Research on Composite coatings for thermal and chemical stability in energy devices

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Composite Coating Technology Evolution and Objectives

Composite coatings have emerged as a critical technology in energy devices, evolving significantly over the past decades to address increasing demands for thermal and chemical stability. The evolution began in the 1970s with basic ceramic coatings, progressing through the 1990s with the introduction of polymer-ceramic hybrids, and accelerating in the 2000s with the development of nanostructured composite systems. This technological progression has been driven by the expanding requirements of energy generation, storage, and conversion systems operating under increasingly extreme conditions.

The fundamental objective of composite coating research is to develop multifunctional protective layers that can withstand high temperatures (often exceeding 1000°C), resist chemical degradation from corrosive environments, and maintain structural integrity under thermal cycling. These coatings must simultaneously provide multiple functionalities including thermal barrier properties, oxidation resistance, and electrochemical stability while maintaining adhesion to diverse substrate materials.

Current research trends indicate a shift toward multi-layer architectures that combine different material classes to achieve synergistic properties. Metal-ceramic composites, ceramic-polymer hybrids, and carbon-based nanocomposites represent the leading material systems under investigation. The incorporation of self-healing mechanisms and stimuli-responsive components represents the cutting edge of this field, aiming to extend component lifetimes through autonomous damage repair.

The technology trajectory shows increasing complexity in coating compositions, with modern systems often incorporating three or more distinct phases to address multiple performance requirements simultaneously. This complexity is managed through advanced deposition techniques such as atomic layer deposition, plasma spray, and solution-based methods that enable precise control over composition and microstructure at multiple length scales.

Looking forward, the field is moving toward predictive design approaches that leverage computational modeling to accelerate material discovery. Machine learning algorithms are beginning to play a role in optimizing coating compositions based on performance data from existing systems. The ultimate goal is to develop "materials by design" methodologies that can rapidly identify optimal coating compositions for specific energy applications.

Key performance targets include extending operational temperature ranges to beyond 1200°C, achieving chemical stability in highly acidic or alkaline environments (pH 1-14), and maintaining functionality for 10+ years under cyclic loading conditions. These ambitious objectives are driven by the needs of next-generation energy technologies including solid oxide fuel cells, concentrated solar power, advanced nuclear systems, and high-temperature batteries.

The fundamental objective of composite coating research is to develop multifunctional protective layers that can withstand high temperatures (often exceeding 1000°C), resist chemical degradation from corrosive environments, and maintain structural integrity under thermal cycling. These coatings must simultaneously provide multiple functionalities including thermal barrier properties, oxidation resistance, and electrochemical stability while maintaining adhesion to diverse substrate materials.

Current research trends indicate a shift toward multi-layer architectures that combine different material classes to achieve synergistic properties. Metal-ceramic composites, ceramic-polymer hybrids, and carbon-based nanocomposites represent the leading material systems under investigation. The incorporation of self-healing mechanisms and stimuli-responsive components represents the cutting edge of this field, aiming to extend component lifetimes through autonomous damage repair.

The technology trajectory shows increasing complexity in coating compositions, with modern systems often incorporating three or more distinct phases to address multiple performance requirements simultaneously. This complexity is managed through advanced deposition techniques such as atomic layer deposition, plasma spray, and solution-based methods that enable precise control over composition and microstructure at multiple length scales.

Looking forward, the field is moving toward predictive design approaches that leverage computational modeling to accelerate material discovery. Machine learning algorithms are beginning to play a role in optimizing coating compositions based on performance data from existing systems. The ultimate goal is to develop "materials by design" methodologies that can rapidly identify optimal coating compositions for specific energy applications.

Key performance targets include extending operational temperature ranges to beyond 1200°C, achieving chemical stability in highly acidic or alkaline environments (pH 1-14), and maintaining functionality for 10+ years under cyclic loading conditions. These ambitious objectives are driven by the needs of next-generation energy technologies including solid oxide fuel cells, concentrated solar power, advanced nuclear systems, and high-temperature batteries.

Market Analysis for Energy Device Protective Coatings

The global market for protective coatings in energy devices is experiencing robust growth, driven by increasing demand for renewable energy solutions and the need for more efficient and durable energy storage systems. The market value for composite coatings specifically designed for thermal and chemical stability in energy applications reached approximately $7.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.8% through 2030.

Fuel cells represent one of the fastest-growing segments within this market, with a particular demand for coatings that can withstand high-temperature operations while resisting chemical degradation. The solid oxide fuel cell (SOFC) segment alone is expected to reach $2.1 billion by 2025, creating significant opportunities for advanced composite coating solutions.

