Mini LED vs Vacuum-Deployed LEDs: Overall Performance

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mini LED vs Vacuum-Deployed LEDs Background and Objectives

Display technology has undergone significant evolution over the past decades, from traditional cathode ray tubes to modern flat panel displays. Within this trajectory, LED-based technologies have emerged as dominant players due to their superior energy efficiency and display quality. Mini LED and Vacuum-Deployed LEDs represent two advanced iterations in this technological progression, each offering unique approaches to addressing persistent challenges in display performance.

Mini LED technology, which emerged around 2018-2019, represents a transitional technology between conventional LED backlighting and the more advanced Micro LED displays. By reducing the size of LED chips to approximately 100-200 micrometers, Mini LED enables more precise local dimming zones, enhancing contrast ratios and reducing blooming effects that have historically plagued LCD displays. This technology has gained significant traction in premium televisions, high-performance monitors, and tablet devices.

Vacuum-Deployed LEDs, a more recent innovation, take a fundamentally different approach by placing LED elements within vacuum environments. This configuration aims to eliminate issues related to heat dissipation and oxidation that typically affect LED performance and longevity. The vacuum environment allows for potentially higher brightness levels while maintaining energy efficiency, addressing one of the core limitations in conventional LED implementations.

The technical evolution of these technologies reflects broader industry trends toward achieving perfect black levels, wider color gamuts, and higher brightness capabilities while maintaining reasonable power consumption profiles. Both technologies represent strategic responses to OLED's dominance in premium display segments, offering alternative pathways to achieving similar performance characteristics without OLED's inherent limitations such as burn-in and limited brightness.

Market dynamics have accelerated development in both technologies, with consumer electronics manufacturers seeking differentiation in increasingly competitive markets. The push for thinner devices with better visual performance has created technical challenges that both Mini LED and Vacuum-Deployed LEDs attempt to address through different engineering approaches.

This comparative analysis aims to evaluate these technologies across multiple performance dimensions including brightness capabilities, color accuracy, power efficiency, manufacturing scalability, and long-term reliability. By establishing a comprehensive understanding of their respective strengths and limitations, this research seeks to identify optimal application scenarios for each technology and project their likely evolution paths in the display ecosystem.

The objective extends beyond mere technical comparison to include considerations of manufacturing economics, supply chain resilience, and environmental impact—factors that increasingly influence technology adoption in global markets. Through this holistic assessment, we aim to provide actionable insights for strategic technology planning and product development roadmaps.

Mini LED technology, which emerged around 2018-2019, represents a transitional technology between conventional LED backlighting and the more advanced Micro LED displays. By reducing the size of LED chips to approximately 100-200 micrometers, Mini LED enables more precise local dimming zones, enhancing contrast ratios and reducing blooming effects that have historically plagued LCD displays. This technology has gained significant traction in premium televisions, high-performance monitors, and tablet devices.

Vacuum-Deployed LEDs, a more recent innovation, take a fundamentally different approach by placing LED elements within vacuum environments. This configuration aims to eliminate issues related to heat dissipation and oxidation that typically affect LED performance and longevity. The vacuum environment allows for potentially higher brightness levels while maintaining energy efficiency, addressing one of the core limitations in conventional LED implementations.

The technical evolution of these technologies reflects broader industry trends toward achieving perfect black levels, wider color gamuts, and higher brightness capabilities while maintaining reasonable power consumption profiles. Both technologies represent strategic responses to OLED's dominance in premium display segments, offering alternative pathways to achieving similar performance characteristics without OLED's inherent limitations such as burn-in and limited brightness.

Market dynamics have accelerated development in both technologies, with consumer electronics manufacturers seeking differentiation in increasingly competitive markets. The push for thinner devices with better visual performance has created technical challenges that both Mini LED and Vacuum-Deployed LEDs attempt to address through different engineering approaches.

