Comparative Analysis of Carbon-negative Concrete and Recycled Concrete

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative and Recycled Concrete Evolution

The evolution of concrete technology has witnessed significant advancements in recent decades, particularly in response to growing environmental concerns. Traditional concrete production accounts for approximately 8% of global CO2 emissions, prompting the development of more sustainable alternatives. Carbon-negative concrete represents a revolutionary approach that emerged in the early 2010s, utilizing innovative chemistry to absorb more carbon dioxide during its lifecycle than is emitted during production.

The concept of carbon-negative concrete was first introduced around 2012, with companies like Carbicrete and CarbonCure pioneering technologies that inject captured CO2 into concrete mixtures. By 2015, these technologies had evolved from laboratory experiments to pilot projects, demonstrating the feasibility of carbon sequestration in building materials. The breakthrough came through the development of alternative cementitious materials that could replace traditional Portland cement while maintaining structural integrity.

Parallel to this development, recycled concrete technology has followed its own evolutionary path since the 1970s. Initially limited to using crushed concrete as aggregate in non-structural applications, the technology has progressively advanced to enable higher percentages of recycled content. The 1990s saw the first standardized specifications for recycled concrete aggregates, while the 2000s brought improved crushing and sorting technologies that significantly enhanced the quality of recycled materials.

A critical milestone occurred around 2018 when carbon-negative and recycled concrete technologies began to converge. Researchers discovered that recycled concrete aggregate could serve as an effective carbon sink when treated with specific mineralization processes. This synergy created opportunities for concrete that was both recycled and carbon-negative, representing a dual environmental benefit.

The technological evolution accelerated after 2020, with the development of geopolymer-based solutions that eliminated the need for Portland cement entirely. These materials utilized industrial byproducts like fly ash and slag, combined with novel activators that promoted carbon absorption. Concurrently, advanced recycling techniques emerged that could separate and repurpose virtually all components of demolished concrete, including the previously challenging cement paste fraction.

Most recently, between 2021-2023, machine learning algorithms have been deployed to optimize concrete formulations that maximize both carbon sequestration potential and recycled content. These algorithms analyze thousands of potential mixture designs to identify optimal combinations of materials based on specific performance requirements, availability of recycled materials, and carbon reduction goals.

The concept of carbon-negative concrete was first introduced around 2012, with companies like Carbicrete and CarbonCure pioneering technologies that inject captured CO2 into concrete mixtures. By 2015, these technologies had evolved from laboratory experiments to pilot projects, demonstrating the feasibility of carbon sequestration in building materials. The breakthrough came through the development of alternative cementitious materials that could replace traditional Portland cement while maintaining structural integrity.

Parallel to this development, recycled concrete technology has followed its own evolutionary path since the 1970s. Initially limited to using crushed concrete as aggregate in non-structural applications, the technology has progressively advanced to enable higher percentages of recycled content. The 1990s saw the first standardized specifications for recycled concrete aggregates, while the 2000s brought improved crushing and sorting technologies that significantly enhanced the quality of recycled materials.

A critical milestone occurred around 2018 when carbon-negative and recycled concrete technologies began to converge. Researchers discovered that recycled concrete aggregate could serve as an effective carbon sink when treated with specific mineralization processes. This synergy created opportunities for concrete that was both recycled and carbon-negative, representing a dual environmental benefit.

The technological evolution accelerated after 2020, with the development of geopolymer-based solutions that eliminated the need for Portland cement entirely. These materials utilized industrial byproducts like fly ash and slag, combined with novel activators that promoted carbon absorption. Concurrently, advanced recycling techniques emerged that could separate and repurpose virtually all components of demolished concrete, including the previously challenging cement paste fraction.

Most recently, between 2021-2023, machine learning algorithms have been deployed to optimize concrete formulations that maximize both carbon sequestration potential and recycled content. These algorithms analyze thousands of potential mixture designs to identify optimal combinations of materials based on specific performance requirements, availability of recycled materials, and carbon reduction goals.