Battery technologies, particularly lithium-ion batteries for electric vehicles and grid storage, constitute another major market driver. The need for thermal management coatings in this sector is critical, as thermal runaway remains a significant safety concern. This segment is projected to grow at 8.3% annually, outpacing the overall market average.

Geographically, Asia-Pacific dominates the market with approximately 42% share, led by China's aggressive expansion in renewable energy infrastructure and battery manufacturing capabilities. North America and Europe follow with 28% and 24% market shares respectively, with particular growth in hydrogen fuel cell applications and grid-scale energy storage solutions.

By material type, ceramic-polymer hybrid coatings hold the largest market share (38%), followed by metal-ceramic composites (27%) and carbon-based nanocomposites (21%). The remaining market comprises various specialized formulations tailored to specific energy applications.

Key customer segments include energy device manufacturers (54%), energy infrastructure developers (28%), and aftermarket service providers (18%). The increasing focus on extending device lifespan and reducing maintenance costs is driving demand for more durable coating solutions with enhanced thermal cycling resistance and chemical stability.

Market challenges include high initial costs of advanced composite coatings, which can be 2-3 times more expensive than conventional alternatives, and technical difficulties in achieving uniform coating deposition on complex geometries. However, the long-term performance benefits and reduced total cost of ownership continue to drive market adoption despite these challenges.

Fuel cells represent one of the fastest-growing segments within this market, with a particular demand for coatings that can withstand high-temperature operations while resisting chemical degradation. The solid oxide fuel cell (SOFC) segment alone is expected to reach $2.1 billion by 2025, creating significant opportunities for advanced composite coating solutions.

Battery technologies, particularly lithium-ion batteries for electric vehicles and grid storage, constitute another major market driver. The need for thermal management coatings in this sector is critical, as thermal runaway remains a significant safety concern. This segment is projected to grow at 8.3% annually, outpacing the overall market average.

Geographically, Asia-Pacific dominates the market with approximately 42% share, led by China's aggressive expansion in renewable energy infrastructure and battery manufacturing capabilities. North America and Europe follow with 28% and 24% market shares respectively, with particular growth in hydrogen fuel cell applications and grid-scale energy storage solutions.

By material type, ceramic-polymer hybrid coatings hold the largest market share (38%), followed by metal-ceramic composites (27%) and carbon-based nanocomposites (21%). The remaining market comprises various specialized formulations tailored to specific energy applications.

Key customer segments include energy device manufacturers (54%), energy infrastructure developers (28%), and aftermarket service providers (18%). The increasing focus on extending device lifespan and reducing maintenance costs is driving demand for more durable coating solutions with enhanced thermal cycling resistance and chemical stability.

Market challenges include high initial costs of advanced composite coatings, which can be 2-3 times more expensive than conventional alternatives, and technical difficulties in achieving uniform coating deposition on complex geometries. However, the long-term performance benefits and reduced total cost of ownership continue to drive market adoption despite these challenges.

Current Challenges in Thermal-Chemical Resistant Coatings

Despite significant advancements in composite coating technologies, several critical challenges persist in developing thermal-chemical resistant coatings for energy devices. The primary obstacle remains achieving simultaneous resistance to extreme temperatures and corrosive chemical environments without compromising other functional properties. Current coating systems often demonstrate excellent performance in either thermal or chemical resistance, but rarely excel in both domains simultaneously.

Material degradation mechanisms at high temperatures present complex challenges, particularly in energy conversion systems where temperatures can exceed 1000°C. Under such conditions, conventional composite coatings experience accelerated diffusion processes, phase transformations, and microstructural instability that significantly reduce their protective capabilities. The thermal expansion mismatch between coating layers and substrates further exacerbates these issues, leading to delamination and crack formation during thermal cycling.

Chemical stability presents another dimension of difficulty, especially in environments containing aggressive species such as sulfur compounds, halogens, and molten salts common in energy applications. These corrosive elements can penetrate through coating defects and grain boundaries, causing accelerated degradation through various mechanisms including selective leaching, intergranular corrosion, and formation of volatile compounds.

The interface stability between different coating layers remains problematic, particularly in multi-layered composite systems designed to provide multiple functionalities. Interdiffusion of elements across interfaces during high-temperature operation can lead to the formation of brittle intermetallic phases or voids, compromising the coating integrity and protective function.

Manufacturing challenges further complicate the development of advanced composite coatings. Current deposition techniques struggle to produce uniform, defect-free coatings with precisely controlled composition and microstructure at industrial scales. Methods capable of depositing high-quality coatings often involve expensive equipment, complex processes, or environmentally hazardous chemicals, limiting their widespread adoption.