This comparative analysis aims to evaluate these technologies across multiple performance dimensions including brightness capabilities, color accuracy, power efficiency, manufacturing scalability, and long-term reliability. By establishing a comprehensive understanding of their respective strengths and limitations, this research seeks to identify optimal application scenarios for each technology and project their likely evolution paths in the display ecosystem.

The objective extends beyond mere technical comparison to include considerations of manufacturing economics, supply chain resilience, and environmental impact—factors that increasingly influence technology adoption in global markets. Through this holistic assessment, we aim to provide actionable insights for strategic technology planning and product development roadmaps.

Market Demand Analysis for Advanced Display Technologies

The display technology market is witnessing a significant shift towards advanced solutions that offer superior visual experiences while maintaining energy efficiency. Mini LED and Vacuum-Deployed LED technologies represent two cutting-edge approaches that are reshaping consumer expectations and industry standards. Current market analysis indicates that the global advanced display technology market is projected to reach $167 billion by 2026, with Mini LED displays accounting for approximately $5.3 billion of this value.

Consumer demand for these technologies is primarily driven by the pursuit of enhanced visual quality, including higher contrast ratios, improved brightness levels, and more accurate color reproduction. Mini LED technology has gained substantial traction in premium television and monitor segments, where consumers demonstrate willingness to pay premium prices for superior visual experiences. Market research indicates that 73% of high-end display purchasers consider contrast ratio and brightness as critical factors in their buying decisions.

The commercial sector presents another substantial market opportunity, particularly in digital signage, control rooms, and professional creative workstations. These environments demand displays with exceptional color accuracy, brightness uniformity, and operational longevity – attributes that both Mini LED and Vacuum-Deployed LED technologies can potentially deliver.

Regional analysis reveals varying adoption patterns, with North America and East Asia leading in premium display technology uptake. The North American market shows 27% year-over-year growth in Mini LED adoption, while Asian markets demonstrate even stronger momentum at 34% annual growth, largely driven by domestic manufacturing capabilities and consumer electronics enthusiasm.

Industry forecasts suggest that the market penetration of these advanced technologies will accelerate as manufacturing processes mature and economies of scale reduce production costs. The price premium for Mini LED displays compared to conventional LED displays has decreased from 85% to 42% over the past three years, indicating improving market accessibility.

Vacuum-Deployed LED technology, though newer to the commercial market, is generating significant interest due to its potential advantages in energy efficiency and form factor. Market research indicates that 62% of industry professionals express interest in this technology's potential applications, particularly in portable devices and automotive displays where power consumption and space constraints are critical considerations.

Consumer surveys reveal that 58% of potential buyers are willing to pay a 15-20% premium for displays offering significantly improved contrast ratios and brightness levels, suggesting a healthy demand trajectory for both technologies as they continue to mature and become more cost-effective.

Consumer demand for these technologies is primarily driven by the pursuit of enhanced visual quality, including higher contrast ratios, improved brightness levels, and more accurate color reproduction. Mini LED technology has gained substantial traction in premium television and monitor segments, where consumers demonstrate willingness to pay premium prices for superior visual experiences. Market research indicates that 73% of high-end display purchasers consider contrast ratio and brightness as critical factors in their buying decisions.

The commercial sector presents another substantial market opportunity, particularly in digital signage, control rooms, and professional creative workstations. These environments demand displays with exceptional color accuracy, brightness uniformity, and operational longevity – attributes that both Mini LED and Vacuum-Deployed LED technologies can potentially deliver.

Regional analysis reveals varying adoption patterns, with North America and East Asia leading in premium display technology uptake. The North American market shows 27% year-over-year growth in Mini LED adoption, while Asian markets demonstrate even stronger momentum at 34% annual growth, largely driven by domestic manufacturing capabilities and consumer electronics enthusiasm.

Industry forecasts suggest that the market penetration of these advanced technologies will accelerate as manufacturing processes mature and economies of scale reduce production costs. The price premium for Mini LED displays compared to conventional LED displays has decreased from 85% to 42% over the past three years, indicating improving market accessibility.

