What technical factors affect Composite coatings hardness wear and adhesion

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Composite Coating Technology Background and Objectives

Composite coatings have emerged as a significant technological advancement in surface engineering over the past several decades. These coatings, which consist of a matrix material embedded with one or more distinct phases, offer enhanced performance characteristics compared to single-phase coatings. The evolution of composite coating technology can be traced back to the mid-20th century, with significant acceleration in development occurring in the 1980s and 1990s as manufacturing processes became more sophisticated.

The technological trajectory has moved from simple metal-matrix composites toward increasingly complex multi-functional systems incorporating ceramics, polymers, and nanomaterials. This progression has been driven by industrial demands for surfaces that can withstand extreme conditions while maintaining structural integrity and functionality. Recent trends indicate a shift toward environmentally friendly coating processes and materials, addressing sustainability concerns while maintaining or improving performance metrics.

The primary technical objective in composite coating development is to achieve optimal combinations of hardness, wear resistance, and adhesion—properties that are often in competition with each other. Hardness typically contributes to wear resistance but may compromise adhesion if excessive. The challenge lies in understanding the complex interrelationships between these properties and the factors that influence them, including composition, microstructure, deposition parameters, and post-treatment processes.

Current research aims to establish predictive models that can guide the design of composite coatings with tailored property profiles for specific applications. This includes developing a comprehensive understanding of how particle size, distribution, volume fraction, and matrix-particle interactions affect the mechanical and tribological behavior of the coating system. Additionally, there is growing interest in self-healing and adaptive composite coatings that can respond to environmental changes or damage.

The global push toward miniaturization in electronics, increased efficiency in energy systems, and extended component lifespans in aerospace and automotive industries has further accelerated research in this field. Emerging applications in biomedical implants, renewable energy infrastructure, and advanced manufacturing processes present new challenges and opportunities for composite coating technology.

Looking forward, the integration of computational modeling, high-throughput experimentation, and in-situ characterization techniques promises to accelerate the development cycle for new composite coating formulations. The convergence of nanotechnology, materials science, and surface engineering is expected to yield breakthrough solutions that address current limitations in hardness, wear resistance, and adhesion performance.

The technological trajectory has moved from simple metal-matrix composites toward increasingly complex multi-functional systems incorporating ceramics, polymers, and nanomaterials. This progression has been driven by industrial demands for surfaces that can withstand extreme conditions while maintaining structural integrity and functionality. Recent trends indicate a shift toward environmentally friendly coating processes and materials, addressing sustainability concerns while maintaining or improving performance metrics.

The primary technical objective in composite coating development is to achieve optimal combinations of hardness, wear resistance, and adhesion—properties that are often in competition with each other. Hardness typically contributes to wear resistance but may compromise adhesion if excessive. The challenge lies in understanding the complex interrelationships between these properties and the factors that influence them, including composition, microstructure, deposition parameters, and post-treatment processes.

Current research aims to establish predictive models that can guide the design of composite coatings with tailored property profiles for specific applications. This includes developing a comprehensive understanding of how particle size, distribution, volume fraction, and matrix-particle interactions affect the mechanical and tribological behavior of the coating system. Additionally, there is growing interest in self-healing and adaptive composite coatings that can respond to environmental changes or damage.

The global push toward miniaturization in electronics, increased efficiency in energy systems, and extended component lifespans in aerospace and automotive industries has further accelerated research in this field. Emerging applications in biomedical implants, renewable energy infrastructure, and advanced manufacturing processes present new challenges and opportunities for composite coating technology.

Looking forward, the integration of computational modeling, high-throughput experimentation, and in-situ characterization techniques promises to accelerate the development cycle for new composite coating formulations. The convergence of nanotechnology, materials science, and surface engineering is expected to yield breakthrough solutions that address current limitations in hardness, wear resistance, and adhesion performance.

Market Analysis for High-Performance Coating Applications

The global market for high-performance coatings continues to expand rapidly, driven by increasing demands across multiple industrial sectors. The composite coatings segment, particularly those engineered for enhanced hardness, wear resistance, and adhesion properties, represents one of the fastest-growing subsectors with a current market valuation exceeding $15 billion and projected annual growth rates of 6.8% through 2028.

