How mechanical and chemical properties determine Composite coatings service life

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Composite Coatings Evolution and Performance Objectives

Composite coatings have evolved significantly over the past decades, transitioning from simple protective layers to sophisticated engineered systems with tailored properties. The evolution began with basic metallic coatings in the early 20th century, progressing through ceramic-based systems in the mid-century, to today's advanced multi-functional composite coatings that combine various materials to achieve superior performance characteristics.

The fundamental objective of composite coating technology is to extend service life while maintaining or enhancing performance under increasingly demanding operational conditions. This requires optimizing both mechanical properties (hardness, adhesion strength, wear resistance, and elasticity) and chemical properties (corrosion resistance, thermal stability, and chemical inertness) to withstand complex environmental stressors.

Recent technological advancements have focused on developing coatings with self-healing capabilities, enhanced durability in extreme environments, and reduced environmental impact. The integration of nanomaterials has revolutionized the field, allowing for unprecedented control over coating microstructure and resulting in significant improvements in both mechanical and chemical performance metrics.

The relationship between mechanical and chemical properties in determining service life represents a complex interplay that varies across different application environments. For instance, in marine applications, chemical resistance to saltwater corrosion may be paramount, while in aerospace applications, thermal stability and mechanical integrity under extreme temperature fluctuations become critical factors.

Current research trends indicate a shift toward predictive modeling approaches that can accurately forecast coating degradation mechanisms and service life based on initial property profiles. These models increasingly incorporate machine learning algorithms to process complex datasets from accelerated aging tests and real-world performance monitoring.

The industry is witnessing growing demand for coatings that can maintain performance integrity while reducing thickness and weight, particularly in transportation and aerospace sectors where fuel efficiency is paramount. This has driven innovation in high-performance thin-film composite coatings that deliver exceptional protection despite minimal material usage.

Performance objectives for next-generation composite coatings include achieving service lifetimes exceeding 25 years in harsh environments, developing truly sustainable formulations free from environmentally harmful components, and creating smart coatings capable of responding adaptively to environmental changes or damage events.

The convergence of materials science, nanotechnology, and computational modeling is expected to yield breakthrough innovations in composite coating technology over the next decade, potentially revolutionizing how we approach surface protection across virtually all industrial sectors.

The fundamental objective of composite coating technology is to extend service life while maintaining or enhancing performance under increasingly demanding operational conditions. This requires optimizing both mechanical properties (hardness, adhesion strength, wear resistance, and elasticity) and chemical properties (corrosion resistance, thermal stability, and chemical inertness) to withstand complex environmental stressors.

Recent technological advancements have focused on developing coatings with self-healing capabilities, enhanced durability in extreme environments, and reduced environmental impact. The integration of nanomaterials has revolutionized the field, allowing for unprecedented control over coating microstructure and resulting in significant improvements in both mechanical and chemical performance metrics.

The relationship between mechanical and chemical properties in determining service life represents a complex interplay that varies across different application environments. For instance, in marine applications, chemical resistance to saltwater corrosion may be paramount, while in aerospace applications, thermal stability and mechanical integrity under extreme temperature fluctuations become critical factors.

Current research trends indicate a shift toward predictive modeling approaches that can accurately forecast coating degradation mechanisms and service life based on initial property profiles. These models increasingly incorporate machine learning algorithms to process complex datasets from accelerated aging tests and real-world performance monitoring.

The industry is witnessing growing demand for coatings that can maintain performance integrity while reducing thickness and weight, particularly in transportation and aerospace sectors where fuel efficiency is paramount. This has driven innovation in high-performance thin-film composite coatings that deliver exceptional protection despite minimal material usage.

Performance objectives for next-generation composite coatings include achieving service lifetimes exceeding 25 years in harsh environments, developing truly sustainable formulations free from environmentally harmful components, and creating smart coatings capable of responding adaptively to environmental changes or damage events.

The convergence of materials science, nanotechnology, and computational modeling is expected to yield breakthrough innovations in composite coating technology over the next decade, potentially revolutionizing how we approach surface protection across virtually all industrial sectors.

Market Analysis of Durable Composite Coating Applications

The global market for durable composite coatings has experienced significant growth in recent years, driven by increasing demand across multiple industries including aerospace, automotive, marine, oil and gas, and construction. The market value reached approximately $11.3 billion in 2022 and is projected to grow at a CAGR of 5.8% through 2028, reflecting the expanding applications of these specialized materials.

