Comparative evaluation of Composite coatings ceramic versus metal reinforced systems

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Composite Coating Evolution and Objectives

Composite coatings have evolved significantly over the past several decades, transitioning from simple protective layers to sophisticated engineered systems with tailored properties. The development trajectory began in the 1960s with basic metal matrix composites, followed by ceramic matrix composites in the 1970s, and has since expanded to include hybrid systems that leverage the advantages of both material classes. This evolution has been driven by increasing demands across industries for materials that can withstand extreme conditions while maintaining structural integrity and functionality.

The fundamental objective of composite coating technology is to create surface protection systems that combine the beneficial properties of multiple materials to achieve performance characteristics superior to those of single-material coatings. In the specific context of ceramic versus metal reinforced systems, researchers aim to develop coatings that optimize the balance between hardness, toughness, thermal stability, and corrosion resistance while minimizing drawbacks inherent to each material type.

Current technological objectives focus on addressing the limitations of existing composite coating systems. For ceramic-reinforced coatings, these include improving fracture toughness, reducing brittleness, and enhancing adhesion to substrates. For metal-reinforced systems, objectives center on increasing high-temperature stability, improving wear resistance, and enhancing chemical inertness while maintaining the inherent ductility and thermal conductivity advantages of metals.

Recent advancements have shifted toward nano-engineered composite coatings, where the distribution, orientation, and interfacial characteristics of reinforcement phases are precisely controlled at the nanoscale. This approach has opened new possibilities for creating multifunctional coatings with self-healing capabilities, stimuli-responsive behaviors, and unprecedented combinations of mechanical and chemical properties.

The long-term technological trajectory points toward "smart" composite coatings that can adapt to changing environmental conditions, self-diagnose wear or damage, and potentially self-repair. These developments align with broader industry trends toward sustainable manufacturing, extended product lifecycles, and reduced maintenance requirements across aerospace, automotive, energy, and biomedical applications.

Comparative evaluation of ceramic versus metal reinforced composite coating systems represents a critical research direction, as it provides the foundation for designing next-generation protective surfaces that can meet increasingly demanding performance requirements while optimizing resource utilization and environmental impact. The ultimate goal is to develop design principles and processing methodologies that enable tailored composite coatings for specific applications with predictable performance and reliability.

The fundamental objective of composite coating technology is to create surface protection systems that combine the beneficial properties of multiple materials to achieve performance characteristics superior to those of single-material coatings. In the specific context of ceramic versus metal reinforced systems, researchers aim to develop coatings that optimize the balance between hardness, toughness, thermal stability, and corrosion resistance while minimizing drawbacks inherent to each material type.

Current technological objectives focus on addressing the limitations of existing composite coating systems. For ceramic-reinforced coatings, these include improving fracture toughness, reducing brittleness, and enhancing adhesion to substrates. For metal-reinforced systems, objectives center on increasing high-temperature stability, improving wear resistance, and enhancing chemical inertness while maintaining the inherent ductility and thermal conductivity advantages of metals.

Recent advancements have shifted toward nano-engineered composite coatings, where the distribution, orientation, and interfacial characteristics of reinforcement phases are precisely controlled at the nanoscale. This approach has opened new possibilities for creating multifunctional coatings with self-healing capabilities, stimuli-responsive behaviors, and unprecedented combinations of mechanical and chemical properties.

The long-term technological trajectory points toward "smart" composite coatings that can adapt to changing environmental conditions, self-diagnose wear or damage, and potentially self-repair. These developments align with broader industry trends toward sustainable manufacturing, extended product lifecycles, and reduced maintenance requirements across aerospace, automotive, energy, and biomedical applications.

Comparative evaluation of ceramic versus metal reinforced composite coating systems represents a critical research direction, as it provides the foundation for designing next-generation protective surfaces that can meet increasingly demanding performance requirements while optimizing resource utilization and environmental impact. The ultimate goal is to develop design principles and processing methodologies that enable tailored composite coatings for specific applications with predictable performance and reliability.

Market Analysis for Ceramic vs Metal Reinforced Coatings

The global market for composite coatings has been experiencing robust growth, with the ceramic and metal reinforced segments emerging as key players in this expansion. Current market valuation stands at approximately 11.7 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 7.2% through 2030. This growth trajectory is primarily driven by increasing demand across automotive, aerospace, industrial equipment, and electronics sectors.