Automotive and aerospace industries remain the primary consumers of advanced composite coatings, collectively accounting for approximately 45% of market share. These sectors demand coatings that can withstand extreme operational conditions while maintaining structural integrity and performance. The transportation equipment manufacturing segment has shown particular interest in coatings that offer superior adhesion properties, as these directly impact product longevity and maintenance requirements.

Industrial machinery and equipment manufacturers constitute the second-largest market segment, with particular emphasis on wear-resistant coatings that can extend component lifecycles and reduce maintenance costs. This sector has demonstrated willingness to adopt premium-priced coating solutions when clear return-on-investment metrics can be established through reduced downtime and extended service intervals.

Regional analysis reveals Asia-Pacific as the dominant market, controlling 38% of global demand, followed by North America (27%) and Europe (24%). China and India are experiencing the most aggressive growth trajectories, driven by rapid industrialization and infrastructure development. The North American market shows strong preference for environmentally compliant formulations, while maintaining performance requirements.

Consumer preference trends indicate growing demand for multi-functional coatings that simultaneously address multiple performance parameters. Coatings that combine exceptional hardness with superior adhesion properties command premium pricing, with customers demonstrating decreased price sensitivity when multiple performance attributes are effectively addressed.

Regulatory factors significantly impact market dynamics, with environmental regulations increasingly restricting certain chemical components traditionally used to enhance coating performance. This has accelerated research into environmentally sustainable alternatives that maintain or exceed performance benchmarks, creating both challenges and opportunities for market participants.

Market forecasts suggest specialized niche applications in electronics, medical devices, and renewable energy infrastructure will emerge as high-growth segments over the next five years, with compound annual growth rates potentially exceeding 9% in these verticals. These applications demand precisely engineered coating solutions with tightly controlled performance parameters.

Automotive and aerospace industries remain the primary consumers of advanced composite coatings, collectively accounting for approximately 45% of market share. These sectors demand coatings that can withstand extreme operational conditions while maintaining structural integrity and performance. The transportation equipment manufacturing segment has shown particular interest in coatings that offer superior adhesion properties, as these directly impact product longevity and maintenance requirements.

Industrial machinery and equipment manufacturers constitute the second-largest market segment, with particular emphasis on wear-resistant coatings that can extend component lifecycles and reduce maintenance costs. This sector has demonstrated willingness to adopt premium-priced coating solutions when clear return-on-investment metrics can be established through reduced downtime and extended service intervals.

Regional analysis reveals Asia-Pacific as the dominant market, controlling 38% of global demand, followed by North America (27%) and Europe (24%). China and India are experiencing the most aggressive growth trajectories, driven by rapid industrialization and infrastructure development. The North American market shows strong preference for environmentally compliant formulations, while maintaining performance requirements.

Consumer preference trends indicate growing demand for multi-functional coatings that simultaneously address multiple performance parameters. Coatings that combine exceptional hardness with superior adhesion properties command premium pricing, with customers demonstrating decreased price sensitivity when multiple performance attributes are effectively addressed.

Regulatory factors significantly impact market dynamics, with environmental regulations increasingly restricting certain chemical components traditionally used to enhance coating performance. This has accelerated research into environmentally sustainable alternatives that maintain or exceed performance benchmarks, creating both challenges and opportunities for market participants.

Market forecasts suggest specialized niche applications in electronics, medical devices, and renewable energy infrastructure will emerge as high-growth segments over the next five years, with compound annual growth rates potentially exceeding 9% in these verticals. These applications demand precisely engineered coating solutions with tightly controlled performance parameters.

Current Challenges in Composite Coating Development

Despite significant advancements in composite coating technologies, several critical challenges continue to impede optimal performance in terms of hardness, wear resistance, and adhesion properties. One of the primary obstacles remains the achievement of consistent microstructure throughout the coating matrix. Variations in particle distribution and agglomeration tendencies create weak points that compromise mechanical integrity, particularly under high-stress applications.

