Composite coatings for EV and renewable energy component performance enhancement

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Composite Coating Technology Background and Objectives

Composite coatings have emerged as a transformative technology in materials science over the past three decades, evolving from simple protective layers to sophisticated multifunctional systems. These advanced coatings combine two or more distinct materials to create surfaces with enhanced properties that exceed those of individual components. The synergistic integration of various materials enables unprecedented performance characteristics critical for modern electric vehicle (EV) and renewable energy applications.

The evolution of composite coating technology has been driven by increasing demands for materials that can withstand extreme operating conditions while maintaining optimal performance. Early developments focused primarily on corrosion resistance and basic wear protection, whereas contemporary research emphasizes multifunctionality, sustainability, and adaptability to dynamic environments.

In the context of electric vehicles and renewable energy systems, component performance faces unique challenges including thermal management issues, electrical conductivity requirements, tribological stress, and exposure to harsh environmental conditions. Traditional single-material coatings have proven inadequate for addressing these multifaceted challenges, necessitating the development of more sophisticated composite solutions.

The primary technical objectives for composite coatings in these applications include enhancing durability to extend component lifespan, improving energy efficiency through reduced friction and optimized thermal management, ensuring electrical performance stability, and maintaining structural integrity under variable operating conditions. Additionally, there is growing emphasis on developing environmentally sustainable coating technologies that minimize the use of toxic materials and reduce environmental impact throughout the product lifecycle.

Recent technological breakthroughs have enabled the precise engineering of composite coatings at the micro and nano scales, allowing for tailored property profiles that address specific application requirements. These advances include the development of self-healing capabilities, smart responsive features, and gradient structures that optimize performance across different operating parameters.

The convergence of materials science, nanotechnology, and advanced manufacturing processes has created unprecedented opportunities for innovation in this field. Computational modeling and simulation tools now enable the prediction of coating behavior under various conditions, accelerating development cycles and reducing costs associated with empirical testing.

Looking forward, the technical trajectory for composite coatings in EV and renewable energy applications aims toward achieving greater functionality integration, enhanced durability under extreme conditions, improved manufacturing scalability, and reduced environmental footprint. These objectives align with broader industry goals of increasing energy efficiency, extending component lifespans, and reducing maintenance requirements in clean energy technologies.

The evolution of composite coating technology has been driven by increasing demands for materials that can withstand extreme operating conditions while maintaining optimal performance. Early developments focused primarily on corrosion resistance and basic wear protection, whereas contemporary research emphasizes multifunctionality, sustainability, and adaptability to dynamic environments.

In the context of electric vehicles and renewable energy systems, component performance faces unique challenges including thermal management issues, electrical conductivity requirements, tribological stress, and exposure to harsh environmental conditions. Traditional single-material coatings have proven inadequate for addressing these multifaceted challenges, necessitating the development of more sophisticated composite solutions.

The primary technical objectives for composite coatings in these applications include enhancing durability to extend component lifespan, improving energy efficiency through reduced friction and optimized thermal management, ensuring electrical performance stability, and maintaining structural integrity under variable operating conditions. Additionally, there is growing emphasis on developing environmentally sustainable coating technologies that minimize the use of toxic materials and reduce environmental impact throughout the product lifecycle.

Recent technological breakthroughs have enabled the precise engineering of composite coatings at the micro and nano scales, allowing for tailored property profiles that address specific application requirements. These advances include the development of self-healing capabilities, smart responsive features, and gradient structures that optimize performance across different operating parameters.

The convergence of materials science, nanotechnology, and advanced manufacturing processes has created unprecedented opportunities for innovation in this field. Computational modeling and simulation tools now enable the prediction of coating behavior under various conditions, accelerating development cycles and reducing costs associated with empirical testing.

Looking forward, the technical trajectory for composite coatings in EV and renewable energy applications aims toward achieving greater functionality integration, enhanced durability under extreme conditions, improved manufacturing scalability, and reduced environmental footprint. These objectives align with broader industry goals of increasing energy efficiency, extending component lifespans, and reducing maintenance requirements in clean energy technologies.

Market Demand Analysis for EV and Renewable Energy Coatings

The electric vehicle (EV) and renewable energy sectors are experiencing unprecedented growth, driving significant demand for advanced composite coatings that enhance component performance, durability, and efficiency. The global EV market is projected to reach $823 billion by 2030, growing at a CAGR of 18.2% from 2021. This rapid expansion creates substantial demand for specialized coatings that address the unique challenges faced by EV components.

