Collaborative Approaches to Carbon-negative Concrete Standardization

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Development History and Objectives

The concept of carbon-negative concrete emerged as a response to the significant environmental impact of traditional cement production, which accounts for approximately 8% of global CO2 emissions. The development trajectory began in the early 2000s when researchers first explored alternative cementitious materials with lower carbon footprints. By 2010, the first commercial carbon-neutral concrete products entered the market, primarily utilizing supplementary cementitious materials (SCMs) like fly ash and slag to reduce Portland cement content.

The evolution toward carbon-negative concrete accelerated around 2015, when companies like Carbicrete and CarbonCure pioneered technologies to sequester CO2 within concrete during the curing process. These innovations marked a crucial shift from merely reducing emissions to actively removing carbon from the atmosphere. The period between 2015-2020 saw significant advancements in carbon mineralization techniques, where CO2 is chemically bound to calcium or magnesium-rich materials to form stable carbonates within the concrete matrix.

By 2021, several pilot projects demonstrated the feasibility of carbon-negative concrete at commercial scale, though widespread adoption remained limited by cost factors and technical performance uncertainties. The industry's technological progression has been characterized by three main approaches: CO2 mineralization, alternative binding materials, and biomass incorporation, each offering different pathways to negative carbon outcomes.

The primary objective of carbon-negative concrete standardization efforts is to establish universally accepted metrics and methodologies for quantifying carbon sequestration in concrete products. This includes developing life cycle assessment (LCA) protocols specifically tailored to account for carbon removal and storage throughout the concrete's lifecycle. Another critical goal is creating performance-based standards that ensure carbon-negative formulations meet or exceed traditional concrete's durability, strength, and workability requirements.

Standardization initiatives also aim to facilitate market adoption by providing certification frameworks that verify carbon-negative claims and enable fair comparison between different products and technologies. The long-term objective extends beyond technical specifications to include regulatory integration, whereby carbon-negative concrete standards become incorporated into building codes and public procurement policies, creating market pull for these innovative materials.

Collaborative approaches to standardization seek to harmonize efforts across geographic regions, preventing the emergence of conflicting standards that could fragment the global market and impede technology transfer. The ultimate goal is establishing a technological foundation that enables the concrete industry to transition from being a major carbon emitter to potentially becoming a significant carbon sink by 2050.

The evolution toward carbon-negative concrete accelerated around 2015, when companies like Carbicrete and CarbonCure pioneered technologies to sequester CO2 within concrete during the curing process. These innovations marked a crucial shift from merely reducing emissions to actively removing carbon from the atmosphere. The period between 2015-2020 saw significant advancements in carbon mineralization techniques, where CO2 is chemically bound to calcium or magnesium-rich materials to form stable carbonates within the concrete matrix.

By 2021, several pilot projects demonstrated the feasibility of carbon-negative concrete at commercial scale, though widespread adoption remained limited by cost factors and technical performance uncertainties. The industry's technological progression has been characterized by three main approaches: CO2 mineralization, alternative binding materials, and biomass incorporation, each offering different pathways to negative carbon outcomes.

The primary objective of carbon-negative concrete standardization efforts is to establish universally accepted metrics and methodologies for quantifying carbon sequestration in concrete products. This includes developing life cycle assessment (LCA) protocols specifically tailored to account for carbon removal and storage throughout the concrete's lifecycle. Another critical goal is creating performance-based standards that ensure carbon-negative formulations meet or exceed traditional concrete's durability, strength, and workability requirements.

Standardization initiatives also aim to facilitate market adoption by providing certification frameworks that verify carbon-negative claims and enable fair comparison between different products and technologies. The long-term objective extends beyond technical specifications to include regulatory integration, whereby carbon-negative concrete standards become incorporated into building codes and public procurement policies, creating market pull for these innovative materials.

