific design tools, manufacturing processes, and testing equipment can be substantial. Balancing the long-term advantages with the upfront costs remains a challenge for many organizations considering chiplet-based solutions.

Lastly, the design and optimization of chiplet-based control interfaces require new approaches and methodologies. Traditional monolithic design practices may not be directly applicable to chiplet architectures. Developing efficient design flows, optimization techniques, and simulation tools tailored for chiplet-based systems is crucial for maximizing the potential of this technology in control interface applications.

Current Chiplet Apps

01 Inter-chiplet communication interfaces

Chiplets utilize specialized control interfaces for communication between different chiplet components. These interfaces manage data transfer, synchronization, and coordination among chiplets, enabling efficient integration of multiple chiplets into a single system-on-chip (SoC) design.- Inter-chiplet communication protocols: Chiplets utilize specialized communication protocols for efficient data transfer between different components. These protocols are designed to handle high-speed, low-latency communication across the chiplet interfaces, ensuring seamless integration and optimal performance of the multi-chip system.

- Power management interfaces: Control interfaces for chiplets include power management systems that regulate voltage and current distribution across different components. These interfaces optimize power consumption, manage thermal constraints, and ensure efficient operation of the overall chiplet-based system.

- Reconfigurable interconnect fabrics: Chiplet control interfaces often incorporate reconfigurable interconnect fabrics that allow for flexible routing of signals between different chiplets. This adaptability enables dynamic optimization of system performance and functionality based on specific application requirements.

- Standardized chiplet interfaces: The development of standardized chiplet interfaces facilitates interoperability between chiplets from different manufacturers. These standardized interfaces define common protocols, signaling methods, and physical connections, enabling easier integration and broader adoption of chiplet technology across the industry.

- Testing and validation interfaces: Chiplet control interfaces include dedicated testing and validation mechanisms to ensure proper functionality and performance of individual chiplets and the overall system. These interfaces allow for in-situ testing, fault detection, and diagnostic capabilities, enhancing the reliability and manufacturability of chiplet-based designs.

02 Power management and control

Control interfaces in chiplet designs incorporate power management features to optimize energy consumption across different chiplets. These interfaces regulate voltage, clock gating, and power states, ensuring efficient operation and thermal management of the overall chiplet-based system.Expand Specific Solutions03 Standardized chiplet interfaces

Development of standardized control interfaces for chiplets to enhance interoperability and modularity. These standards define protocols, signaling, and physical connections, allowing chiplets from different manufacturers to be easily integrated and controlled within a single system.Expand Specific Solutions04 Reconfigurable control interfaces

Implementation of reconfigurable control interfaces in chiplet designs to adapt to varying system requirements. These interfaces allow dynamic adjustment of communication protocols, bandwidth allocation, and functionality, enhancing the flexibility and scalability of chiplet-based systems.Expand Specific Solutions05 Security features in chiplet interfaces

Integration of security mechanisms within chiplet control interfaces to protect against unauthorized access and data breaches. These features include encryption, authentication protocols, and secure boot processes, ensuring the integrity and confidentiality of inter-chiplet communications.Expand Specific Solutions

Key Industry Players

The chiplet applications in cutting-edge control interfaces market is in a growth phase, driven by increasing demand for modular and scalable semiconductor solutions. The global market size is projected to expand significantly in the coming years, fueled by advancements in heterogeneous integration technologies. In terms of technical maturity, industry leaders like Intel, AMD, and Xilinx are at the forefront, having already commercialized chiplet-based products. However, companies such as Micron, Samsung, and VIA Technologies are also making strides in chiplet development, indicating a competitive landscape with varying levels of technological readiness across players.

Micron Technology, Inc.

Technical Solution: Micron's approach to chiplet applications in cutting-edge control interfaces primarily focuses on advanced memory solutions. Their Hybrid Memory Cube (HMC) technology, while not strictly a chiplet design, demonstrates their capability in 3D stacking of memory dies with a logic layer, which is crucial for high-performance control systems[13]. For more direct chiplet applications, Micron is developing their 3D NAND technology, which stacks multiple memory layers vertically. This can be integrated with logic chiplets to create high-capacity, low-latency memory subsystems for complex control interfaces[14]. Micron is also exploring the use of through-silicon vias (TSVs) and microbumps for inter-chiplet connections, potentially enabling tighter integration of memory with processing elements in future control system designs[15].

