Composite coatings for EV and renewable energy storage component protection

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Composite Coating Technology Background and Objectives

Composite coatings have emerged as a critical technology in the protection of components used in electric vehicles (EV) and renewable energy storage systems. The evolution of these specialized coatings can be traced back to the early 2000s when the limitations of traditional single-material coatings became apparent in increasingly demanding applications. As energy storage technologies advanced, the need for more robust protective solutions that could withstand extreme conditions while maintaining functionality became paramount.

The technological trajectory of composite coatings has been characterized by progressive integration of multiple materials to achieve synergistic properties. Initial developments focused primarily on corrosion resistance, but quickly expanded to address thermal management, electrical insulation, and mechanical durability simultaneously. This multi-functional approach represents a significant paradigm shift from conventional coating technologies that typically excelled in only one or two protective aspects.

Recent advancements in nanotechnology have dramatically accelerated innovation in this field, enabling the development of composite coatings with precisely engineered structures at the nanoscale. These next-generation coatings incorporate various functional nanoparticles, carbon nanotubes, graphene, and ceramic materials to create unprecedented combinations of properties tailored specifically for energy storage applications.

The primary technical objective in this domain is to develop composite coating systems that can significantly extend the operational lifespan of critical EV and renewable energy storage components while enhancing their performance under extreme conditions. Specific goals include achieving superior protection against electrochemical corrosion in battery systems, mitigating thermal runaway risks, and maintaining structural integrity under cyclic mechanical stresses.

Another crucial objective is the development of environmentally sustainable coating technologies that minimize the use of toxic materials while maintaining or improving protective capabilities. This aligns with the broader sustainability goals of the renewable energy and electric vehicle sectors, creating a harmonious technological ecosystem.

Looking forward, the field is trending toward smart composite coatings with self-healing capabilities, in-situ monitoring functions, and adaptive responses to environmental changes. These advanced features represent the frontier of coating technology and hold tremendous potential for revolutionizing component protection in next-generation energy storage systems.

The convergence of materials science, electrochemistry, and surface engineering is expected to yield breakthrough solutions that address current limitations while opening new possibilities for energy storage design and implementation. This interdisciplinary approach will be essential for meeting the increasingly demanding requirements of future EV and renewable energy applications.

The technological trajectory of composite coatings has been characterized by progressive integration of multiple materials to achieve synergistic properties. Initial developments focused primarily on corrosion resistance, but quickly expanded to address thermal management, electrical insulation, and mechanical durability simultaneously. This multi-functional approach represents a significant paradigm shift from conventional coating technologies that typically excelled in only one or two protective aspects.

Recent advancements in nanotechnology have dramatically accelerated innovation in this field, enabling the development of composite coatings with precisely engineered structures at the nanoscale. These next-generation coatings incorporate various functional nanoparticles, carbon nanotubes, graphene, and ceramic materials to create unprecedented combinations of properties tailored specifically for energy storage applications.

The primary technical objective in this domain is to develop composite coating systems that can significantly extend the operational lifespan of critical EV and renewable energy storage components while enhancing their performance under extreme conditions. Specific goals include achieving superior protection against electrochemical corrosion in battery systems, mitigating thermal runaway risks, and maintaining structural integrity under cyclic mechanical stresses.

Another crucial objective is the development of environmentally sustainable coating technologies that minimize the use of toxic materials while maintaining or improving protective capabilities. This aligns with the broader sustainability goals of the renewable energy and electric vehicle sectors, creating a harmonious technological ecosystem.

Looking forward, the field is trending toward smart composite coatings with self-healing capabilities, in-situ monitoring functions, and adaptive responses to environmental changes. These advanced features represent the frontier of coating technology and hold tremendous potential for revolutionizing component protection in next-generation energy storage systems.

The convergence of materials science, electrochemistry, and surface engineering is expected to yield breakthrough solutions that address current limitations while opening new possibilities for energy storage design and implementation. This interdisciplinary approach will be essential for meeting the increasingly demanding requirements of future EV and renewable energy applications.

Market Analysis for EV and Energy Storage Protective Solutions

The global market for protective coatings in electric vehicle (EV) and renewable energy storage applications is experiencing robust growth, driven by the accelerating transition towards sustainable energy solutions. Current market valuations indicate that the protective coatings segment specifically for these applications reached approximately $3.2 billion in 2022, with projections suggesting a compound annual growth rate (CAGR) of 18.7% through 2030.