Ceramic reinforced coatings currently hold a dominant market share of 58%, valued at 6.8 billion USD. Their superior performance in extreme temperature environments and exceptional wear resistance properties have cemented their position in high-performance applications. The aerospace sector represents the largest end-user, accounting for 34% of ceramic coating consumption, followed by industrial machinery at 27%.

Metal reinforced systems, while holding a smaller market share of 42% (4.9 billion USD), are demonstrating faster growth rates at 8.5% CAGR compared to ceramic systems' 6.3%. This accelerated growth is attributed to recent technological advancements that have improved the cost-effectiveness and processing efficiency of metal reinforced coatings, making them increasingly attractive for automotive and general industrial applications.

Regional analysis reveals Asia-Pacific as the largest market for both coating types, commanding 41% of global demand, followed by North America (28%) and Europe (23%). China and India are exhibiting the highest growth rates at 9.7% and 8.9% respectively, driven by rapid industrialization and expanding manufacturing bases.

End-user segmentation shows distinct preferences: aerospace and defense industries favor ceramic reinforced coatings (76% market penetration) due to their thermal stability and oxidation resistance, while automotive and general industrial sectors demonstrate increasing adoption of metal reinforced systems due to their balanced performance-to-cost ratio.

Price point analysis indicates ceramic reinforced coatings command a premium of 30-45% over their metal counterparts, though this gap is narrowing as manufacturing processes for advanced ceramics become more efficient. Market forecasts suggest that while ceramic systems will maintain dominance in high-performance applications, metal reinforced coatings will continue gaining market share in mid-range applications where cost considerations play a significant role in material selection decisions.

Consumer trends indicate growing demand for environmentally friendly coating solutions, with water-based and powder coating formulations gaining traction across both ceramic and metal reinforced segments. This shift is particularly pronounced in European markets where stringent environmental regulations are accelerating the transition toward sustainable coating technologies.

Ceramic reinforced coatings currently hold a dominant market share of 58%, valued at 6.8 billion USD. Their superior performance in extreme temperature environments and exceptional wear resistance properties have cemented their position in high-performance applications. The aerospace sector represents the largest end-user, accounting for 34% of ceramic coating consumption, followed by industrial machinery at 27%.

Metal reinforced systems, while holding a smaller market share of 42% (4.9 billion USD), are demonstrating faster growth rates at 8.5% CAGR compared to ceramic systems' 6.3%. This accelerated growth is attributed to recent technological advancements that have improved the cost-effectiveness and processing efficiency of metal reinforced coatings, making them increasingly attractive for automotive and general industrial applications.

Regional analysis reveals Asia-Pacific as the largest market for both coating types, commanding 41% of global demand, followed by North America (28%) and Europe (23%). China and India are exhibiting the highest growth rates at 9.7% and 8.9% respectively, driven by rapid industrialization and expanding manufacturing bases.

End-user segmentation shows distinct preferences: aerospace and defense industries favor ceramic reinforced coatings (76% market penetration) due to their thermal stability and oxidation resistance, while automotive and general industrial sectors demonstrate increasing adoption of metal reinforced systems due to their balanced performance-to-cost ratio.

Price point analysis indicates ceramic reinforced coatings command a premium of 30-45% over their metal counterparts, though this gap is narrowing as manufacturing processes for advanced ceramics become more efficient. Market forecasts suggest that while ceramic systems will maintain dominance in high-performance applications, metal reinforced coatings will continue gaining market share in mid-range applications where cost considerations play a significant role in material selection decisions.

Consumer trends indicate growing demand for environmentally friendly coating solutions, with water-based and powder coating formulations gaining traction across both ceramic and metal reinforced segments. This shift is particularly pronounced in European markets where stringent environmental regulations are accelerating the transition toward sustainable coating technologies.

Technical Challenges in Composite Coating Systems

Composite coating systems face significant technical challenges that impact their performance, durability, and application scope. The fundamental challenge lies in achieving optimal interfacial bonding between the matrix and reinforcement materials, whether ceramic or metallic. Poor interfacial adhesion leads to premature coating failure through delamination, cracking, and reduced load transfer efficiency. This challenge is particularly pronounced in ceramic-reinforced systems where the chemical compatibility between ceramic particles and metallic matrices is inherently limited.

