Comparative study of Composite coatings polymer versus hybrid matrix systems

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Composite Coating Technology Evolution and Objectives

Composite coating technology has evolved significantly over the past several decades, transitioning from simple protective layers to sophisticated engineered systems with multifunctional properties. The journey began in the 1960s with basic polymer coatings primarily designed for corrosion protection, followed by the introduction of particle-reinforced polymer composites in the 1970s that offered enhanced mechanical properties. The 1990s marked a pivotal shift with the emergence of hybrid matrix systems, combining organic and inorganic components to achieve synergistic performance benefits previously unattainable with single-matrix systems.

The technological evolution accelerated in the early 2000s with advancements in nanotechnology, enabling precise control over coating microstructures and interfaces. This period saw the development of nanocomposite coatings with dramatically improved barrier properties, wear resistance, and functional capabilities. Recent innovations have focused on smart composite coatings with self-healing, stimuli-responsive, and adaptive characteristics, representing the cutting edge of current technology.

Today's composite coating landscape is characterized by a dichotomy between traditional polymer-based systems and more advanced hybrid matrix architectures. Polymer matrix composites continue to dominate commercial applications due to their established processing methods, cost-effectiveness, and reliable performance in conventional environments. Meanwhile, hybrid matrix systems are gaining traction in high-performance sectors where extreme conditions or multifunctionality justify their higher complexity and cost.

The primary objective of current research in this field is to systematically compare polymer versus hybrid matrix systems across multiple performance dimensions, including mechanical durability, chemical resistance, thermal stability, and functional properties. This comparative analysis aims to establish quantitative relationships between matrix composition, microstructure, and performance outcomes to enable more informed material selection and design optimization.

Additional research goals include developing predictive models for composite coating behavior under various service conditions, identifying key performance indicators for specific application requirements, and establishing standardized testing protocols that accurately reflect real-world performance. There is also significant interest in addressing sustainability challenges through the development of bio-based composite coatings and environmentally friendly processing methods.

The ultimate technological objective is to create a comprehensive framework for designing application-specific composite coatings with optimized performance-to-cost ratios, whether based on polymer or hybrid matrices. This framework would incorporate materials selection guidelines, processing parameters, and performance prediction tools to accelerate innovation and commercialization of next-generation coating technologies across industries ranging from automotive and aerospace to construction and consumer goods.

The technological evolution accelerated in the early 2000s with advancements in nanotechnology, enabling precise control over coating microstructures and interfaces. This period saw the development of nanocomposite coatings with dramatically improved barrier properties, wear resistance, and functional capabilities. Recent innovations have focused on smart composite coatings with self-healing, stimuli-responsive, and adaptive characteristics, representing the cutting edge of current technology.

Today's composite coating landscape is characterized by a dichotomy between traditional polymer-based systems and more advanced hybrid matrix architectures. Polymer matrix composites continue to dominate commercial applications due to their established processing methods, cost-effectiveness, and reliable performance in conventional environments. Meanwhile, hybrid matrix systems are gaining traction in high-performance sectors where extreme conditions or multifunctionality justify their higher complexity and cost.

The primary objective of current research in this field is to systematically compare polymer versus hybrid matrix systems across multiple performance dimensions, including mechanical durability, chemical resistance, thermal stability, and functional properties. This comparative analysis aims to establish quantitative relationships between matrix composition, microstructure, and performance outcomes to enable more informed material selection and design optimization.

Additional research goals include developing predictive models for composite coating behavior under various service conditions, identifying key performance indicators for specific application requirements, and establishing standardized testing protocols that accurately reflect real-world performance. There is also significant interest in addressing sustainability challenges through the development of bio-based composite coatings and environmentally friendly processing methods.

The ultimate technological objective is to create a comprehensive framework for designing application-specific composite coatings with optimized performance-to-cost ratios, whether based on polymer or hybrid matrices. This framework would incorporate materials selection guidelines, processing parameters, and performance prediction tools to accelerate innovation and commercialization of next-generation coating technologies across industries ranging from automotive and aerospace to construction and consumer goods.