Collaborative approaches to standardization seek to harmonize efforts across geographic regions, preventing the emergence of conflicting standards that could fragment the global market and impede technology transfer. The ultimate goal is establishing a technological foundation that enables the concrete industry to transition from being a major carbon emitter to potentially becoming a significant carbon sink by 2050.

Market Analysis for Sustainable Construction Materials

The sustainable construction materials market is experiencing unprecedented growth, driven by increasing environmental concerns and regulatory pressures to reduce carbon emissions in the building sector. The global green building materials market was valued at approximately $256 billion in 2020 and is projected to reach $425 billion by 2027, with a compound annual growth rate of 8.6%. Carbon-negative concrete represents one of the most promising segments within this market, addressing the critical issue that traditional concrete production accounts for nearly 8% of global CO2 emissions.

Demand for carbon-negative concrete solutions is primarily driven by three key factors: stringent environmental regulations, growing corporate sustainability commitments, and increasing consumer awareness. The European Union's Green Deal and carbon border adjustment mechanism have created strong market incentives for low-carbon building materials. Similarly, the United States' Inflation Reduction Act has allocated substantial funding for sustainable infrastructure development, creating a favorable market environment for innovative concrete technologies.

Market segmentation reveals varying adoption rates across different construction sectors. Commercial buildings lead the adoption curve, with 42% of new commercial construction projects in developed markets incorporating some form of sustainable concrete. Infrastructure projects follow at 35%, while residential construction lags at 18%, presenting a significant growth opportunity. Geographically, Europe dominates the sustainable concrete market with approximately 40% market share, followed by North America (30%) and Asia-Pacific (20%).

Consumer willingness to pay premiums for sustainable building materials has shown positive trends, with surveys indicating that commercial developers are willing to accept 5-15% cost increases for materials that significantly reduce carbon footprints. However, price sensitivity remains a critical factor in residential markets, where the premium tolerance rarely exceeds 3-7%.

The competitive landscape for carbon-negative concrete is characterized by both established industry players and innovative startups. Traditional cement manufacturers are investing heavily in sustainable alternatives, while technology-focused startups are pioneering novel approaches to carbon capture and alternative binding agents. This has created a dynamic market environment with increasing collaboration between industry incumbents and technology innovators.

Future market projections indicate that carbon-negative concrete could capture up to 25% of the global concrete market by 2035, representing a potential market value of $130 billion. This growth trajectory is supported by the convergence of technological advancements, regulatory pressures, and shifting consumer preferences toward sustainable building practices.

Demand for carbon-negative concrete solutions is primarily driven by three key factors: stringent environmental regulations, growing corporate sustainability commitments, and increasing consumer awareness. The European Union's Green Deal and carbon border adjustment mechanism have created strong market incentives for low-carbon building materials. Similarly, the United States' Inflation Reduction Act has allocated substantial funding for sustainable infrastructure development, creating a favorable market environment for innovative concrete technologies.

Market segmentation reveals varying adoption rates across different construction sectors. Commercial buildings lead the adoption curve, with 42% of new commercial construction projects in developed markets incorporating some form of sustainable concrete. Infrastructure projects follow at 35%, while residential construction lags at 18%, presenting a significant growth opportunity. Geographically, Europe dominates the sustainable concrete market with approximately 40% market share, followed by North America (30%) and Asia-Pacific (20%).

Consumer willingness to pay premiums for sustainable building materials has shown positive trends, with surveys indicating that commercial developers are willing to accept 5-15% cost increases for materials that significantly reduce carbon footprints. However, price sensitivity remains a critical factor in residential markets, where the premium tolerance rarely exceeds 3-7%.

The competitive landscape for carbon-negative concrete is characterized by both established industry players and innovative startups. Traditional cement manufacturers are investing heavily in sustainable alternatives, while technology-focused startups are pioneering novel approaches to carbon capture and alternative binding agents. This has created a dynamic market environment with increasing collaboration between industry incumbents and technology innovators.