The interface bonding between reinforcement particles and the matrix represents another persistent challenge. Inadequate chemical compatibility often results in poor interfacial adhesion, creating stress concentration points that initiate coating failure. This issue becomes more pronounced as the volume fraction of reinforcement particles increases to enhance hardness and wear resistance properties.

Thermal mismatch between substrate materials and composite coatings continues to plague long-term performance stability. The differential thermal expansion coefficients generate residual stresses during thermal cycling, leading to microcrack formation and eventual delamination. This challenge is particularly evident in applications involving frequent temperature fluctuations, such as in aerospace components and high-temperature industrial equipment.

Porosity control remains elusive in many composite coating deposition techniques. Conventional methods often introduce unintended voids and microcracks during the consolidation process, significantly reducing effective load-bearing capacity and creating pathways for corrosive media penetration. These defects serve as initiation sites for premature coating failure under mechanical loading conditions.

The scalability of laboratory-proven coating formulations to industrial-scale production presents significant technical hurdles. Process parameters that yield excellent results in controlled laboratory environments often fail to translate effectively to mass production settings, resulting in inconsistent coating quality and performance variability across batches.

Environmental degradation mechanisms, particularly in aggressive service conditions, continue to challenge coating durability. The synergistic effects of mechanical wear, chemical attack, and thermal cycling accelerate coating deterioration through complex mechanisms that are difficult to predict and mitigate through conventional design approaches.

Quantitative characterization and predictive modeling of composite coating performance remain underdeveloped. Current testing methodologies often fail to accurately simulate real-world service conditions, leading to discrepancies between laboratory performance metrics and actual field performance. This gap hampers the development of optimized coating systems tailored for specific application requirements.

The interface bonding between reinforcement particles and the matrix represents another persistent challenge. Inadequate chemical compatibility often results in poor interfacial adhesion, creating stress concentration points that initiate coating failure. This issue becomes more pronounced as the volume fraction of reinforcement particles increases to enhance hardness and wear resistance properties.

Thermal mismatch between substrate materials and composite coatings continues to plague long-term performance stability. The differential thermal expansion coefficients generate residual stresses during thermal cycling, leading to microcrack formation and eventual delamination. This challenge is particularly evident in applications involving frequent temperature fluctuations, such as in aerospace components and high-temperature industrial equipment.

Porosity control remains elusive in many composite coating deposition techniques. Conventional methods often introduce unintended voids and microcracks during the consolidation process, significantly reducing effective load-bearing capacity and creating pathways for corrosive media penetration. These defects serve as initiation sites for premature coating failure under mechanical loading conditions.

The scalability of laboratory-proven coating formulations to industrial-scale production presents significant technical hurdles. Process parameters that yield excellent results in controlled laboratory environments often fail to translate effectively to mass production settings, resulting in inconsistent coating quality and performance variability across batches.

Environmental degradation mechanisms, particularly in aggressive service conditions, continue to challenge coating durability. The synergistic effects of mechanical wear, chemical attack, and thermal cycling accelerate coating deterioration through complex mechanisms that are difficult to predict and mitigate through conventional design approaches.

Quantitative characterization and predictive modeling of composite coating performance remain underdeveloped. Current testing methodologies often fail to accurately simulate real-world service conditions, leading to discrepancies between laboratory performance metrics and actual field performance. This gap hampers the development of optimized coating systems tailored for specific application requirements.

Current Technical Solutions for Coating Performance

01 Metal matrix composite coatings for enhanced hardness

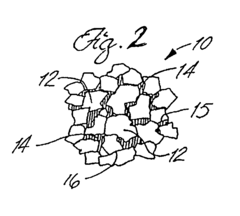

Metal matrix composite coatings incorporate hard particles such as carbides, nitrides, or ceramic materials into a metal matrix to significantly enhance surface hardness. These coatings typically use metals like nickel, chromium, or aluminum as the matrix material, with reinforcing particles distributed throughout. The resulting composite structure provides superior hardness compared to single-component coatings, making them suitable for applications requiring resistance to deformation and indentation.- Metal-based composite coatings for enhanced hardness: Metal-based composite coatings, particularly those incorporating hard particles like carbides, nitrides, or oxides into metal matrices, significantly improve surface hardness. These coatings typically use metals such as nickel, chromium, or titanium as the matrix material, with reinforcing particles distributed throughout to create a composite structure that resists deformation. The distribution and size of these particles play crucial roles in determining the final hardness properties of the coating.