Market Demand for Sustainable Construction Materials

The global construction industry is witnessing a significant shift towards sustainable building materials, driven by increasing environmental concerns and regulatory pressures. The market for sustainable construction materials, particularly carbon-negative concrete and recycled concrete, has experienced substantial growth over the past decade. This growth trajectory is expected to continue as governments worldwide implement stricter carbon emission regulations and sustainability standards for construction projects.

Current market analysis indicates that the global green concrete market reached approximately $26.2 billion in 2021 and is projected to grow at a compound annual growth rate (CAGR) of 9.1% through 2030. This expansion is primarily fueled by the urgent need to reduce the construction industry's carbon footprint, which currently accounts for nearly 8% of global CO2 emissions, with traditional concrete production being a major contributor.

The demand for carbon-negative concrete solutions has seen remarkable growth, particularly in developed regions such as Europe and North America. This innovative material, which actively sequesters carbon during its lifecycle, appeals to environmentally conscious developers and public infrastructure projects aiming for net-zero carbon goals. Market research shows that carbon-negative concrete commands a premium of 15-30% over conventional concrete, yet this price differential is gradually narrowing as production scales up and technology matures.

Recycled concrete, meanwhile, has gained significant market traction in urban centers where construction and demolition waste management presents both environmental challenges and economic opportunities. The global recycled concrete aggregate market was valued at $8.7 billion in 2022, with projections indicating growth to $14.5 billion by 2027. Regions with limited natural aggregate resources or high landfill costs demonstrate particularly strong demand for recycled concrete products.

Industry surveys reveal that 67% of major construction firms have incorporated sustainable concrete alternatives into their procurement strategies, with 42% specifically targeting carbon-negative or recycled concrete options. This trend is reinforced by government procurement policies that increasingly mandate minimum recycled content or maximum carbon footprint requirements for public infrastructure projects.

Consumer preferences are also evolving, with 73% of commercial property developers reporting that sustainable building materials positively impact property values and marketability. The growing influence of green building certification systems such as LEED, BREEAM, and Green Star has further accelerated market demand for innovative concrete solutions that contribute to sustainability ratings.

Despite positive market signals, adoption barriers persist, including concerns about long-term performance, limited supply chain infrastructure, and inconsistent regulatory frameworks across different regions. However, these challenges are gradually being addressed through industry standardization efforts and increased investment in production capacity.

Current market analysis indicates that the global green concrete market reached approximately $26.2 billion in 2021 and is projected to grow at a compound annual growth rate (CAGR) of 9.1% through 2030. This expansion is primarily fueled by the urgent need to reduce the construction industry's carbon footprint, which currently accounts for nearly 8% of global CO2 emissions, with traditional concrete production being a major contributor.

The demand for carbon-negative concrete solutions has seen remarkable growth, particularly in developed regions such as Europe and North America. This innovative material, which actively sequesters carbon during its lifecycle, appeals to environmentally conscious developers and public infrastructure projects aiming for net-zero carbon goals. Market research shows that carbon-negative concrete commands a premium of 15-30% over conventional concrete, yet this price differential is gradually narrowing as production scales up and technology matures.

Recycled concrete, meanwhile, has gained significant market traction in urban centers where construction and demolition waste management presents both environmental challenges and economic opportunities. The global recycled concrete aggregate market was valued at $8.7 billion in 2022, with projections indicating growth to $14.5 billion by 2027. Regions with limited natural aggregate resources or high landfill costs demonstrate particularly strong demand for recycled concrete products.

Industry surveys reveal that 67% of major construction firms have incorporated sustainable concrete alternatives into their procurement strategies, with 42% specifically targeting carbon-negative or recycled concrete options. This trend is reinforced by government procurement policies that increasingly mandate minimum recycled content or maximum carbon footprint requirements for public infrastructure projects.

