Composite coatings for electronics energy storage and device protection

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Composite Coating Technology Evolution and Objectives

Composite coating technologies have evolved significantly over the past decades, transforming from simple protective layers to sophisticated multifunctional systems. The journey began in the 1960s with basic polymer coatings primarily focused on corrosion protection, followed by the introduction of ceramic-based coatings in the 1970s that offered improved thermal resistance. The 1980s witnessed the emergence of early composite coatings combining multiple materials to achieve enhanced properties beyond what single-component systems could provide.

The 1990s marked a pivotal shift with the development of nanocomposite coatings, incorporating nanoscale particles to dramatically improve performance characteristics. By the early 2000s, researchers began exploring functional composite coatings specifically designed for electronics applications, addressing challenges in thermal management and electrical insulation. The past decade has seen remarkable advancements in smart composite coatings with self-healing capabilities, stimuli-responsive features, and enhanced energy storage properties.

Current technological objectives in composite coating research for electronics energy storage and device protection center around several key areas. Researchers aim to develop coatings that can simultaneously protect electronic components from environmental factors while enhancing energy storage capacity. This dual functionality represents a significant departure from traditional approaches that treated protection and energy storage as separate concerns.

Another critical objective involves improving the power density and cycle life of energy storage devices through advanced coating technologies. By engineering composite coatings at the nanoscale, researchers seek to create materials that facilitate faster ion transport while maintaining structural integrity over thousands of charge-discharge cycles. This includes developing coatings that can withstand extreme temperature fluctuations, mechanical stress, and exposure to various chemicals without degradation.

Sustainability has emerged as an equally important objective, with efforts focused on developing environmentally friendly coating materials and processes. This includes reducing or eliminating toxic components, designing for recyclability, and minimizing energy consumption during manufacturing. The industry is moving toward water-based systems and bio-inspired materials that offer comparable or superior performance to conventional solvent-based coatings.

Integration capabilities represent another frontier, with researchers working to develop composite coatings that can be seamlessly incorporated into existing manufacturing processes. The goal is to create coating technologies that can be applied at scale without requiring significant modifications to production lines, thereby facilitating faster industry adoption and commercialization.

The 1990s marked a pivotal shift with the development of nanocomposite coatings, incorporating nanoscale particles to dramatically improve performance characteristics. By the early 2000s, researchers began exploring functional composite coatings specifically designed for electronics applications, addressing challenges in thermal management and electrical insulation. The past decade has seen remarkable advancements in smart composite coatings with self-healing capabilities, stimuli-responsive features, and enhanced energy storage properties.

Current technological objectives in composite coating research for electronics energy storage and device protection center around several key areas. Researchers aim to develop coatings that can simultaneously protect electronic components from environmental factors while enhancing energy storage capacity. This dual functionality represents a significant departure from traditional approaches that treated protection and energy storage as separate concerns.

Another critical objective involves improving the power density and cycle life of energy storage devices through advanced coating technologies. By engineering composite coatings at the nanoscale, researchers seek to create materials that facilitate faster ion transport while maintaining structural integrity over thousands of charge-discharge cycles. This includes developing coatings that can withstand extreme temperature fluctuations, mechanical stress, and exposure to various chemicals without degradation.

Sustainability has emerged as an equally important objective, with efforts focused on developing environmentally friendly coating materials and processes. This includes reducing or eliminating toxic components, designing for recyclability, and minimizing energy consumption during manufacturing. The industry is moving toward water-based systems and bio-inspired materials that offer comparable or superior performance to conventional solvent-based coatings.

Integration capabilities represent another frontier, with researchers working to develop composite coatings that can be seamlessly incorporated into existing manufacturing processes. The goal is to create coating technologies that can be applied at scale without requiring significant modifications to production lines, thereby facilitating faster industry adoption and commercialization.

Market Analysis for Electronics Protection Solutions

The global market for electronic protection solutions has witnessed substantial growth in recent years, driven primarily by the increasing complexity and miniaturization of electronic devices. The composite coatings sector specifically has emerged as a critical segment, with the market value reaching approximately 8.7 billion USD in 2022 and projected to grow at a CAGR of 6.2% through 2028.