Long-term durability under combined thermal-chemical-mechanical stresses represents perhaps the most significant unsolved challenge. Accelerated testing methodologies poorly predict actual field performance, making it difficult to validate new coating systems without extensive real-world testing. The synergistic effects of multiple degradation mechanisms operating simultaneously are particularly difficult to model and mitigate.

Cost-effectiveness remains a critical barrier to widespread implementation. Many advanced coating solutions incorporate expensive rare earth elements or precious metals, making them economically unfeasible for large-scale energy applications. Developing alternatives using abundant, low-cost materials without sacrificing performance represents a significant research challenge that must be addressed to enable broader adoption of these protective technologies.

Material degradation mechanisms at high temperatures present complex challenges, particularly in energy conversion systems where temperatures can exceed 1000°C. Under such conditions, conventional composite coatings experience accelerated diffusion processes, phase transformations, and microstructural instability that significantly reduce their protective capabilities. The thermal expansion mismatch between coating layers and substrates further exacerbates these issues, leading to delamination and crack formation during thermal cycling.

Chemical stability presents another dimension of difficulty, especially in environments containing aggressive species such as sulfur compounds, halogens, and molten salts common in energy applications. These corrosive elements can penetrate through coating defects and grain boundaries, causing accelerated degradation through various mechanisms including selective leaching, intergranular corrosion, and formation of volatile compounds.

The interface stability between different coating layers remains problematic, particularly in multi-layered composite systems designed to provide multiple functionalities. Interdiffusion of elements across interfaces during high-temperature operation can lead to the formation of brittle intermetallic phases or voids, compromising the coating integrity and protective function.

Manufacturing challenges further complicate the development of advanced composite coatings. Current deposition techniques struggle to produce uniform, defect-free coatings with precisely controlled composition and microstructure at industrial scales. Methods capable of depositing high-quality coatings often involve expensive equipment, complex processes, or environmentally hazardous chemicals, limiting their widespread adoption.

Long-term durability under combined thermal-chemical-mechanical stresses represents perhaps the most significant unsolved challenge. Accelerated testing methodologies poorly predict actual field performance, making it difficult to validate new coating systems without extensive real-world testing. The synergistic effects of multiple degradation mechanisms operating simultaneously are particularly difficult to model and mitigate.

Cost-effectiveness remains a critical barrier to widespread implementation. Many advanced coating solutions incorporate expensive rare earth elements or precious metals, making them economically unfeasible for large-scale energy applications. Developing alternatives using abundant, low-cost materials without sacrificing performance represents a significant research challenge that must be addressed to enable broader adoption of these protective technologies.

Existing Composite Coating Solutions for Energy Applications

01 Ceramic-based composite coatings for thermal stability

Ceramic-based composite coatings provide excellent thermal stability for various applications. These coatings typically incorporate materials such as zirconia, alumina, or silicon carbide to withstand high temperatures. The ceramic matrix offers resistance to thermal degradation, preventing structural changes at elevated temperatures. These coatings can be applied through various methods including plasma spraying, chemical vapor deposition, or sol-gel processes to create thermally stable protective layers on substrates.- Ceramic-based composite coatings for thermal stability: Ceramic-based composite coatings provide excellent thermal stability at high temperatures. These coatings typically incorporate materials such as zirconia, alumina, or silicon carbide that maintain structural integrity under extreme heat conditions. The ceramic components create a protective barrier that prevents substrate degradation and reduces thermal conductivity. These coatings can withstand temperature fluctuations without cracking or delaminating, making them suitable for applications in high-temperature environments such as turbine blades, combustion chambers, and industrial furnaces.

- Polymer-metal hybrid coatings for chemical resistance: Polymer-metal hybrid coatings combine the flexibility of polymers with the durability of metals to create surfaces with enhanced chemical stability. These composite coatings resist corrosion, oxidation, and degradation when exposed to aggressive chemicals, acids, and solvents. The polymer component typically provides a barrier against chemical penetration while the metallic elements contribute to structural integrity and additional protection. These coatings can be formulated with various polymer types and metal particles to tailor the chemical resistance properties for specific environmental conditions and applications.

- Nanoparticle-reinforced coatings for enhanced stability: Incorporating nanoparticles into coating formulations significantly improves both thermal and chemical stability. Nanoparticles such as carbon nanotubes, graphene, nano-silica, or metal oxide nanoparticles create a reinforced matrix that enhances the coating's resistance to degradation. These particles fill microscopic voids, strengthen interfacial bonding, and create tortuous paths that prevent penetration of corrosive substances. The high surface area of nanoparticles also contributes to improved heat distribution and dissipation, resulting in coatings that maintain integrity under thermal cycling and chemical exposure.