Consumer preferences are also evolving, with 73% of commercial property developers reporting that sustainable building materials positively impact property values and marketability. The growing influence of green building certification systems such as LEED, BREEAM, and Green Star has further accelerated market demand for innovative concrete solutions that contribute to sustainability ratings.

Despite positive market signals, adoption barriers persist, including concerns about long-term performance, limited supply chain infrastructure, and inconsistent regulatory frameworks across different regions. However, these challenges are gradually being addressed through industry standardization efforts and increased investment in production capacity.

Technical Challenges in Green Concrete Development

The development of green concrete faces numerous technical challenges that must be addressed to achieve widespread adoption. The primary obstacle lies in achieving comparable or superior mechanical properties to traditional concrete while maintaining environmental benefits. Carbon-negative concrete formulations often struggle to match the compressive strength and durability of conventional Portland cement concrete, particularly in early-stage strength development, which can extend construction timelines and increase costs.

Material inconsistency presents another significant challenge. Recycled concrete aggregates (RCA) exhibit variable quality depending on their source, processing methods, and contamination levels. This inconsistency makes standardization difficult and creates uncertainty in structural performance, limiting engineer confidence in specifying these materials for critical applications.

Carbon sequestration technologies integrated into concrete production face scalability issues. While laboratory demonstrations show promising CO2 absorption capabilities, translating these processes to industrial scale production remains technically complex and economically challenging. Current carbon mineralization techniques often require specialized equipment, precise process control, and extended curing times that disrupt conventional construction workflows.

Durability concerns persist across green concrete variants. Recycled concrete typically exhibits higher porosity and water absorption rates than virgin aggregate concrete, potentially compromising long-term performance in freeze-thaw conditions or aggressive environments. Similarly, some carbon-negative formulations show increased susceptibility to carbonation and chloride penetration, raising questions about reinforcement protection in structural applications.

Mix design optimization represents a multivariable challenge. Engineers must balance contradictory requirements: maximizing recycled content and carbon sequestration while maintaining workability, strength development, and long-term performance. This optimization becomes increasingly complex when considering regional variations in available materials and climate conditions affecting concrete performance.

Testing and certification frameworks lag behind innovation. Current standards and building codes were largely developed for conventional concrete, creating regulatory barriers for novel green concrete formulations. The development of appropriate testing protocols that accurately predict long-term performance of these innovative materials requires significant research investment and industry consensus.

Cost-effectiveness remains a persistent challenge. While recycled concrete can reduce material costs, the processing required to achieve consistent quality often offsets these savings. Carbon-negative technologies typically add production complexity and cost that must be justified through carbon pricing mechanisms or regulatory incentives to achieve market competitiveness against conventional concrete.

Material inconsistency presents another significant challenge. Recycled concrete aggregates (RCA) exhibit variable quality depending on their source, processing methods, and contamination levels. This inconsistency makes standardization difficult and creates uncertainty in structural performance, limiting engineer confidence in specifying these materials for critical applications.

Carbon sequestration technologies integrated into concrete production face scalability issues. While laboratory demonstrations show promising CO2 absorption capabilities, translating these processes to industrial scale production remains technically complex and economically challenging. Current carbon mineralization techniques often require specialized equipment, precise process control, and extended curing times that disrupt conventional construction workflows.

Durability concerns persist across green concrete variants. Recycled concrete typically exhibits higher porosity and water absorption rates than virgin aggregate concrete, potentially compromising long-term performance in freeze-thaw conditions or aggressive environments. Similarly, some carbon-negative formulations show increased susceptibility to carbonation and chloride penetration, raising questions about reinforcement protection in structural applications.

Mix design optimization represents a multivariable challenge. Engineers must balance contradictory requirements: maximizing recycled content and carbon sequestration while maintaining workability, strength development, and long-term performance. This optimization becomes increasingly complex when considering regional variations in available materials and climate conditions affecting concrete performance.