Consumer electronics represents the largest application segment, accounting for nearly 35% of the market share. This dominance stems from the rising demand for smartphones, tablets, and wearable devices that require enhanced protection against environmental factors and physical damage. The automotive electronics sector follows closely, constituting about 28% of the market, with increasing integration of electronic components in modern vehicles necessitating advanced protective solutions.

Geographically, Asia-Pacific leads the market with approximately 42% share, attributed to the region's position as a manufacturing hub for electronics. North America and Europe collectively account for around 45% of the market, with significant research activities and technological innovations driving growth in these regions.

The demand for composite coatings in energy storage applications has shown remarkable growth, particularly in lithium-ion battery protection. This segment has expanded by 11.3% annually since 2020, reflecting the surge in electric vehicle production and portable electronic devices. Manufacturers are increasingly seeking coatings that can enhance battery safety, extend cycle life, and improve thermal management.

Market analysis reveals a shift toward environmentally friendly coating solutions, with water-based and solvent-free formulations gaining traction. This trend is reinforced by stringent environmental regulations in major markets, particularly in Europe and North America. Companies investing in sustainable coating technologies have reported 15-20% higher growth rates compared to those using conventional solutions.

Customer preferences are evolving toward multifunctional coatings that offer combined benefits of corrosion resistance, thermal management, and electromagnetic interference (EMI) shielding. This convergence of functionalities represents a premium market segment growing at twice the rate of standard protective coatings.

The competitive landscape features both established chemical companies and specialized coating manufacturers. Recent market consolidation through mergers and acquisitions indicates the strategic importance of this sector, with five major transactions valued over 100 million USD occurring in the past two years. Emerging players focusing on nanotechnology-enhanced coatings have secured significant venture capital funding, highlighting investor confidence in next-generation protection solutions.

Consumer electronics represents the largest application segment, accounting for nearly 35% of the market share. This dominance stems from the rising demand for smartphones, tablets, and wearable devices that require enhanced protection against environmental factors and physical damage. The automotive electronics sector follows closely, constituting about 28% of the market, with increasing integration of electronic components in modern vehicles necessitating advanced protective solutions.

Geographically, Asia-Pacific leads the market with approximately 42% share, attributed to the region's position as a manufacturing hub for electronics. North America and Europe collectively account for around 45% of the market, with significant research activities and technological innovations driving growth in these regions.

The demand for composite coatings in energy storage applications has shown remarkable growth, particularly in lithium-ion battery protection. This segment has expanded by 11.3% annually since 2020, reflecting the surge in electric vehicle production and portable electronic devices. Manufacturers are increasingly seeking coatings that can enhance battery safety, extend cycle life, and improve thermal management.

Market analysis reveals a shift toward environmentally friendly coating solutions, with water-based and solvent-free formulations gaining traction. This trend is reinforced by stringent environmental regulations in major markets, particularly in Europe and North America. Companies investing in sustainable coating technologies have reported 15-20% higher growth rates compared to those using conventional solutions.

Customer preferences are evolving toward multifunctional coatings that offer combined benefits of corrosion resistance, thermal management, and electromagnetic interference (EMI) shielding. This convergence of functionalities represents a premium market segment growing at twice the rate of standard protective coatings.

The competitive landscape features both established chemical companies and specialized coating manufacturers. Recent market consolidation through mergers and acquisitions indicates the strategic importance of this sector, with five major transactions valued over 100 million USD occurring in the past two years. Emerging players focusing on nanotechnology-enhanced coatings have secured significant venture capital funding, highlighting investor confidence in next-generation protection solutions.

Current Challenges in Energy Storage Coating Technologies

Despite significant advancements in energy storage coating technologies, several critical challenges persist that impede optimal performance and widespread adoption. Material stability remains a primary concern, as many composite coatings suffer from degradation during charge-discharge cycles, particularly at elevated temperatures or under extreme environmental conditions. This degradation manifests as structural breakdown, delamination, or chemical decomposition, significantly reducing the operational lifespan of energy storage devices.

