Chiplet Innovations Enabling Revolutionary Technology Growth

JUL 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Chiplet Evolution and Objectives

The evolution of chiplets represents a paradigm shift in semiconductor design and manufacturing, addressing the challenges posed by Moore's Law and the increasing demand for more powerful and efficient computing systems. Chiplets have emerged as a revolutionary approach to overcome the limitations of traditional monolithic chip designs, enabling the integration of multiple smaller dies onto a single package.

The concept of chiplets can be traced back to the early 2000s, but it gained significant traction in the mid-2010s as the semiconductor industry faced mounting difficulties in scaling down transistor sizes. The primary objective of chiplet technology is to disaggregate complex system-on-chip (SoC) designs into smaller, more manageable components that can be manufactured separately and then integrated using advanced packaging techniques.

This approach offers several advantages, including improved yield, reduced costs, and enhanced flexibility in chip design. By allowing different components to be fabricated using optimal process nodes, chiplets enable the creation of heterogeneous systems that combine the best features of various technologies. This modular approach also facilitates faster time-to-market and easier customization of chip designs for specific applications.

As the technology has progressed, key objectives for chiplet innovation have emerged. These include developing standardized interfaces for seamless integration, improving inter-chiplet communication bandwidth and latency, and enhancing thermal management in multi-die packages. Additionally, there is a focus on advancing packaging technologies to support higher density interconnects and more complex chiplet arrangements.

The evolution of chiplets is closely tied to advancements in packaging technologies, such as 2.5D and 3D integration. These technologies have enabled the creation of high-bandwidth interconnects between chiplets, crucial for realizing the full potential of disaggregated designs. The development of silicon interposers and through-silicon vias (TSVs) has been instrumental in facilitating efficient communication between chiplets and the package substrate.

Looking ahead, the objectives for chiplet technology include further miniaturization of interconnects, development of more sophisticated design tools and methodologies, and the establishment of industry-wide standards for chiplet integration. There is also a growing emphasis on improving energy efficiency and reducing the overall power consumption of chiplet-based systems, aligning with the broader goals of sustainable computing.

The concept of chiplets can be traced back to the early 2000s, but it gained significant traction in the mid-2010s as the semiconductor industry faced mounting difficulties in scaling down transistor sizes. The primary objective of chiplet technology is to disaggregate complex system-on-chip (SoC) designs into smaller, more manageable components that can be manufactured separately and then integrated using advanced packaging techniques.

This approach offers several advantages, including improved yield, reduced costs, and enhanced flexibility in chip design. By allowing different components to be fabricated using optimal process nodes, chiplets enable the creation of heterogeneous systems that combine the best features of various technologies. This modular approach also facilitates faster time-to-market and easier customization of chip designs for specific applications.

As the technology has progressed, key objectives for chiplet innovation have emerged. These include developing standardized interfaces for seamless integration, improving inter-chiplet communication bandwidth and latency, and enhancing thermal management in multi-die packages. Additionally, there is a focus on advancing packaging technologies to support higher density interconnects and more complex chiplet arrangements.

The evolution of chiplets is closely tied to advancements in packaging technologies, such as 2.5D and 3D integration. These technologies have enabled the creation of high-bandwidth interconnects between chiplets, crucial for realizing the full potential of disaggregated designs. The development of silicon interposers and through-silicon vias (TSVs) has been instrumental in facilitating efficient communication between chiplets and the package substrate.

Looking ahead, the objectives for chiplet technology include further miniaturization of interconnects, development of more sophisticated design tools and methodologies, and the establishment of industry-wide standards for chiplet integration. There is also a growing emphasis on improving energy efficiency and reducing the overall power consumption of chiplet-based systems, aligning with the broader goals of sustainable computing.

Market Demand Analysis for Chiplet Technology

The market demand for chiplet technology has been experiencing significant growth, driven by the increasing need for high-performance computing solutions across various industries. As traditional monolithic chip designs approach their physical limits, chiplets offer a promising alternative to continue advancing semiconductor capabilities while managing costs and improving yields.