Future market projections indicate that carbon-negative concrete could capture up to 25% of the global concrete market by 2035, representing a potential market value of $130 billion. This growth trajectory is supported by the convergence of technological advancements, regulatory pressures, and shifting consumer preferences toward sustainable building practices.

Global Status and Barriers in Carbon-negative Concrete Technology

Carbon-negative concrete technology has seen varied development across different regions globally. Leading countries in this field include the Netherlands, Sweden, and Canada, where significant research and pilot projects have demonstrated the feasibility of carbon-negative concrete production. These nations have established research centers dedicated to sustainable construction materials and have implemented supportive policy frameworks that encourage innovation in this sector.

Despite these advancements, the global adoption of carbon-negative concrete faces substantial barriers. Technical challenges remain prominent, particularly in scaling production methods that can effectively sequester carbon while maintaining concrete's structural integrity and durability. The carbonation process, which is essential for carbon sequestration in concrete, requires precise control of environmental conditions that are difficult to standardize across different manufacturing facilities and geographic locations.

Regulatory frameworks present another significant obstacle. Most building codes and construction standards worldwide were developed for traditional concrete and do not adequately address carbon-negative alternatives. This regulatory gap creates uncertainty for manufacturers and contractors, limiting market adoption. Additionally, the certification processes for new construction materials are often lengthy and costly, deterring smaller companies from entering the market.

Economic barriers further complicate the landscape. The production costs of carbon-negative concrete currently exceed those of conventional concrete by approximately 15-30%, depending on the technology used and local material availability. This price premium, coupled with the construction industry's traditionally low profit margins, makes widespread adoption challenging without additional incentives or regulatory mandates.

Knowledge gaps and technical expertise shortages represent another significant barrier. Many construction professionals lack familiarity with carbon-negative concrete technologies, their application methods, and performance characteristics. This knowledge deficit extends to engineering firms, architects, and building inspectors, creating a systemic barrier to adoption even where the technology is available.

Infrastructure limitations also impede progress. The production of carbon-negative concrete often requires specialized equipment and facilities that differ from traditional concrete manufacturing. The capital investment needed to retrofit existing plants or build new ones represents a substantial financial hurdle for the industry, particularly in developing economies where capital access is more constrained.

Collaborative standardization efforts are emerging but remain fragmented. Organizations such as the International Organization for Standardization (ISO) and various national standards bodies have begun developing frameworks for low-carbon concrete, but comprehensive standards specifically addressing carbon-negative concrete are still in nascent stages. This standardization gap creates market uncertainty and hampers international trade in these innovative materials.

Despite these advancements, the global adoption of carbon-negative concrete faces substantial barriers. Technical challenges remain prominent, particularly in scaling production methods that can effectively sequester carbon while maintaining concrete's structural integrity and durability. The carbonation process, which is essential for carbon sequestration in concrete, requires precise control of environmental conditions that are difficult to standardize across different manufacturing facilities and geographic locations.

Regulatory frameworks present another significant obstacle. Most building codes and construction standards worldwide were developed for traditional concrete and do not adequately address carbon-negative alternatives. This regulatory gap creates uncertainty for manufacturers and contractors, limiting market adoption. Additionally, the certification processes for new construction materials are often lengthy and costly, deterring smaller companies from entering the market.

Economic barriers further complicate the landscape. The production costs of carbon-negative concrete currently exceed those of conventional concrete by approximately 15-30%, depending on the technology used and local material availability. This price premium, coupled with the construction industry's traditionally low profit margins, makes widespread adoption challenging without additional incentives or regulatory mandates.

Knowledge gaps and technical expertise shortages represent another significant barrier. Many construction professionals lack familiarity with carbon-negative concrete technologies, their application methods, and performance characteristics. This knowledge deficit extends to engineering firms, architects, and building inspectors, creating a systemic barrier to adoption even where the technology is available.