Market Analysis for Polymer and Hybrid Matrix Coatings

The global market for composite coatings has been experiencing robust growth, with the polymer and hybrid matrix systems segment showing particularly strong performance. Current market valuation for polymer matrix composite coatings stands at approximately $8.7 billion, with projections indicating growth to reach $12.3 billion by 2027, representing a compound annual growth rate (CAGR) of 7.2%. Hybrid matrix systems, though currently a smaller segment valued at $3.4 billion, are demonstrating accelerated growth rates of 9.5% annually.

Key market drivers include increasing demand from automotive and aerospace industries seeking lightweight, high-performance materials that contribute to fuel efficiency and reduced emissions. The construction sector represents another significant market, particularly in regions experiencing infrastructure development booms such as Southeast Asia and the Middle East, where these coatings provide enhanced durability and corrosion resistance.

Regional analysis reveals North America and Europe as mature markets with stable growth rates of 5-6%, while Asia-Pacific leads in terms of volume consumption and growth potential, with China and India collectively accounting for 38% of global demand growth. Latin America and Africa remain emerging markets with considerable untapped potential, particularly in industrial applications.

End-user segmentation indicates that transportation accounts for 34% of market share, followed by industrial applications (28%), construction (22%), and consumer goods (16%). Within these segments, polymer matrix systems dominate in applications requiring cost-effectiveness and established performance parameters, while hybrid systems are gaining traction in premium applications where enhanced properties justify higher costs.

Market challenges include volatile raw material prices, with petroleum-derived polymer components experiencing price fluctuations of 15-20% in recent years. Environmental regulations present both challenges and opportunities, with stricter VOC emission standards driving innovation in water-based and eco-friendly formulations. The European Union's REACH regulations and similar frameworks in other regions continue to reshape product development priorities.

Customer preference analysis reveals increasing demand for multi-functional coatings that combine properties such as corrosion resistance, thermal stability, and self-healing capabilities. This trend favors hybrid matrix systems, which can more readily incorporate diverse functional components. Price sensitivity varies significantly by application, with industrial and automotive sectors demonstrating greater willingness to invest in premium solutions that offer demonstrable performance advantages and lifecycle cost benefits.

Key market drivers include increasing demand from automotive and aerospace industries seeking lightweight, high-performance materials that contribute to fuel efficiency and reduced emissions. The construction sector represents another significant market, particularly in regions experiencing infrastructure development booms such as Southeast Asia and the Middle East, where these coatings provide enhanced durability and corrosion resistance.

Regional analysis reveals North America and Europe as mature markets with stable growth rates of 5-6%, while Asia-Pacific leads in terms of volume consumption and growth potential, with China and India collectively accounting for 38% of global demand growth. Latin America and Africa remain emerging markets with considerable untapped potential, particularly in industrial applications.

End-user segmentation indicates that transportation accounts for 34% of market share, followed by industrial applications (28%), construction (22%), and consumer goods (16%). Within these segments, polymer matrix systems dominate in applications requiring cost-effectiveness and established performance parameters, while hybrid systems are gaining traction in premium applications where enhanced properties justify higher costs.

Market challenges include volatile raw material prices, with petroleum-derived polymer components experiencing price fluctuations of 15-20% in recent years. Environmental regulations present both challenges and opportunities, with stricter VOC emission standards driving innovation in water-based and eco-friendly formulations. The European Union's REACH regulations and similar frameworks in other regions continue to reshape product development priorities.

Customer preference analysis reveals increasing demand for multi-functional coatings that combine properties such as corrosion resistance, thermal stability, and self-healing capabilities. This trend favors hybrid matrix systems, which can more readily incorporate diverse functional components. Price sensitivity varies significantly by application, with industrial and automotive sectors demonstrating greater willingness to invest in premium solutions that offer demonstrable performance advantages and lifecycle cost benefits.

Current Technological Status and Challenges in Composite Coatings

The global landscape of composite coating technology has witnessed significant advancements in recent years, with polymer and hybrid matrix systems emerging as dominant approaches. Currently, polymer-based composite coatings hold approximately 65% of the market share, while hybrid systems have rapidly expanded to capture about 30%, demonstrating accelerated growth rates of 12-15% annually compared to the 7-9% growth of traditional polymer systems.