- Multi-layer composite coatings for extreme environments: Multi-layer composite coating systems provide superior protection in environments requiring both thermal and chemical stability. These coatings feature strategically designed layers with complementary properties - typically including a primer layer for adhesion, intermediate layers for specific protective functions, and a top layer for environmental resistance. The layered structure allows for the incorporation of different materials that work synergistically to resist thermal degradation, chemical attack, and mechanical wear. This approach enables customization for specific applications where multiple types of protection are required simultaneously.

- Self-healing composite coatings for long-term stability: Self-healing composite coatings represent an advanced solution for maintaining long-term thermal and chemical stability. These coatings incorporate encapsulated healing agents that are released when the coating is damaged, automatically repairing cracks or breaches before they can compromise the coating's protective function. The self-healing mechanism may utilize various approaches including microcapsules containing reactive materials, reversible chemical bonds, or shape memory materials. This technology significantly extends coating lifespan in harsh environments by preventing the propagation of damage that would otherwise lead to coating failure and substrate degradation.

02 Polymer-metal hybrid coatings for chemical resistance

Polymer-metal hybrid coatings combine the flexibility of polymers with the durability of metals to create chemically resistant surfaces. These composite coatings incorporate metal particles or compounds within a polymer matrix to enhance resistance against corrosive chemicals and solvents. The synergistic effect between the polymer and metal components provides superior chemical stability compared to single-component coatings. These hybrid systems can be tailored to resist specific chemical environments by selecting appropriate polymer bases and metal additives.Expand Specific Solutions03 Nanoparticle-reinforced coatings for enhanced stability

Incorporating nanoparticles into coating formulations significantly enhances both thermal and chemical stability. Nanoparticles such as carbon nanotubes, graphene, or metal oxide nanoparticles create a reinforced network within the coating matrix. This nanoscale reinforcement improves resistance to thermal degradation and chemical attack by creating tortuous paths that limit diffusion of aggressive substances. The high surface area of nanoparticles also promotes stronger interfacial bonding with the matrix, resulting in coatings with superior durability under extreme conditions.Expand Specific Solutions04 Multi-layer composite coatings for barrier protection

Multi-layer composite coating systems provide enhanced thermal and chemical stability through strategically designed layer structures. These systems typically consist of different functional layers, each contributing specific protective properties. The layered architecture can include a primer layer for adhesion, intermediate layers for thermal or chemical resistance, and a top layer for environmental protection. This approach allows for the combination of materials with complementary properties to create coatings that maintain stability across a wide range of challenging conditions.Expand Specific Solutions05 Self-healing composite coatings for long-term stability

Self-healing composite coatings incorporate active components that can repair damage automatically, maintaining thermal and chemical stability over extended periods. These innovative coatings contain encapsulated healing agents that are released when the coating is damaged, initiating a repair process. Some systems utilize thermally activated healing mechanisms that respond to temperature fluctuations. The self-healing capability prevents the propagation of defects that would otherwise compromise the coating's protective properties, significantly extending service life in harsh environments.Expand Specific Solutions

Leading Companies and Research Institutions in Coating Industry

The composite coatings market for thermal and chemical stability in energy devices is in a growth phase, characterized by increasing demand for advanced materials that enhance device performance and longevity. The market size is expanding rapidly due to the rising adoption of renewable energy technologies and energy storage systems. Technologically, the field shows varying maturity levels with companies like Robert Bosch, Siemens, and LG Energy Solution leading commercial applications, while research institutions like Northeastern University and the European Space Agency drive innovation. Companies such as Praxair Technology, TDK Electronics, and BASF are developing specialized coating solutions that address thermal management challenges, while Boeing and Northrop Grumman focus on high-performance applications for aerospace energy systems. The competitive landscape features both established industrial giants and specialized materials technology firms working to improve coating durability and efficiency.

Praxair Technology, Inc.

Technical Solution: Praxair Technology has developed advanced thermal spray coating solutions specifically engineered for extreme operating environments in energy devices. Their flagship technology involves suspension and solution precursor plasma spray (SPS/SPPS) processes to create nanostructured composite coatings with enhanced thermal and chemical stability. These coatings typically combine yttria-stabilized zirconia (YSZ) with aluminum oxide and rare earth zirconates to achieve superior thermal barrier properties while maintaining chemical resistance. Praxair's proprietary HVOF (High Velocity Oxygen Fuel) process enables the deposition of dense cermet coatings with porosity levels below 1%, providing exceptional corrosion and wear resistance. For solid oxide fuel cell applications, Praxair has pioneered specialized composite coatings that maintain electrochemical performance at operating temperatures of 600-800°C while preventing chromium poisoning and other degradation mechanisms. Their latest innovation involves functionally graded composite coatings that gradually transition from metallic to ceramic compositions, minimizing thermal expansion mismatch issues and enhancing coating durability through thousands of thermal cycles.