Battery systems represent a primary application area, where thermal management coatings are essential for maintaining optimal operating temperatures and extending battery life. The EV battery thermal management market alone is expected to grow at 22.3% CAGR through 2028, creating a substantial sub-market for specialized composite coatings that can withstand extreme conditions while providing thermal regulation properties.

Motor and power electronics components require coatings that offer electrical insulation, corrosion resistance, and heat dissipation capabilities. With the increasing power density of EV drivetrains, these components face more severe operating conditions, accelerating coating material innovation. Industry reports indicate that approximately 40% of EV manufacturers are actively seeking advanced coating solutions to improve motor efficiency and longevity.

In the renewable energy sector, wind turbine components face harsh environmental conditions including UV exposure, salt spray, temperature fluctuations, and mechanical stress. The global wind turbine coatings market is projected to reach $15.4 billion by 2027, with anti-corrosion and anti-icing coatings seeing particularly strong demand growth in offshore installations.

Solar panel applications represent another significant market segment, where protective coatings that enhance light transmission while providing self-cleaning properties can improve energy conversion efficiency by up to 3-5%. With global solar capacity additions expected to exceed 200 GW annually by 2025, even small efficiency improvements translate to substantial market opportunities.

Regional analysis reveals that Asia-Pacific dominates manufacturing demand for these coatings, with China, Japan, and South Korea leading in EV production. European markets show the strongest demand for high-performance renewable energy coatings, driven by aggressive climate policies and offshore wind development. North America represents a rapidly growing market, particularly for coatings that can withstand extreme weather conditions.

Customer requirements are evolving toward multifunctional coatings that simultaneously address multiple challenges, such as combined thermal management and electromagnetic shielding properties. This trend is driving innovation in composite formulations that incorporate nanomaterials, creating premium market segments with higher margins and technological barriers to entry.

Battery systems represent a primary application area, where thermal management coatings are essential for maintaining optimal operating temperatures and extending battery life. The EV battery thermal management market alone is expected to grow at 22.3% CAGR through 2028, creating a substantial sub-market for specialized composite coatings that can withstand extreme conditions while providing thermal regulation properties.

Motor and power electronics components require coatings that offer electrical insulation, corrosion resistance, and heat dissipation capabilities. With the increasing power density of EV drivetrains, these components face more severe operating conditions, accelerating coating material innovation. Industry reports indicate that approximately 40% of EV manufacturers are actively seeking advanced coating solutions to improve motor efficiency and longevity.

In the renewable energy sector, wind turbine components face harsh environmental conditions including UV exposure, salt spray, temperature fluctuations, and mechanical stress. The global wind turbine coatings market is projected to reach $15.4 billion by 2027, with anti-corrosion and anti-icing coatings seeing particularly strong demand growth in offshore installations.

Solar panel applications represent another significant market segment, where protective coatings that enhance light transmission while providing self-cleaning properties can improve energy conversion efficiency by up to 3-5%. With global solar capacity additions expected to exceed 200 GW annually by 2025, even small efficiency improvements translate to substantial market opportunities.

Regional analysis reveals that Asia-Pacific dominates manufacturing demand for these coatings, with China, Japan, and South Korea leading in EV production. European markets show the strongest demand for high-performance renewable energy coatings, driven by aggressive climate policies and offshore wind development. North America represents a rapidly growing market, particularly for coatings that can withstand extreme weather conditions.

Customer requirements are evolving toward multifunctional coatings that simultaneously address multiple challenges, such as combined thermal management and electromagnetic shielding properties. This trend is driving innovation in composite formulations that incorporate nanomaterials, creating premium market segments with higher margins and technological barriers to entry.

Current State and Challenges in Composite Coating Technology

Composite coating technology for electric vehicle (EV) and renewable energy components has witnessed significant advancements globally, yet faces several critical challenges. Currently, the most widely adopted composite coatings include polymer matrix composites reinforced with ceramic particles, carbon-based nanocomposites, and metal matrix composites with dispersed reinforcement phases. These coatings have demonstrated promising performance in enhancing wear resistance, corrosion protection, and thermal management for critical components in EVs and renewable energy systems.

In the EV sector, composite coatings are primarily applied to battery components, electric motor parts, and structural elements to improve durability and efficiency. The renewable energy industry utilizes these coatings for wind turbine blades, solar panel frames, and energy storage systems to extend service life under harsh environmental conditions. However, despite their growing adoption, several technological barriers remain unresolved.

A significant challenge is achieving uniform dispersion of reinforcement materials within the matrix, particularly when incorporating nanomaterials such as carbon nanotubes or graphene. Agglomeration issues frequently compromise the mechanical integrity and functional properties of the coating. Additionally, the adhesion between composite coatings and substrate materials presents persistent difficulties, especially under thermal cycling and mechanical stress conditions typical in EV and renewable energy applications.