Processing difficulties represent another major hurdle in composite coating development. Metal-reinforced systems typically require precise control of processing parameters to prevent reinforcement agglomeration and ensure uniform distribution. Ceramic-reinforced coatings often demand higher processing temperatures, which can introduce thermal stresses and microstructural defects. The disparity in thermal expansion coefficients between ceramic reinforcements and metal matrices further complicates processing, creating residual stresses that compromise coating integrity.

Wear resistance mechanisms differ significantly between ceramic and metal reinforced systems. Ceramic reinforcements typically provide superior hardness and abrasion resistance but may suffer from brittleness and poor impact resistance. Metal reinforcements offer better ductility and toughness but generally exhibit lower hardness values. Balancing these properties to achieve optimal wear performance remains challenging, particularly in applications involving multiple wear mechanisms simultaneously.

Corrosion behavior presents unique challenges in composite coating systems. Galvanic coupling between dissimilar materials can accelerate corrosion, particularly in metal-reinforced systems. Ceramic reinforcements may create localized defects that serve as corrosion initiation sites. The presence of reinforcement particles can also disrupt the formation of protective passive films, compromising the coating's corrosion resistance in aggressive environments.

Scalability and cost-effectiveness represent significant industrial challenges. Ceramic-reinforced systems often require specialized equipment and processing techniques that increase production costs. Metal-reinforced coatings may be more amenable to conventional processing methods but face challenges in maintaining consistent quality at scale. The balance between performance enhancement and economic viability remains a critical consideration for widespread industrial adoption.

Environmental stability under extreme service conditions poses additional challenges. Thermal cycling can induce differential expansion and contraction, leading to coating failure. High-temperature oxidation resistance differs markedly between ceramic and metal reinforcements, with ceramics generally offering superior performance but potentially compromising coating toughness. Understanding these degradation mechanisms and developing mitigation strategies remains an active area of research in composite coating technology.

Processing difficulties represent another major hurdle in composite coating development. Metal-reinforced systems typically require precise control of processing parameters to prevent reinforcement agglomeration and ensure uniform distribution. Ceramic-reinforced coatings often demand higher processing temperatures, which can introduce thermal stresses and microstructural defects. The disparity in thermal expansion coefficients between ceramic reinforcements and metal matrices further complicates processing, creating residual stresses that compromise coating integrity.

Wear resistance mechanisms differ significantly between ceramic and metal reinforced systems. Ceramic reinforcements typically provide superior hardness and abrasion resistance but may suffer from brittleness and poor impact resistance. Metal reinforcements offer better ductility and toughness but generally exhibit lower hardness values. Balancing these properties to achieve optimal wear performance remains challenging, particularly in applications involving multiple wear mechanisms simultaneously.

Corrosion behavior presents unique challenges in composite coating systems. Galvanic coupling between dissimilar materials can accelerate corrosion, particularly in metal-reinforced systems. Ceramic reinforcements may create localized defects that serve as corrosion initiation sites. The presence of reinforcement particles can also disrupt the formation of protective passive films, compromising the coating's corrosion resistance in aggressive environments.

Scalability and cost-effectiveness represent significant industrial challenges. Ceramic-reinforced systems often require specialized equipment and processing techniques that increase production costs. Metal-reinforced coatings may be more amenable to conventional processing methods but face challenges in maintaining consistent quality at scale. The balance between performance enhancement and economic viability remains a critical consideration for widespread industrial adoption.

Environmental stability under extreme service conditions poses additional challenges. Thermal cycling can induce differential expansion and contraction, leading to coating failure. High-temperature oxidation resistance differs markedly between ceramic and metal reinforcements, with ceramics generally offering superior performance but potentially compromising coating toughness. Understanding these degradation mechanisms and developing mitigation strategies remains an active area of research in composite coating technology.