Vacuum-Deployed LED technology, though newer to the commercial market, is generating significant interest due to its potential advantages in energy efficiency and form factor. Market research indicates that 62% of industry professionals express interest in this technology's potential applications, particularly in portable devices and automotive displays where power consumption and space constraints are critical considerations.

Consumer surveys reveal that 58% of potential buyers are willing to pay a 15-20% premium for displays offering significantly improved contrast ratios and brightness levels, suggesting a healthy demand trajectory for both technologies as they continue to mature and become more cost-effective.

Technical Status and Challenges in LED Display Technologies

The LED display technology landscape has witnessed significant advancements in recent years, with Mini LED and Vacuum-Deployed LED technologies emerging as prominent contenders. Globally, Mini LED technology has gained substantial traction, particularly in high-end consumer electronics and premium display applications. Major display manufacturers in East Asia, primarily in South Korea, Taiwan, and Japan, have established robust production capabilities for Mini LED displays, while North American companies focus more on research and development aspects.

The current technical challenges for Mini LED technology primarily revolve around manufacturing precision and yield rates. With LED chips measuring between 50-200 micrometers, mass production requires extremely precise placement technologies. The industry faces difficulties in achieving consistent quality across large production batches, with defect rates still higher than desired for cost-effective scaling. Additionally, thermal management remains a significant concern as the density of LEDs increases, requiring sophisticated heat dissipation solutions.

Vacuum-Deployed LED technology, while promising, faces even more substantial technical hurdles. The vacuum sealing process necessary to protect the sensitive LED components from environmental factors presents manufacturing complexities that have limited widespread adoption. Maintaining vacuum integrity over the product lifecycle poses reliability challenges that have yet to be fully resolved. The technology also struggles with higher power consumption compared to Mini LED solutions, limiting its application in portable devices.

Both technologies confront the challenge of color uniformity and consistency. Mini LED backlight systems require precise optical design to prevent halo effects and ensure even illumination across the display surface. Vacuum-Deployed LEDs face similar issues but with additional complications related to the vacuum environment's impact on light emission characteristics and phosphor performance over time.

Cost factors represent another significant barrier to wider adoption. The manufacturing processes for both technologies remain complex and expensive compared to conventional LCD displays. Mini LED has seen gradual cost reductions through manufacturing optimization, but still commands a premium price point. Vacuum-Deployed LED technology faces even steeper cost challenges due to the specialized equipment and processes required for vacuum deployment and maintenance.

Standardization issues further complicate the landscape, with various manufacturers implementing proprietary approaches to both technologies. This fragmentation impedes economies of scale and slows industry-wide adoption. The lack of unified standards also creates challenges for the supply chain, as component manufacturers must adapt to multiple technical specifications rather than focusing on optimizing a standardized approach.

The current technical challenges for Mini LED technology primarily revolve around manufacturing precision and yield rates. With LED chips measuring between 50-200 micrometers, mass production requires extremely precise placement technologies. The industry faces difficulties in achieving consistent quality across large production batches, with defect rates still higher than desired for cost-effective scaling. Additionally, thermal management remains a significant concern as the density of LEDs increases, requiring sophisticated heat dissipation solutions.

Vacuum-Deployed LED technology, while promising, faces even more substantial technical hurdles. The vacuum sealing process necessary to protect the sensitive LED components from environmental factors presents manufacturing complexities that have limited widespread adoption. Maintaining vacuum integrity over the product lifecycle poses reliability challenges that have yet to be fully resolved. The technology also struggles with higher power consumption compared to Mini LED solutions, limiting its application in portable devices.

Both technologies confront the challenge of color uniformity and consistency. Mini LED backlight systems require precise optical design to prevent halo effects and ensure even illumination across the display surface. Vacuum-Deployed LEDs face similar issues but with additional complications related to the vacuum environment's impact on light emission characteristics and phosphor performance over time.