In the United States and Europe, research institutions have made substantial progress in developing high-performance polymer composite coatings with enhanced durability and chemical resistance. Notable achievements include the development of self-healing polymer matrices that can extend coating lifespans by up to 40% compared to conventional systems. Meanwhile, Asian markets, particularly China and Japan, have focused on cost-effective hybrid solutions that balance performance with economic viability.

The primary technical challenges facing composite coating development revolve around four key areas. First, adhesion stability remains problematic, particularly in hybrid systems where interfacial bonding between organic and inorganic components can deteriorate under extreme environmental conditions. Research indicates that approximately 35% of hybrid coating failures stem from adhesion issues, compared to 22% in pure polymer systems.

Second, dispersion uniformity presents significant difficulties, especially in hybrid matrices where achieving homogeneous distribution of nanoparticles remains elusive. Current manufacturing processes can only achieve 80-85% dispersion uniformity in hybrid systems, compared to 90-95% in polymer-based alternatives, resulting in inconsistent performance characteristics.

Third, environmental resistance varies considerably between systems. While polymer matrices excel in flexibility and impact resistance, they typically underperform in UV and chemical resistance compared to hybrid counterparts. Conversely, hybrid systems demonstrate superior thermal stability but often exhibit brittleness under mechanical stress, with crack propagation rates approximately 1.5 times higher than polymer-based coatings.

Finally, scalability and manufacturing complexity represent significant barriers to widespread adoption. Hybrid matrix systems require more sophisticated processing equipment and tighter parameter control, increasing production costs by 25-40% compared to polymer-based alternatives. This cost differential has limited industrial-scale implementation despite the performance advantages hybrid systems offer in specific applications.

Geographically, research leadership is distributed across multiple regions, with North America leading in polymer matrix innovation, Europe pioneering environmentally friendly formulations, and Asia advancing rapidly in hybrid system development and cost optimization strategies.

In the United States and Europe, research institutions have made substantial progress in developing high-performance polymer composite coatings with enhanced durability and chemical resistance. Notable achievements include the development of self-healing polymer matrices that can extend coating lifespans by up to 40% compared to conventional systems. Meanwhile, Asian markets, particularly China and Japan, have focused on cost-effective hybrid solutions that balance performance with economic viability.

The primary technical challenges facing composite coating development revolve around four key areas. First, adhesion stability remains problematic, particularly in hybrid systems where interfacial bonding between organic and inorganic components can deteriorate under extreme environmental conditions. Research indicates that approximately 35% of hybrid coating failures stem from adhesion issues, compared to 22% in pure polymer systems.

Second, dispersion uniformity presents significant difficulties, especially in hybrid matrices where achieving homogeneous distribution of nanoparticles remains elusive. Current manufacturing processes can only achieve 80-85% dispersion uniformity in hybrid systems, compared to 90-95% in polymer-based alternatives, resulting in inconsistent performance characteristics.

Third, environmental resistance varies considerably between systems. While polymer matrices excel in flexibility and impact resistance, they typically underperform in UV and chemical resistance compared to hybrid counterparts. Conversely, hybrid systems demonstrate superior thermal stability but often exhibit brittleness under mechanical stress, with crack propagation rates approximately 1.5 times higher than polymer-based coatings.

Finally, scalability and manufacturing complexity represent significant barriers to widespread adoption. Hybrid matrix systems require more sophisticated processing equipment and tighter parameter control, increasing production costs by 25-40% compared to polymer-based alternatives. This cost differential has limited industrial-scale implementation despite the performance advantages hybrid systems offer in specific applications.

Geographically, research leadership is distributed across multiple regions, with North America leading in polymer matrix innovation, Europe pioneering environmentally friendly formulations, and Asia advancing rapidly in hybrid system development and cost optimization strategies.