Aerospace and automotive sectors represent the largest market segments, collectively accounting for over 40% of the total market share. This dominance stems from the critical need for coatings that can withstand extreme operational conditions while providing weight reduction benefits. The aerospace industry particularly values composite coatings that offer superior resistance to thermal cycling, UV radiation, and chemical exposure at high altitudes.

Industrial applications follow closely behind, with significant adoption in heavy machinery, pipelines, and processing equipment. In these environments, the primary market drivers are corrosion prevention and extended maintenance intervals, which directly impact operational costs and equipment lifespan. The marine sector represents another substantial market, where composite coatings must withstand constant exposure to saltwater, biofouling, and mechanical stresses from wave action.

Regional analysis reveals that North America and Europe currently lead the market with approximately 30% and 28% market share respectively, due to their established aerospace and automotive manufacturing bases. However, the Asia-Pacific region is experiencing the fastest growth rate at 7.2% annually, driven by rapid industrialization in China and India, along with expanding manufacturing capabilities.

Customer demand patterns show increasing preference for coatings with demonstrable longevity metrics and performance guarantees. End-users are increasingly willing to pay premium prices for coatings that offer verified extended service life, as the total cost of ownership calculations favor higher initial investment in exchange for reduced maintenance frequency and operational downtime.

Market research indicates a growing trend toward environmentally compliant formulations, with water-based and high-solids composite coatings gaining market share. This shift is particularly pronounced in Europe and North America, where regulatory frameworks increasingly restrict VOC emissions and certain chemical components. Manufacturers who can deliver high-performance, environmentally compliant coatings are capturing premium market segments and establishing competitive advantages.

The competitive landscape features both specialized coating manufacturers and diversified chemical companies, with recent merger and acquisition activity suggesting market consolidation as players seek to expand their technological capabilities and geographic reach.

Aerospace and automotive sectors represent the largest market segments, collectively accounting for over 40% of the total market share. This dominance stems from the critical need for coatings that can withstand extreme operational conditions while providing weight reduction benefits. The aerospace industry particularly values composite coatings that offer superior resistance to thermal cycling, UV radiation, and chemical exposure at high altitudes.

Industrial applications follow closely behind, with significant adoption in heavy machinery, pipelines, and processing equipment. In these environments, the primary market drivers are corrosion prevention and extended maintenance intervals, which directly impact operational costs and equipment lifespan. The marine sector represents another substantial market, where composite coatings must withstand constant exposure to saltwater, biofouling, and mechanical stresses from wave action.

Regional analysis reveals that North America and Europe currently lead the market with approximately 30% and 28% market share respectively, due to their established aerospace and automotive manufacturing bases. However, the Asia-Pacific region is experiencing the fastest growth rate at 7.2% annually, driven by rapid industrialization in China and India, along with expanding manufacturing capabilities.

Customer demand patterns show increasing preference for coatings with demonstrable longevity metrics and performance guarantees. End-users are increasingly willing to pay premium prices for coatings that offer verified extended service life, as the total cost of ownership calculations favor higher initial investment in exchange for reduced maintenance frequency and operational downtime.

Market research indicates a growing trend toward environmentally compliant formulations, with water-based and high-solids composite coatings gaining market share. This shift is particularly pronounced in Europe and North America, where regulatory frameworks increasingly restrict VOC emissions and certain chemical components. Manufacturers who can deliver high-performance, environmentally compliant coatings are capturing premium market segments and establishing competitive advantages.

The competitive landscape features both specialized coating manufacturers and diversified chemical companies, with recent merger and acquisition activity suggesting market consolidation as players seek to expand their technological capabilities and geographic reach.

Current Challenges in Composite Coating Durability

Despite significant advancements in composite coating technologies, several critical challenges persist in ensuring long-term durability and reliable service life prediction. The complex interplay between mechanical and chemical properties creates multifaceted degradation mechanisms that current testing methodologies struggle to fully characterize and predict.