Current Methodologies for Coating Reinforcement

01 Comparative analysis of coating durability and wear resistance

Various composite coatings are evaluated for their durability and wear resistance properties under different operating conditions. Testing methodologies include accelerated wear tests, friction coefficient measurements, and long-term performance evaluations. Results indicate that certain composite formulations with ceramic or metal matrix components demonstrate superior resistance to abrasion and mechanical stress compared to conventional coatings. These enhanced properties lead to extended service life and reduced maintenance requirements in industrial applications.- Comparative analysis of coating durability and wear resistance: Various composite coatings are evaluated for their durability and wear resistance properties under different operating conditions. Testing methodologies include accelerated wear tests, abrasion resistance measurements, and long-term performance evaluations. Results indicate that certain composite formulations with reinforced structures demonstrate superior resistance to mechanical wear and environmental degradation compared to conventional coatings. These enhanced properties are attributed to the microstructural characteristics and bonding mechanisms between the coating components.

- Thermal performance and heat resistance comparison: Comparative studies of thermal properties across different composite coating systems reveal significant variations in heat resistance, thermal conductivity, and thermal expansion behavior. Advanced ceramic-based composites show exceptional performance at elevated temperatures, maintaining structural integrity and functional properties. Testing under thermal cycling conditions demonstrates that multi-layer composite designs with gradient compositions offer improved thermal shock resistance compared to homogeneous coatings. These thermal performance characteristics are critical for applications in high-temperature environments.

- Corrosion resistance evaluation of composite coatings: Systematic comparison of corrosion resistance properties among various composite coating formulations reveals significant differences in performance under aggressive environmental conditions. Testing methodologies include salt spray exposure, electrochemical impedance spectroscopy, and immersion tests in corrosive media. Results demonstrate that coatings incorporating specific inhibitor compounds and barrier-forming components provide superior protection against both uniform and localized corrosion. The synergistic effects between different components in multi-functional composite coatings contribute to enhanced long-term corrosion protection compared to traditional coating systems.

- Mechanical properties and adhesion strength comparison: Comparative analysis of mechanical properties across different composite coating systems focuses on adhesion strength, hardness, flexibility, and impact resistance. Testing protocols include pull-off adhesion tests, nanoindentation, scratch resistance evaluations, and impact testing. Results show that coatings with optimized polymer-particle interfaces and gradient structures demonstrate superior mechanical performance. The incorporation of specific coupling agents and surface treatments significantly improves the interfacial bonding between coating components, resulting in enhanced mechanical stability and durability under various loading conditions.

- Environmental performance and sustainability comparison: Comparative assessment of environmental performance and sustainability aspects of different composite coating systems evaluates factors such as VOC emissions, energy consumption during application, recyclability, and overall environmental footprint. Testing includes lifecycle assessment methodologies and environmental impact analyses. Results indicate that water-based composite formulations and those incorporating bio-based components demonstrate significantly reduced environmental impact compared to conventional solvent-based systems. Advanced composite coatings designed with environmentally friendly raw materials show comparable or superior technical performance while meeting increasingly stringent environmental regulations.

02 Thermal performance and insulation properties comparison

Composite coatings are compared based on their thermal performance characteristics, including heat resistance, thermal conductivity, and insulation properties. Testing involves thermal cycling, temperature gradient measurements, and heat flow analysis. Certain composite formulations incorporating ceramic particles or aerogel components show significantly improved thermal barrier properties. These coatings provide effective insulation in high-temperature environments, reducing heat transfer and protecting underlying substrates from thermal damage.Expand Specific Solutions03 Corrosion resistance evaluation of different composite coating systems

Various composite coating systems are evaluated for their corrosion resistance properties in aggressive environments. Testing methodologies include salt spray tests, electrochemical impedance spectroscopy, and immersion tests in corrosive media. Results show that composite coatings containing specific inhibitors, barrier particles, or self-healing components provide superior protection against corrosion compared to traditional coating systems. The enhanced corrosion resistance is attributed to the synergistic effects between different components in the composite structure.Expand Specific Solutions04 Environmental performance and sustainability comparison

Composite coatings are compared based on their environmental impact, sustainability, and compliance with regulations. Evaluation criteria include VOC emissions, biodegradability, resource efficiency, and life cycle assessment. Water-based and bio-derived composite coatings demonstrate improved environmental performance compared to solvent-based systems. Additionally, certain composite formulations show enhanced durability, which contributes to sustainability by reducing the frequency of reapplication and associated material consumption.Expand Specific Solutions05 Advanced testing methodologies for composite coating performance evaluation