Interface management presents another substantial challenge. The boundary between coating layers and substrate materials often develops imperfections that compromise electrical conductivity and mechanical integrity. These interface issues can lead to increased internal resistance, reduced energy efficiency, and potential safety hazards in high-power applications. Current coating technologies struggle to maintain consistent interface quality across large surface areas and complex geometries.

Scalability of manufacturing processes represents a significant bottleneck in commercialization efforts. Laboratory-scale coating techniques that yield excellent performance characteristics often prove difficult to scale to industrial production volumes without sacrificing quality or increasing costs prohibitively. Techniques such as atomic layer deposition offer precise control but remain too slow and expensive for mass production of large-format energy storage devices.

Environmental and safety concerns further complicate the development landscape. Many high-performance coating materials incorporate rare earth elements, toxic compounds, or environmentally persistent substances that raise sustainability questions. Regulatory frameworks increasingly demand reduced environmental footprints, pushing researchers toward greener alternatives that may not match the performance of conventional materials.

Multifunctionality requirements add complexity to coating design. Modern electronic devices demand coatings that simultaneously provide energy storage capabilities, thermal management, electromagnetic shielding, and physical protection. Balancing these sometimes competing requirements within a single coating system presents formidable materials science challenges.

Cost-effectiveness remains a persistent obstacle, particularly for consumer electronics applications. Advanced composite coatings often require expensive precursors, specialized equipment, and precise processing conditions that drive up manufacturing costs. The industry continues to seek economically viable solutions that maintain performance standards while reducing production expenses.

Characterization and testing methodologies also present challenges, as standardized protocols for evaluating composite coating performance in energy storage applications remain underdeveloped. This hampers comparative analysis between different coating technologies and slows the validation process for new innovations entering the market.

Interface management presents another substantial challenge. The boundary between coating layers and substrate materials often develops imperfections that compromise electrical conductivity and mechanical integrity. These interface issues can lead to increased internal resistance, reduced energy efficiency, and potential safety hazards in high-power applications. Current coating technologies struggle to maintain consistent interface quality across large surface areas and complex geometries.

Scalability of manufacturing processes represents a significant bottleneck in commercialization efforts. Laboratory-scale coating techniques that yield excellent performance characteristics often prove difficult to scale to industrial production volumes without sacrificing quality or increasing costs prohibitively. Techniques such as atomic layer deposition offer precise control but remain too slow and expensive for mass production of large-format energy storage devices.

Environmental and safety concerns further complicate the development landscape. Many high-performance coating materials incorporate rare earth elements, toxic compounds, or environmentally persistent substances that raise sustainability questions. Regulatory frameworks increasingly demand reduced environmental footprints, pushing researchers toward greener alternatives that may not match the performance of conventional materials.

Multifunctionality requirements add complexity to coating design. Modern electronic devices demand coatings that simultaneously provide energy storage capabilities, thermal management, electromagnetic shielding, and physical protection. Balancing these sometimes competing requirements within a single coating system presents formidable materials science challenges.

Cost-effectiveness remains a persistent obstacle, particularly for consumer electronics applications. Advanced composite coatings often require expensive precursors, specialized equipment, and precise processing conditions that drive up manufacturing costs. The industry continues to seek economically viable solutions that maintain performance standards while reducing production expenses.

Characterization and testing methodologies also present challenges, as standardized protocols for evaluating composite coating performance in energy storage applications remain underdeveloped. This hampers comparative analysis between different coating technologies and slows the validation process for new innovations entering the market.

Existing Composite Coating Methodologies

01 Metal-based composite coatings

Metal-based composite coatings combine metallic materials with other components to enhance properties such as corrosion resistance, wear resistance, and durability. These coatings often incorporate metal particles, alloys, or compounds within a matrix to create protective layers for various industrial applications. The combination of different metallic elements allows for customized performance characteristics suited to specific environmental conditions and mechanical requirements.- Metal-based composite coatings for corrosion protection: Metal-based composite coatings provide enhanced corrosion protection for various substrates. These coatings typically incorporate metal particles or compounds such as zinc, aluminum, or nickel within a matrix to create a protective barrier. The composite structure offers improved adhesion, durability, and resistance to environmental factors compared to traditional single-layer coatings. These coatings can be applied through various methods including electroplating, thermal spraying, or chemical deposition techniques.