Testing and certification frameworks lag behind innovation. Current standards and building codes were largely developed for conventional concrete, creating regulatory barriers for novel green concrete formulations. The development of appropriate testing protocols that accurately predict long-term performance of these innovative materials requires significant research investment and industry consensus.

Cost-effectiveness remains a persistent challenge. While recycled concrete can reduce material costs, the processing required to achieve consistent quality often offsets these savings. Carbon-negative technologies typically add production complexity and cost that must be justified through carbon pricing mechanisms or regulatory incentives to achieve market competitiveness against conventional concrete.

Current Solutions for Carbon Sequestration in Concrete

01 Carbon capture and sequestration in concrete

Technologies that enable concrete to absorb and permanently store carbon dioxide during the curing process, transforming it from a carbon source to a carbon sink. These methods involve specialized formulations that react with CO2, mineralizing it within the concrete matrix. This approach not only reduces the carbon footprint of concrete production but can potentially make concrete carbon-negative by sequestering more CO2 than is emitted during manufacturing.- CO2 capture and sequestration in concrete: Technologies that enable concrete to capture and store carbon dioxide during its production or curing process, turning it into a carbon sink rather than a carbon source. These methods involve incorporating materials that can react with and permanently sequester CO2, such as specific mineral additives or binders that undergo carbonation reactions. This approach not only reduces the carbon footprint of concrete production but can potentially make concrete carbon-negative by storing more CO2 than is emitted during its manufacturing.

- Alternative binders and supplementary cementitious materials: The use of alternative binding materials and supplementary cementitious materials (SCMs) to partially or completely replace traditional Portland cement in concrete mixtures. These materials include industrial byproducts like fly ash, slag, silica fume, and natural pozzolans, as well as novel binders such as geopolymers and alkali-activated materials. By reducing the amount of Portland cement used, these alternatives significantly lower the carbon emissions associated with concrete production while often improving certain performance characteristics of the final product.

- Recycled concrete aggregate technologies: Methods for processing and utilizing demolished concrete as aggregate in new concrete mixes. These technologies involve crushing, sorting, and treating old concrete to produce recycled concrete aggregate (RCA) that can partially or fully replace virgin aggregates. Advanced processing techniques can improve the quality of recycled aggregates by removing contaminants and residual cement paste, enhancing the mechanical properties of the resulting concrete while diverting construction waste from landfills and reducing the environmental impact of aggregate mining.

- Enhanced carbonation curing processes: Specialized curing techniques that expose fresh concrete to controlled amounts of carbon dioxide to accelerate hardening and strength development while simultaneously sequestering CO2. These processes can be applied during precast manufacturing or on-site curing and involve optimized exposure conditions such as pressure, temperature, and humidity to maximize carbon uptake. Enhanced carbonation not only reduces the carbon footprint of concrete but can also improve its durability, reduce permeability, and increase resistance to chemical attacks.

- Waste incorporation and circular economy approaches: Innovative methods for incorporating various industrial and agricultural waste materials into concrete formulations beyond traditional recycled aggregates. These approaches include using plastic waste, glass cullet, wood ash, rice husk ash, and other waste streams as partial replacements for cement or aggregates. Such circular economy strategies not only reduce the environmental impact of concrete production but also help solve waste management challenges by converting problematic waste materials into valuable construction resources, creating multiple environmental benefits.