Scalability of production represents another major hurdle. While laboratory-scale processes demonstrate excellent results, transitioning to industrial-scale manufacturing while maintaining consistent quality and performance remains problematic. Current deposition techniques such as electrodeposition, thermal spraying, and sol-gel methods each present limitations in terms of coating thickness control, processing time, or equipment costs.

Environmental considerations also pose challenges, as traditional coating processes often involve toxic solvents and high energy consumption. The industry is under increasing pressure to develop more sustainable coating technologies with reduced environmental footprint, while simultaneously meeting stringent performance requirements.

Geographically, research and development in composite coating technology is concentrated in North America, Europe, and East Asia, with China, the United States, Germany, and Japan leading patent filings. Academic-industrial collaborations have accelerated in recent years, particularly focusing on nanomaterial-enhanced coatings and environmentally friendly deposition processes.

The durability of composite coatings under extreme operating conditions remains a critical concern, particularly for components exposed to high temperatures, rapid thermal cycling, and corrosive environments. Current coating systems often demonstrate performance degradation over time, necessitating the development of more robust solutions with predictable service life characteristics.

In the EV sector, composite coatings are primarily applied to battery components, electric motor parts, and structural elements to improve durability and efficiency. The renewable energy industry utilizes these coatings for wind turbine blades, solar panel frames, and energy storage systems to extend service life under harsh environmental conditions. However, despite their growing adoption, several technological barriers remain unresolved.

A significant challenge is achieving uniform dispersion of reinforcement materials within the matrix, particularly when incorporating nanomaterials such as carbon nanotubes or graphene. Agglomeration issues frequently compromise the mechanical integrity and functional properties of the coating. Additionally, the adhesion between composite coatings and substrate materials presents persistent difficulties, especially under thermal cycling and mechanical stress conditions typical in EV and renewable energy applications.

Scalability of production represents another major hurdle. While laboratory-scale processes demonstrate excellent results, transitioning to industrial-scale manufacturing while maintaining consistent quality and performance remains problematic. Current deposition techniques such as electrodeposition, thermal spraying, and sol-gel methods each present limitations in terms of coating thickness control, processing time, or equipment costs.

Environmental considerations also pose challenges, as traditional coating processes often involve toxic solvents and high energy consumption. The industry is under increasing pressure to develop more sustainable coating technologies with reduced environmental footprint, while simultaneously meeting stringent performance requirements.

Geographically, research and development in composite coating technology is concentrated in North America, Europe, and East Asia, with China, the United States, Germany, and Japan leading patent filings. Academic-industrial collaborations have accelerated in recent years, particularly focusing on nanomaterial-enhanced coatings and environmentally friendly deposition processes.

The durability of composite coatings under extreme operating conditions remains a critical concern, particularly for components exposed to high temperatures, rapid thermal cycling, and corrosive environments. Current coating systems often demonstrate performance degradation over time, necessitating the development of more robust solutions with predictable service life characteristics.

Current Composite Coating Technical Solutions

01 Corrosion resistance enhancement in composite coatings

Composite coatings can be formulated with specific additives to enhance corrosion resistance properties. These formulations typically incorporate anti-corrosive agents, barrier materials, or sacrificial elements that protect the underlying substrate from environmental degradation. The coatings create a protective barrier that prevents moisture, oxygen, and corrosive chemicals from reaching the substrate, thereby extending the service life of the coated components in harsh environments.- Corrosion resistance enhancement in composite coatings: Composite coatings can be formulated with specific additives to enhance corrosion resistance properties. These formulations typically incorporate anti-corrosive agents, barrier materials, and sacrificial elements that work together to protect the underlying substrate from environmental degradation. The coatings create a protective barrier that prevents moisture, oxygen, and corrosive substances from reaching the substrate, thereby extending the service life of the coated components in harsh environments.

- Wear and abrasion resistance in composite coatings: Advanced composite coatings can be engineered to provide superior wear and abrasion resistance through the incorporation of hard particles such as ceramics, carbides, or nanoparticles. These particles are dispersed within a matrix material to create a surface that can withstand mechanical stress, friction, and abrasive conditions. The resulting coatings exhibit improved hardness, reduced coefficient of friction, and enhanced durability, making them suitable for applications in high-wear environments such as industrial machinery, automotive components, and cutting tools.