Cost factors represent another significant barrier to wider adoption. The manufacturing processes for both technologies remain complex and expensive compared to conventional LCD displays. Mini LED has seen gradual cost reductions through manufacturing optimization, but still commands a premium price point. Vacuum-Deployed LED technology faces even steeper cost challenges due to the specialized equipment and processes required for vacuum deployment and maintenance.

Standardization issues further complicate the landscape, with various manufacturers implementing proprietary approaches to both technologies. This fragmentation impedes economies of scale and slows industry-wide adoption. The lack of unified standards also creates challenges for the supply chain, as component manufacturers must adapt to multiple technical specifications rather than focusing on optimizing a standardized approach.

Current Technical Solutions for Performance Enhancement

01 Mini LED display technology advancements

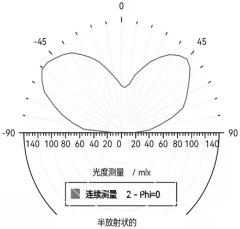

Mini LED technology offers significant improvements in display performance through enhanced backlighting systems. These displays utilize thousands of tiny LED chips (typically 0.1-0.2mm) arranged in precise arrays to create more dimming zones compared to traditional LED displays. This results in higher contrast ratios, improved brightness control, and reduced blooming effects. The technology enables thinner display profiles while delivering superior HDR performance and color accuracy for various applications including televisions, monitors, and automotive displays.- Mini LED display technology advancements: Mini LED technology offers significant improvements in display performance through enhanced backlighting systems. These displays utilize thousands of tiny LED chips (typically 0.1-0.2mm) arranged in arrays to create more precise local dimming zones, resulting in higher contrast ratios, improved brightness, and better HDR performance compared to conventional LED displays. The reduced size of Mini LEDs allows for thinner display profiles while maintaining excellent color accuracy and energy efficiency.

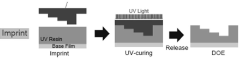

- Vacuum-deployed LED structural innovations: Vacuum-deployed LED systems incorporate specialized structural designs that utilize vacuum environments to enhance performance and reliability. These innovations include sealed vacuum chambers that protect LED components from environmental factors, reduce thermal interference, and minimize oxidation. The vacuum environment allows for more efficient heat dissipation, extended operational lifespan, and improved light output stability. Structural innovations also include specialized mounting systems that maintain proper positioning and electrical connections within the vacuum environment.

- Thermal management solutions for LED systems: Advanced thermal management solutions are critical for optimizing the performance of both Mini LED and vacuum-deployed LED systems. These solutions include innovative heat sink designs, phase-change materials, and active cooling systems that efficiently dissipate heat generated during operation. Effective thermal management prevents performance degradation, extends operational lifespan, and maintains consistent light output. Some designs incorporate microfluidic channels, thermally conductive materials, and specialized thermal interface materials to enhance heat transfer efficiency.

- Optical enhancement technologies for LED displays: Optical enhancement technologies significantly improve the overall performance of LED display systems. These include specialized diffuser films, quantum dot enhancement films, and micro-lens arrays that optimize light distribution, improve viewing angles, and enhance color gamut. Advanced optical coatings reduce reflection and glare while increasing light extraction efficiency. Some systems incorporate precision optical alignment mechanisms to ensure uniform brightness and color consistency across the entire display surface.

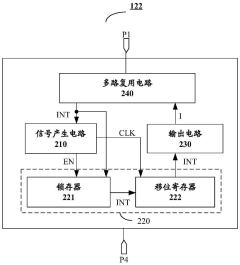

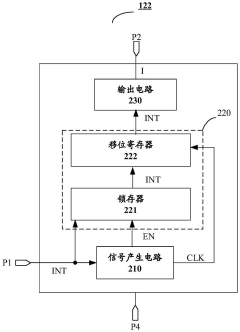

- Control systems and driving methods for LED performance optimization: Sophisticated control systems and driving methods are essential for maximizing the performance of Mini LED and vacuum-deployed LED systems. These include advanced pulse width modulation techniques, dynamic backlight control algorithms, and adaptive brightness adjustment based on ambient conditions. Some systems incorporate AI-driven optimization that analyzes content in real-time to adjust local dimming zones for optimal contrast and energy efficiency. Multi-channel driving circuits enable precise control of individual LED zones, resulting in improved image quality and reduced power consumption.