Existing Formulation and Application Methodologies

01 Metal-based composite coatings

Metal-based composite coatings combine metallic materials with other components to enhance properties such as corrosion resistance, wear resistance, and durability. These coatings often incorporate particles or fibers within a metal matrix to create superior surface protection. The metal matrix provides structural integrity while the embedded materials contribute specific functional properties, making these coatings suitable for demanding industrial applications.- Metal-based composite coatings: Metal-based composite coatings involve the application of metallic materials combined with other substances to create protective layers with enhanced properties. These coatings typically offer improved corrosion resistance, wear protection, and thermal stability. The metal components may include aluminum, zinc, nickel, or various alloys, often combined with ceramic particles, polymers, or other reinforcing materials to achieve specific performance characteristics for industrial applications.

- Polymer-based composite coatings: Polymer-based composite coatings utilize organic polymers as matrix materials enhanced with various fillers or reinforcing agents. These coatings provide benefits such as chemical resistance, flexibility, and adhesion to different substrates. The polymer matrices may include epoxies, polyurethanes, acrylics, or fluoropolymers, often incorporating additives like nanoparticles, fibers, or functional compounds to improve specific properties such as scratch resistance, UV stability, or self-healing capabilities.

- Ceramic and inorganic composite coatings: Ceramic and inorganic composite coatings consist of non-metallic inorganic materials that provide exceptional hardness, thermal resistance, and chemical stability. These coatings typically incorporate materials such as silicon carbide, alumina, zirconia, or various oxides, often combined with binding agents or other functional materials. They are particularly valuable in high-temperature applications, offering protection against oxidation, wear, and thermal shock while maintaining structural integrity under extreme conditions.

- Multi-layer composite coating systems: Multi-layer composite coating systems involve the strategic application of different coating layers to achieve complementary protective properties. These systems typically include primer layers for adhesion, intermediate layers for specific functional properties, and topcoats for environmental protection. The layered approach allows for optimization of different properties such as corrosion resistance, thermal insulation, wear protection, and aesthetic appearance, with each layer serving a specific purpose in the overall coating performance.

- Functional and smart composite coatings: Functional and smart composite coatings go beyond traditional protective properties to provide additional capabilities such as self-healing, sensing, or responsive behavior. These advanced coatings incorporate functional additives like phase-change materials, conductive particles, or stimuli-responsive compounds that can adapt to environmental changes. Applications include self-cleaning surfaces, anti-icing coatings, antimicrobial protection, and coatings that can indicate damage or wear through visual or electrical signals, representing the cutting edge of coating technology.

02 Polymer-based composite coatings

Polymer-based composite coatings utilize various polymeric materials as matrices with added functional components to achieve specific properties. These coatings offer advantages such as flexibility, chemical resistance, and ease of application. By incorporating different additives, fillers, or reinforcing materials into the polymer matrix, these coatings can be tailored for applications ranging from protective barriers to decorative finishes, with enhanced durability and performance characteristics.Expand Specific Solutions03 Ceramic and inorganic composite coatings

Ceramic and inorganic composite coatings combine ceramic materials with other components to create high-performance surface treatments. These coatings typically offer exceptional thermal stability, hardness, and wear resistance. The ceramic matrix provides temperature resistance while additional components can enhance properties such as thermal conductivity or electrical insulation. These coatings are particularly valuable in high-temperature applications or environments requiring extreme durability and chemical resistance.Expand Specific Solutions04 Nanocomposite coating technologies

Nanocomposite coatings incorporate nanoscale particles or structures within a matrix material to achieve enhanced properties not possible with conventional materials. By dispersing nanoparticles throughout the coating matrix, these technologies can significantly improve hardness, wear resistance, corrosion protection, and other functional properties. The nanoscale components create unique interfaces and interactions within the coating structure, resulting in superior performance characteristics for specialized industrial and commercial applications.Expand Specific Solutions05 Multi-layer composite coating systems

Multi-layer composite coating systems utilize strategically designed layers of different materials to achieve optimized performance characteristics. Each layer in the system serves a specific function, such as adhesion promotion, corrosion inhibition, or surface finishing. By combining complementary materials in a structured arrangement, these systems can provide comprehensive protection and functionality that single-layer coatings cannot achieve. These sophisticated coating architectures are particularly valuable in demanding environments requiring multiple performance attributes.Expand Specific Solutions