In the data center and cloud computing sector, the demand for chiplet-based solutions is particularly strong. Major cloud service providers and hyperscalers are seeking more efficient and powerful processors to handle the exponential growth in data processing and artificial intelligence workloads. Chiplets allow for the integration of specialized components, such as high-performance CPU cores, GPU units, and AI accelerators, on a single package, meeting the diverse computational needs of modern data centers.

The telecommunications industry, especially with the ongoing rollout of 5G networks and the development of 6G technology, is another key driver of chiplet demand. Network infrastructure equipment requires increasingly complex and power-efficient chips to handle the massive data throughput and low-latency requirements of next-generation wireless networks. Chiplet technology enables the creation of highly integrated and customizable solutions for base stations and network switches.

In the automotive sector, the transition towards electric vehicles and autonomous driving systems is fueling the need for advanced semiconductor solutions. Chiplets offer the flexibility to combine different types of processors, sensors, and communication modules required for these sophisticated automotive applications, while also addressing the stringent reliability and safety requirements of the industry.

The consumer electronics market is also showing growing interest in chiplet technology. As smartphones, tablets, and other personal devices continue to evolve, manufacturers are looking for ways to incorporate more features and capabilities without significantly increasing power consumption or device size. Chiplets provide a pathway to create more powerful and energy-efficient mobile processors and system-on-chip (SoC) designs.

Furthermore, the emerging fields of edge computing and Internet of Things (IoT) are creating new opportunities for chiplet-based solutions. These applications often require a combination of processing power, energy efficiency, and connectivity features that can be efficiently addressed through the modular approach of chiplet technology.

The market demand for chiplets is also being influenced by geopolitical factors and supply chain considerations. As countries and companies seek to reduce their dependence on single sources for critical semiconductor components, chiplet technology offers a way to diversify chip production and create more resilient supply chains.

In the data center and cloud computing sector, the demand for chiplet-based solutions is particularly strong. Major cloud service providers and hyperscalers are seeking more efficient and powerful processors to handle the exponential growth in data processing and artificial intelligence workloads. Chiplets allow for the integration of specialized components, such as high-performance CPU cores, GPU units, and AI accelerators, on a single package, meeting the diverse computational needs of modern data centers.

The telecommunications industry, especially with the ongoing rollout of 5G networks and the development of 6G technology, is another key driver of chiplet demand. Network infrastructure equipment requires increasingly complex and power-efficient chips to handle the massive data throughput and low-latency requirements of next-generation wireless networks. Chiplet technology enables the creation of highly integrated and customizable solutions for base stations and network switches.

In the automotive sector, the transition towards electric vehicles and autonomous driving systems is fueling the need for advanced semiconductor solutions. Chiplets offer the flexibility to combine different types of processors, sensors, and communication modules required for these sophisticated automotive applications, while also addressing the stringent reliability and safety requirements of the industry.

The consumer electronics market is also showing growing interest in chiplet technology. As smartphones, tablets, and other personal devices continue to evolve, manufacturers are looking for ways to incorporate more features and capabilities without significantly increasing power consumption or device size. Chiplets provide a pathway to create more powerful and energy-efficient mobile processors and system-on-chip (SoC) designs.

Furthermore, the emerging fields of edge computing and Internet of Things (IoT) are creating new opportunities for chiplet-based solutions. These applications often require a combination of processing power, energy efficiency, and connectivity features that can be efficiently addressed through the modular approach of chiplet technology.

The market demand for chiplets is also being influenced by geopolitical factors and supply chain considerations. As countries and companies seek to reduce their dependence on single sources for critical semiconductor components, chiplet technology offers a way to diversify chip production and create more resilient supply chains.