This growth is primarily fueled by the exponential increase in EV adoption worldwide. Global EV sales surpassed 10 million units in 2022, representing a 55% year-over-year increase. Major markets including China, Europe, and North America are witnessing particularly strong demand, with China alone accounting for over 60% of global EV sales. This rapid expansion creates substantial demand for specialized protective coatings that can enhance component longevity and performance.

The energy storage sector presents another significant market opportunity, with utility-scale battery storage installations growing at 27% annually. Grid-scale energy storage deployments reached 15.1 GWh in 2022, with forecasts indicating a potential market size of over 500 GWh by 2030. This growth directly translates to increased demand for advanced protective coating solutions that can ensure operational reliability and safety.

Customer requirements in this market segment are evolving rapidly, with key demands centered around enhanced corrosion resistance, thermal management capabilities, and extended component lifespans. Battery manufacturers specifically seek coatings that can mitigate thermal runaway risks while providing excellent chemical resistance against electrolyte exposure. EV manufacturers prioritize lightweight solutions that do not compromise structural integrity or add significant weight to vehicle components.

Regional market analysis reveals distinct patterns in adoption and application preferences. Asian markets, particularly Japan and South Korea, demonstrate strong preference for nano-composite coatings with self-healing properties. European manufacturers tend to prioritize environmentally sustainable coating solutions with minimal VOC emissions, driven by stringent regulatory frameworks. North American markets show balanced demand across various coating technologies, with particular interest in solutions offering extended warranty periods.

Price sensitivity varies significantly across market segments, with high-performance applications willing to absorb premium pricing for demonstrable performance advantages. The industrial energy storage segment shows greater price elasticity compared to the automotive sector, where cost pressures remain intense due to overall vehicle pricing constraints.

This growth is primarily fueled by the exponential increase in EV adoption worldwide. Global EV sales surpassed 10 million units in 2022, representing a 55% year-over-year increase. Major markets including China, Europe, and North America are witnessing particularly strong demand, with China alone accounting for over 60% of global EV sales. This rapid expansion creates substantial demand for specialized protective coatings that can enhance component longevity and performance.

The energy storage sector presents another significant market opportunity, with utility-scale battery storage installations growing at 27% annually. Grid-scale energy storage deployments reached 15.1 GWh in 2022, with forecasts indicating a potential market size of over 500 GWh by 2030. This growth directly translates to increased demand for advanced protective coating solutions that can ensure operational reliability and safety.

Customer requirements in this market segment are evolving rapidly, with key demands centered around enhanced corrosion resistance, thermal management capabilities, and extended component lifespans. Battery manufacturers specifically seek coatings that can mitigate thermal runaway risks while providing excellent chemical resistance against electrolyte exposure. EV manufacturers prioritize lightweight solutions that do not compromise structural integrity or add significant weight to vehicle components.

Regional market analysis reveals distinct patterns in adoption and application preferences. Asian markets, particularly Japan and South Korea, demonstrate strong preference for nano-composite coatings with self-healing properties. European manufacturers tend to prioritize environmentally sustainable coating solutions with minimal VOC emissions, driven by stringent regulatory frameworks. North American markets show balanced demand across various coating technologies, with particular interest in solutions offering extended warranty periods.

Price sensitivity varies significantly across market segments, with high-performance applications willing to absorb premium pricing for demonstrable performance advantages. The industrial energy storage segment shows greater price elasticity compared to the automotive sector, where cost pressures remain intense due to overall vehicle pricing constraints.

Current Challenges in Composite Coating Development

Despite significant advancements in composite coating technologies for energy storage applications, several critical challenges continue to impede optimal performance and widespread adoption. Material compatibility issues remain at the forefront, as coatings must simultaneously adhere to diverse substrate materials while providing effective protection against multiple degradation mechanisms. The complex electrochemical environments in both EV batteries and renewable energy storage systems create particularly demanding conditions that few coating systems can fully withstand over extended operational lifetimes.