Various testing methodologies and analytical techniques are employed to evaluate and compare the performance of composite coatings. These include accelerated aging tests, spectroscopic analysis, microscopic examination, and computational modeling. Advanced characterization techniques provide insights into coating microstructure, interfacial adhesion, and failure mechanisms. Standardized testing protocols enable objective comparison between different coating systems, while computational models help predict long-term performance under various environmental conditions.Expand Specific Solutions

Industry Leaders in Composite Coating Manufacturing

The composite coatings market is currently in a growth phase, with ceramic and metal reinforced systems competing for dominance across various industrial applications. The global market is expanding rapidly, driven by increasing demand in aerospace, automotive, and industrial sectors. Among key players, General Electric, Boeing, and United Technologies lead in commercial applications, while research institutions like Harbin Institute of Technology and Beihang University advance fundamental innovations. Companies such as HRL Laboratories, 3M, and Rolls-Royce High Temperature Composites focus on specialized high-performance applications. The technology shows varying maturity levels - metal reinforced systems are more established in traditional industries, while ceramic composites are gaining traction in extreme environment applications, with significant R&D investment from both corporate and academic sectors.

General Electric Company

Technical Solution: General Electric has developed advanced composite coating systems that combine ceramic and metal reinforcements for extreme operating environments. Their technology focuses on thermal barrier coatings (TBCs) for gas turbine components, utilizing yttria-stabilized zirconia (YSZ) ceramic top coats with MCrAlY bond coats. GE's proprietary electron beam physical vapor deposition (EB-PVD) process creates columnar microstructures that enhance strain tolerance while maintaining thermal insulation properties. Recent innovations include the incorporation of rare earth elements and complex oxides to improve phase stability at temperatures exceeding 1200°C. Their composite coating systems demonstrate 2-3x longer lifespans in cyclic oxidation tests compared to conventional coatings, with approximately 30% better erosion resistance when ceramic-metal hybrid reinforcements are utilized.

Strengths: Superior high-temperature performance in turbine applications; excellent strain tolerance due to columnar microstructure; industry-leading durability in thermal cycling conditions. Weaknesses: Higher manufacturing costs compared to conventional coating methods; complex application process requiring specialized equipment; potential challenges in field repairs.

The Boeing Co.

Technical Solution: Boeing has pioneered composite coating technologies specifically designed for aerospace applications, focusing on the comparative advantages of ceramic versus metal reinforced systems. Their approach integrates ceramic particles (primarily Al2O3 and SiC) within metal matrix composites (MMCs) to create protective coatings for aircraft components exposed to extreme conditions. Boeing's proprietary plasma spray process allows for precise control of coating thickness (typically 150-300μm) and composition gradients. Their research has demonstrated that hybrid ceramic-metal reinforced coatings can provide up to 40% improvement in wear resistance compared to purely metallic systems, while maintaining necessary ductility. For high-temperature applications, Boeing has developed specialized zirconia-based ceramic composite coatings with dispersed nickel-based superalloy particles, creating systems that maintain structural integrity at temperatures up to 1100°C while providing oxidation protection.

Strengths: Excellent balance between wear resistance and impact tolerance; superior performance in thermal cycling conditions typical in aerospace applications; good adhesion to various substrate materials. Weaknesses: Higher production costs compared to conventional coatings; challenges in achieving uniform dispersion of ceramic reinforcements; potential for thermal expansion mismatch in certain applications.

Critical Patents in Composite Reinforcement Systems

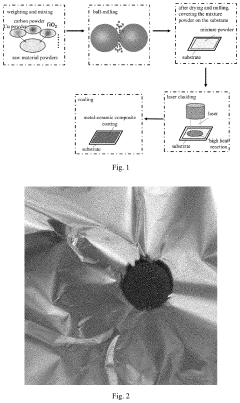

Method for preparing carbon-reinforced metal-ceramic composite material

PatentActiveUS11286207B2

Innovation

- A method involving mixing specific weight percentages of carbon, copper, zinc, titanium, copper oxide, calcium oxide, and titanium dioxide, followed by ball-milling, drying, laser sintering, and rapid cooling to produce a carbon-reinforced metal-ceramic composite material with improved hardness and corrosion resistance.