Chiplet Challenges and Current Limitations

Despite the promising potential of chiplet technology, several significant challenges and limitations currently hinder its widespread adoption and full realization of benefits. One of the primary obstacles is the complexity of inter-chiplet communication. Ensuring high-speed, low-latency data transfer between multiple chiplets remains a formidable task, requiring advanced packaging technologies and sophisticated interconnect solutions.

The lack of standardization in chiplet interfaces and protocols presents another major hurdle. Without industry-wide standards, interoperability between chiplets from different manufacturers becomes difficult, limiting the flexibility and cost-effectiveness that chiplet technology promises. This fragmentation also complicates the design and verification processes, potentially increasing time-to-market and development costs.

Thermal management poses a significant challenge in chiplet-based designs. As multiple chiplets are integrated into a single package, heat dissipation becomes more complex, potentially leading to performance bottlenecks and reliability issues. Innovative cooling solutions and thermal-aware design strategies are crucial to address this limitation.

Power distribution and management across multiple chiplets introduce additional complexities. Ensuring efficient power delivery to each chiplet while maintaining overall system power efficiency requires advanced power management techniques and careful design considerations. This challenge becomes more pronounced as the number of chiplets in a system increases.

The yield and testing of individual chiplets present both opportunities and challenges. While chiplet technology allows for better yield management by separating large monolithic dies into smaller components, it also introduces new testing requirements. Ensuring the reliability and performance of each chiplet before integration, as well as testing the final assembled product, demands new methodologies and potentially increases manufacturing complexity.

Manufacturing and assembly processes for chiplet-based systems are still evolving. The precise alignment and bonding of multiple chiplets require advanced packaging technologies and equipment, which may not be widely available or cost-effective for all manufacturers. This limitation could potentially restrict the adoption of chiplet technology, particularly for smaller companies or in certain market segments.

Lastly, the design and optimization of chiplet-based systems present new challenges for engineers and tool vendors. Existing EDA tools and design methodologies may need significant adaptation to fully support chiplet-based design flows, including aspects such as system-level optimization, inter-chiplet communication modeling, and thermal analysis across multiple chiplets.

The lack of standardization in chiplet interfaces and protocols presents another major hurdle. Without industry-wide standards, interoperability between chiplets from different manufacturers becomes difficult, limiting the flexibility and cost-effectiveness that chiplet technology promises. This fragmentation also complicates the design and verification processes, potentially increasing time-to-market and development costs.

Thermal management poses a significant challenge in chiplet-based designs. As multiple chiplets are integrated into a single package, heat dissipation becomes more complex, potentially leading to performance bottlenecks and reliability issues. Innovative cooling solutions and thermal-aware design strategies are crucial to address this limitation.

Power distribution and management across multiple chiplets introduce additional complexities. Ensuring efficient power delivery to each chiplet while maintaining overall system power efficiency requires advanced power management techniques and careful design considerations. This challenge becomes more pronounced as the number of chiplets in a system increases.

The yield and testing of individual chiplets present both opportunities and challenges. While chiplet technology allows for better yield management by separating large monolithic dies into smaller components, it also introduces new testing requirements. Ensuring the reliability and performance of each chiplet before integration, as well as testing the final assembled product, demands new methodologies and potentially increases manufacturing complexity.

Manufacturing and assembly processes for chiplet-based systems are still evolving. The precise alignment and bonding of multiple chiplets require advanced packaging technologies and equipment, which may not be widely available or cost-effective for all manufacturers. This limitation could potentially restrict the adoption of chiplet technology, particularly for smaller companies or in certain market segments.

Lastly, the design and optimization of chiplet-based systems present new challenges for engineers and tool vendors. Existing EDA tools and design methodologies may need significant adaptation to fully support chiplet-based design flows, including aspects such as system-level optimization, inter-chiplet communication modeling, and thermal analysis across multiple chiplets.