Infrastructure limitations also impede progress. The production of carbon-negative concrete often requires specialized equipment and facilities that differ from traditional concrete manufacturing. The capital investment needed to retrofit existing plants or build new ones represents a substantial financial hurdle for the industry, particularly in developing economies where capital access is more constrained.

Collaborative standardization efforts are emerging but remain fragmented. Organizations such as the International Organization for Standardization (ISO) and various national standards bodies have begun developing frameworks for low-carbon concrete, but comprehensive standards specifically addressing carbon-negative concrete are still in nascent stages. This standardization gap creates market uncertainty and hampers international trade in these innovative materials.

Current Standardization Frameworks for Low-carbon Concrete

01 Carbon capture and sequestration in concrete production

Various methods for capturing and sequestering carbon dioxide during concrete production processes to create carbon-negative concrete. These technologies involve incorporating CO2 during the curing process, using specialized additives that react with CO2, and developing manufacturing processes that actively absorb more carbon than they emit, resulting in a net negative carbon footprint for the final concrete product.- Carbon capture and sequestration in concrete: Technologies that enable concrete to absorb and permanently store carbon dioxide during the curing process, transforming it from a carbon source to a carbon sink. These methods involve specialized formulations that promote carbonation reactions, where CO2 is chemically bound to the concrete matrix, resulting in improved strength while reducing the overall carbon footprint of the material.

- Alternative cementitious materials for carbon reduction: Development of cement alternatives that significantly reduce carbon emissions compared to traditional Portland cement. These include supplementary cementitious materials (SCMs) like fly ash, slag, and natural pozzolans, as well as novel binders that require less energy to produce and generate fewer emissions during manufacturing while maintaining or improving concrete performance characteristics.

- Standardization frameworks for carbon-negative concrete: Establishment of testing protocols, certification systems, and regulatory frameworks specifically designed for carbon-negative concrete products. These standards define measurement methodologies for carbon sequestration, performance requirements, durability testing, and lifecycle assessment approaches to verify and quantify the environmental benefits of carbon-negative concrete technologies.

- Enhanced carbonation techniques and accelerators: Methods to accelerate and optimize the carbonation process in concrete, including specialized curing chambers, pressure systems, and chemical accelerators that promote faster and more complete carbon dioxide absorption. These techniques control factors such as humidity, temperature, and CO2 concentration to maximize carbon sequestration while ensuring proper concrete development.

- Monitoring and verification systems for carbon sequestration: Technologies and methodologies for accurately measuring, monitoring, and verifying the amount of carbon sequestered in concrete over time. These include embedded sensors, non-destructive testing methods, and digital tracking systems that provide data on carbon uptake throughout the concrete lifecycle, supporting carbon credit certification and regulatory compliance.

02 Alternative cementitious materials for carbon reduction

Development of alternative cementitious materials that reduce or eliminate the need for traditional Portland cement, which is carbon-intensive. These alternatives include geopolymers, alkali-activated materials, and supplementary cementitious materials derived from industrial byproducts or natural sources. These materials can significantly reduce carbon emissions in concrete production while maintaining or improving performance characteristics.Expand Specific Solutions03 Standardization frameworks and testing protocols

Establishment of standardization frameworks, testing protocols, and certification systems specifically designed for carbon-negative concrete. These standards define measurement methodologies, performance criteria, and quality assurance procedures to verify carbon negativity claims and ensure consistent product quality across the industry. The frameworks also address lifecycle assessment methods to accurately quantify carbon footprint.Expand Specific Solutions04 Carbonation enhancement technologies

Technologies that enhance the natural carbonation process in concrete, accelerating the rate at which concrete absorbs CO2 from the atmosphere throughout its lifecycle. These include specialized admixtures, surface treatments, and curing techniques that promote carbonation while maintaining structural integrity. Enhanced carbonation can transform conventional concrete into a carbon sink over its service life.Expand Specific Solutions05 Industrial waste incorporation for carbon reduction