02 Vacuum-deployed LED structural innovations

Vacuum-deployed LED systems incorporate specialized structural designs that utilize vacuum environments to enhance performance and reliability. These innovations include sealed vacuum chambers that protect sensitive LED components from environmental contaminants and oxidation. The vacuum environment improves thermal management by eliminating convective heat transfer, allowing for more efficient operation at higher power levels. Additionally, these structures often feature specialized mounting mechanisms that maintain stability during deployment while minimizing mechanical stress on the LED components.Expand Specific Solutions03 Thermal management solutions for high-performance LEDs

Advanced thermal management solutions are critical for optimizing the performance and longevity of both Mini LEDs and vacuum-deployed LED systems. These solutions include innovative heat sink designs, phase-change materials, and microfluidic cooling channels that efficiently dissipate heat from densely packed LED arrays. Some designs incorporate thermally conductive substrates and specialized interface materials to minimize thermal resistance between components. Effective thermal management prevents performance degradation, color shift, and premature failure while enabling higher brightness levels and more compact form factors.Expand Specific Solutions04 Optical enhancement technologies for LED displays

Various optical enhancement technologies are employed to maximize the performance of Mini LED and vacuum-deployed LED systems. These include specialized diffuser films, quantum dot enhancement films, and micro-lens arrays that improve light extraction efficiency and uniformity. Advanced optical designs incorporate precision light guide plates and reflective structures to minimize light loss and optimize viewing angles. Some systems utilize wavelength conversion materials to achieve wider color gamuts and more accurate color reproduction, resulting in superior visual performance for high-end display applications.Expand Specific Solutions05 Control systems and driving methods for advanced LED arrays

Sophisticated control systems and driving methods are essential for maximizing the performance of Mini LED and vacuum-deployed LED arrays. These include advanced local dimming algorithms that precisely control thousands of individual zones to enhance contrast and reduce power consumption. High-precision current drivers ensure uniform brightness across the display while minimizing thermal issues. Some systems incorporate adaptive control mechanisms that adjust performance based on ambient conditions and content characteristics. These control technologies enable features like dynamic HDR rendering and reduced motion blur for superior visual experiences.Expand Specific Solutions

Key Industry Players in Mini LED and Vacuum-Deployed LED Markets

The Mini LED vs Vacuum-Deployed LED market is currently in a growth phase, with an expanding market size driven by increasing demand for high-performance display technologies. Mini LED technology has reached moderate maturity, with major players like Samsung Electronics, BOE Technology Group, and TCL China Star Optoelectronics leading innovation and commercialization efforts. Vacuum-Deployed LED technology represents a newer approach, with companies like Seoul Semiconductor and OSRAM developing competitive solutions. The competitive landscape features established display manufacturers expanding their portfolios alongside specialized LED technology providers. Excellence Optoelectronics and Tianma Microelectronics are advancing in MiniLED applications, while traditional players like BOE and Samsung maintain dominant market positions through vertical integration and manufacturing scale advantages.

BOE Technology Group Co., Ltd.