- Polymer-ceramic composite coatings for thermal applications: Polymer-ceramic composite coatings combine the flexibility of polymers with the thermal resistance of ceramic materials to create coatings suitable for high-temperature applications. These coatings typically consist of ceramic particles dispersed within a polymer matrix, providing thermal insulation, heat resistance, and durability. The composite structure allows for customization of thermal properties while maintaining application flexibility. These coatings find applications in aerospace, automotive, and industrial equipment exposed to thermal cycling or extreme temperatures.

- Nanoparticle-reinforced composite coatings for enhanced mechanical properties: Nanoparticle-reinforced composite coatings incorporate nanoscale materials to significantly improve mechanical properties such as hardness, wear resistance, and toughness. These coatings typically contain nanoparticles such as carbon nanotubes, graphene, or metal oxide nanoparticles dispersed within a matrix material. The nanoscale reinforcement provides exceptional strength-to-weight ratios and can enhance other functional properties including electrical conductivity or antimicrobial activity. Application methods include sol-gel processes, electrophoretic deposition, or spray techniques that ensure uniform nanoparticle distribution.

- Self-healing composite coatings for extended service life: Self-healing composite coatings contain active components that can repair damage automatically, extending the service life of the protected substrate. These coatings typically incorporate microcapsules filled with healing agents, shape memory polymers, or reversible chemical bonds that activate upon damage. When cracks or scratches occur, the healing mechanism is triggered, restoring the coating integrity and maintaining protection. This technology is particularly valuable for applications where maintenance access is limited or where continuous protection is critical.

- Environmentally friendly composite coatings with reduced VOCs: Environmentally friendly composite coatings are formulated to reduce volatile organic compounds (VOCs) and other harmful substances while maintaining performance characteristics. These coatings typically use water-based systems, powder coating technologies, or bio-derived components as alternatives to traditional solvent-based formulations. The composite structure often incorporates natural materials, renewable resources, or recycled content to further reduce environmental impact. These coatings meet increasingly stringent environmental regulations while providing necessary protection and aesthetic properties for various applications.

02 Polymer-based composite coatings

Polymer-based composite coatings utilize various polymeric materials as matrices that can be reinforced with additives to improve specific properties. These coatings provide benefits such as chemical resistance, flexibility, and adhesion to different substrates. By incorporating functional additives into polymer matrices, these composite coatings can be tailored for applications ranging from protective finishes to specialized industrial coatings with enhanced performance characteristics.Expand Specific Solutions03 Ceramic and inorganic composite coatings

Ceramic and inorganic composite coatings combine ceramic materials with other components to create high-performance surface treatments. These coatings typically offer excellent thermal resistance, hardness, and chemical stability. The incorporation of various inorganic materials allows for the development of coatings that can withstand extreme temperatures and harsh environments, making them suitable for applications in aerospace, energy production, and manufacturing industries.Expand Specific Solutions04 Nanocomposite coating technologies

Nanocomposite coatings incorporate nanoscale particles or structures within a coating matrix to achieve enhanced properties not possible with conventional materials. These advanced coatings exhibit improved hardness, wear resistance, and self-healing capabilities due to the unique properties of nanomaterials. The controlled dispersion of nanoparticles within the coating matrix enables the development of multifunctional surfaces with applications in electronics, automotive, and medical industries.Expand Specific Solutions05 Environmentally friendly composite coatings

Environmentally friendly composite coatings focus on sustainable materials and processes that reduce environmental impact while maintaining performance requirements. These coatings often utilize water-based formulations, bio-derived components, or low-VOC technologies to minimize pollution and health hazards. The development of green composite coating technologies addresses increasing regulatory requirements and market demand for sustainable industrial products without compromising on protective qualities and durability.Expand Specific Solutions

Industry Leaders in Electronics Coating Solutions

The composite coatings market for electronics energy storage and device protection is in a growth phase, characterized by increasing demand for advanced protective solutions in consumer electronics and energy storage applications. The market size is expanding rapidly due to the proliferation of electronic devices requiring protection from environmental factors and enhanced energy storage capabilities. Technologically, the field shows moderate maturity with established players like PPG Industries, DuPont, and Samsung Electronics offering commercial solutions, while innovative companies such as Favored Nanotechnology, HzO, and Forge Nano are advancing nano-coating technologies. Companies like Aspen Aerogels and SGL Carbon are developing specialized materials for energy storage applications, while research institutions including Harbin Institute of Technology and Technical University of Liberec contribute to fundamental advancements. The competitive landscape features both traditional chemical companies and electronics manufacturers seeking differentiation through proprietary coating technologies.