Methods for incorporating industrial waste materials such as fly ash, slag, and silica fume into concrete formulations to reduce carbon footprint. These waste materials can partially replace cement, reducing emissions associated with cement production while simultaneously solving waste disposal problems. The resulting concrete can achieve carbon-negative status when combined with other carbon capture technologies.Expand Specific Solutions

Leading Organizations in Carbon-negative Concrete Innovation

The carbon-negative concrete standardization field is in an early growth phase, characterized by increasing collaboration between academic institutions and commercial entities. The market is expanding rapidly, driven by global decarbonization initiatives, with projections suggesting significant growth as construction industries seek sustainable alternatives. While still evolving, the technology shows promising maturity levels with companies like CarbonCure Technologies, Solidia Technologies, and Carbicrete leading commercial implementation. Academic institutions including Southeast University and Worcester Polytechnic Institute are advancing research foundations, while established players such as Heidelberg Materials and Holcim Technology are integrating carbon-negative approaches into their portfolios. The competitive landscape features both specialized startups focused exclusively on carbon-negative solutions and traditional cement manufacturers adapting their offerings to meet emerging sustainability standards.

CarbonCure Technologies, Inc.

Technical Solution: CarbonCure has developed a technology that injects captured CO2 into fresh concrete during mixing, where it mineralizes and becomes permanently embedded. Their system can be retrofitted into existing concrete plants with minimal disruption to operations. The technology reduces the carbon footprint of concrete by approximately 5-8% while maintaining or improving concrete performance characteristics. CarbonCure has established partnerships with over 500 concrete producers across 25 countries and has developed a comprehensive measurement and verification system that quantifies CO2 utilization, enabling concrete producers to issue verified carbon reports. Their approach has been recognized by multiple certification bodies and has been incorporated into several green building standards.

Strengths: Easily retrofitted into existing plants; provides immediate carbon reduction without compromising concrete quality; extensive market penetration; robust verification system. Weaknesses: Limited to moderate CO2 reduction compared to some alternative approaches; requires continuous supply of captured CO2; primarily addresses the manufacturing process rather than the entire lifecycle.

Carbicrete, Inc.

Technical Solution: Carbicrete has pioneered a carbon-negative concrete manufacturing process that eliminates cement entirely, replacing it with steel slag, an industrial by-product. Their innovative curing process injects CO2 into the concrete mixture, where it reacts with the slag to create calcium carbonate, effectively sequestering carbon while providing structural strength. Each Carbicrete concrete block can sequester approximately 2kg of CO2, making the final product carbon-negative. The company has developed a comprehensive standardization framework that includes detailed specifications for material composition, curing parameters, and performance testing protocols. Carbicrete has established partnerships with major construction companies and material suppliers to ensure consistent quality and scalability of their technology.

Strengths: Truly carbon-negative approach; eliminates cement entirely; utilizes industrial waste products; comprehensive standardization framework. Weaknesses: Currently limited to precast applications; requires significant changes to existing manufacturing processes; performance in extreme conditions still being validated; requires reliable access to steel slag.

Key Patents and Research in Carbon Sequestration Concrete

Carbon negative concrete production through the use of sustainable materials

PatentInactiveUS20230002276A1

Innovation

- Incorporating biochar, a high-carbon residue produced through low-oxygen pyrolysis, into concrete mixtures to sequester carbon and reduce emissions, while optimizing pyrolysis processes to power plants using syngas for self-sustainability and carbon neutrality.

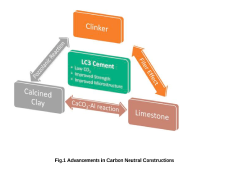

Carbon-neutral concrete solutions for sustainable infrastructure

PatentPendingIN202441036149A

Innovation

- The use of supplementary cementitious materials like fly ash, slag, and calcined clays, combined with carbon capture technologies and recycled aggregates, along with lifecycle assessment and carbon offsetting initiatives, aims to minimize emissions and enhance the sustainability of concrete production.