A primary challenge lies in the accurate simulation of real-world environmental conditions during accelerated testing. Laboratory tests often fail to replicate the synergistic effects of multiple stressors such as UV radiation, temperature cycling, moisture, chemical exposure, and mechanical loading that coatings experience simultaneously in service. This disconnect leads to significant discrepancies between predicted and actual performance in field applications.

The heterogeneous nature of composite coatings presents another substantial obstacle. The interface between matrix and reinforcement phases represents a critical vulnerability where degradation often initiates. Current analytical techniques lack sufficient resolution to monitor interfacial changes in real-time during service, limiting our understanding of failure progression mechanisms.

Quantifying the relationship between microstructural evolution and macroscopic property degradation remains problematic. As composite coatings age, subtle changes in cross-linking density, crystallinity, phase separation, and molecular orientation occur gradually, but their cumulative effects on mechanical integrity and chemical resistance are difficult to model mathematically.

The industry also faces challenges in standardization of testing protocols. Different sectors employ varied methodologies for durability assessment, making cross-comparison of performance data difficult and hindering the development of universal design principles for optimizing service life.

Emerging nanomaterial-enhanced composite coatings introduce additional complexity, as their long-term stability and potential for nanoparticle release during weathering raise both performance and regulatory concerns that current testing frameworks are ill-equipped to address.

The development of reliable non-destructive evaluation techniques for in-service monitoring represents another frontier challenge. Current methods often cannot detect incipient damage until significant degradation has already occurred, limiting preventative maintenance opportunities.

Finally, the integration of durability data into predictive computational models remains incomplete. While machine learning approaches show promise, the multiscale nature of degradation processes—from molecular to macroscopic—creates significant challenges in developing unified models that can accurately forecast service life across diverse operating environments and coating compositions.

A primary challenge lies in the accurate simulation of real-world environmental conditions during accelerated testing. Laboratory tests often fail to replicate the synergistic effects of multiple stressors such as UV radiation, temperature cycling, moisture, chemical exposure, and mechanical loading that coatings experience simultaneously in service. This disconnect leads to significant discrepancies between predicted and actual performance in field applications.

The heterogeneous nature of composite coatings presents another substantial obstacle. The interface between matrix and reinforcement phases represents a critical vulnerability where degradation often initiates. Current analytical techniques lack sufficient resolution to monitor interfacial changes in real-time during service, limiting our understanding of failure progression mechanisms.

Quantifying the relationship between microstructural evolution and macroscopic property degradation remains problematic. As composite coatings age, subtle changes in cross-linking density, crystallinity, phase separation, and molecular orientation occur gradually, but their cumulative effects on mechanical integrity and chemical resistance are difficult to model mathematically.

The industry also faces challenges in standardization of testing protocols. Different sectors employ varied methodologies for durability assessment, making cross-comparison of performance data difficult and hindering the development of universal design principles for optimizing service life.

Emerging nanomaterial-enhanced composite coatings introduce additional complexity, as their long-term stability and potential for nanoparticle release during weathering raise both performance and regulatory concerns that current testing frameworks are ill-equipped to address.

The development of reliable non-destructive evaluation techniques for in-service monitoring represents another frontier challenge. Current methods often cannot detect incipient damage until significant degradation has already occurred, limiting preventative maintenance opportunities.

Finally, the integration of durability data into predictive computational models remains incomplete. While machine learning approaches show promise, the multiscale nature of degradation processes—from molecular to macroscopic—creates significant challenges in developing unified models that can accurately forecast service life across diverse operating environments and coating compositions.

Contemporary Approaches to Service Life Prediction

01 Corrosion-resistant composite coatings

Composite coatings designed with corrosion-resistant properties significantly extend service life in harsh environments. These coatings typically incorporate multiple layers with different functional materials that work together to prevent oxidation and chemical degradation. Advanced formulations may include ceramic particles, metal oxides, or polymer matrices with embedded corrosion inhibitors that provide long-term protection against environmental factors, thereby extending the operational lifespan of coated components.- Corrosion-resistant composite coatings: Composite coatings with enhanced corrosion resistance properties can significantly extend service life in harsh environments. These coatings typically incorporate corrosion inhibitors, barrier materials, or sacrificial elements that protect the underlying substrate. Advanced formulations may include multiple layers with different functionalities or self-healing capabilities that automatically repair minor damage, preventing corrosion progression and extending the overall service life of the coated component.