DuPont de Nemours, Inc.

Technical Solution: DuPont has pioneered composite coating solutions for electronics energy storage through their advanced materials science platform. Their technology centers on hybrid organic-inorganic nanocomposite coatings that provide multifunctional protection. DuPont's approach incorporates siloxane-based polymers with ceramic nanoparticles (typically 20-50 nm in diameter) to create conformal protective layers with thickness precision control between 1-100 μm. These coatings demonstrate remarkable thermal conductivity (1.5-3.0 W/m·K) while maintaining electrical insulation properties. For battery applications, DuPont has developed specialized coatings that enhance thermal management by efficiently dissipating heat from energy storage components, reducing hotspot formation by up to 40%. Their proprietary cross-linking chemistry enables coatings to withstand operational temperatures from -40°C to +180°C while providing chemical resistance against electrolyte degradation products. DuPont's coatings also incorporate self-healing mechanisms that can repair microcracks through reversible hydrogen bonding networks.

Strengths: Exceptional thermal stability and chemical resistance; versatile application methods including spray, dip, and roll-to-roll processing; strong intellectual property portfolio in nanocomposite materials. Weaknesses: Higher initial implementation costs; requires precise application parameters for optimal performance; some formulations have limited shelf life before application.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed proprietary composite coating technologies specifically engineered for next-generation energy storage devices. Their approach centers on multi-functional nanocomposite coatings that integrate graphene derivatives with ceramic particles in polymer matrices. These coatings provide exceptional barrier properties while enhancing thermal management in battery systems. Samsung's technology utilizes precisely controlled deposition techniques to create uniform layers ranging from 0.5-15 μm with nanoscale precision. Their coatings incorporate functionalized graphene oxide sheets (lateral dimensions of 1-5 μm) that create tortuous pathways for moisture and oxygen diffusion, reducing permeation rates by over 95% compared to conventional coatings. For high-energy density batteries, Samsung has engineered flame-retardant composite coatings containing phosphorus-nitrogen compounds that can withstand direct flame exposure for up to 10 minutes without ignition. Their coatings also feature self-diagnostic capabilities through embedded conductive networks that can detect mechanical damage before catastrophic failure occurs.

Strengths: Excellent integration with existing battery manufacturing processes; superior moisture and oxygen barrier properties; enhanced thermal management capabilities that improve device safety. Weaknesses: Complex manufacturing process requiring specialized equipment; higher material costs compared to traditional coatings; potential challenges with long-term adhesion to certain substrates.

Key Innovations in Energy Storage Protection Materials

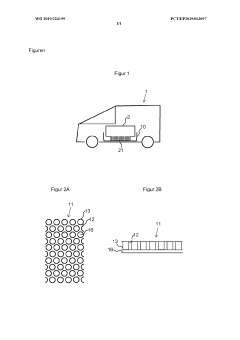

Stored energy source protected by a composite material

PatentWO2019224199A1

Innovation

- A composite material comprising fibers and graphite foil is used to protect energy storage devices, providing mechanical protection and enhanced passive cooling by absorbing and dissipating heat, thereby reducing the risk of damage and extending the service life.

Composite coating, preparation method, and device

PatentPendingUS20250011621A1

Innovation

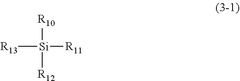

- A composite plasma polymeric coating is developed, comprising specific monomers with aromatic rings, ester groups, and organosilanes, which are deposited using a plasma chemical vapor deposition process, forming a multi-layer structure with improved hardness, corrosion resistance, and hydrophobicity, enhancing bonding to substrates and providing excellent anti-corrosion and wear resistance.