Durability under extreme temperature cycling presents another significant hurdle. Coatings must maintain structural integrity and protective properties across temperature ranges from -40°C to over 80°C, especially in EV applications where rapid charging generates substantial thermal stress. Current composite coating formulations often exhibit microcracking or delamination after repeated thermal cycling, compromising their protective capabilities.

Cost-effectiveness at scale remains problematic for advanced composite coatings. Many high-performance formulations incorporate expensive components such as graphene, carbon nanotubes, or specialized ceramic particles that significantly increase production costs. Manufacturing processes for uniform application at industrial scale also present technical difficulties, particularly for components with complex geometries common in energy storage systems.

Environmental and regulatory constraints further complicate development efforts. As global regulations increasingly restrict certain chemical compounds traditionally used in coating technologies, reformulation with environmentally acceptable alternatives often results in performance compromises. This regulatory landscape varies significantly across global markets, creating additional complexity for manufacturers operating internationally.

Multifunctionality requirements represent perhaps the most challenging aspect of current development efforts. Modern energy storage applications demand coatings that simultaneously provide corrosion resistance, thermal management, electrical insulation or conductivity (depending on the specific component), and in some cases, self-healing capabilities. Creating composite systems that effectively balance these sometimes contradictory properties requires sophisticated material science approaches not yet fully realized.

Testing and validation methodologies also present significant challenges. Accelerated aging tests often fail to accurately predict real-world performance, particularly for newer coating technologies without extensive field history. The lack of standardized testing protocols specific to energy storage applications further complicates comparative evaluation and quality assurance processes.

Durability under extreme temperature cycling presents another significant hurdle. Coatings must maintain structural integrity and protective properties across temperature ranges from -40°C to over 80°C, especially in EV applications where rapid charging generates substantial thermal stress. Current composite coating formulations often exhibit microcracking or delamination after repeated thermal cycling, compromising their protective capabilities.

Cost-effectiveness at scale remains problematic for advanced composite coatings. Many high-performance formulations incorporate expensive components such as graphene, carbon nanotubes, or specialized ceramic particles that significantly increase production costs. Manufacturing processes for uniform application at industrial scale also present technical difficulties, particularly for components with complex geometries common in energy storage systems.

Environmental and regulatory constraints further complicate development efforts. As global regulations increasingly restrict certain chemical compounds traditionally used in coating technologies, reformulation with environmentally acceptable alternatives often results in performance compromises. This regulatory landscape varies significantly across global markets, creating additional complexity for manufacturers operating internationally.

Multifunctionality requirements represent perhaps the most challenging aspect of current development efforts. Modern energy storage applications demand coatings that simultaneously provide corrosion resistance, thermal management, electrical insulation or conductivity (depending on the specific component), and in some cases, self-healing capabilities. Creating composite systems that effectively balance these sometimes contradictory properties requires sophisticated material science approaches not yet fully realized.

Testing and validation methodologies also present significant challenges. Accelerated aging tests often fail to accurately predict real-world performance, particularly for newer coating technologies without extensive field history. The lack of standardized testing protocols specific to energy storage applications further complicates comparative evaluation and quality assurance processes.

Existing Composite Coating Solutions for Energy Applications

01 Polymer-based composite coatings for corrosion protection

Polymer-based composite coatings provide effective corrosion protection for various substrates. These coatings typically incorporate polymers such as epoxy, polyurethane, or acrylic resins combined with functional additives to enhance barrier properties. The addition of nanoparticles or other reinforcing materials improves the mechanical strength and durability of the coating while maintaining excellent adhesion to the substrate. These composite systems create a protective barrier that prevents moisture, oxygen, and corrosive agents from reaching the underlying material.- Polymer-based composite coatings for corrosion protection: Polymer-based composite coatings provide effective corrosion protection for various substrates. These coatings typically incorporate polymeric materials such as epoxy, polyurethane, or acrylic resins combined with functional additives to enhance barrier properties. The addition of nanoparticles or other reinforcing materials improves the mechanical strength and durability of the coating while maintaining excellent adhesion to the substrate. These composite systems create a physical barrier that prevents corrosive agents from reaching the protected surface.