- Ceramic and cermet coatings for extreme wear resistance: Ceramic and cermet (ceramic-metal) composite coatings provide exceptional wear resistance in harsh operating conditions. These coatings typically consist of hard ceramic phases such as aluminum oxide, zirconium oxide, or silicon carbide, sometimes combined with metallic binders for improved toughness. The multi-phase structure creates a balance between hardness and fracture toughness, allowing the coating to withstand abrasive, erosive, and sliding wear mechanisms while maintaining structural integrity under mechanical stress.

- Polymer-based composite coatings with enhanced adhesion: Polymer-based composite coatings incorporate various fillers and additives to improve adhesion to substrates while maintaining good wear resistance. These coatings often utilize epoxy, polyurethane, or fluoropolymer matrices reinforced with particles or fibers. Surface treatment techniques and coupling agents are employed to enhance the interfacial bonding between the coating and substrate. The flexibility of the polymer matrix combined with the reinforcing elements creates coatings that can adhere well even under thermal cycling and mechanical stress.

- Multi-layer and gradient composite coating structures: Multi-layer and functionally gradient composite coatings feature strategically designed layers with varying compositions to optimize hardness, wear resistance, and adhesion simultaneously. These systems typically include an adhesion-promoting base layer, intermediate layers with gradually changing properties, and a hard wear-resistant top layer. This architecture allows for stress distribution across the coating system, preventing delamination while maintaining high surface hardness and wear resistance. The gradient transition between layers minimizes internal stresses and improves overall coating performance.

- Nanostructured composite coatings for superior mechanical properties: Nanostructured composite coatings utilize nanoscale reinforcing elements to achieve exceptional combinations of hardness, wear resistance, and adhesion. These coatings incorporate nanoparticles, nanotubes, or nanolayers that create unique interfaces and mechanical properties not achievable with conventional materials. The nanoscale features disrupt crack propagation pathways and provide high-density grain boundaries that strengthen the coating. Advanced deposition techniques like plasma spraying, physical vapor deposition, or electrodeposition are typically used to control the nanostructure formation.

02 Nanoparticle reinforcement for wear resistance

Incorporating nanoparticles into coating formulations significantly improves wear resistance properties. These nanoparticles, which may include nano-ceramics, nano-oxides, or nano-carbides, create a reinforced structure that resists abrasion and erosion. The small particle size allows for uniform distribution throughout the coating matrix, preventing crack propagation and enhancing the overall durability of the surface against mechanical wear under harsh operating conditions.Expand Specific Solutions03 Multi-layer coating systems for adhesion improvement

Multi-layer coating systems utilize strategically designed layers to optimize adhesion between the substrate and the functional top coat. These systems typically include a primer layer specifically formulated to bond strongly with the substrate material, intermediate layers that provide gradient properties, and a top layer that delivers the desired surface characteristics. This layered approach minimizes internal stresses and thermal expansion mismatches, resulting in superior adhesion performance even under thermal cycling or mechanical stress.Expand Specific Solutions04 Surface treatment techniques for coating performance

Various surface treatment techniques are employed to enhance the performance of composite coatings. These include mechanical treatments like shot peening or grit blasting, chemical treatments such as etching or activation, and thermal treatments that modify the substrate surface properties. These pre-coating treatments create optimal surface conditions by increasing surface area, removing contaminants, and creating anchor points that significantly improve coating adhesion, hardness, and wear resistance in the final product.Expand Specific Solutions05 Thermal spray technologies for composite coating deposition