Strengths: Industry-leading thermal spray technology with precise control over coating microstructure; extensive material science expertise in high-temperature ceramics; proven performance in commercial energy systems; ability to coat complex geometries. Weaknesses: High initial equipment investment costs; requires specialized operator training; some coating processes have relatively slow deposition rates; limited ability to coat internal surfaces of complex components.

Siemens AG

Technical Solution: Siemens AG has developed sophisticated composite coating systems specifically designed for gas turbines and other high-temperature energy conversion devices. Their technology centers on MCrAlY-based coatings (where M represents nickel, cobalt, or iron) combined with ceramic thermal barrier coatings (TBCs) to create multi-layered protective systems. These coatings are applied through various processes including high-velocity oxygen fuel (HVOF) spraying and electron beam physical vapor deposition (EB-PVD), achieving thicknesses between 100-500 μm depending on application requirements. Siemens' latest innovation involves the incorporation of rare earth elements like yttrium and gadolinium into the coating matrix, which significantly improves oxide scale adhesion and extends coating lifetime by up to 30%. For hydrogen-based energy systems, Siemens has developed specialized composite coatings that resist hydrogen embrittlement while maintaining thermal stability at operating temperatures exceeding 800°C. Their coatings feature engineered porosity structures that enhance strain tolerance while maintaining thermal insulation properties.

Strengths: Exceptional high-temperature performance (up to 1300°C); excellent resistance to thermal cycling; proven long-term durability in harsh operating environments; comprehensive quality control processes. Weaknesses: Complex and expensive application processes; requires specialized equipment and expertise; limited repairability in field conditions; potential for coating spallation under extreme thermal cycling.

Key Patents and Innovations in Thermal-Chemical Stability

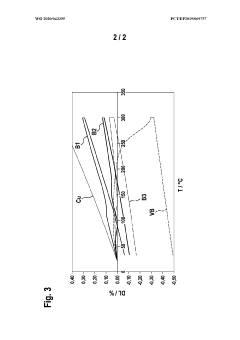

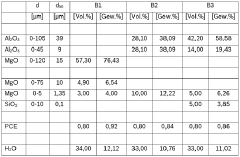

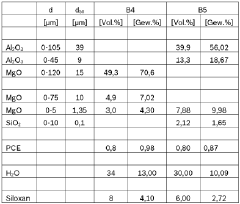

Potting compound, method for electrically isolating an electrical or electronic component, and electrically isolated component

PatentWO2020043395A1

Innovation

- A casting compound comprising reactive particles that react with water to form thermally stable hydrate phases, combined with high filler content and a crosslinkable synthetic resin, allowing for high thermal conductivity and reduced thermal expansion, along with a method involving heat treatment and drying to achieve dimensional stability and hydrophobic pore closure.