- Wear-resistant composite coating technologies: Wear-resistant composite coatings are designed to withstand mechanical abrasion, friction, and impact, thereby extending the service life of components in high-wear applications. These coatings often incorporate hard particles such as ceramics, carbides, or nanoparticles dispersed in a metal or polymer matrix. The combination of hard particles and a tough matrix provides superior wear resistance while maintaining adequate toughness. Advanced manufacturing techniques ensure optimal particle distribution and strong interfacial bonding for maximum durability.

- Thermal barrier composite coatings: Thermal barrier composite coatings protect components from high-temperature environments, extending service life by preventing thermal degradation. These multi-layered systems typically consist of a bond coat and a ceramic top coat with low thermal conductivity. The coatings provide thermal insulation, oxidation resistance, and can accommodate thermal expansion mismatches between the substrate and coating. Advanced formulations may include graded compositions or novel ceramic materials that enhance temperature resistance and thermal cycling performance.

- Environmental factors affecting coating service life: Environmental factors significantly impact the service life of composite coatings. UV radiation, moisture, temperature fluctuations, chemical exposure, and biological factors can all accelerate coating degradation. Understanding these environmental stressors allows for the development of coatings with specific resistance properties tailored to the intended application environment. Testing protocols that simulate accelerated aging under various environmental conditions help predict service life and optimize coating formulations for specific deployment scenarios.

- Advanced testing and prediction methods for coating service life: Advanced testing and prediction methods are essential for accurately estimating the service life of composite coatings. These include accelerated aging tests, electrochemical impedance spectroscopy, computational modeling, and machine learning approaches that correlate coating properties with performance data. Non-destructive evaluation techniques allow for real-time monitoring of coating degradation in service. These methods enable more accurate prediction of coating longevity, optimization of maintenance schedules, and development of coatings with improved durability and reliability.

02 Wear-resistant composite coating technologies

Wear-resistant composite coatings are engineered to withstand mechanical abrasion and friction, significantly extending the service life of industrial components. These coatings typically combine hard particles such as carbides, nitrides, or diamond with a metal or polymer matrix to create surfaces with superior hardness and toughness. Advanced manufacturing techniques like thermal spraying, electrodeposition, or physical vapor deposition are employed to optimize the microstructure and adhesion of these coatings, resulting in enhanced durability under high-stress operating conditions.Expand Specific Solutions03 Self-healing composite coating systems

Self-healing composite coatings represent an innovative approach to extending service life through autonomous repair mechanisms. These advanced coatings contain microcapsules or vascular networks filled with healing agents that are released when damage occurs, effectively sealing cracks and preventing further deterioration. Some systems utilize shape memory polymers or reversible chemical bonds that can restore coating integrity after mechanical damage or environmental stress, significantly prolonging the functional lifespan of the protected surface without requiring manual intervention.Expand Specific Solutions04 Thermal barrier composite coatings

Thermal barrier composite coatings are specifically designed to protect substrates from extreme temperature environments, substantially extending service life of components in high-temperature applications. These coatings typically consist of ceramic top layers with low thermal conductivity combined with metallic bond coats that provide adhesion and oxidation resistance. The multi-layer structure creates thermal gradients that shield the underlying material from heat damage, while engineered porosity and phase composition optimize thermal insulation properties and thermal expansion compatibility, allowing components to withstand thermal cycling and extreme operating conditions.Expand Specific Solutions05 Environmental and weathering resistant composite coatings

Environmental and weathering resistant composite coatings are formulated to withstand prolonged exposure to UV radiation, moisture, temperature fluctuations, and atmospheric pollutants. These coatings typically incorporate UV stabilizers, antioxidants, and hydrophobic components within a polymer matrix, often reinforced with nanoparticles or specialized fillers that enhance barrier properties. Advanced formulations may include photocatalytic materials that break down surface contaminants or self-cleaning properties that prevent accumulation of environmental deposits, maintaining coating integrity and appearance over extended periods in outdoor applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The composite coatings service life market is currently in a growth phase, with increasing demand across aerospace, automotive, and energy sectors. The global market size is estimated to exceed $10 billion, driven by rising requirements for durable protective solutions in harsh environments. Technical maturity varies significantly across applications, with aerospace leaders like Boeing and Safran Ceramics demonstrating advanced capabilities in high-performance composite coatings. Chemical giants including BASF, Dow Global Technologies, and Nippon Paint are advancing chemical property innovations, while energy companies such as EDF and CNOOC are focusing on specialized applications for extreme conditions. Research institutions like the Institute of Metal Research CAS and University of Houston are bridging fundamental understanding with industrial applications, creating a competitive landscape where mechanical-chemical property optimization determines market leadership.