- Metal-ceramic composite coatings for thermal and wear protection: Metal-ceramic composite coatings combine the toughness of metals with the hardness and thermal resistance of ceramics to provide superior protection against wear, heat, and mechanical damage. These coatings are typically applied through thermal spray processes, physical vapor deposition, or electroplating techniques. The ceramic phase provides hardness and thermal insulation, while the metal phase contributes ductility and thermal conductivity. This combination results in coatings with excellent thermal shock resistance and wear protection for high-temperature applications.

- Self-healing composite coatings for extended protection: Self-healing composite coatings incorporate active components that can repair damage automatically when it occurs. These systems typically contain microcapsules or vascular networks filled with healing agents that are released upon crack formation. Alternatively, they may utilize intrinsically self-healing polymers that can reform bonds after damage. This autonomous repair capability significantly extends the service life of protective coatings by addressing minor damage before it leads to coating failure, thereby providing continuous protection without manual intervention.

- Environmentally friendly composite coatings for sustainable protection: Environmentally friendly composite coatings are formulated to provide effective protection while minimizing environmental impact. These coatings typically replace traditional toxic components with bio-based materials, water-based formulations, or low-VOC alternatives. Natural fibers, plant-derived polymers, and renewable resources are incorporated to create sustainable protective systems. These green composite coatings maintain protective performance while reducing environmental footprint, making them suitable for applications where environmental considerations are paramount.

- Multi-functional composite coatings for comprehensive protection: Multi-functional composite coatings provide simultaneous protection against multiple threats by combining different protective mechanisms in a single coating system. These coatings may incorporate antimicrobial agents, UV stabilizers, flame retardants, and anti-fouling components alongside traditional protective elements. The synergistic effect of these various functional additives results in comprehensive protection against corrosion, microbial growth, UV degradation, and other damaging factors. This approach reduces the need for multiple coating layers while providing enhanced overall protection for the substrate.

02 Metal-ceramic composite coatings for thermal and wear protection

Metal-ceramic composite coatings combine the toughness of metals with the hardness and thermal resistance of ceramics to provide superior protection against wear, heat, and mechanical stress. These coatings are typically applied through thermal spray processes, physical vapor deposition, or electroplating techniques. The ceramic components provide hardness and thermal insulation, while the metallic phase contributes ductility and thermal conductivity. This combination results in coatings with excellent thermal barrier properties and enhanced resistance to abrasion, making them ideal for high-temperature applications in aerospace, automotive, and industrial settings.Expand Specific Solutions03 Self-healing composite coatings for extended protection

Self-healing composite coatings incorporate active components that can repair damage automatically when it occurs, extending the protective lifetime of the coating. These systems typically contain microcapsules or vascular networks filled with healing agents that are released upon crack formation. Alternatively, they may utilize intrinsic self-healing mechanisms based on reversible chemical bonds or phase changes. The self-healing capability prevents small defects from developing into catastrophic failures, maintaining the protective function of the coating even after mechanical damage or environmental stress. This technology is particularly valuable for applications where maintenance is difficult or costly.Expand Specific Solutions04 Environmentally friendly composite coatings for sustainable protection

Environmentally friendly composite coatings provide effective protection while minimizing ecological impact through the use of bio-based materials, water-based formulations, or low-VOC systems. These coatings often incorporate renewable resources such as plant oils, cellulose derivatives, or chitosan as alternatives to petroleum-based components. Advanced formulation techniques ensure that these green coatings maintain performance comparable to conventional systems while reducing environmental footprint. The elimination of toxic components like heavy metals and hazardous solvents makes these coatings safer for both applicators and end-users, aligning with global sustainability initiatives and increasingly stringent environmental regulations.Expand Specific Solutions05 Multi-functional composite coatings for comprehensive protection

Multi-functional composite coatings provide simultaneous protection against multiple threats by combining various protective mechanisms in a single coating system. These advanced coatings may offer concurrent resistance to corrosion, wear, UV radiation, microbial growth, and fire. The multi-functionality is achieved through careful selection and combination of different components, often arranged in layered structures or through the incorporation of multifunctional additives. Smart responsive elements may also be included to adapt protection based on environmental conditions. This approach reduces the need for multiple separate coating applications, saving time and resources while providing comprehensive protection for complex applications in demanding environments.Expand Specific Solutions

Leading Manufacturers and Research Institutions Analysis

The composite coatings market for EV and renewable energy storage protection is in a growth phase, driven by increasing demand for advanced materials that enhance component durability and performance. The market is expanding rapidly with projections indicating significant growth as EV adoption accelerates globally. Technologically, the field shows varying maturity levels with established players like PPG Industries and Dow Global Technologies leading in industrial applications, while newer entrants such as Aspen Aerogels and Rivian Holdings are developing specialized solutions. Companies including Siemens, Covestro, and SGL Carbon are advancing material science innovations, particularly in thermal management and corrosion resistance. Asian manufacturers like Shanghai Spaceflight Institute and Econess Energy are increasingly competitive, focusing on cost-effective solutions for mass market applications.