02 Recycled aggregate concrete formulations

Methods for incorporating recycled concrete aggregates (RCA) from demolished structures into new concrete mixes. These formulations address the challenges of using recycled materials, such as higher water absorption and lower strength, through specialized mix designs and additives. By replacing virgin aggregates with recycled concrete, these technologies reduce the environmental impact associated with aggregate mining and concrete waste disposal while maintaining structural performance requirements.Expand Specific Solutions03 Alternative cementitious materials for reduced carbon emissions

Development of alternative binding materials that can partially or completely replace traditional Portland cement, which is responsible for significant CO2 emissions. These include geopolymers, alkali-activated materials, and supplementary cementitious materials derived from industrial byproducts such as fly ash, slag, and silica fume. These materials require less energy to produce and generate fewer carbon emissions while providing comparable or superior performance characteristics to conventional cement.Expand Specific Solutions04 Enhanced carbonation techniques for concrete

Accelerated carbonation processes that promote the absorption of atmospheric CO2 by concrete during its lifecycle. These techniques involve controlling curing conditions, introducing catalysts, or modifying concrete porosity to optimize carbon uptake. Some methods include exposing fresh concrete to CO2-rich environments or injecting CO2 during mixing. These approaches enhance the natural carbonation process that occurs in concrete, increasing the amount of carbon sequestered over time.Expand Specific Solutions05 Waste incorporation in concrete beyond recycled aggregates

Technologies for incorporating various waste materials beyond recycled concrete into new concrete formulations. These include industrial byproducts, plastic waste, glass, rubber, and other non-traditional materials that can replace portions of the aggregate or cement. These approaches not only divert waste from landfills but can also improve specific properties of concrete such as thermal insulation, weight reduction, or durability while reducing the overall carbon footprint of the material.Expand Specific Solutions

Leading Companies in Sustainable Concrete Industry

The carbon-negative and recycled concrete market is in a growth phase, with increasing demand driven by sustainability regulations and construction industry's decarbonization efforts. Market size is expanding rapidly, projected to reach significant scale by 2030 as green building materials gain traction. Technological maturity varies across players: established companies like Cemex Research Group AG and Vicat SA have advanced commercial solutions, while innovative startups like Neustark AG are pioneering carbon mineralization technologies. Academic institutions (ETH Zurich, Tongji University) are accelerating R&D through collaborative research. Government research centers (CNRS) and industrial giants (thyssenkrupp) are investing heavily in scaling these technologies, indicating a competitive landscape transitioning from experimental to commercial applications.

Cemex Research Group AG

Technical Solution: Cemex has developed a proprietary carbon-negative concrete solution called "Vertua," which incorporates innovative clinker substitution technologies and carbon capture mechanisms. Their approach combines supplementary cementitious materials (SCMs) like fly ash and slag with novel carbon-capturing aggregates. Cemex's technology involves a two-pronged strategy: first reducing emissions during production through alternative fuels and raw materials, then actively sequestering CO2 through specialized concrete formulations that can absorb carbon throughout their lifecycle. Their research has demonstrated that Vertua concrete can achieve up to 70% lower carbon footprint compared to conventional concrete, with some applications reaching carbon neutrality or even negative emissions when accounting for lifetime carbon sequestration.

Strengths: Global scale implementation capability, comprehensive approach combining production efficiency and carbon capture, backed by extensive R&D infrastructure. Weaknesses: Higher initial production costs, requires specialized knowledge for implementation, and performance characteristics may differ from traditional concrete in some applications.

Swiss Federal Institute of Technology

Technical Solution: The Swiss Federal Institute of Technology (ETH Zurich) has developed groundbreaking research in both carbon-negative concrete and recycled concrete technologies. Their approach centers on the development of novel binders that can replace traditional Portland cement while actively sequestering CO2. ETH researchers have pioneered the use of calcium silicate hydrates (C-S-H) with modified surface properties that enhance carbonation while maintaining structural integrity. Their recycled concrete technology focuses on "selective demolition" techniques that preserve the quality of reclaimed materials, combined with specialized treatment processes to enhance the properties of recycled aggregates. A key innovation is their development of "smart demolition" protocols that optimize the recycling potential of concrete structures at end-of-life. Research data indicates their carbon-negative formulations can achieve net carbon sequestration of up to 50 kg CO2 per cubic meter, while their recycled concrete technologies can incorporate up to 90% recycled content without significant performance penalties.