Leading Manufacturers and Research Institutions Analysis

The composite coatings market is experiencing robust growth, transitioning from early adoption to mainstream implementation across multiple industries. The market is expanding at a significant rate due to increasing demand for advanced protective and functional surface treatments. In terms of technological maturity, polymer matrix systems represent the established technology with companies like PPG Industries, DuPont, and Rohm & Haas leading development with decades of expertise. Meanwhile, hybrid matrix systems are emerging as the innovative frontier, with research institutions (MIT, EPFL, ETH Zurich) and specialized manufacturers (Favored Nanotechnology, Wolfspeed) driving advancements. The competitive landscape shows a strategic convergence between traditional chemical companies expanding their portfolios and specialized technology firms focusing on niche applications, particularly in aerospace, automotive, and electronics sectors.

PPG Industries Ohio, Inc.

Technical Solution: PPG Industries has developed advanced composite coating systems that combine polymer matrices with inorganic components to create hybrid solutions. Their technology focuses on electrodeposition coatings that incorporate silica nanoparticles into polymer matrices, creating a synergistic effect that enhances corrosion resistance and mechanical properties. The company's approach involves controlled dispersion of nanoparticles within the polymer matrix to prevent agglomeration, which is achieved through proprietary surface modification techniques. PPG's hybrid matrix systems demonstrate superior weatherability compared to conventional polymer coatings, with accelerated testing showing up to 40% improvement in UV resistance and gloss retention. Their composite coatings also feature self-healing capabilities through the incorporation of microcapsules containing healing agents that are released upon mechanical damage to the coating surface[1][3].

Strengths: Superior corrosion protection and chemical resistance compared to pure polymer systems; excellent adhesion properties across various substrates; enhanced durability in extreme environmental conditions. Weaknesses: Higher production costs compared to conventional polymer coatings; more complex application processes requiring specialized equipment; potential challenges in achieving consistent nanoparticle dispersion at industrial scale.

DuPont de Nemours, Inc.

Technical Solution: DuPont has pioneered hybrid matrix composite coating systems that integrate organic polymers with inorganic components at the molecular level. Their technology platform utilizes sol-gel chemistry to create interpenetrating networks where silica or other inorganic phases are chemically bonded to polymer chains. This approach results in coatings with significantly improved thermal stability, with decomposition temperatures increased by up to 75°C compared to pure polymer counterparts. DuPont's hybrid coatings demonstrate exceptional barrier properties, reducing oxygen permeability by approximately 60% compared to conventional polymer coatings. The company has developed proprietary crosslinking technologies that enable precise control over the mechanical properties of the final coating, allowing customization from flexible to rigid applications. Their hybrid matrix systems also incorporate self-cleaning functionalities through the integration of photocatalytic nanoparticles that decompose organic contaminants upon exposure to light[2][5].

Strengths: Exceptional chemical resistance against acids, bases, and organic solvents; superior thermal stability allowing application in high-temperature environments; excellent barrier properties against moisture and gases. Weaknesses: Higher initial cost compared to traditional polymer coatings; more complex formulation requiring precise control of reaction parameters; potential limitations in color options and aesthetic properties due to inorganic components.

Key Patents and Scientific Breakthroughs in Composite Coatings

Hybrid polymer-matrix composite and processing method

PatentPendingUS20230235129A1

Innovation

- Processing the hybrid polymer-matrix composite in a twin-screw extruder, where each reinforcement fiber is fed through a specific feeder to adjust temperature and shear, ensuring adequate dispersion and encapsulation by the polymer matrix, optimizing interfacial interactions and homogenization.

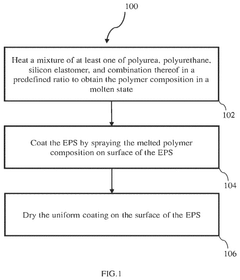

Polymer composition and process for coating expanded polystyrene with the polymer composition

PatentPendingUS20250043094A1

Innovation

- A hybrid polymer composition comprising a mixture of polyurea, polyurethane, and silicon elastomer in specific ratios, applied using a matrix coating process, which imparts high impact and abrasion resistance, elongation strength, flexural strength, and anti-static properties to EPS, while preventing discoloration due to the use of aliphatic compounds.