Advanced thermal spray technologies enable the deposition of high-performance composite coatings with excellent hardness, wear resistance, and adhesion properties. These processes include high-velocity oxy-fuel (HVOF) spraying, plasma spraying, cold spraying, and detonation gun spraying. Each technique offers specific advantages in terms of coating density, bond strength, and microstructure control. The selection of appropriate spray parameters and powder characteristics allows for customization of coating properties to meet specific application requirements.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The composite coatings market is in a growth phase, characterized by increasing demand for enhanced surface properties across industrial applications. The global market size is expanding due to rising needs in aerospace, automotive, and manufacturing sectors. Technologically, the field shows varying maturity levels, with established players like Kennametal and TDK Corp offering advanced solutions while research institutions like China University of Mining & Technology and Kyushu University drive innovation. Companies such as Boeing, Baker Hughes, and Vestas Wind Systems represent key end-users implementing these technologies. The competitive landscape features specialized coating manufacturers (Castagra Products, Nippon ITF) alongside diversified industrial giants (Proterial, OSG Corp), with collaboration between academic and industrial players accelerating development of coatings with superior hardness, wear resistance, and adhesion properties.

Kennametal, Inc.

Technical Solution: Kennametal has developed advanced PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition) coating technologies specifically engineered to enhance hardness, wear resistance, and adhesion in extreme applications. Their proprietary AlTiN-based multilayer coatings achieve hardness values exceeding 35 GPa through controlled nanolayered structures that impede crack propagation. The company's KCSM40 coating system incorporates a gradient interlayer that transitions from substrate to coating, significantly improving adhesion by reducing interfacial stress. Kennametal's recent innovations include incorporating nanocomposite structures with amorphous phases that provide enhanced toughness while maintaining extreme hardness. Their coatings typically employ a three-zone architecture: an adhesion layer, a transition zone, and a functional outer layer, optimized through computational modeling to predict performance under specific loading conditions.

Strengths: Superior adhesion through gradient interfaces; exceptional hardness-to-toughness ratio; customizable solutions for specific industrial applications. Weaknesses: Higher production costs compared to conventional coatings; complex deposition processes requiring specialized equipment; potential limitations in high-temperature oxidation resistance above 900°C.

The Boeing Co.

Technical Solution: Boeing has pioneered composite coating technologies specifically designed for aerospace applications where weight reduction, corrosion resistance, and thermal stability are critical. Their proprietary thermal spray coating systems utilize high-velocity oxygen fuel (HVOF) processes to create dense, well-bonded carbide-based coatings with hardness values exceeding 1200 HV. Boeing's research has focused on incorporating ceramic nanoparticles (Al2O3, SiC) into metal matrix composites to enhance wear resistance while maintaining adequate ductility. Their patented multi-functional coating architecture includes a compliant bond coat that accommodates thermal expansion mismatch, followed by a functionally graded intermediate layer, and topped with a nanostructured wear-resistant surface. Boeing has also developed specialized surface preparation techniques using laser ablation that creates controlled surface roughness profiles, significantly improving mechanical interlocking and coating adhesion strength by up to 40% compared to conventional methods.

Strengths: Exceptional adhesion under thermal cycling conditions; superior wear resistance in aerospace environments; excellent weight-to-performance ratio. Weaknesses: High manufacturing costs; complex application processes requiring specialized equipment; limited applicability outside aerospace sector due to cost constraints.

Key Patents and Innovations in Composite Coatings

Composite material

PatentPendingUS20220251698A1

Innovation

- A composite material with a conductive layer comprising embedded filaments in a polymeric matrix, allowing direct deposition of coatings without intermediate layers, enhancing electrical conductivity and mechanical bonding through simultaneous curing of the substrate and conductive layer.

Multiple processes of high pressures and temperatures for sintered bodies

PatentInactiveUS7682557B2

Innovation

- A method involving a combination of traditional low-pressure sintering processes, such as HIP or vacuum sintering, and high-pressure, high-temperature sintering processes to form composite materials with improved mechanical properties, including increased toughness and hardness, by subjecting green bodies to multiple cycles of these processes.

Material Selection and Compatibility Factors

Material selection and compatibility represent critical determinants in the performance of composite coatings, directly influencing their hardness, wear resistance, and adhesion properties. The selection of appropriate matrix materials and reinforcement phases must be approached systematically, considering both mechanical and chemical compatibility factors to achieve optimal coating performance.