Strengths: Cutting-edge scientific approach with strong theoretical foundations, comprehensive lifecycle perspective from demolition to new construction, excellent material performance characteristics. Weaknesses: Technologies still primarily in research phase with limited commercial implementation, requires specialized knowledge and equipment, higher initial costs compared to conventional solutions.

Key Innovations in CO2 Absorption Technologies

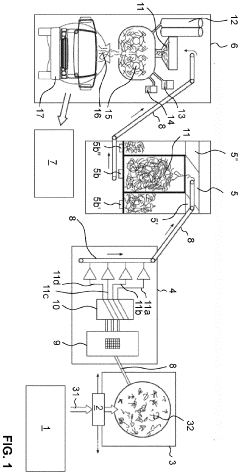

Carbonation of recycled concrete

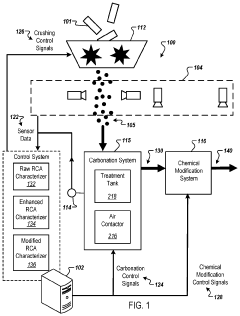

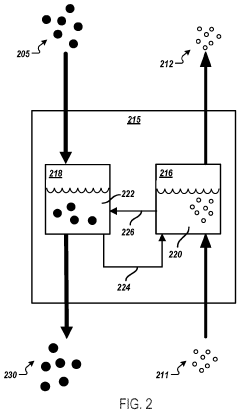

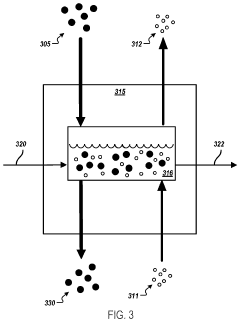

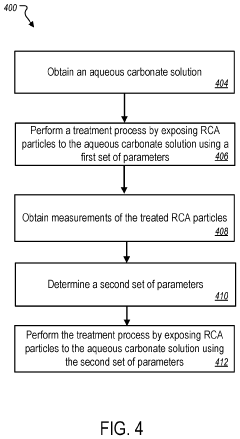

PatentPendingUS20240034675A1

Innovation

- A process and system for treating recycled concrete aggregate (RCA) using an aqueous alkaline solution to capture carbon dioxide, forming an aqueous carbonate solution that sequesters carbon into RCA particles, enhancing their strength and durability, while minimizing energy consumption.

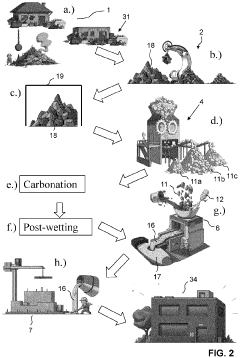

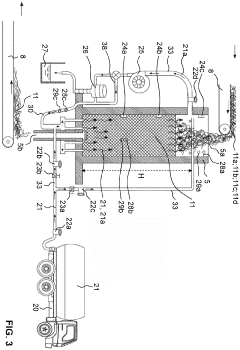

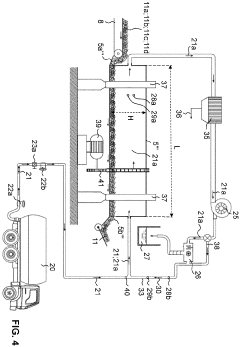

Large scale carbonation of concrete waste

PatentPendingEP4116274A1

Innovation

- A method involving controlled carbonation of concrete aggregates in a reactor vessel with defined CO2 levels and temperature control, optimizing grain size distribution and water content to enhance CO2 storage and mechanical properties, allowing for high-quality concrete production with minimal cement usage and reduced environmental impact.