Current Chiplet Integration Solutions

01 Advanced packaging technologies for chiplets

Chiplet technology growth is driven by advancements in packaging techniques. These include innovative methods for integrating multiple chiplets into a single package, improving interconnects between chiplets, and developing new materials for better thermal management and electrical performance.- Advanced packaging technologies for chiplets: Chiplet technology growth is driven by advancements in packaging techniques. These include innovative methods for integrating multiple chiplets into a single package, improving interconnects between chiplets, and developing new substrate materials to enhance overall performance and efficiency.

- Heterogeneous integration of chiplets: The growth of chiplet technology is facilitated by the ability to integrate diverse types of chiplets, each optimized for specific functions. This heterogeneous integration allows for the combination of different process nodes and technologies within a single package, leading to improved performance and cost-effectiveness.

- Chiplet interconnect and communication protocols: Advancements in chiplet interconnect technologies and standardized communication protocols are crucial for chiplet technology growth. These developments enable seamless integration and efficient data transfer between chiplets, supporting higher bandwidth and lower latency in complex multi-chiplet systems.

- Thermal management and power efficiency in chiplet designs: Chiplet technology growth is supported by innovations in thermal management and power efficiency. This includes developing advanced cooling solutions, optimizing power distribution networks, and implementing intelligent power management techniques to address the challenges of high-performance multi-chiplet systems.

- Design and verification tools for chiplet-based systems: The expansion of chiplet technology is facilitated by the development of specialized design and verification tools. These tools enable efficient chiplet-based system design, simulation, and testing, addressing the complexities of multi-chiplet architectures and ensuring optimal performance and reliability.

02 Chiplet design and architecture optimization

The growth of chiplet technology involves optimizing chiplet designs and architectures. This includes developing modular chiplet designs, improving die-to-die interfaces, and creating efficient chiplet-based system architectures to enhance overall performance and functionality.Expand Specific Solutions03 Artificial intelligence and machine learning integration in chiplets

Chiplet technology is advancing with the integration of AI and ML capabilities. This involves developing specialized chiplets for AI/ML workloads, optimizing interconnects for data-intensive applications, and creating heterogeneous computing solutions using chiplet-based designs.Expand Specific Solutions04 Manufacturing and testing innovations for chiplets

The growth of chiplet technology is supported by advancements in manufacturing and testing processes. This includes developing new fabrication techniques for chiplets, improving yield management, and creating innovative testing methodologies for chiplet-based systems.Expand Specific Solutions05 Standardization and interoperability in chiplet ecosystems

Chiplet technology growth is facilitated by efforts towards standardization and improved interoperability. This involves developing industry standards for chiplet interfaces, creating open ecosystems for chiplet integration, and establishing protocols for seamless communication between chiplets from different manufacturers.Expand Specific Solutions

Key Players in Chiplet Industry

The chiplet innovation landscape is currently in a dynamic growth phase, with significant market potential and increasing technological maturity. Major players like Intel, Samsung, and Qualcomm are investing heavily in this area, recognizing its potential to revolutionize semiconductor design and manufacturing. The market is expanding rapidly, driven by demand for more efficient and powerful computing solutions across various sectors. Emerging companies like Primemas and D-Matrix are introducing innovative approaches, while established firms such as IBM and Micron are leveraging their expertise to develop advanced chiplet technologies. The competitive landscape is characterized by a mix of large corporations and specialized startups, all vying to establish dominance in this transformative field.

Micron Technology, Inc.

Technical Solution: Micron's approach to chiplet technology primarily focuses on advanced memory solutions and their integration with logic dies. They have been developing Hybrid Memory Cube (HMC) technology, which stacks multiple DRAM dies vertically and connects them to a logic layer using through-silicon vias (TSVs)[13]. This approach significantly increases memory bandwidth and reduces power consumption. Micron is also working on 3D NAND technologies that can be considered a form of vertical chiplet stacking for storage applications[14]. Their research extends to heterogeneous memory system architectures, where different types of memory (e.g., DRAM, NAND, and emerging memories like 3D XPoint) can be integrated into a single package, optimizing performance and capacity for specific workloads[15].