The matrix material serves as the foundation of composite coatings and must be selected based on specific application requirements. Metallic matrices (such as nickel, chromium, and cobalt alloys) typically offer excellent bonding with substrates and good corrosion resistance, while ceramic matrices provide superior hardness and thermal stability. Polymer matrices, though less common in high-wear applications, offer advantages in chemical resistance and processing flexibility. The intrinsic properties of these matrices establish the baseline performance characteristics upon which reinforcement phases can build.

Reinforcement phase selection significantly impacts coating hardness and wear resistance. Hard ceramic particles (Al₂O₃, SiC, WC) dramatically enhance hardness and wear resistance but may create challenges for uniform distribution and interfacial bonding. Carbon-based reinforcements (graphene, carbon nanotubes) offer excellent mechanical properties with lower density, though their dispersion remains technically challenging. The size distribution, morphology, and volume fraction of reinforcement phases must be carefully controlled to optimize performance without compromising coating integrity.

Interfacial compatibility between matrix and reinforcement phases represents perhaps the most critical factor affecting coating performance. Poor interfacial bonding leads to particle pullout during wear, dramatically reducing coating lifespan. Surface modification techniques for reinforcement particles, including silane coupling agents for ceramic particles or functionalization of carbon-based materials, can significantly improve interfacial adhesion. The wettability between matrix and reinforcement materials must be optimized to ensure strong mechanical interlocking and chemical bonding.

Thermal expansion coefficient matching between coating components and the substrate is essential for maintaining coating adhesion during thermal cycling. Significant mismatches generate internal stresses that can lead to coating delamination or cracking. This consideration becomes particularly critical in applications involving temperature fluctuations, where differential expansion can compromise coating integrity over time.

Chemical compatibility must also be evaluated to prevent undesirable reactions between coating components or with the operating environment. Galvanic corrosion can occur between dissimilar metals in the coating system, while certain reinforcement phases may react with the matrix material during high-temperature processing, forming brittle intermetallic compounds that compromise mechanical properties. Environmental factors such as pH, temperature, and chemical exposure in the intended application environment must inform material selection decisions.

The matrix material serves as the foundation of composite coatings and must be selected based on specific application requirements. Metallic matrices (such as nickel, chromium, and cobalt alloys) typically offer excellent bonding with substrates and good corrosion resistance, while ceramic matrices provide superior hardness and thermal stability. Polymer matrices, though less common in high-wear applications, offer advantages in chemical resistance and processing flexibility. The intrinsic properties of these matrices establish the baseline performance characteristics upon which reinforcement phases can build.

Reinforcement phase selection significantly impacts coating hardness and wear resistance. Hard ceramic particles (Al₂O₃, SiC, WC) dramatically enhance hardness and wear resistance but may create challenges for uniform distribution and interfacial bonding. Carbon-based reinforcements (graphene, carbon nanotubes) offer excellent mechanical properties with lower density, though their dispersion remains technically challenging. The size distribution, morphology, and volume fraction of reinforcement phases must be carefully controlled to optimize performance without compromising coating integrity.

Interfacial compatibility between matrix and reinforcement phases represents perhaps the most critical factor affecting coating performance. Poor interfacial bonding leads to particle pullout during wear, dramatically reducing coating lifespan. Surface modification techniques for reinforcement particles, including silane coupling agents for ceramic particles or functionalization of carbon-based materials, can significantly improve interfacial adhesion. The wettability between matrix and reinforcement materials must be optimized to ensure strong mechanical interlocking and chemical bonding.

Thermal expansion coefficient matching between coating components and the substrate is essential for maintaining coating adhesion during thermal cycling. Significant mismatches generate internal stresses that can lead to coating delamination or cracking. This consideration becomes particularly critical in applications involving temperature fluctuations, where differential expansion can compromise coating integrity over time.

Chemical compatibility must also be evaluated to prevent undesirable reactions between coating components or with the operating environment. Galvanic corrosion can occur between dissimilar metals in the coating system, while certain reinforcement phases may react with the matrix material during high-temperature processing, forming brittle intermetallic compounds that compromise mechanical properties. Environmental factors such as pH, temperature, and chemical exposure in the intended application environment must inform material selection decisions.