- Thermal performance and heat resistance of composite coatings: Composite coatings can be designed to provide thermal insulation, heat reflection, or heat resistance properties. These coatings incorporate materials with low thermal conductivity, high temperature stability, or reflective properties to manage heat transfer across surfaces. The formulations may include ceramic particles, reflective pigments, or phase change materials that help maintain temperature stability. Such coatings find applications in aerospace, automotive, and industrial settings where temperature management is critical for component performance and longevity.

- Environmental durability and weathering resistance: Composite coatings can be formulated to withstand harsh environmental conditions including UV radiation, moisture, temperature fluctuations, and chemical exposure. These coatings typically incorporate UV stabilizers, antioxidants, and moisture-resistant polymers that work synergistically to prevent degradation. The enhanced weathering resistance ensures that the coating maintains its protective and aesthetic properties over extended periods of outdoor exposure, making these formulations particularly valuable for architectural, marine, and outdoor infrastructure applications.

- Adhesion and interfacial properties of composite coatings: The performance of composite coatings heavily depends on their adhesion to substrates and the interfacial properties between coating components. Advanced formulations incorporate adhesion promoters, coupling agents, and surface preparation techniques to enhance bonding strength. The interface between the coating matrix and reinforcing particles or fibers is engineered to optimize stress transfer and prevent delamination. These improvements in adhesion and interfacial properties result in coatings with better mechanical integrity, impact resistance, and longer service life across various applications.

02 Wear and abrasion resistance improvement

Composite coatings can be engineered to provide superior wear and abrasion resistance through the incorporation of hard particles or self-lubricating components. These coatings typically contain ceramic particles, metal carbides, or other hard materials dispersed in a metal or polymer matrix. The resulting composite structure combines the toughness of the matrix with the hardness of the reinforcing particles, creating a surface that can withstand mechanical stress, friction, and abrasive conditions in industrial applications.Expand Specific Solutions03 Thermal and electrical performance optimization

Composite coatings can be designed to provide specific thermal and electrical properties through careful selection of constituent materials. These coatings may incorporate materials with high thermal conductivity for heat dissipation applications or thermally insulating components for barrier functions. Similarly, electrically conductive fillers can be added to create pathways for electrical current, while insulating matrices can provide dielectric properties. The balance of these components allows for customization of the coating's performance in various thermal and electrical environments.Expand Specific Solutions04 Environmental and chemical resistance properties

Composite coatings can be formulated to withstand exposure to harsh chemicals, UV radiation, and extreme environmental conditions. These coatings typically incorporate materials that are chemically inert or specifically resistant to targeted chemicals. The composite structure may include barrier layers that prevent penetration of aggressive substances, UV absorbers that protect against solar degradation, or hydrophobic components that repel water and contaminants. This combination of properties ensures long-term performance in challenging operational environments.Expand Specific Solutions05 Advanced manufacturing techniques for performance enhancement

The performance of composite coatings can be significantly influenced by the manufacturing and application methods used. Advanced techniques such as plasma spraying, electrodeposition, sol-gel processing, and physical vapor deposition enable precise control over coating microstructure, thickness uniformity, and interfacial adhesion. These processes can be optimized to minimize defects, enhance bonding strength, and create tailored surface morphologies that contribute to specific performance characteristics such as self-cleaning, anti-icing, or antimicrobial properties.Expand Specific Solutions

Key Industry Players in Advanced Coating Solutions

The composite coatings market for EV and renewable energy components is in a growth phase, driven by increasing demand for performance enhancement in these sectors. The market is expanding rapidly with a projected size of several billion dollars by 2030, as manufacturers seek solutions for improved durability, efficiency, and sustainability. Technologically, the field shows varying maturity levels, with established players like PPG Industries, Nippon Paint, and Axalta offering advanced solutions, while newer entrants from the battery sector (SK ON, Jiangsu Zenergy, Aspen Aerogels) are developing specialized coatings for energy storage applications. Automotive giants including GM, BMW, and Toyota are actively integrating these technologies into their EV platforms, while materials specialists such as Eastman Chemical and KCC Corp are advancing the chemical formulation aspects, creating a competitive landscape balanced between traditional coating manufacturers and technology-focused newcomers.

GM Global Technology Operations LLC

Technical Solution: General Motors has developed proprietary composite coating technologies specifically for EV battery thermal management and renewable energy applications. Their approach utilizes boron nitride nanosheets dispersed in polymer matrices to create thermally conductive yet electrically insulating coatings essential for battery safety and performance. GM's coatings employ a hierarchical structure with multiple functional layers - the innermost layer provides thermal conductivity (>4 W/m·K), middle layers offer electrical insulation and fire resistance, while outer layers provide environmental protection. For renewable energy applications, GM has engineered composite coatings with self-cleaning properties through the incorporation of superhydrophobic silica nanoparticles that prevent dust accumulation on solar panels. Their coatings also feature proprietary corrosion inhibitors that form protective layers when exposed to environmental contaminants, extending component lifespans in harsh environments typical of renewable energy installations.