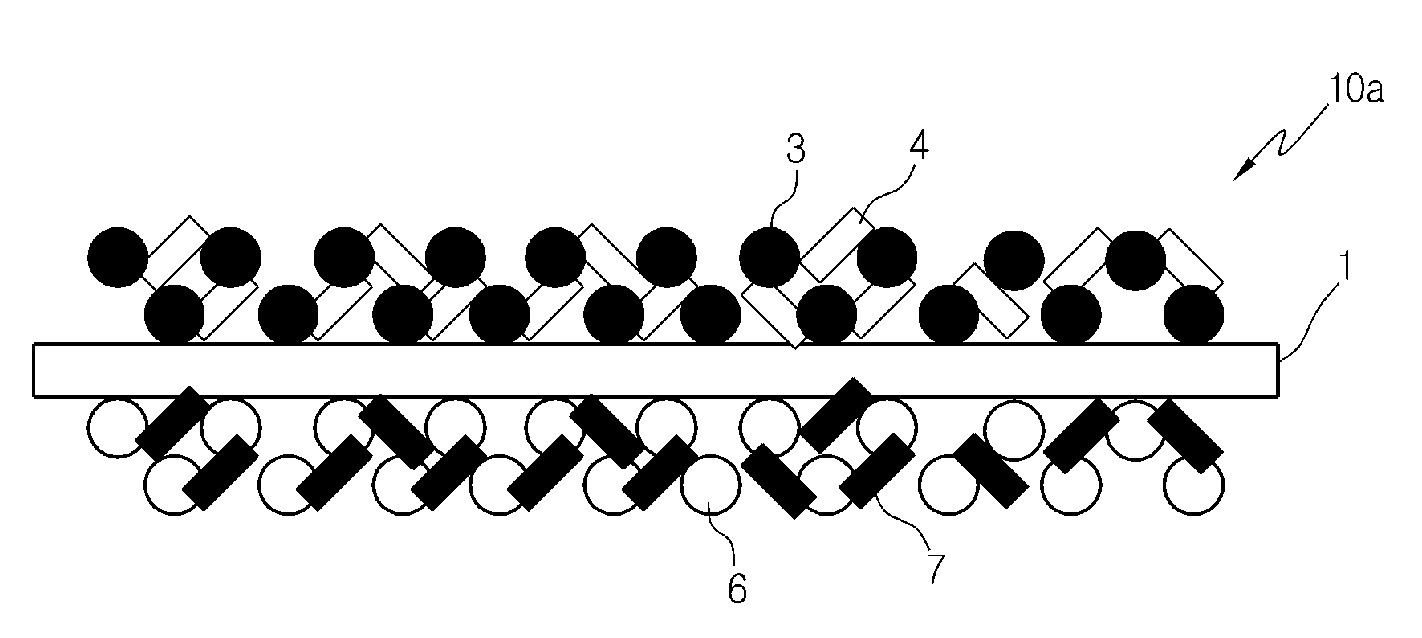

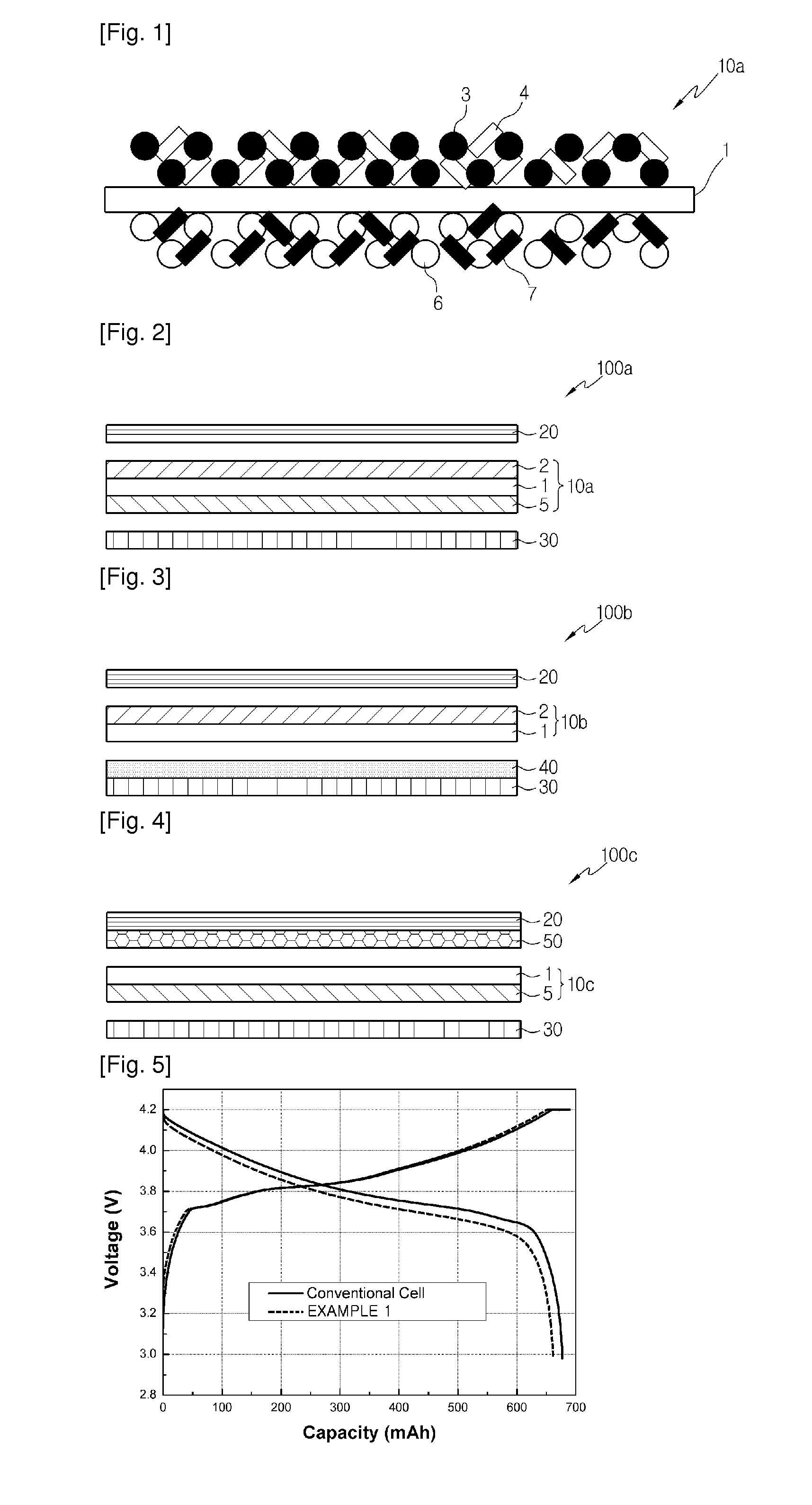

Electrochemical device and its manufacturing method

PatentActiveUS20100003590A1

Innovation

- An electrochemical device with a composite separator featuring porous coating layers made of cathode and anode active material particles and binder polymers on both surfaces of a porous substrate, eliminating the need for additional electrode active material coatings and improving thermal stability.

Environmental Impact and Sustainability Considerations

The development of composite coatings for energy devices necessitates careful consideration of environmental impacts throughout their lifecycle. Traditional coating materials often contain heavy metals, volatile organic compounds (VOCs), and other environmentally harmful substances that pose significant ecological risks during production, application, and disposal phases. Modern research increasingly focuses on developing eco-friendly alternatives that maintain or exceed performance standards while minimizing environmental footprint.

Water-based and solvent-free coating systems represent a significant advancement in reducing VOC emissions during application processes. These systems not only decrease air pollution but also minimize occupational health risks for workers in manufacturing facilities. Additionally, the incorporation of bio-derived components in composite coatings, such as lignin-based carbon materials and cellulose nanocrystals, offers renewable alternatives to petroleum-based ingredients while providing comparable thermal and chemical stability properties.

Life cycle assessment (LCA) methodologies are becoming essential tools in evaluating the environmental sustainability of composite coating technologies. Recent studies indicate that advanced ceramic-polymer hybrid coatings can reduce the overall carbon footprint of energy devices by extending operational lifetimes and improving energy efficiency. The extended service life of properly coated components significantly reduces resource consumption and waste generation associated with frequent replacements.

End-of-life considerations present both challenges and opportunities for composite coating technologies. Recyclability and biodegradability of coating materials are increasingly important design parameters. Research into delamination techniques that allow for separation of coating layers from substrates facilitates more effective recycling processes. Some innovative approaches include designing thermally reversible bonds within coating matrices that enable controlled disassembly at end-of-life.