The Boeing Co.

Technical Solution: Boeing has pioneered advanced composite coating systems specifically designed for aerospace applications where service life under extreme conditions is critical. Their approach integrates nanomaterial-enhanced polymer matrices with precisely engineered mechanical properties to withstand thermal cycling, vibration, and impact resistance. Boeing's proprietary coating systems feature gradient-structured compositions that transition from hard, wear-resistant outer surfaces to more flexible underlayers that accommodate substrate movement. Their research has demonstrated that controlling crystallinity and cross-linking density at the molecular level significantly extends coating durability. Boeing employs accelerated weathering and mechanical stress testing protocols that simulate decades of service conditions to validate coating performance. Their latest developments include self-diagnostic coatings with embedded sensors that can detect mechanical strain or chemical attack before visible damage occurs, allowing for predictive maintenance rather than reactive repairs.

Strengths: Exceptional resistance to UV degradation and thermal cycling; superior impact and abrasion resistance while maintaining flexibility; comprehensive testing protocols that accurately predict real-world performance. Weaknesses: High manufacturing costs limit applications primarily to high-value aerospace components; complex application processes require specialized training and equipment.

BASF SE

Technical Solution: BASF SE has developed advanced composite coating systems that integrate both mechanical and chemical resistance properties to extend service life. Their technology focuses on multi-layer protective coating systems with specialized polymer matrices reinforced with nano-fillers. These coatings employ cross-linking chemistry that creates strong covalent bonds within the polymer structure, enhancing mechanical durability while maintaining flexibility. BASF's approach includes incorporating self-healing mechanisms that can repair microcracks through encapsulated healing agents that release upon damage detection. Their research has demonstrated that optimizing the interface between coating layers significantly improves adhesion strength and reduces delamination risks. BASF's composite coatings typically feature corrosion inhibitors strategically dispersed throughout the matrix, providing active protection against environmental degradation while maintaining mechanical integrity over time.

Strengths: Superior chemical resistance across diverse environments including acidic, alkaline, and solvent exposures; excellent adhesion properties that maintain coating integrity under thermal cycling. Weaknesses: Higher initial application costs compared to conventional coatings; some formulations may require specialized application equipment and controlled curing conditions.

Critical Patents in Composite Coating Longevity

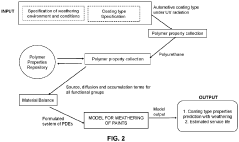

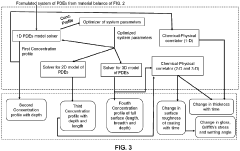

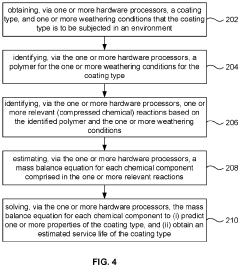

Systems and methods for predicting properties of coating types and estimating service life thereof

PatentActiveEP4369347A1

Innovation

- A processor-implemented method and system that estimate the service life of coatings by solving mass balance equations using Partial Difference Equations (PDE) solvers and chemical-physical correlators, considering changes in concentration profiles over time and environmental conditions to predict properties like surface roughness, thickness, gloss, and wetting angle.

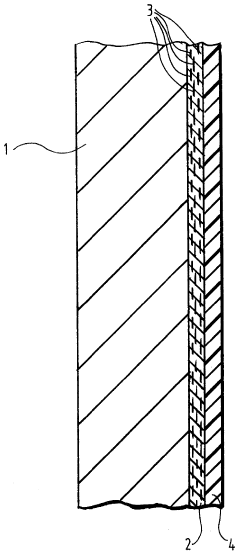

Method for coating a surface and composite coating

PatentWO1999049990A1

Innovation

- A composite coating method combining a zinc primer layer with a lacquer layer, where the lacquer layer is applied via powder coating, incorporating hard material particles for reinforcement, and using environmentally friendly water-borne zinc primer and epoxy-based enamelled powder lacquer for enhanced adhesion and water-resistance.