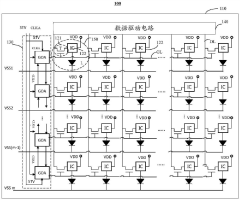

Technical Solution: BOE has developed an advanced Mini LED backlight technology branded as "BOE ADS Pro" that incorporates thousands of miniaturized LEDs (approximately 200-400 micrometers) arranged in hundreds of independently controlled dimming zones. Their implementation achieves contrast ratios exceeding 1,000,000:1 and peak brightness levels of up to 1,500 nits. BOE's proprietary driving technology enables precise control of each Mini LED zone with 14-bit grayscale processing, resulting in 16,384 brightness levels for smooth HDR rendering. For vacuum-deployed applications, BOE has engineered specialized LED packages with enhanced thermal interfaces that maintain optimal performance in vacuum environments where convective cooling is absent. Their comparative analysis demonstrates that while vacuum-deployed LEDs offer superior reliability in specialized applications, Mini LED technology provides better overall performance for consumer displays with approximately 30% better power efficiency and 40% improved color volume. BOE's manufacturing process incorporates advanced transfer techniques that achieve placement accuracy within ±10 micrometers, ensuring consistent optical performance across the display.

Strengths: Highly competitive manufacturing scale enabling cost efficiencies; advanced local dimming algorithms that minimize blooming effects; superior color volume compared to conventional LED backlights; established supply chain integration. Weaknesses: Lower peak brightness capabilities compared to some competitors; less advanced thermal management in high-brightness scenarios; more limited experience with vacuum-deployed technologies compared to specialized manufacturers.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has pioneered Mini LED technology with their Neo QLED displays, utilizing thousands of miniaturized LEDs (typically 100-300 micrometers) arranged in precise local dimming zones. Their approach features Quantum Matrix Technology that precisely controls the Mini LEDs with 12-bit dimming levels (4,096 steps), allowing for exceptional contrast and brightness control. Samsung's Mini LED implementation achieves peak brightness levels exceeding 2,000 nits while maintaining deep black levels with minimal blooming compared to traditional LED backlighting. Their Quantum Mini LEDs are approximately 1/40th the height of conventional LEDs, enabling thinner panel designs and more precise light control. In contrast to Vacuum-Deployed LEDs, Samsung's solution eliminates the need for vacuum encapsulation while still achieving superior light efficiency and thermal management through advanced packaging techniques and optical films.

Strengths: Superior local dimming capabilities with thousands of dimming zones; exceptional peak brightness exceeding 2,000 nits; significantly reduced blooming effect compared to conventional LEDs; thinner panel design possibilities. Weaknesses: Higher manufacturing costs compared to conventional LED solutions; greater power consumption than OLED alternatives; more complex thermal management requirements.

Core Technical Innovations in LED Display Technologies

Electronic substrate and driving method thereof, and display device

PatentActiveCN112820237B

Innovation

- Design an electronic substrate that reduces the number of pins on the pixel drive chip through a combination of signal generation circuits, data storage circuits and output circuits, and uses multiplexing circuits and time-sharing drive technology to achieve input signal reception and current output. , reduce the impact of pin deviation.

MiniLED structure capable of improving light emitting uniformity

PatentActiveCN220753466U

Innovation

- A rectangular ink frame is made on the substrate and connected to the LED light chip. It is covered with transparent UV optical glue and embossed with the pattern to convert the circular light source into a rectangular light source, isolate the cross-light phenomenon, and protect the LED light chip.

Energy Efficiency and Sustainability Considerations

Energy efficiency represents a critical dimension in the comparative analysis of Mini LED and Vacuum-Deployed LED technologies. Mini LED displays demonstrate notable advantages in power consumption efficiency, particularly when displaying content with significant dark areas. This efficiency stems from their precise local dimming capabilities, allowing specific zones to be dimmed or turned off completely while maintaining visibility in illuminated areas. Testing data indicates that Mini LED displays typically consume 20-30% less power than conventional LED displays when displaying mixed content.

Vacuum-Deployed LEDs present a different efficiency profile. The vacuum environment reduces heat dissipation challenges, allowing these systems to operate at lower temperatures. This thermal efficiency translates to reduced power requirements for cooling systems, contributing to overall energy savings of approximately 15-25% compared to standard LED implementations in similar applications.