Policy Incentives for Carbon-negative Building Materials

Policy incentives play a crucial role in accelerating the adoption of carbon-negative concrete and other sustainable building materials. Governments worldwide are implementing various policy mechanisms to encourage the construction industry to transition toward more environmentally friendly practices.

Carbon pricing mechanisms represent one of the most direct policy approaches, with carbon taxes and cap-and-trade systems creating financial incentives for reducing emissions. In regions with established carbon markets, concrete manufacturers are increasingly motivated to develop carbon-negative alternatives to avoid carbon costs and potentially generate additional revenue through carbon credits.

Green building codes and standards are evolving to incorporate carbon-negative materials. Several jurisdictions have updated their building codes to include provisions for low-carbon concrete, with some pioneering regions beginning to introduce requirements specifically for carbon-negative options. These regulatory frameworks create market demand by mandating certain performance standards.

Public procurement policies have emerged as powerful market drivers. Government construction projects represent a significant portion of concrete demand in many countries. By implementing preferential purchasing requirements for carbon-negative building materials, public agencies can create substantial initial markets that help scale production and drive down costs.

Tax incentives and subsidies further support market development through accelerated depreciation allowances, tax credits for manufacturers investing in carbon-negative technologies, and direct subsidies for research and development. These financial tools help offset the initially higher costs associated with innovative materials and production processes.

Research grants and innovation funds directed specifically toward carbon-negative concrete development have increased substantially in recent years. These programs support fundamental research, pilot projects, and commercialization efforts, addressing the technical challenges of scaling carbon-negative concrete production.

International collaboration frameworks are also emerging, with cross-border initiatives to harmonize standards and share best practices. These collaborative efforts help prevent market fragmentation and create consistent incentives across regions, facilitating global adoption of carbon-negative building materials.

The effectiveness of these policy incentives varies significantly based on local market conditions, existing regulatory frameworks, and political priorities. The most successful approaches typically combine multiple policy instruments in comprehensive packages that address different market barriers simultaneously.

Carbon pricing mechanisms represent one of the most direct policy approaches, with carbon taxes and cap-and-trade systems creating financial incentives for reducing emissions. In regions with established carbon markets, concrete manufacturers are increasingly motivated to develop carbon-negative alternatives to avoid carbon costs and potentially generate additional revenue through carbon credits.

Green building codes and standards are evolving to incorporate carbon-negative materials. Several jurisdictions have updated their building codes to include provisions for low-carbon concrete, with some pioneering regions beginning to introduce requirements specifically for carbon-negative options. These regulatory frameworks create market demand by mandating certain performance standards.

Public procurement policies have emerged as powerful market drivers. Government construction projects represent a significant portion of concrete demand in many countries. By implementing preferential purchasing requirements for carbon-negative building materials, public agencies can create substantial initial markets that help scale production and drive down costs.

Tax incentives and subsidies further support market development through accelerated depreciation allowances, tax credits for manufacturers investing in carbon-negative technologies, and direct subsidies for research and development. These financial tools help offset the initially higher costs associated with innovative materials and production processes.

Research grants and innovation funds directed specifically toward carbon-negative concrete development have increased substantially in recent years. These programs support fundamental research, pilot projects, and commercialization efforts, addressing the technical challenges of scaling carbon-negative concrete production.

International collaboration frameworks are also emerging, with cross-border initiatives to harmonize standards and share best practices. These collaborative efforts help prevent market fragmentation and create consistent incentives across regions, facilitating global adoption of carbon-negative building materials.

The effectiveness of these policy incentives varies significantly based on local market conditions, existing regulatory frameworks, and political priorities. The most successful approaches typically combine multiple policy instruments in comprehensive packages that address different market barriers simultaneously.