Regulatory frameworks worldwide are evolving to address environmental concerns related to coating technologies. The European Union's REACH regulations, California's Proposition 65, and similar initiatives in Asia are driving the transition toward greener coating formulations. Companies investing in environmentally sustainable coating technologies not only ensure regulatory compliance but also gain competitive advantages in increasingly eco-conscious markets.

Water consumption and contamination represent additional environmental considerations in coating processes. Closed-loop water systems and advanced filtration technologies are being implemented to minimize freshwater usage and prevent release of contaminants. Some cutting-edge research explores completely dry application methods that eliminate water requirements altogether while maintaining coating performance for energy device applications.

Water-based and solvent-free coating systems represent a significant advancement in reducing VOC emissions during application processes. These systems not only decrease air pollution but also minimize occupational health risks for workers in manufacturing facilities. Additionally, the incorporation of bio-derived components in composite coatings, such as lignin-based carbon materials and cellulose nanocrystals, offers renewable alternatives to petroleum-based ingredients while providing comparable thermal and chemical stability properties.

Life cycle assessment (LCA) methodologies are becoming essential tools in evaluating the environmental sustainability of composite coating technologies. Recent studies indicate that advanced ceramic-polymer hybrid coatings can reduce the overall carbon footprint of energy devices by extending operational lifetimes and improving energy efficiency. The extended service life of properly coated components significantly reduces resource consumption and waste generation associated with frequent replacements.

End-of-life considerations present both challenges and opportunities for composite coating technologies. Recyclability and biodegradability of coating materials are increasingly important design parameters. Research into delamination techniques that allow for separation of coating layers from substrates facilitates more effective recycling processes. Some innovative approaches include designing thermally reversible bonds within coating matrices that enable controlled disassembly at end-of-life.