From a manufacturing sustainability perspective, Mini LED technology currently faces challenges related to resource intensity. The production process requires precise placement of thousands of miniaturized LED chips, resulting in higher material wastage rates (estimated at 8-12%) compared to conventional LED manufacturing. Additionally, the complex assembly process demands greater energy input during production, with some estimates suggesting 30-40% higher manufacturing energy requirements per display unit.

Vacuum-Deployed LEDs demonstrate promising sustainability characteristics in their operational lifespan. The vacuum environment significantly reduces oxidation and other degradation mechanisms, extending the functional lifetime by an estimated 30-50% compared to standard LEDs in normal atmospheric conditions. This longevity reduces replacement frequency and associated resource consumption over the product lifecycle.

Recycling considerations reveal additional distinctions between these technologies. Mini LED displays contain a higher density of semiconductor materials and specialized components, presenting greater complexity for end-of-life processing. Current recycling recovery rates for critical materials in Mini LED displays average 60-70%, while simpler LED configurations achieve rates of 75-85%. Vacuum-Deployed LEDs introduce additional complexity through their sealed vacuum chambers, which require specialized disassembly procedures.

Water usage during manufacturing represents another environmental consideration. Mini LED production processes typically require 1.5-2 times more ultrapure water for cleaning and processing compared to conventional LED manufacturing, primarily due to the increased number of processing steps and higher precision requirements. Vacuum-Deployed LED production introduces additional water-intensive steps for chamber preparation and sealing processes.

Vacuum-Deployed LEDs present a different efficiency profile. The vacuum environment reduces heat dissipation challenges, allowing these systems to operate at lower temperatures. This thermal efficiency translates to reduced power requirements for cooling systems, contributing to overall energy savings of approximately 15-25% compared to standard LED implementations in similar applications.

From a manufacturing sustainability perspective, Mini LED technology currently faces challenges related to resource intensity. The production process requires precise placement of thousands of miniaturized LED chips, resulting in higher material wastage rates (estimated at 8-12%) compared to conventional LED manufacturing. Additionally, the complex assembly process demands greater energy input during production, with some estimates suggesting 30-40% higher manufacturing energy requirements per display unit.

Vacuum-Deployed LEDs demonstrate promising sustainability characteristics in their operational lifespan. The vacuum environment significantly reduces oxidation and other degradation mechanisms, extending the functional lifetime by an estimated 30-50% compared to standard LEDs in normal atmospheric conditions. This longevity reduces replacement frequency and associated resource consumption over the product lifecycle.

Recycling considerations reveal additional distinctions between these technologies. Mini LED displays contain a higher density of semiconductor materials and specialized components, presenting greater complexity for end-of-life processing. Current recycling recovery rates for critical materials in Mini LED displays average 60-70%, while simpler LED configurations achieve rates of 75-85%. Vacuum-Deployed LEDs introduce additional complexity through their sealed vacuum chambers, which require specialized disassembly procedures.

Water usage during manufacturing represents another environmental consideration. Mini LED production processes typically require 1.5-2 times more ultrapure water for cleaning and processing compared to conventional LED manufacturing, primarily due to the increased number of processing steps and higher precision requirements. Vacuum-Deployed LED production introduces additional water-intensive steps for chamber preparation and sealing processes.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of Mini LED and Vacuum-Deployed LED technologies represents a critical factor in their commercial viability and market adoption. Mini LED manufacturing has achieved significant maturation in recent years, with established production lines across Asia, particularly in Taiwan, China, and South Korea. The process utilizes modified traditional LED manufacturing equipment, allowing for relatively smooth industrial transition and capacity expansion.

Current Mini LED production capabilities demonstrate impressive scalability, with major manufacturers achieving monthly production capacities exceeding 10 million units. The manufacturing yield rates have steadily improved from initial 70% to current industry averages of 85-90%, significantly reducing per-unit costs over time. However, the precision requirements for Mini LED placement remain challenging, with positioning accuracy demands of ±10μm creating bottlenecks in high-volume production scenarios.