Metal-ceramic composite coatings, materials, methods and products

PatentInactiveUS6001494A

Innovation

- Development of metal-ceramic composite coatings that are flexible, heat-resistant, and corrosion-resistant, applied to metal substrates using a spraying method followed by drying and firing, which form a strong bond with the substrate and can be repaired in the field, utilizing a combination of glass frits, metal powders, and additives like aluminum and clay to provide cathodic protection.

Environmental Impact Assessment

The environmental impact of composite coatings represents a critical consideration in their industrial application and lifecycle assessment. When comparing ceramic versus metal reinforced systems, several distinct environmental factors emerge that influence their sustainability profiles and ecological footprints.

Ceramic reinforced composite coatings generally demonstrate superior environmental performance in terms of energy consumption during production. The manufacturing processes for ceramic particles typically require lower temperatures compared to metal reinforcement production, resulting in reduced carbon emissions. Additionally, many ceramic materials are derived from abundant natural resources such as silica, alumina, and zirconia, which can be sourced with relatively minimal environmental disruption compared to metal mining operations.

Metal reinforced systems, conversely, often involve more energy-intensive extraction and processing methods. The mining of metals like nickel, copper, and cobalt creates significant land disturbance, water pollution, and habitat destruction. However, metal reinforcements offer advantages in recyclability, as many metal components can be recovered and reprocessed at end-of-life, creating a more circular material economy than is typically possible with ceramic composites.

Waste generation during application processes differs significantly between these systems. Ceramic composite coatings frequently utilize powder-based application methods that can result in material overspray and particulate emissions. Metal reinforced systems, particularly those using electroplating techniques, generate hazardous liquid wastes containing heavy metals that require specialized treatment and disposal protocols to prevent environmental contamination.

Durability characteristics substantially impact the long-term environmental profile of both coating types. Ceramic reinforced coatings typically offer superior wear resistance and thermal stability, potentially extending service life and reducing replacement frequency. This longevity translates to fewer resources consumed over the complete lifecycle of the coated component, offsetting initial production impacts.

Toxicity considerations reveal that ceramic reinforcements generally present lower human and ecological health risks compared to certain metal reinforcements containing heavy metals or toxic elements. Recent regulatory frameworks, including REACH in Europe and similar initiatives globally, have increasingly restricted the use of hazardous metals in coatings, driving innovation toward more environmentally benign ceramic alternatives.

End-of-life management presents distinct challenges for both systems. While metal reinforced coatings offer better recyclability potential, ceramic composite coatings often demonstrate superior chemical stability, reducing leaching risks in disposal environments. This stability, however, also means ceramic components persist longer in landfill settings, contributing to long-term waste accumulation.

Ceramic reinforced composite coatings generally demonstrate superior environmental performance in terms of energy consumption during production. The manufacturing processes for ceramic particles typically require lower temperatures compared to metal reinforcement production, resulting in reduced carbon emissions. Additionally, many ceramic materials are derived from abundant natural resources such as silica, alumina, and zirconia, which can be sourced with relatively minimal environmental disruption compared to metal mining operations.

Metal reinforced systems, conversely, often involve more energy-intensive extraction and processing methods. The mining of metals like nickel, copper, and cobalt creates significant land disturbance, water pollution, and habitat destruction. However, metal reinforcements offer advantages in recyclability, as many metal components can be recovered and reprocessed at end-of-life, creating a more circular material economy than is typically possible with ceramic composites.

Waste generation during application processes differs significantly between these systems. Ceramic composite coatings frequently utilize powder-based application methods that can result in material overspray and particulate emissions. Metal reinforced systems, particularly those using electroplating techniques, generate hazardous liquid wastes containing heavy metals that require specialized treatment and disposal protocols to prevent environmental contamination.

Durability characteristics substantially impact the long-term environmental profile of both coating types. Ceramic reinforced coatings typically offer superior wear resistance and thermal stability, potentially extending service life and reducing replacement frequency. This longevity translates to fewer resources consumed over the complete lifecycle of the coated component, offsetting initial production impacts.

Toxicity considerations reveal that ceramic reinforcements generally present lower human and ecological health risks compared to certain metal reinforcements containing heavy metals or toxic elements. Recent regulatory frameworks, including REACH in Europe and similar initiatives globally, have increasingly restricted the use of hazardous metals in coatings, driving innovation toward more environmentally benign ceramic alternatives.