Regulatory frameworks worldwide are evolving to address environmental concerns related to coating technologies. The European Union's REACH regulations, California's Proposition 65, and similar initiatives in Asia are driving the transition toward greener coating formulations. Companies investing in environmentally sustainable coating technologies not only ensure regulatory compliance but also gain competitive advantages in increasingly eco-conscious markets.

Water consumption and contamination represent additional environmental considerations in coating processes. Closed-loop water systems and advanced filtration technologies are being implemented to minimize freshwater usage and prevent release of contaminants. Some cutting-edge research explores completely dry application methods that eliminate water requirements altogether while maintaining coating performance for energy device applications.

Material Science Breakthroughs Enabling Coating Performance

Recent breakthroughs in materials science have revolutionized the development of composite coatings for energy devices, particularly in enhancing thermal and chemical stability. The integration of nanomaterials has been a pivotal advancement, with carbon nanotubes and graphene demonstrating exceptional thermal conductivity and mechanical strength when incorporated into coating matrices. These nanomaterials create highly effective thermal pathways while simultaneously reinforcing the structural integrity of the coating.

Ceramic-polymer hybrid systems represent another significant breakthrough, combining the high-temperature resistance of ceramics with the flexibility and processability of polymers. Advanced sol-gel techniques have enabled precise control over the molecular architecture of these hybrids, resulting in coatings that maintain stability across extreme temperature gradients while resisting chemical degradation from electrolytes and reactive species.

Self-healing capabilities have emerged as a transformative feature in modern composite coatings. Microcapsule-based systems containing healing agents can automatically repair microscopic damage, extending coating lifespans in harsh operating environments. This autonomous repair mechanism significantly reduces maintenance requirements and enhances the overall reliability of energy devices.

Surface functionalization techniques have advanced considerably, allowing for tailored interactions between coatings and their operating environments. Hydrophobic and oleophobic treatments create protective barriers against moisture and organic contaminants, while specialized functional groups can be introduced to enhance adhesion to specific substrates or provide selective permeability to certain ions or molecules.

High-entropy alloy coatings represent a cutting-edge development, comprising multiple principal elements in near-equiatomic proportions. These coatings exhibit remarkable phase stability at elevated temperatures due to their high configurational entropy, along with superior resistance to oxidation and corrosion in aggressive chemical environments.

Computational materials science has accelerated coating development through predictive modeling and simulation. Machine learning algorithms now enable rapid screening of potential coating compositions, while molecular dynamics simulations provide insights into degradation mechanisms at atomic scales. These computational approaches have significantly reduced development cycles and enabled the discovery of non-intuitive material combinations with superior performance characteristics.

Atomic layer deposition (ALD) has emerged as a precision coating technique capable of depositing ultra-thin, highly conformal layers with atomic-level thickness control. This breakthrough has enabled the creation of multi-layered composite coatings with precisely engineered interfaces, optimizing both thermal management and chemical resistance properties for specific energy device applications.

Ceramic-polymer hybrid systems represent another significant breakthrough, combining the high-temperature resistance of ceramics with the flexibility and processability of polymers. Advanced sol-gel techniques have enabled precise control over the molecular architecture of these hybrids, resulting in coatings that maintain stability across extreme temperature gradients while resisting chemical degradation from electrolytes and reactive species.

Self-healing capabilities have emerged as a transformative feature in modern composite coatings. Microcapsule-based systems containing healing agents can automatically repair microscopic damage, extending coating lifespans in harsh operating environments. This autonomous repair mechanism significantly reduces maintenance requirements and enhances the overall reliability of energy devices.

Surface functionalization techniques have advanced considerably, allowing for tailored interactions between coatings and their operating environments. Hydrophobic and oleophobic treatments create protective barriers against moisture and organic contaminants, while specialized functional groups can be introduced to enhance adhesion to specific substrates or provide selective permeability to certain ions or molecules.

High-entropy alloy coatings represent a cutting-edge development, comprising multiple principal elements in near-equiatomic proportions. These coatings exhibit remarkable phase stability at elevated temperatures due to their high configurational entropy, along with superior resistance to oxidation and corrosion in aggressive chemical environments.

Computational materials science has accelerated coating development through predictive modeling and simulation. Machine learning algorithms now enable rapid screening of potential coating compositions, while molecular dynamics simulations provide insights into degradation mechanisms at atomic scales. These computational approaches have significantly reduced development cycles and enabled the discovery of non-intuitive material combinations with superior performance characteristics.

Atomic layer deposition (ALD) has emerged as a precision coating technique capable of depositing ultra-thin, highly conformal layers with atomic-level thickness control. This breakthrough has enabled the creation of multi-layered composite coatings with precisely engineered interfaces, optimizing both thermal management and chemical resistance properties for specific energy device applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!