Strengths: High-density memory integration, potential for significant bandwidth improvements in memory-intensive control systems. Weaknesses: Limited to memory-centric applications, may require partnerships for full system-on-chip solutions.

Intel Corp.

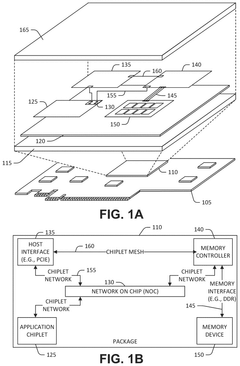

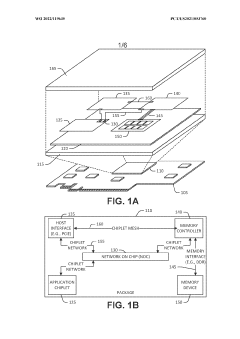

Technical Solution: Intel's approach to Chiplet applications in cutting-edge control interfaces focuses on their Foveros 3D packaging technology. This advanced packaging solution allows for the vertical stacking of multiple chiplets, enabling high-bandwidth connections between different functional blocks[1]. For control interfaces, Intel utilizes their EMIB (Embedded Multi-die Interconnect Bridge) technology, which provides high-speed, short-reach interconnects between chiplets[2]. This combination allows for modular chip design, where different functional units can be fabricated on separate dies and then integrated into a single package. Intel's Ponte Vecchio GPU, for instance, uses both Foveros and EMIB to interconnect multiple chiplets, demonstrating the technology's applicability in complex control systems[3].

Strengths: High integration density, improved performance, and power efficiency. Flexibility in mixing and matching different process nodes. Weaknesses: Increased complexity in thermal management and potential yield issues in 3D stacking.

Core Chiplet Patents

Edge interface placements to enable chiplet rotation into multi-chiplet cluster

PatentPendingUS20240332257A1

Innovation

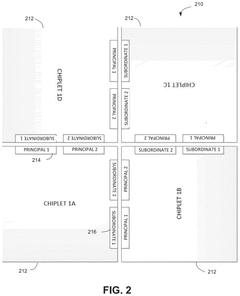

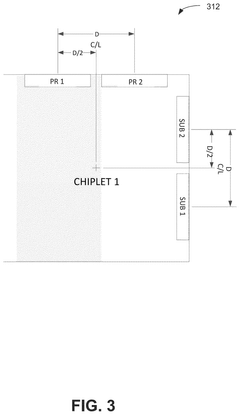

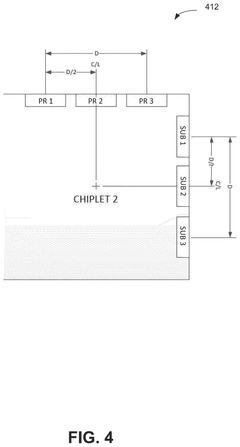

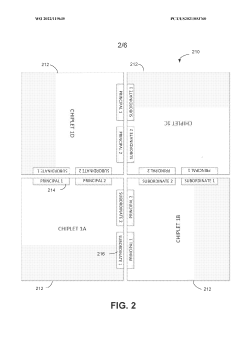

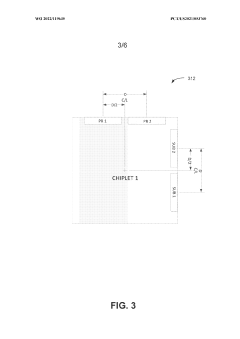

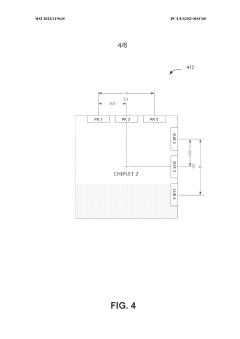

- The implementation of a chiplet architecture that uses a network-on-chip (NOC) with a chiplet protocol interface (CPI) to facilitate high-speed, flexible inter-chiplet communication, combined with a tightly packed matrix arrangement of chiplets and I/O micro-bumps for close-coupled interconnects, allowing for proper alignment and minimal footprint.