Environmental Impact and Sustainability Factors

The environmental impact of composite coatings extends far beyond their immediate application, encompassing their entire lifecycle from raw material extraction to disposal. When evaluating how mechanical and chemical properties determine service life, environmental factors emerge as critical considerations that can significantly accelerate or mitigate degradation processes.

Exposure to UV radiation represents one of the most pervasive environmental challenges for composite coatings. The photochemical reactions triggered by UV exposure can break down polymer matrices, leading to chain scission and subsequent deterioration of mechanical properties such as tensile strength and impact resistance. Coatings with superior UV stabilizers and antioxidants demonstrate markedly extended service life in outdoor applications.

Temperature fluctuations and thermal cycling impose considerable stress on composite coatings due to differential thermal expansion between coating layers and substrates. This mismatch can induce internal stresses, leading to microcracking and delamination. Formulations with optimized thermal expansion coefficients and enhanced adhesion properties show improved resistance to these environmental stressors.

Chemical exposure from industrial pollutants, marine environments, and acid rain presents another significant challenge. The chemical resistance of composite coatings is directly linked to their crosslinking density, polymer type, and filler composition. Coatings with higher crosslinking density typically exhibit superior chemical resistance but may sacrifice flexibility, illustrating the complex property trade-offs that influence service life.

From a sustainability perspective, the longevity of composite coatings has profound implications for resource conservation and waste reduction. Extended service life directly translates to reduced material consumption, lower maintenance requirements, and decreased environmental footprint. However, this benefit must be balanced against the potential environmental impact of the additives and stabilizers used to achieve this longevity.

Recent advances in bio-based composite coatings represent a promising direction for reducing environmental impact while maintaining performance. These formulations incorporate renewable raw materials and biodegradable components, potentially offering end-of-life advantages. However, their mechanical and chemical properties often still lag behind conventional petroleum-based systems, particularly in demanding applications requiring extended service life.

Life Cycle Assessment (LCA) studies reveal that the environmental impact of composite coatings is dominated by the use phase rather than production or disposal phases, emphasizing the importance of durability in overall sustainability. This finding underscores the critical relationship between mechanical and chemical properties and environmental performance, suggesting that optimizing for longevity may often align with sustainability goals.

Exposure to UV radiation represents one of the most pervasive environmental challenges for composite coatings. The photochemical reactions triggered by UV exposure can break down polymer matrices, leading to chain scission and subsequent deterioration of mechanical properties such as tensile strength and impact resistance. Coatings with superior UV stabilizers and antioxidants demonstrate markedly extended service life in outdoor applications.

Temperature fluctuations and thermal cycling impose considerable stress on composite coatings due to differential thermal expansion between coating layers and substrates. This mismatch can induce internal stresses, leading to microcracking and delamination. Formulations with optimized thermal expansion coefficients and enhanced adhesion properties show improved resistance to these environmental stressors.

Chemical exposure from industrial pollutants, marine environments, and acid rain presents another significant challenge. The chemical resistance of composite coatings is directly linked to their crosslinking density, polymer type, and filler composition. Coatings with higher crosslinking density typically exhibit superior chemical resistance but may sacrifice flexibility, illustrating the complex property trade-offs that influence service life.

From a sustainability perspective, the longevity of composite coatings has profound implications for resource conservation and waste reduction. Extended service life directly translates to reduced material consumption, lower maintenance requirements, and decreased environmental footprint. However, this benefit must be balanced against the potential environmental impact of the additives and stabilizers used to achieve this longevity.

Recent advances in bio-based composite coatings represent a promising direction for reducing environmental impact while maintaining performance. These formulations incorporate renewable raw materials and biodegradable components, potentially offering end-of-life advantages. However, their mechanical and chemical properties often still lag behind conventional petroleum-based systems, particularly in demanding applications requiring extended service life.

Life Cycle Assessment (LCA) studies reveal that the environmental impact of composite coatings is dominated by the use phase rather than production or disposal phases, emphasizing the importance of durability in overall sustainability. This finding underscores the critical relationship between mechanical and chemical properties and environmental performance, suggesting that optimizing for longevity may often align with sustainability goals.