PPG Industries Ohio, Inc.

Technical Solution: PPG has developed advanced composite coating systems specifically designed for EV battery components and renewable energy storage applications. Their technology incorporates nano-ceramic particles dispersed in polymer matrices to create multi-functional protective layers. These coatings feature self-healing capabilities through microencapsulated healing agents that release upon mechanical damage, automatically repairing microcracks before they propagate. PPG's coatings also integrate thermal management properties with phase-change materials that absorb excess heat during rapid charging and high-load conditions. The company has pioneered electrochemically stable formulations that resist degradation from electrolyte contact while maintaining electrical insulation properties. Their multi-layer approach includes a base corrosion-resistant layer, a middle thermal management layer, and a top impact-resistant layer, providing comprehensive protection for battery cells and modules.

Strengths: Superior corrosion resistance in harsh electrochemical environments; excellent thermal management capabilities that enhance battery safety and longevity; self-healing properties that extend component lifespan. Weaknesses: Higher initial application costs compared to conventional coatings; requires specialized application equipment and processes; some formulations may have limited high-temperature performance.

Dow Global Technologies LLC

Technical Solution: Dow has engineered a comprehensive composite coating platform for EV and renewable energy storage protection called ElectraSeal™. This technology utilizes silicone-modified polyurethane matrices reinforced with graphene nanoplatelets to create lightweight yet durable protective barriers. The coatings feature gradient functionality, with varying compositions through the thickness to address multiple protection requirements simultaneously. Their proprietary formulations incorporate flame-retardant additives that form an intumescent char upon exposure to high temperatures, providing critical fire protection for battery systems. Dow's coatings also feature hydrophobic surface treatments that prevent water ingress while maintaining breathability to allow safe gas release from battery cells during normal operation. The company has developed specialized application methods that ensure uniform coverage on complex geometries typical in energy storage components, with rapid cure cycles compatible with high-volume manufacturing processes.

Strengths: Exceptional chemical resistance against electrolytes and cooling fluids; superior flame retardancy meeting stringent safety standards; excellent adhesion to multiple substrate materials including metals, composites, and polymers. Weaknesses: More complex application process requiring precise control of environmental conditions; higher material costs compared to conventional coatings; potential for longer cure times in certain formulations.

Key Innovations in Protective Coating Materials Science

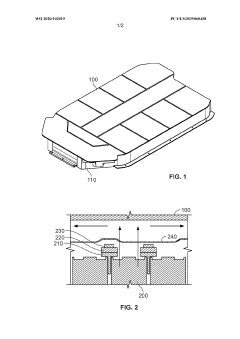

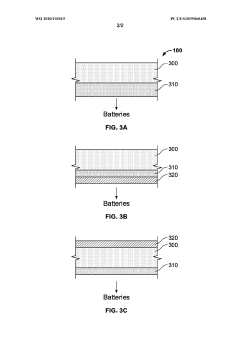

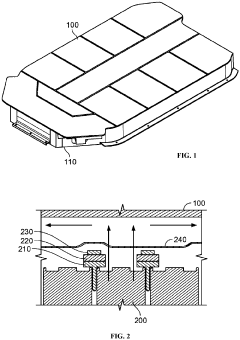

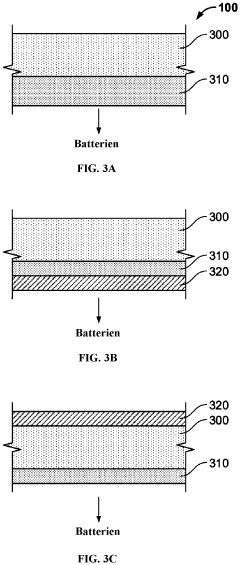

Electric vehicle battery pack cover having composite structure

PatentWO2020102019A1

Innovation

- A composite structure for the battery pack cover featuring a fiber-reinforced multiple-ply body with a high-hardness, high-melting point, fire- and abrasion-resistant coating, optionally combined with a metallic layer to reduce electromagnetic interference, providing structural rigidity and enhanced fire resistance.