Environmental Impact and Sustainability Considerations

The environmental impact of composite coating processes has become increasingly significant as industries face stricter regulations and growing sustainability demands. Traditional coating methods often involve volatile organic compounds (VOCs), heavy metals, and energy-intensive processes that contribute to environmental degradation. The hardness, wear resistance, and adhesion properties of composite coatings are now being evaluated not only for performance but also for their environmental footprint throughout the entire lifecycle.

Water-based coating systems have emerged as environmentally friendly alternatives to solvent-based systems, reducing VOC emissions while maintaining acceptable mechanical properties. However, these systems often face challenges in achieving comparable hardness and wear resistance to conventional coatings. Research indicates that optimizing particle dispersion and crosslinking mechanisms in water-based formulations can significantly improve performance metrics while maintaining environmental benefits.

Energy consumption during coating application and curing processes represents another critical environmental consideration. High-temperature curing requirements for optimal adhesion and hardness properties contribute substantially to the carbon footprint of coating operations. Recent innovations in UV-curable and ambient-temperature curing systems demonstrate promising approaches to reducing energy demands while maintaining coating integrity and performance characteristics.

The toxicity of coating components presents significant environmental and health concerns. Traditional hardening agents and wear-resistant additives often contain heavy metals or other hazardous substances that pose risks during application, use, and disposal. Biobased alternatives derived from renewable resources are showing potential as sustainable substitutes, though challenges remain in matching the performance of conventional materials, particularly in extreme wear conditions.

End-of-life considerations for composite coatings are increasingly important in sustainability assessments. Coatings that cannot be easily separated from substrates complicate recycling efforts and may lead to increased waste. Developing coatings with controlled degradability or recyclability without compromising wear resistance and adhesion represents a frontier in sustainable coating technology.

Life Cycle Assessment (LCA) methodologies are now being applied to evaluate the comprehensive environmental impact of composite coating systems. These assessments consider raw material extraction, manufacturing processes, application methods, service life, and disposal scenarios. Research indicates that coatings with extended durability and wear resistance may offset higher initial environmental impacts through reduced replacement frequency and resource conservation over time.

Regulatory frameworks worldwide are evolving to address environmental concerns associated with coating technologies. REACH regulations in Europe, EPA guidelines in the United States, and similar initiatives globally are driving innovation toward greener coating solutions that maintain technical performance while reducing environmental harm.

Water-based coating systems have emerged as environmentally friendly alternatives to solvent-based systems, reducing VOC emissions while maintaining acceptable mechanical properties. However, these systems often face challenges in achieving comparable hardness and wear resistance to conventional coatings. Research indicates that optimizing particle dispersion and crosslinking mechanisms in water-based formulations can significantly improve performance metrics while maintaining environmental benefits.

Energy consumption during coating application and curing processes represents another critical environmental consideration. High-temperature curing requirements for optimal adhesion and hardness properties contribute substantially to the carbon footprint of coating operations. Recent innovations in UV-curable and ambient-temperature curing systems demonstrate promising approaches to reducing energy demands while maintaining coating integrity and performance characteristics.

The toxicity of coating components presents significant environmental and health concerns. Traditional hardening agents and wear-resistant additives often contain heavy metals or other hazardous substances that pose risks during application, use, and disposal. Biobased alternatives derived from renewable resources are showing potential as sustainable substitutes, though challenges remain in matching the performance of conventional materials, particularly in extreme wear conditions.

End-of-life considerations for composite coatings are increasingly important in sustainability assessments. Coatings that cannot be easily separated from substrates complicate recycling efforts and may lead to increased waste. Developing coatings with controlled degradability or recyclability without compromising wear resistance and adhesion represents a frontier in sustainable coating technology.

Life Cycle Assessment (LCA) methodologies are now being applied to evaluate the comprehensive environmental impact of composite coating systems. These assessments consider raw material extraction, manufacturing processes, application methods, service life, and disposal scenarios. Research indicates that coatings with extended durability and wear resistance may offset higher initial environmental impacts through reduced replacement frequency and resource conservation over time.

Regulatory frameworks worldwide are evolving to address environmental concerns associated with coating technologies. REACH regulations in Europe, EPA guidelines in the United States, and similar initiatives globally are driving innovation toward greener coating solutions that maintain technical performance while reducing environmental harm.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!