Environmental Impact and Sustainability Considerations

The environmental footprint of composite coatings for electronics energy storage and device protection has become increasingly significant as electronic waste continues to grow globally. Traditional coating materials often contain heavy metals, volatile organic compounds (VOCs), and other environmentally harmful substances that pose serious challenges to ecological systems and human health when improperly disposed of or recycled.

Recent advancements in green chemistry have led to the development of bio-based composite coatings that utilize renewable resources such as cellulose, chitosan, and plant-derived polymers. These sustainable alternatives demonstrate comparable performance characteristics while significantly reducing environmental impact throughout their lifecycle. Studies indicate that bio-based coatings can reduce carbon emissions by up to 40% compared to petroleum-based counterparts.

Water-based coating systems represent another sustainable direction, eliminating the need for harmful solvents that contribute to air pollution and ozone depletion. These formulations have overcome initial performance limitations through advanced emulsion technologies and nano-additives, now offering competitive protection properties while meeting stringent environmental regulations in major markets.

End-of-life considerations have become central to coating development strategies. Modern composite coatings increasingly incorporate design-for-disassembly principles, allowing for more efficient separation of materials during recycling processes. Some innovative formulations feature triggered degradation mechanisms that activate under specific recycling conditions, facilitating material recovery without compromising performance during the product's operational life.

Energy consumption during coating application and curing processes presents another environmental challenge. Traditional thermal curing methods require significant energy inputs, contributing to the carbon footprint of electronic devices. UV-curable and room-temperature curing composite coatings have emerged as energy-efficient alternatives, reducing processing energy requirements by up to 70% while maintaining or enhancing protective properties.

Regulatory frameworks worldwide are increasingly prioritizing sustainability in electronic materials. The European Union's Restriction of Hazardous Substances (RoHS) directive, China's Restriction of Hazardous Substances (China RoHS), and similar regulations in other regions have accelerated the transition toward environmentally benign coating technologies. Companies investing in sustainable coating solutions gain competitive advantages through regulatory compliance readiness and alignment with growing consumer demand for environmentally responsible electronics.

Life Cycle Assessment (LCA) methodologies are becoming standard practice in evaluating coating technologies, providing comprehensive analysis of environmental impacts from raw material extraction through manufacturing, use, and disposal. These assessments reveal that advanced composite coatings can significantly extend device lifespans, thereby reducing electronic waste generation and associated environmental burdens.

Recent advancements in green chemistry have led to the development of bio-based composite coatings that utilize renewable resources such as cellulose, chitosan, and plant-derived polymers. These sustainable alternatives demonstrate comparable performance characteristics while significantly reducing environmental impact throughout their lifecycle. Studies indicate that bio-based coatings can reduce carbon emissions by up to 40% compared to petroleum-based counterparts.

Water-based coating systems represent another sustainable direction, eliminating the need for harmful solvents that contribute to air pollution and ozone depletion. These formulations have overcome initial performance limitations through advanced emulsion technologies and nano-additives, now offering competitive protection properties while meeting stringent environmental regulations in major markets.

End-of-life considerations have become central to coating development strategies. Modern composite coatings increasingly incorporate design-for-disassembly principles, allowing for more efficient separation of materials during recycling processes. Some innovative formulations feature triggered degradation mechanisms that activate under specific recycling conditions, facilitating material recovery without compromising performance during the product's operational life.

Energy consumption during coating application and curing processes presents another environmental challenge. Traditional thermal curing methods require significant energy inputs, contributing to the carbon footprint of electronic devices. UV-curable and room-temperature curing composite coatings have emerged as energy-efficient alternatives, reducing processing energy requirements by up to 70% while maintaining or enhancing protective properties.

Regulatory frameworks worldwide are increasingly prioritizing sustainability in electronic materials. The European Union's Restriction of Hazardous Substances (RoHS) directive, China's Restriction of Hazardous Substances (China RoHS), and similar regulations in other regions have accelerated the transition toward environmentally benign coating technologies. Companies investing in sustainable coating solutions gain competitive advantages through regulatory compliance readiness and alignment with growing consumer demand for environmentally responsible electronics.

Life Cycle Assessment (LCA) methodologies are becoming standard practice in evaluating coating technologies, providing comprehensive analysis of environmental impacts from raw material extraction through manufacturing, use, and disposal. These assessments reveal that advanced composite coatings can significantly extend device lifespans, thereby reducing electronic waste generation and associated environmental burdens.