Accelerated Testing Methodologies and Standards

Accelerated testing methodologies play a crucial role in predicting the service life of composite coatings by simulating long-term exposure conditions in compressed timeframes. These methodologies enable researchers and manufacturers to evaluate how mechanical and chemical properties evolve under various environmental stressors, providing valuable insights into coating durability without waiting for natural aging processes.

Standard accelerated tests for composite coatings include salt spray testing (ASTM B117), which evaluates corrosion resistance by exposing samples to salt fog environments. This test particularly reveals how chemical properties like adhesion strength and barrier protection degrade when subjected to chloride ions and moisture. The correlation between salt spray hours and actual service life varies by application but offers comparative performance metrics.

UV exposure testing (ASTM G154) simulates solar radiation effects on composite coatings, particularly relevant for outdoor applications. This methodology specifically targets chemical degradation mechanisms like photodegradation of polymeric matrices, which can compromise mechanical integrity over time. Modern UV chambers incorporate temperature and moisture cycling to better replicate real-world conditions.

Thermal cycling tests (ASTM D6944) evaluate how mechanical properties respond to temperature fluctuations, revealing potential delamination, cracking, or adhesion failure due to differential thermal expansion between coating layers or between coating and substrate. These tests are particularly valuable for coatings deployed in environments with significant temperature variations.

Mechanical property degradation is commonly assessed through standardized methods including adhesion testing (ASTM D3359), impact resistance (ASTM D2794), and abrasion resistance (ASTM D4060). These tests quantify how environmental exposure affects fundamental mechanical properties that determine coating longevity.

Chemical resistance testing employs immersion protocols (ASTM D1308) to evaluate coating performance when exposed to specific chemicals relevant to the intended application environment. These tests reveal degradation mechanisms including swelling, dissolution, or chemical reactions that compromise coating integrity.

The development of correlation models between accelerated testing results and actual field performance represents a significant advancement in service life prediction. These models typically incorporate Arrhenius equations and other mathematical relationships to translate accelerated aging data into realistic service life estimates based on known degradation mechanisms of both mechanical and chemical properties.

International standards organizations including ISO, ASTM, and NACE continue to refine testing methodologies to improve correlation with real-world performance, with recent emphasis on combined-effect testing that simultaneously evaluates multiple stressors to better simulate complex service environments.

Standard accelerated tests for composite coatings include salt spray testing (ASTM B117), which evaluates corrosion resistance by exposing samples to salt fog environments. This test particularly reveals how chemical properties like adhesion strength and barrier protection degrade when subjected to chloride ions and moisture. The correlation between salt spray hours and actual service life varies by application but offers comparative performance metrics.

UV exposure testing (ASTM G154) simulates solar radiation effects on composite coatings, particularly relevant for outdoor applications. This methodology specifically targets chemical degradation mechanisms like photodegradation of polymeric matrices, which can compromise mechanical integrity over time. Modern UV chambers incorporate temperature and moisture cycling to better replicate real-world conditions.

Thermal cycling tests (ASTM D6944) evaluate how mechanical properties respond to temperature fluctuations, revealing potential delamination, cracking, or adhesion failure due to differential thermal expansion between coating layers or between coating and substrate. These tests are particularly valuable for coatings deployed in environments with significant temperature variations.

Mechanical property degradation is commonly assessed through standardized methods including adhesion testing (ASTM D3359), impact resistance (ASTM D2794), and abrasion resistance (ASTM D4060). These tests quantify how environmental exposure affects fundamental mechanical properties that determine coating longevity.

Chemical resistance testing employs immersion protocols (ASTM D1308) to evaluate coating performance when exposed to specific chemicals relevant to the intended application environment. These tests reveal degradation mechanisms including swelling, dissolution, or chemical reactions that compromise coating integrity.

The development of correlation models between accelerated testing results and actual field performance represents a significant advancement in service life prediction. These models typically incorporate Arrhenius equations and other mathematical relationships to translate accelerated aging data into realistic service life estimates based on known degradation mechanisms of both mechanical and chemical properties.

International standards organizations including ISO, ASTM, and NACE continue to refine testing methodologies to improve correlation with real-world performance, with recent emphasis on combined-effect testing that simultaneously evaluates multiple stressors to better simulate complex service environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!