Edge interface placements to enable chiplet rotation into multi-chiplet cluster

PatentWO2022119635A2

Innovation

- The placement of I/O pads at the edges of chiplets in a symmetrical arrangement relative to the centerline, allowing for rotation to achieve proper alignment and close-coupled interconnects, thereby facilitating dense packaging and minimizing the system footprint.

Chiplet Standards

Chiplet standards play a crucial role in enabling the widespread adoption and interoperability of chiplet-based designs in cutting-edge control interfaces. These standards define the protocols, interfaces, and specifications that allow different chiplets to communicate and work together seamlessly within a single package.

One of the most prominent chiplet standards is the Universal Chiplet Interconnect Express (UCIe), which was introduced in 2022. UCIe provides a standardized die-to-die interconnect that enables high-bandwidth, low-latency communication between chiplets. This standard supports both package-level and die-level integration, allowing for flexible and scalable designs in control interface applications.

Another important standard is the Advanced Interface Bus (AIB), developed by Intel. AIB defines a high-speed, low-power interface for die-to-die communication, which is particularly useful for control interfaces that require rapid data exchange between different functional units.

The Open Compute Project (OCP) has also contributed to chiplet standardization efforts through its Open Domain-Specific Architecture (ODSA) subproject. The ODSA aims to create open standards for chiplet-based designs, including specifications for physical interfaces, protocols, and testing methodologies.

In the realm of control interfaces, the RISC-V instruction set architecture (ISA) has gained significant traction as a standard for chiplet-based designs. RISC-V's modular and extensible nature aligns well with the chiplet approach, allowing designers to create customized control interfaces by combining different RISC-V cores and accelerators.

The development of these standards has been driven by industry consortia and collaborations between major semiconductor companies. For instance, the UCIe standard is supported by a consortium that includes Intel, AMD, Arm, TSMC, and Samsung, among others. This collaborative approach ensures that the standards are widely adopted and meet the diverse needs of the industry.

As chiplet technology continues to evolve, these standards are expected to undergo further refinement and expansion. Future iterations may address challenges such as improved power management, enhanced security features, and support for emerging technologies like photonic interconnects. The ongoing development of chiplet standards will be crucial in enabling more sophisticated and efficient control interfaces in various applications, from automotive systems to industrial automation and beyond.

One of the most prominent chiplet standards is the Universal Chiplet Interconnect Express (UCIe), which was introduced in 2022. UCIe provides a standardized die-to-die interconnect that enables high-bandwidth, low-latency communication between chiplets. This standard supports both package-level and die-level integration, allowing for flexible and scalable designs in control interface applications.

Another important standard is the Advanced Interface Bus (AIB), developed by Intel. AIB defines a high-speed, low-power interface for die-to-die communication, which is particularly useful for control interfaces that require rapid data exchange between different functional units.

The Open Compute Project (OCP) has also contributed to chiplet standardization efforts through its Open Domain-Specific Architecture (ODSA) subproject. The ODSA aims to create open standards for chiplet-based designs, including specifications for physical interfaces, protocols, and testing methodologies.

In the realm of control interfaces, the RISC-V instruction set architecture (ISA) has gained significant traction as a standard for chiplet-based designs. RISC-V's modular and extensible nature aligns well with the chiplet approach, allowing designers to create customized control interfaces by combining different RISC-V cores and accelerators.

The development of these standards has been driven by industry consortia and collaborations between major semiconductor companies. For instance, the UCIe standard is supported by a consortium that includes Intel, AMD, Arm, TSMC, and Samsung, among others. This collaborative approach ensures that the standards are widely adopted and meet the diverse needs of the industry.

As chiplet technology continues to evolve, these standards are expected to undergo further refinement and expansion. Future iterations may address challenges such as improved power management, enhanced security features, and support for emerging technologies like photonic interconnects. The ongoing development of chiplet standards will be crucial in enabling more sophisticated and efficient control interfaces in various applications, from automotive systems to industrial automation and beyond.

Thermal Management

Thermal management is a critical aspect of chiplet applications in cutting-edge control interfaces. As chiplets become more prevalent in advanced computing systems, the challenge of managing heat dissipation becomes increasingly complex. The compact nature of chiplet designs, combined with the high-performance requirements of modern control interfaces, necessitates innovative approaches to thermal management.