Strengths: Expertise in memory technologies, advanced 3D stacking capabilities, and solutions for high-bandwidth memory applications. Weaknesses: Limited focus on logic integration compared to full SoC manufacturers.

Intel Corp.

Technical Solution: Intel's Chiplet innovations focus on their Foveros 3D packaging technology, which allows for vertical stacking of chiplets. This approach enables the integration of heterogeneous architectures and process nodes in a single package. Intel's Meteor Lake processors utilize this technology, combining compute, graphics, and AI tiles[1]. The company has also introduced advanced interconnect technologies like EMIB (Embedded Multi-die Interconnect Bridge) for high-bandwidth, low-power connections between chiplets[2]. Intel's roadmap includes plans for further miniaturization and performance improvements through their PowerVia and RibbonFET technologies, which are expected to enhance chiplet integration and overall system performance[3].

Strengths: Advanced 3D packaging technology, heterogeneous integration capabilities, and a clear roadmap for future innovations. Weaknesses: Potential complexity in manufacturing and higher initial costs compared to traditional monolithic designs.

Core Chiplet Innovations

Chiplet arrangement

PatentPendingEP4451135A1

Innovation

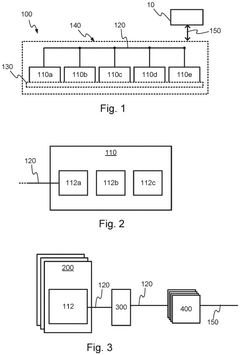

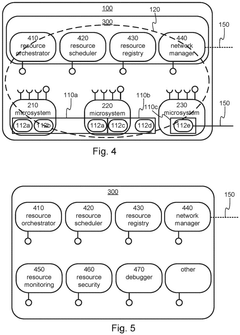

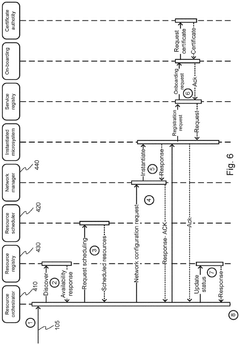

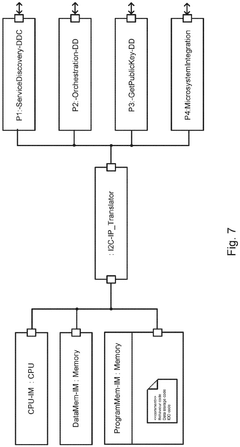

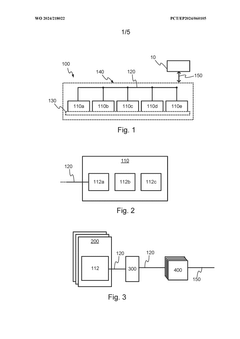

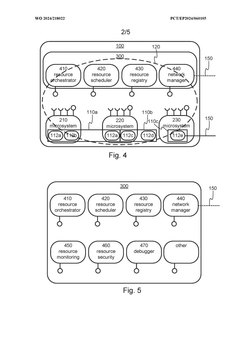

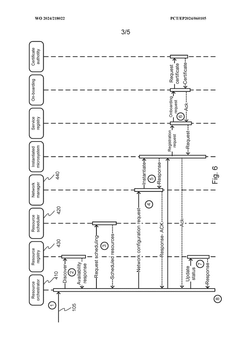

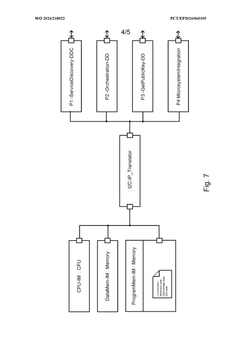

- A chiplet arrangement with a control plane that orchestrates microsystems and microservices, allowing for dynamic instantiation based on hardware resource availability and utilization, featuring a resource orchestrator, network manager, and resource scheduler to optimize resource utilization, scalability, and power management.