Environmental Impact and Sustainability Assessment

The environmental impact of composite coating systems has become a critical consideration in material selection across industries. Polymer-based composite coatings generally demonstrate lower environmental footprints during production compared to hybrid matrix systems, primarily due to lower energy requirements and reduced emissions during manufacturing processes. Life cycle assessments indicate that polymer composites typically consume 30-45% less energy during fabrication than their hybrid counterparts that incorporate inorganic components.

However, hybrid matrix systems often demonstrate superior durability and longer service life, which can offset their initially higher environmental impact through reduced replacement frequency. Studies show that certain hybrid coatings can extend service intervals by 40-60% compared to conventional polymer systems, resulting in significant resource conservation over the complete product lifecycle.

Waste management presents distinct challenges for both systems. Polymer composite coatings frequently face recycling difficulties due to their complex formulations and cross-linked structures. Only 12-18% of polymer composite waste is currently effectively recycled globally. Hybrid systems, while sometimes containing potentially hazardous inorganic components, often offer better separation possibilities that can facilitate more efficient material recovery at end-of-life.

Emerging sustainable formulations are rapidly transforming both categories. Bio-based polymers derived from renewable resources are increasingly incorporated into composite coatings, reducing dependence on petroleum-based raw materials. Similarly, hybrid systems are evolving to incorporate naturally occurring minerals and biodegradable components that minimize environmental persistence.

Regulatory frameworks worldwide are progressively imposing stricter controls on volatile organic compounds (VOCs) and hazardous substances in coating systems. Polymer composites have generally adapted more quickly to these requirements, with water-based formulations achieving market penetration rates of approximately 65% in architectural applications. Hybrid systems, while traditionally more dependent on solvent-based chemistry, are now experiencing accelerated innovation toward compliant formulations.

Carbon footprint analysis reveals that transportation impacts differ significantly between the systems. Polymer composites typically offer weight advantages of 15-25% compared to hybrid alternatives, potentially reducing fuel consumption and associated emissions during distribution and throughout the operational phase of coated products, particularly in mobile applications such as automotive and aerospace components.

However, hybrid matrix systems often demonstrate superior durability and longer service life, which can offset their initially higher environmental impact through reduced replacement frequency. Studies show that certain hybrid coatings can extend service intervals by 40-60% compared to conventional polymer systems, resulting in significant resource conservation over the complete product lifecycle.

Waste management presents distinct challenges for both systems. Polymer composite coatings frequently face recycling difficulties due to their complex formulations and cross-linked structures. Only 12-18% of polymer composite waste is currently effectively recycled globally. Hybrid systems, while sometimes containing potentially hazardous inorganic components, often offer better separation possibilities that can facilitate more efficient material recovery at end-of-life.

Emerging sustainable formulations are rapidly transforming both categories. Bio-based polymers derived from renewable resources are increasingly incorporated into composite coatings, reducing dependence on petroleum-based raw materials. Similarly, hybrid systems are evolving to incorporate naturally occurring minerals and biodegradable components that minimize environmental persistence.

Regulatory frameworks worldwide are progressively imposing stricter controls on volatile organic compounds (VOCs) and hazardous substances in coating systems. Polymer composites have generally adapted more quickly to these requirements, with water-based formulations achieving market penetration rates of approximately 65% in architectural applications. Hybrid systems, while traditionally more dependent on solvent-based chemistry, are now experiencing accelerated innovation toward compliant formulations.

Carbon footprint analysis reveals that transportation impacts differ significantly between the systems. Polymer composites typically offer weight advantages of 15-25% compared to hybrid alternatives, potentially reducing fuel consumption and associated emissions during distribution and throughout the operational phase of coated products, particularly in mobile applications such as automotive and aerospace components.

Performance Benchmarking and Testing Protocols

Standardized performance evaluation methodologies are essential for objective comparison between polymer-based and hybrid matrix composite coating systems. The testing protocols must encompass mechanical, chemical, thermal, and environmental resistance properties to provide comprehensive performance benchmarks that guide material selection decisions in various applications.