Environmental Impact Assessment Methodologies

Environmental impact assessment methodologies for carbon-negative concrete and recycled concrete require comprehensive frameworks that accurately measure their ecological footprints throughout their lifecycle. The Life Cycle Assessment (LCA) methodology stands as the primary approach, evaluating environmental impacts from raw material extraction through manufacturing, transportation, use, and end-of-life disposal. For carbon-negative concrete, LCA must account for carbon sequestration mechanisms, quantifying CO2 absorption during curing and service life against emissions during production.

The Product Environmental Footprint (PEF) methodology offers a standardized approach to assess multiple environmental impact categories beyond carbon emissions, including water usage, resource depletion, and ecosystem toxicity. This multi-criteria assessment is particularly valuable when comparing carbon-negative concrete with recycled concrete, as it prevents burden-shifting between environmental impact categories.

Environmental Product Declarations (EPDs) provide standardized documentation of environmental performance based on ISO 14025 standards. These third-party verified documents enable fair comparison between different concrete types and support decision-making in sustainable construction projects. The development of concrete-specific Product Category Rules (PCRs) has enhanced the reliability of these comparisons.

Carbon accounting methodologies differ significantly between the two concrete types. For carbon-negative concrete, methodologies must accurately measure carbon sequestration through carbonation processes, while recycled concrete assessment focuses on avoided emissions from waste diversion and reduced virgin material extraction. The Greenhouse Gas Protocol provides guidance for these calculations, though industry-specific adaptations are often necessary.

Water footprint assessment methodologies are increasingly important, evaluating both direct water consumption and indirect impacts on water quality. The Water Footprint Network methodology distinguishes between blue, green, and grey water footprints, providing a comprehensive view of water resource impacts for both concrete types.

Emerging methodologies include real-time monitoring systems that track environmental performance throughout the concrete lifecycle using embedded sensors and IoT technology. These systems enable continuous assessment rather than point-in-time evaluations, offering more accurate environmental impact data. Additionally, social impact assessment methodologies are being integrated with environmental assessments to provide a more holistic sustainability evaluation, considering factors such as community health impacts and labor conditions in the concrete supply chain.

The Product Environmental Footprint (PEF) methodology offers a standardized approach to assess multiple environmental impact categories beyond carbon emissions, including water usage, resource depletion, and ecosystem toxicity. This multi-criteria assessment is particularly valuable when comparing carbon-negative concrete with recycled concrete, as it prevents burden-shifting between environmental impact categories.

Environmental Product Declarations (EPDs) provide standardized documentation of environmental performance based on ISO 14025 standards. These third-party verified documents enable fair comparison between different concrete types and support decision-making in sustainable construction projects. The development of concrete-specific Product Category Rules (PCRs) has enhanced the reliability of these comparisons.

Carbon accounting methodologies differ significantly between the two concrete types. For carbon-negative concrete, methodologies must accurately measure carbon sequestration through carbonation processes, while recycled concrete assessment focuses on avoided emissions from waste diversion and reduced virgin material extraction. The Greenhouse Gas Protocol provides guidance for these calculations, though industry-specific adaptations are often necessary.

Water footprint assessment methodologies are increasingly important, evaluating both direct water consumption and indirect impacts on water quality. The Water Footprint Network methodology distinguishes between blue, green, and grey water footprints, providing a comprehensive view of water resource impacts for both concrete types.

Emerging methodologies include real-time monitoring systems that track environmental performance throughout the concrete lifecycle using embedded sensors and IoT technology. These systems enable continuous assessment rather than point-in-time evaluations, offering more accurate environmental impact data. Additionally, social impact assessment methodologies are being integrated with environmental assessments to provide a more holistic sustainability evaluation, considering factors such as community health impacts and labor conditions in the concrete supply chain.

Regulatory Framework for Low-carbon Building Materials

The regulatory landscape for low-carbon building materials has evolved significantly in recent years, reflecting growing global concerns about climate change and environmental sustainability. Carbon-negative concrete and recycled concrete are subject to various regulatory frameworks that differ across regions but share common objectives of reducing carbon emissions and promoting circular economy principles in construction.