Chiplet arrangement

PatentWO2024218022A1

Innovation

- A chiplet arrangement with a control plane that orchestrates microsystems and microservices, utilizing a resource orchestrator, network manager, and resource scheduler to dynamically instantiate and manage hardware resources based on availability and utilization, enabling optimized resource utilization, scalability, and reduced power consumption.

Chiplet Ecosystem Development

The development of the chiplet ecosystem is a critical factor in enabling the revolutionary growth of chiplet technology. This ecosystem encompasses a wide range of stakeholders, including semiconductor manufacturers, design houses, packaging companies, and equipment suppliers, all working together to advance chiplet-based solutions.

At the core of this ecosystem are the foundries and integrated device manufacturers (IDMs) that produce the individual chiplets. These companies are investing heavily in advanced manufacturing processes and packaging technologies to support the production of high-performance, energy-efficient chiplets. They are also developing standardized interfaces and protocols to ensure interoperability between chiplets from different manufacturers.

Design houses play a crucial role in the ecosystem by creating innovative chiplet-based architectures and system-on-chip (SoC) designs. They are leveraging the flexibility of chiplets to mix and match different functional blocks, enabling rapid product development and customization. This approach allows for the integration of best-in-class components from various sources, optimizing overall system performance.

Packaging companies are another vital component of the chiplet ecosystem. They are developing advanced packaging technologies such as 2.5D and 3D integration, which are essential for interconnecting multiple chiplets in a single package. These companies are working on improving thermal management, signal integrity, and power delivery to support increasingly complex chiplet-based designs.

Equipment suppliers are also contributing significantly to the ecosystem by developing specialized tools and processes for chiplet manufacturing and integration. This includes advanced lithography systems, wafer bonding equipment, and inspection tools tailored for chiplet production and assembly.

The chiplet ecosystem is further supported by industry consortia and standards organizations. These groups are working to establish common specifications and protocols, such as the Universal Chiplet Interconnect Express (UCIe) standard, which aims to ensure interoperability and reduce design complexity across the ecosystem.

As the chiplet ecosystem continues to mature, we are seeing increased collaboration between ecosystem partners. This collaboration is driving innovation in areas such as die-to-die interconnects, power management, and system-level optimization. The ecosystem is also expanding to include software developers and system integrators, who are creating tools and methodologies to fully leverage the potential of chiplet-based designs.

At the core of this ecosystem are the foundries and integrated device manufacturers (IDMs) that produce the individual chiplets. These companies are investing heavily in advanced manufacturing processes and packaging technologies to support the production of high-performance, energy-efficient chiplets. They are also developing standardized interfaces and protocols to ensure interoperability between chiplets from different manufacturers.

Design houses play a crucial role in the ecosystem by creating innovative chiplet-based architectures and system-on-chip (SoC) designs. They are leveraging the flexibility of chiplets to mix and match different functional blocks, enabling rapid product development and customization. This approach allows for the integration of best-in-class components from various sources, optimizing overall system performance.

Packaging companies are another vital component of the chiplet ecosystem. They are developing advanced packaging technologies such as 2.5D and 3D integration, which are essential for interconnecting multiple chiplets in a single package. These companies are working on improving thermal management, signal integrity, and power delivery to support increasingly complex chiplet-based designs.

Equipment suppliers are also contributing significantly to the ecosystem by developing specialized tools and processes for chiplet manufacturing and integration. This includes advanced lithography systems, wafer bonding equipment, and inspection tools tailored for chiplet production and assembly.

The chiplet ecosystem is further supported by industry consortia and standards organizations. These groups are working to establish common specifications and protocols, such as the Universal Chiplet Interconnect Express (UCIe) standard, which aims to ensure interoperability and reduce design complexity across the ecosystem.