Mechanical performance testing typically includes adhesion strength measurements using pull-off or cross-cut tests according to ASTM D4541 and ASTM D3359 standards. Hardness evaluations commonly employ Pencil Hardness (ASTM D3363), Shore Durometer, or nano-indentation techniques depending on coating thickness and intended application. Impact resistance (ASTM D2794) and flexibility (ASTM D522) tests further characterize durability under mechanical stress conditions.

Chemical resistance protocols involve immersion testing in various solvents, acids, bases, and industrial chemicals relevant to the intended application environment. Exposure periods typically range from 24 hours to several months with periodic evaluation of appearance, weight change, and retention of mechanical properties. Standardized salt spray testing (ASTM B117) remains the industry benchmark for corrosion resistance, though cyclic corrosion tests provide more realistic performance predictions.

Weatherability assessment requires accelerated aging protocols using QUV exposure (ASTM G154) or Xenon arc chambers (ASTM G155) to simulate UV degradation, temperature cycling, and moisture effects. These tests typically measure gloss retention, color stability, chalking resistance, and mechanical property retention after specified exposure periods. For outdoor applications, real-world exposure testing at standardized facilities in different climate zones provides validation data.

Thermal performance evaluation includes thermal cycling tests, heat aging protocols, and coefficient of thermal expansion measurements. For specialized applications, flame retardancy testing according to UL 94 standards and smoke generation assessments may be required. Abrasion resistance testing using Taber abraser (ASTM D4060) quantifies wear resistance under standardized conditions.

Advanced characterization techniques such as scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDX), and Fourier-transform infrared spectroscopy (FTIR) provide deeper insights into coating microstructure, composition, and degradation mechanisms. These analytical methods help establish structure-property relationships that inform future coating formulation improvements.

Standardized reporting formats should include detailed test parameters, statistical analysis of results, and clear performance comparisons between polymer and hybrid matrix systems across all tested properties. This comprehensive benchmarking approach enables objective evaluation of the performance advantages and limitations of each coating system for specific application requirements.

Mechanical performance testing typically includes adhesion strength measurements using pull-off or cross-cut tests according to ASTM D4541 and ASTM D3359 standards. Hardness evaluations commonly employ Pencil Hardness (ASTM D3363), Shore Durometer, or nano-indentation techniques depending on coating thickness and intended application. Impact resistance (ASTM D2794) and flexibility (ASTM D522) tests further characterize durability under mechanical stress conditions.

Chemical resistance protocols involve immersion testing in various solvents, acids, bases, and industrial chemicals relevant to the intended application environment. Exposure periods typically range from 24 hours to several months with periodic evaluation of appearance, weight change, and retention of mechanical properties. Standardized salt spray testing (ASTM B117) remains the industry benchmark for corrosion resistance, though cyclic corrosion tests provide more realistic performance predictions.

Weatherability assessment requires accelerated aging protocols using QUV exposure (ASTM G154) or Xenon arc chambers (ASTM G155) to simulate UV degradation, temperature cycling, and moisture effects. These tests typically measure gloss retention, color stability, chalking resistance, and mechanical property retention after specified exposure periods. For outdoor applications, real-world exposure testing at standardized facilities in different climate zones provides validation data.

Thermal performance evaluation includes thermal cycling tests, heat aging protocols, and coefficient of thermal expansion measurements. For specialized applications, flame retardancy testing according to UL 94 standards and smoke generation assessments may be required. Abrasion resistance testing using Taber abraser (ASTM D4060) quantifies wear resistance under standardized conditions.

Advanced characterization techniques such as scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDX), and Fourier-transform infrared spectroscopy (FTIR) provide deeper insights into coating microstructure, composition, and degradation mechanisms. These analytical methods help establish structure-property relationships that inform future coating formulation improvements.

Standardized reporting formats should include detailed test parameters, statistical analysis of results, and clear performance comparisons between polymer and hybrid matrix systems across all tested properties. This comprehensive benchmarking approach enables objective evaluation of the performance advantages and limitations of each coating system for specific application requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!