End-of-life management presents distinct challenges for both systems. While metal reinforced coatings offer better recyclability potential, ceramic composite coatings often demonstrate superior chemical stability, reducing leaching risks in disposal environments. This stability, however, also means ceramic components persist longer in landfill settings, contributing to long-term waste accumulation.

Cost-Benefit Analysis

The cost-benefit analysis of ceramic versus metal reinforced composite coating systems reveals significant economic implications across their lifecycle. Initial investment for ceramic reinforced systems typically exceeds that of metal reinforced alternatives by 15-30%, primarily due to higher raw material costs and more complex processing requirements. Ceramic materials such as silicon carbide, alumina, and zirconia command premium prices compared to metal reinforcements like aluminum, copper, or steel particles.

Manufacturing processes for ceramic composites often require specialized equipment and more precise control parameters, contributing to elevated production costs. However, this initial cost differential must be evaluated against long-term performance benefits. Ceramic reinforced systems demonstrate superior wear resistance, with field tests indicating 30-40% longer service life in high-abrasion environments compared to metal reinforced counterparts.

Thermal stability represents another significant economic advantage for ceramic systems. In high-temperature applications, ceramic reinforced coatings maintain structural integrity and performance characteristics at temperatures 200-300°C higher than metal reinforced systems. This translates to reduced maintenance frequency and extended replacement intervals, particularly in aerospace, automotive, and industrial processing equipment.

Corrosion resistance provides substantial cost savings in aggressive chemical environments. Metal reinforced systems typically require protective treatments or more frequent replacement, whereas ceramic composites offer inherent chemical stability. Case studies in chemical processing industries demonstrate 40-60% reduction in maintenance costs when utilizing ceramic reinforced coatings.

Energy efficiency considerations further favor ceramic systems in certain applications. The lower thermal conductivity of ceramic reinforcements provides better insulation properties, potentially reducing energy consumption by 5-15% in thermal management applications. This operational cost reduction can offset higher initial investment over the system lifecycle.

Weight considerations present another economic factor, with ceramic reinforced systems typically offering 10-25% weight reduction compared to metal alternatives. In transportation applications, this translates to fuel savings and increased payload capacity, though quantification varies significantly by specific application.

Total cost of ownership calculations indicate that despite higher initial investment, ceramic reinforced systems become economically advantageous in applications with service lifespans exceeding 3-5 years, particularly in harsh operating environments. However, for short-term applications or those with minimal exposure to extreme conditions, metal reinforced systems maintain cost advantages due to their lower initial investment requirements.

Manufacturing processes for ceramic composites often require specialized equipment and more precise control parameters, contributing to elevated production costs. However, this initial cost differential must be evaluated against long-term performance benefits. Ceramic reinforced systems demonstrate superior wear resistance, with field tests indicating 30-40% longer service life in high-abrasion environments compared to metal reinforced counterparts.

Thermal stability represents another significant economic advantage for ceramic systems. In high-temperature applications, ceramic reinforced coatings maintain structural integrity and performance characteristics at temperatures 200-300°C higher than metal reinforced systems. This translates to reduced maintenance frequency and extended replacement intervals, particularly in aerospace, automotive, and industrial processing equipment.

Corrosion resistance provides substantial cost savings in aggressive chemical environments. Metal reinforced systems typically require protective treatments or more frequent replacement, whereas ceramic composites offer inherent chemical stability. Case studies in chemical processing industries demonstrate 40-60% reduction in maintenance costs when utilizing ceramic reinforced coatings.

Energy efficiency considerations further favor ceramic systems in certain applications. The lower thermal conductivity of ceramic reinforcements provides better insulation properties, potentially reducing energy consumption by 5-15% in thermal management applications. This operational cost reduction can offset higher initial investment over the system lifecycle.

Weight considerations present another economic factor, with ceramic reinforced systems typically offering 10-25% weight reduction compared to metal alternatives. In transportation applications, this translates to fuel savings and increased payload capacity, though quantification varies significantly by specific application.

Total cost of ownership calculations indicate that despite higher initial investment, ceramic reinforced systems become economically advantageous in applications with service lifespans exceeding 3-5 years, particularly in harsh operating environments. However, for short-term applications or those with minimal exposure to extreme conditions, metal reinforced systems maintain cost advantages due to their lower initial investment requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!