EV battery pack cover WITH COMPOSITE STRUCTURE

PatentPendingDE112019005663T5

Innovation

- A fiber-reinforced composite multi-layer body with a high-hardness, fire- and abrasion-resistant coating, optionally combined with a metal layer, to provide structural rigidity, fire containment, and electromagnetic interference protection.

Environmental Impact and Sustainability Considerations

The environmental impact of composite coatings for EV and renewable energy storage components extends far beyond their immediate protective functions. These coatings significantly contribute to sustainability through extended component lifespans, reducing the frequency of replacements and associated resource consumption. By preventing corrosion and degradation, composite coatings minimize waste generation and decrease the environmental footprint of energy storage systems throughout their lifecycle.

Material selection for these coatings presents both challenges and opportunities for environmental stewardship. Traditional coating systems often contain volatile organic compounds (VOCs), heavy metals, and other environmentally harmful substances. The industry is rapidly transitioning toward water-based formulations, bio-derived components, and VOC-free alternatives that maintain or exceed performance standards while reducing ecological impact. Recent advancements in green chemistry have yielded promising bio-based polymers and naturally derived additives that can replace petroleum-based ingredients.

Energy consumption during coating application and curing processes represents another critical environmental consideration. Conventional thermal curing methods require substantial energy inputs, contributing to carbon emissions. Emerging technologies such as UV-curable coatings, electron beam curing, and room-temperature curing systems offer significant energy savings, with some solutions reducing energy requirements by up to 70% compared to traditional thermal processes.

End-of-life management for coated components presents unique recycling challenges. The composite nature of these coatings can complicate material separation and recovery processes. Research into designing coatings with built-in degradation triggers or easy separation mechanisms is advancing, allowing for more efficient recycling of base materials. Some innovative approaches include pH-responsive polymers that facilitate coating removal under specific controlled conditions without damaging the underlying substrate.

Regulatory frameworks worldwide are increasingly emphasizing environmental compliance for coating technologies. The European Union's REACH regulations, California's stringent VOC limits, and similar global initiatives are driving innovation toward greener coating solutions. Companies investing in environmentally responsible coating technologies not only ensure regulatory compliance but often realize cost benefits through reduced waste treatment requirements and improved public perception.

Carbon footprint reduction represents a quantifiable benefit of advanced composite coatings. Life cycle assessments indicate that high-performance protective coatings can reduce the overall carbon footprint of energy storage systems by 15-30% through extended service life and improved operational efficiency. This contribution to carbon reduction aligns perfectly with the broader sustainability goals of the renewable energy and electric vehicle sectors.

Material selection for these coatings presents both challenges and opportunities for environmental stewardship. Traditional coating systems often contain volatile organic compounds (VOCs), heavy metals, and other environmentally harmful substances. The industry is rapidly transitioning toward water-based formulations, bio-derived components, and VOC-free alternatives that maintain or exceed performance standards while reducing ecological impact. Recent advancements in green chemistry have yielded promising bio-based polymers and naturally derived additives that can replace petroleum-based ingredients.

Energy consumption during coating application and curing processes represents another critical environmental consideration. Conventional thermal curing methods require substantial energy inputs, contributing to carbon emissions. Emerging technologies such as UV-curable coatings, electron beam curing, and room-temperature curing systems offer significant energy savings, with some solutions reducing energy requirements by up to 70% compared to traditional thermal processes.

End-of-life management for coated components presents unique recycling challenges. The composite nature of these coatings can complicate material separation and recovery processes. Research into designing coatings with built-in degradation triggers or easy separation mechanisms is advancing, allowing for more efficient recycling of base materials. Some innovative approaches include pH-responsive polymers that facilitate coating removal under specific controlled conditions without damaging the underlying substrate.