Scalability and Manufacturing Process Optimization

Scaling up composite coating technologies from laboratory to industrial production presents significant challenges that require systematic optimization approaches. Current manufacturing processes for electronic protective coatings typically involve multi-step procedures including substrate preparation, precursor formulation, deposition, and post-treatment. The transition to mass production demands careful consideration of process parameters to maintain coating quality while increasing throughput.

Key scalability factors include deposition rate, uniformity across large substrates, and process reproducibility. Traditional methods such as spin coating and dip coating, while effective at laboratory scale, face limitations in handling larger electronic components. Roll-to-roll processing emerges as a promising approach for continuous production of coated flexible electronics, enabling throughput rates exceeding 100 m²/min under optimized conditions.

Process optimization strategies must address several critical variables simultaneously. Temperature control during deposition and curing significantly impacts coating microstructure and adhesion properties. Recent advancements in precision temperature management systems have reduced variation to ±1°C across production lines, resulting in more consistent coating performance. Similarly, atmospheric conditions including humidity and oxygen levels require strict control to prevent defect formation.

Material waste reduction represents another optimization frontier. Conventional spray coating methods typically achieve material utilization rates of 30-40%, while newer electrostatic-assisted deposition techniques have demonstrated efficiency improvements to 65-75%. These advances directly impact production economics and environmental sustainability of coating operations.

Automation and real-time monitoring systems have revolutionized quality control in composite coating manufacturing. Integrated optical inspection systems can detect coating thickness variations and surface defects at production speeds, enabling immediate process adjustments. Machine learning algorithms increasingly supplement these systems by identifying subtle parameter correlations that affect coating performance.

Energy consumption optimization remains crucial for sustainable manufacturing. Traditional thermal curing processes consume significant energy, whereas emerging technologies like UV-assisted curing and selective laser sintering offer energy reductions of 40-60% while maintaining or improving coating performance characteristics. These approaches also reduce processing time, further enhancing production throughput.

The integration of these optimization strategies requires holistic production system design. Modular manufacturing lines that can accommodate different coating formulations with minimal reconfiguration time represent the current industry benchmark, allowing manufacturers to respond rapidly to changing market demands while maintaining consistent quality standards.

Key scalability factors include deposition rate, uniformity across large substrates, and process reproducibility. Traditional methods such as spin coating and dip coating, while effective at laboratory scale, face limitations in handling larger electronic components. Roll-to-roll processing emerges as a promising approach for continuous production of coated flexible electronics, enabling throughput rates exceeding 100 m²/min under optimized conditions.

Process optimization strategies must address several critical variables simultaneously. Temperature control during deposition and curing significantly impacts coating microstructure and adhesion properties. Recent advancements in precision temperature management systems have reduced variation to ±1°C across production lines, resulting in more consistent coating performance. Similarly, atmospheric conditions including humidity and oxygen levels require strict control to prevent defect formation.

Material waste reduction represents another optimization frontier. Conventional spray coating methods typically achieve material utilization rates of 30-40%, while newer electrostatic-assisted deposition techniques have demonstrated efficiency improvements to 65-75%. These advances directly impact production economics and environmental sustainability of coating operations.

Automation and real-time monitoring systems have revolutionized quality control in composite coating manufacturing. Integrated optical inspection systems can detect coating thickness variations and surface defects at production speeds, enabling immediate process adjustments. Machine learning algorithms increasingly supplement these systems by identifying subtle parameter correlations that affect coating performance.

Energy consumption optimization remains crucial for sustainable manufacturing. Traditional thermal curing processes consume significant energy, whereas emerging technologies like UV-assisted curing and selective laser sintering offer energy reductions of 40-60% while maintaining or improving coating performance characteristics. These approaches also reduce processing time, further enhancing production throughput.

The integration of these optimization strategies requires holistic production system design. Modular manufacturing lines that can accommodate different coating formulations with minimal reconfiguration time represent the current industry benchmark, allowing manufacturers to respond rapidly to changing market demands while maintaining consistent quality standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!