As the chiplet ecosystem continues to mature, we are seeing increased collaboration between ecosystem partners. This collaboration is driving innovation in areas such as die-to-die interconnects, power management, and system-level optimization. The ecosystem is also expanding to include software developers and system integrators, who are creating tools and methodologies to fully leverage the potential of chiplet-based designs.

Chiplet Standardization Efforts

Chiplet standardization efforts have become a crucial aspect of the semiconductor industry's push towards more advanced and efficient chip designs. These efforts aim to establish common interfaces, protocols, and design methodologies that enable seamless integration of diverse chiplets from different manufacturers. The development of industry-wide standards is essential for fostering innovation, reducing costs, and accelerating time-to-market for chiplet-based products.

One of the most prominent standardization initiatives is the Universal Chiplet Interconnect Express (UCIe), which was introduced in 2022. UCIe focuses on creating a unified die-to-die interconnect standard that allows chiplets from various vendors to communicate effectively. This standard encompasses both the physical layer and the protocol layer, ensuring compatibility across different chiplet designs and manufacturing processes.

Another significant standardization effort is the Open Compute Project's (OCP) Chiplet Design Exchange (CDX) format. CDX aims to standardize the way chiplet designs are described and exchanged between different tools and organizations. This initiative facilitates collaboration among chiplet designers and manufacturers, streamlining the integration process and reducing potential compatibility issues.

The CHIPS Alliance, an open-source hardware initiative, has also been actively working on chiplet standardization. Their efforts include developing open-source tools and methodologies for chiplet design and integration, as well as promoting interoperability between different chiplet technologies.

Standardization efforts extend beyond interconnects and design exchanges to include power management, thermal considerations, and testing methodologies for chiplet-based systems. The development of standardized power delivery and thermal management techniques is crucial for ensuring optimal performance and reliability in multi-chiplet designs.

As chiplet technology continues to evolve, standardization efforts are likely to expand into new areas, such as 3D integration and advanced packaging techniques. These efforts will play a vital role in enabling the next generation of high-performance, energy-efficient computing systems that leverage the full potential of chiplet-based architectures.

The success of chiplet standardization efforts relies heavily on collaboration between industry leaders, research institutions, and standards organizations. As these initiatives progress, they will pave the way for a more diverse and competitive chiplet ecosystem, ultimately driving innovation and technological advancements in the semiconductor industry.

One of the most prominent standardization initiatives is the Universal Chiplet Interconnect Express (UCIe), which was introduced in 2022. UCIe focuses on creating a unified die-to-die interconnect standard that allows chiplets from various vendors to communicate effectively. This standard encompasses both the physical layer and the protocol layer, ensuring compatibility across different chiplet designs and manufacturing processes.

Another significant standardization effort is the Open Compute Project's (OCP) Chiplet Design Exchange (CDX) format. CDX aims to standardize the way chiplet designs are described and exchanged between different tools and organizations. This initiative facilitates collaboration among chiplet designers and manufacturers, streamlining the integration process and reducing potential compatibility issues.

The CHIPS Alliance, an open-source hardware initiative, has also been actively working on chiplet standardization. Their efforts include developing open-source tools and methodologies for chiplet design and integration, as well as promoting interoperability between different chiplet technologies.

Standardization efforts extend beyond interconnects and design exchanges to include power management, thermal considerations, and testing methodologies for chiplet-based systems. The development of standardized power delivery and thermal management techniques is crucial for ensuring optimal performance and reliability in multi-chiplet designs.

As chiplet technology continues to evolve, standardization efforts are likely to expand into new areas, such as 3D integration and advanced packaging techniques. These efforts will play a vital role in enabling the next generation of high-performance, energy-efficient computing systems that leverage the full potential of chiplet-based architectures.

The success of chiplet standardization efforts relies heavily on collaboration between industry leaders, research institutions, and standards organizations. As these initiatives progress, they will pave the way for a more diverse and competitive chiplet ecosystem, ultimately driving innovation and technological advancements in the semiconductor industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!