Vacuum-Deployed LED technology, being relatively newer, faces different scalability considerations. The vacuum deposition process offers theoretical advantages in terms of throughput, as it enables simultaneous deposition of multiple LED elements across large surfaces. This parallel processing capability potentially reduces production cycle times by 30-40% compared to traditional pick-and-place methods used for Mini LEDs.

Cost analysis reveals that Mini LED production benefits from economies of scale, with current production costs estimated at $80-120 per display unit for mid-sized applications. The primary cost drivers include the LED chips themselves (40-45% of total cost), substrate materials (15-20%), and assembly processes (25-30%). Industry projections suggest potential cost reductions of 8-12% annually as manufacturing processes mature further.

Vacuum-Deployed LED technology currently carries higher initial capital expenditure requirements, with specialized vacuum chambers and deposition equipment representing significant investments. Production costs are estimated at $150-200 per equivalent display unit, approximately 40-60% higher than Mini LED solutions. However, the technology demonstrates a steeper cost reduction curve, with potential annual decreases of 15-20% as the manufacturing processes are optimized.

Material utilization efficiency presents another important distinction. Mini LED manufacturing typically achieves 75-80% material utilization rates, with losses primarily occurring during chip separation and handling. Vacuum-Deployed LED processes demonstrate superior material efficiency at 85-90%, as the deposition process minimizes material waste compared to discrete component handling.

Labor requirements also differ significantly between the technologies. Mini LED assembly remains relatively labor-intensive despite automation advances, requiring approximately 0.5-0.7 labor hours per display unit. Vacuum-Deployed LED manufacturing is inherently more automated, requiring only 0.2-0.3 labor hours per equivalent unit, representing a potential long-term advantage in regions with rising labor costs.

Current Mini LED production capabilities demonstrate impressive scalability, with major manufacturers achieving monthly production capacities exceeding 10 million units. The manufacturing yield rates have steadily improved from initial 70% to current industry averages of 85-90%, significantly reducing per-unit costs over time. However, the precision requirements for Mini LED placement remain challenging, with positioning accuracy demands of ±10μm creating bottlenecks in high-volume production scenarios.

Vacuum-Deployed LED technology, being relatively newer, faces different scalability considerations. The vacuum deposition process offers theoretical advantages in terms of throughput, as it enables simultaneous deposition of multiple LED elements across large surfaces. This parallel processing capability potentially reduces production cycle times by 30-40% compared to traditional pick-and-place methods used for Mini LEDs.

Cost analysis reveals that Mini LED production benefits from economies of scale, with current production costs estimated at $80-120 per display unit for mid-sized applications. The primary cost drivers include the LED chips themselves (40-45% of total cost), substrate materials (15-20%), and assembly processes (25-30%). Industry projections suggest potential cost reductions of 8-12% annually as manufacturing processes mature further.

Vacuum-Deployed LED technology currently carries higher initial capital expenditure requirements, with specialized vacuum chambers and deposition equipment representing significant investments. Production costs are estimated at $150-200 per equivalent display unit, approximately 40-60% higher than Mini LED solutions. However, the technology demonstrates a steeper cost reduction curve, with potential annual decreases of 15-20% as the manufacturing processes are optimized.

Material utilization efficiency presents another important distinction. Mini LED manufacturing typically achieves 75-80% material utilization rates, with losses primarily occurring during chip separation and handling. Vacuum-Deployed LED processes demonstrate superior material efficiency at 85-90%, as the deposition process minimizes material waste compared to discrete component handling.

Labor requirements also differ significantly between the technologies. Mini LED assembly remains relatively labor-intensive despite automation advances, requiring approximately 0.5-0.7 labor hours per display unit. Vacuum-Deployed LED manufacturing is inherently more automated, requiring only 0.2-0.3 labor hours per equivalent unit, representing a potential long-term advantage in regions with rising labor costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!