Regulatory frameworks worldwide are increasingly emphasizing environmental compliance for coating technologies. The European Union's REACH regulations, California's stringent VOC limits, and similar global initiatives are driving innovation toward greener coating solutions. Companies investing in environmentally responsible coating technologies not only ensure regulatory compliance but often realize cost benefits through reduced waste treatment requirements and improved public perception.

Carbon footprint reduction represents a quantifiable benefit of advanced composite coatings. Life cycle assessments indicate that high-performance protective coatings can reduce the overall carbon footprint of energy storage systems by 15-30% through extended service life and improved operational efficiency. This contribution to carbon reduction aligns perfectly with the broader sustainability goals of the renewable energy and electric vehicle sectors.

Durability Testing and Performance Standards

Durability testing and performance standards for composite coatings in EV and renewable energy storage applications have evolved significantly to address the unique challenges these environments present. The testing protocols must simulate extreme conditions including temperature fluctuations (-40°C to 85°C), high humidity (up to 95% RH), salt spray exposure (1000+ hours), and electrochemical stress that components experience during operational lifetimes of 10-15 years.

Industry standards such as ISO 20340 for protective paint systems and ASTM B117 for salt spray testing provide baseline requirements, but specialized standards have emerged specifically for energy storage applications. The SAE J2380 standard for EV battery durability and IEC 61427 for renewable energy storage systems have become critical benchmarks that manufacturers must meet to ensure market acceptance.

Accelerated aging tests represent a cornerstone of durability assessment, with protocols designed to compress years of environmental exposure into weeks or months of testing. These include cyclic corrosion testing (CCT), thermal shock cycling, and UV exposure combined with moisture cycling. Advanced methodologies now incorporate electrochemical impedance spectroscopy (EIS) to monitor coating degradation in real-time during testing, providing deeper insights into failure mechanisms.

Performance metrics for composite coatings have become increasingly stringent, with requirements for less than 5% degradation in protective properties after 3000 hours of accelerated testing. Adhesion strength retention (ASTM D3359), impact resistance (ASTM D2794), and chemical resistance to electrolytes and coolants must maintain at least 90% of initial values throughout the testing regime.

Emerging test methodologies focus on simulating real-world conditions more accurately. These include combined environmental cycling with mechanical stress, mimicking the vibration and thermal expansion stresses experienced during vehicle operation. Additionally, new standards are incorporating testing for resistance to emerging fast-charging protocols, where thermal management becomes critical for coating integrity.

The development of digital twin modeling for coating performance prediction represents the cutting edge of durability assessment. These models integrate real-time sensor data from field applications with laboratory test results to create predictive algorithms for coating performance over time. This approach is gradually being incorporated into standards development, allowing for more precise lifetime predictions and maintenance scheduling.

Industry standards such as ISO 20340 for protective paint systems and ASTM B117 for salt spray testing provide baseline requirements, but specialized standards have emerged specifically for energy storage applications. The SAE J2380 standard for EV battery durability and IEC 61427 for renewable energy storage systems have become critical benchmarks that manufacturers must meet to ensure market acceptance.

Accelerated aging tests represent a cornerstone of durability assessment, with protocols designed to compress years of environmental exposure into weeks or months of testing. These include cyclic corrosion testing (CCT), thermal shock cycling, and UV exposure combined with moisture cycling. Advanced methodologies now incorporate electrochemical impedance spectroscopy (EIS) to monitor coating degradation in real-time during testing, providing deeper insights into failure mechanisms.

Performance metrics for composite coatings have become increasingly stringent, with requirements for less than 5% degradation in protective properties after 3000 hours of accelerated testing. Adhesion strength retention (ASTM D3359), impact resistance (ASTM D2794), and chemical resistance to electrolytes and coolants must maintain at least 90% of initial values throughout the testing regime.

Emerging test methodologies focus on simulating real-world conditions more accurately. These include combined environmental cycling with mechanical stress, mimicking the vibration and thermal expansion stresses experienced during vehicle operation. Additionally, new standards are incorporating testing for resistance to emerging fast-charging protocols, where thermal management becomes critical for coating integrity.

The development of digital twin modeling for coating performance prediction represents the cutting edge of durability assessment. These models integrate real-time sensor data from field applications with laboratory test results to create predictive algorithms for coating performance over time. This approach is gradually being incorporated into standards development, allowing for more precise lifetime predictions and maintenance scheduling.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!