Life Cycle Assessment Methodologies for Concrete Standards

Life Cycle Assessment (LCA) methodologies form the backbone of evaluating environmental impacts across the concrete production lifecycle, particularly crucial for carbon-negative concrete standardization efforts. Current LCA frameworks for concrete typically follow ISO 14040 and 14044 standards, which establish principles for goal definition, inventory analysis, impact assessment, and interpretation. However, these generalized approaches often lack specificity for carbon-negative concrete technologies, creating inconsistencies in measurement and reporting.

The development of standardized LCA methodologies specifically for carbon-negative concrete requires addressing several key challenges. First, system boundary definitions must be expanded to include carbon capture, utilization, and storage (CCUS) processes that are integral to carbon-negative formulations. Traditional boundaries focusing solely on production emissions prove inadequate when evaluating technologies designed to sequester more carbon than they emit.

Functional unit definition presents another methodological challenge. While conventional concrete standards typically use compressive strength as the primary functional parameter, carbon-negative variants may require multi-parameter functional units that balance strength, durability, carbon sequestration capacity, and service life. This multi-dimensional approach enables fair comparison between traditional and innovative formulations.

Allocation methods for co-products and by-products in carbon-negative concrete production chains demand particular attention. Many carbon-negative technologies incorporate industrial by-products or novel materials with complex upstream processes. Standardized allocation rules must be established to prevent inconsistent environmental burden distribution across the value chain.

Temporal considerations represent a significant methodological innovation needed for carbon-negative concrete LCA standards. Unlike conventional materials, carbon-negative concrete may sequester carbon gradually over decades, requiring dynamic LCA models that account for time-dependent carbon fluxes rather than static snapshots of environmental impact.

Data quality and availability remain persistent challenges, with many innovative carbon-negative technologies lacking comprehensive environmental data. Collaborative approaches to standardization must include provisions for data sharing platforms, proxy data guidelines, and uncertainty analysis protocols to ensure meaningful comparisons despite data limitations.

Harmonization of impact assessment methods specifically relevant to carbon-negative concrete is essential, focusing particularly on global warming potential calculations that accurately reflect negative emissions. This requires consensus on appropriate characterization factors and time horizons for greenhouse gas impacts.

The development of standardized LCA methodologies specifically for carbon-negative concrete requires addressing several key challenges. First, system boundary definitions must be expanded to include carbon capture, utilization, and storage (CCUS) processes that are integral to carbon-negative formulations. Traditional boundaries focusing solely on production emissions prove inadequate when evaluating technologies designed to sequester more carbon than they emit.

Functional unit definition presents another methodological challenge. While conventional concrete standards typically use compressive strength as the primary functional parameter, carbon-negative variants may require multi-parameter functional units that balance strength, durability, carbon sequestration capacity, and service life. This multi-dimensional approach enables fair comparison between traditional and innovative formulations.

Allocation methods for co-products and by-products in carbon-negative concrete production chains demand particular attention. Many carbon-negative technologies incorporate industrial by-products or novel materials with complex upstream processes. Standardized allocation rules must be established to prevent inconsistent environmental burden distribution across the value chain.

Temporal considerations represent a significant methodological innovation needed for carbon-negative concrete LCA standards. Unlike conventional materials, carbon-negative concrete may sequester carbon gradually over decades, requiring dynamic LCA models that account for time-dependent carbon fluxes rather than static snapshots of environmental impact.

Data quality and availability remain persistent challenges, with many innovative carbon-negative technologies lacking comprehensive environmental data. Collaborative approaches to standardization must include provisions for data sharing platforms, proxy data guidelines, and uncertainty analysis protocols to ensure meaningful comparisons despite data limitations.

Harmonization of impact assessment methods specifically relevant to carbon-negative concrete is essential, focusing particularly on global warming potential calculations that accurately reflect negative emissions. This requires consensus on appropriate characterization factors and time horizons for greenhouse gas impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!