One of the primary concerns in chiplet-based control interfaces is the concentration of heat-generating components in a small area. This localized heat generation can lead to thermal hotspots, potentially causing performance degradation or even system failure if not properly addressed. To mitigate these issues, designers are implementing advanced cooling solutions tailored specifically for chiplet architectures.

Liquid cooling has emerged as a promising technique for managing thermal loads in chiplet-based systems. By circulating a coolant directly over or through the chiplets, heat can be efficiently removed from the source. This approach allows for more uniform heat distribution and can handle higher thermal densities compared to traditional air cooling methods.

Another innovative solution is the use of thermal interface materials (TIMs) optimized for chiplet applications. These materials are designed to enhance heat transfer between the chiplets and the cooling system, reducing thermal resistance and improving overall cooling efficiency. Advanced TIMs, such as phase-change materials or metal-based composites, are being developed to meet the specific needs of chiplet architectures.

The integration of on-chip thermal sensors and dynamic thermal management techniques is also gaining traction in chiplet-based control interfaces. These sensors provide real-time temperature data, allowing the system to adjust performance parameters and cooling strategies dynamically. This adaptive approach ensures optimal thermal management while maintaining system performance and reliability.

Furthermore, the physical design of chiplets themselves is being optimized for improved thermal characteristics. This includes the strategic placement of high-power components, the use of thermally conductive materials in the chiplet substrate, and the implementation of thermal vias to facilitate heat dissipation. Some designs even incorporate dedicated thermal management layers within the chiplet stack.

As chiplet technology continues to evolve, researchers are exploring novel cooling concepts such as microfluidic cooling channels integrated directly into the chiplet package. These microscale cooling solutions promise even greater thermal management capabilities, potentially enabling higher performance and more compact designs in future control interface applications.

In conclusion, effective thermal management is essential for realizing the full potential of chiplet applications in cutting-edge control interfaces. The ongoing development of advanced cooling technologies, materials, and design strategies is crucial for addressing the thermal challenges posed by these high-performance, compact systems.

One of the primary concerns in chiplet-based control interfaces is the concentration of heat-generating components in a small area. This localized heat generation can lead to thermal hotspots, potentially causing performance degradation or even system failure if not properly addressed. To mitigate these issues, designers are implementing advanced cooling solutions tailored specifically for chiplet architectures.

Liquid cooling has emerged as a promising technique for managing thermal loads in chiplet-based systems. By circulating a coolant directly over or through the chiplets, heat can be efficiently removed from the source. This approach allows for more uniform heat distribution and can handle higher thermal densities compared to traditional air cooling methods.

Another innovative solution is the use of thermal interface materials (TIMs) optimized for chiplet applications. These materials are designed to enhance heat transfer between the chiplets and the cooling system, reducing thermal resistance and improving overall cooling efficiency. Advanced TIMs, such as phase-change materials or metal-based composites, are being developed to meet the specific needs of chiplet architectures.

The integration of on-chip thermal sensors and dynamic thermal management techniques is also gaining traction in chiplet-based control interfaces. These sensors provide real-time temperature data, allowing the system to adjust performance parameters and cooling strategies dynamically. This adaptive approach ensures optimal thermal management while maintaining system performance and reliability.

Furthermore, the physical design of chiplets themselves is being optimized for improved thermal characteristics. This includes the strategic placement of high-power components, the use of thermally conductive materials in the chiplet substrate, and the implementation of thermal vias to facilitate heat dissipation. Some designs even incorporate dedicated thermal management layers within the chiplet stack.

As chiplet technology continues to evolve, researchers are exploring novel cooling concepts such as microfluidic cooling channels integrated directly into the chiplet package. These microscale cooling solutions promise even greater thermal management capabilities, potentially enabling higher performance and more compact designs in future control interface applications.

In conclusion, effective thermal management is essential for realizing the full potential of chiplet applications in cutting-edge control interfaces. The ongoing development of advanced cooling technologies, materials, and design strategies is crucial for addressing the thermal challenges posed by these high-performance, compact systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!