In the European Union, the Construction Products Regulation (CPR) establishes harmonized rules for the marketing of construction products, with recent amendments focusing specifically on environmental performance. The EU Taxonomy for Sustainable Activities includes specific criteria for low-carbon construction materials, providing clear benchmarks for what constitutes sustainable concrete products. Additionally, the European Green Deal has set ambitious targets for carbon neutrality by 2050, driving stricter regulations on embodied carbon in building materials.

North American regulatory frameworks vary by jurisdiction, with California leading through its Buy Clean California Act, which requires state agencies to consider the Global Warming Potential (GWP) of construction materials in procurement decisions. The LEED certification system, while voluntary, has become a de facto standard influencing regulatory development across the continent, with specific credits awarded for the use of low-carbon concrete alternatives.

Asian markets, particularly China and Japan, have implemented national standards for recycled concrete aggregates and are developing carbon intensity metrics for concrete production. Singapore's Green Mark certification system includes specific provisions for carbon-negative and recycled concrete materials, influencing regional regulatory approaches.

International standards organizations play a crucial role in harmonizing these diverse regulatory frameworks. ISO 14067 for carbon footprint of products and ISO 20887 for design for disassembly and adaptability provide standardized methodologies for assessing the environmental impact of concrete products. The World Green Building Council's Net Zero Carbon Buildings Commitment has further accelerated regulatory development worldwide.

Emerging regulatory trends include the implementation of carbon pricing mechanisms specifically targeting construction materials, mandatory Environmental Product Declarations (EPDs) for concrete products, and performance-based specifications rather than prescriptive standards. These approaches allow for innovation while ensuring environmental objectives are met. Carbon border adjustment mechanisms are also being considered to prevent "carbon leakage" through imported construction materials.

For manufacturers and developers working with carbon-negative and recycled concrete, navigating this complex regulatory landscape requires continuous monitoring of evolving standards and early engagement with certification bodies to ensure compliance and market access.

In the European Union, the Construction Products Regulation (CPR) establishes harmonized rules for the marketing of construction products, with recent amendments focusing specifically on environmental performance. The EU Taxonomy for Sustainable Activities includes specific criteria for low-carbon construction materials, providing clear benchmarks for what constitutes sustainable concrete products. Additionally, the European Green Deal has set ambitious targets for carbon neutrality by 2050, driving stricter regulations on embodied carbon in building materials.

North American regulatory frameworks vary by jurisdiction, with California leading through its Buy Clean California Act, which requires state agencies to consider the Global Warming Potential (GWP) of construction materials in procurement decisions. The LEED certification system, while voluntary, has become a de facto standard influencing regulatory development across the continent, with specific credits awarded for the use of low-carbon concrete alternatives.

Asian markets, particularly China and Japan, have implemented national standards for recycled concrete aggregates and are developing carbon intensity metrics for concrete production. Singapore's Green Mark certification system includes specific provisions for carbon-negative and recycled concrete materials, influencing regional regulatory approaches.

International standards organizations play a crucial role in harmonizing these diverse regulatory frameworks. ISO 14067 for carbon footprint of products and ISO 20887 for design for disassembly and adaptability provide standardized methodologies for assessing the environmental impact of concrete products. The World Green Building Council's Net Zero Carbon Buildings Commitment has further accelerated regulatory development worldwide.

Emerging regulatory trends include the implementation of carbon pricing mechanisms specifically targeting construction materials, mandatory Environmental Product Declarations (EPDs) for concrete products, and performance-based specifications rather than prescriptive standards. These approaches allow for innovation while ensuring environmental objectives are met. Carbon border adjustment mechanisms are also being considered to prevent "carbon leakage" through imported construction materials.

For manufacturers and developers working with carbon-negative and recycled concrete, navigating this complex regulatory landscape requires continuous monitoring of evolving standards and early engagement with certification bodies to ensure compliance and market access.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!