Strengths: Excellent thermal management capabilities with demonstrated 20% improvement in heat dissipation; superior adhesion to multiple substrate materials; comprehensive protection against thermal, electrical, and environmental stresses. Weaknesses: Higher material and application costs compared to conventional coatings; complex multi-step application process; requires specialized equipment for optimal performance.

PPG Industries Ohio, Inc.

Technical Solution: PPG has developed advanced nanocomposite coatings specifically engineered for EV battery components and renewable energy applications. Their technology incorporates ceramic nanoparticles into polymer matrices to create thermally conductive yet electrically insulating coatings. These coatings utilize a proprietary dispersion method that ensures uniform distribution of nanoparticles throughout the matrix, preventing agglomeration that would otherwise compromise performance. PPG's composite coatings feature multi-layer architectures with gradient functionality - providing thermal management, corrosion resistance, and dielectric protection simultaneously. For EV applications, their coatings incorporate phase-change materials that absorb excess heat during rapid charging cycles, maintaining optimal battery temperature ranges and extending component lifespan. The coatings also feature self-healing capabilities through microencapsulated healing agents that release upon mechanical damage.

Strengths: Superior thermal management properties with demonstrated 15-20% improvement in heat dissipation; excellent adhesion to multiple substrate materials; comprehensive protection against multiple failure modes. Weaknesses: Higher initial application cost compared to conventional coatings; requires specialized application equipment; curing process demands precise temperature control.

Core Patents and Technical Literature Analysis

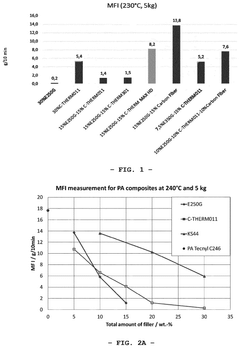

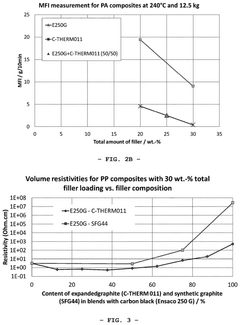

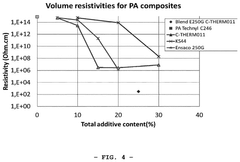

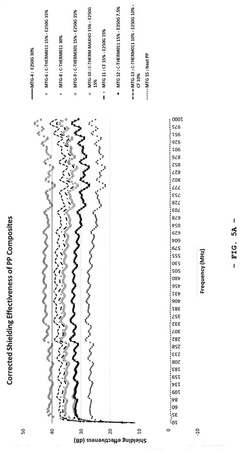

Composition comprising carbon black and expanded graphite and shaped articles and substrate coatings comprising same, uses thereof and methods for reducing volume resistivity and for providing electromagnetic interference shielding as well as thermal conductivity

PatentPendingUS20240409747A1

Innovation

- A composition comprising carbon black and expanded graphite, optimized in terms of weight percentage and particle characteristics, is used to enhance electrical conductivity, EMI shielding, and thermal conductivity, allowing for reduced filler loadings without compromising processability or mechanical properties.

Composite coating agent for positive electrode material, high-nickel single-crystal positive electrode material, and battery

PatentPendingEP4531140A1

Innovation

- A composite coating agent comprising multiple coating elements (Ni, Mn, Co, B; Mg, Al, Nb, W, Mo; Ti, Cr, Zr, Y, Sr) is applied to form a coating layer on high-nickel single-crystal positive electrode materials, enhancing stability and conductivity through chemical bonding and reducing residual alkali and micro-cracks.

Environmental Impact and Sustainability Considerations

The environmental footprint of composite coatings used in electric vehicles (EVs) and renewable energy components represents a critical consideration in their development and application. Life cycle assessment (LCA) studies indicate that while these advanced coatings significantly extend component lifespans and improve energy efficiency, their production processes often involve energy-intensive manufacturing and potentially hazardous materials. The environmental impact varies considerably across different coating types, with some nano-enhanced composites requiring specialized production methods that consume substantial energy.

Recent advancements have focused on developing more sustainable coating formulations that reduce or eliminate volatile organic compounds (VOCs) and heavy metals. Water-based composite coating systems have emerged as environmentally preferable alternatives to traditional solvent-based systems, reducing harmful emissions by up to 80% during application processes. Additionally, bio-based composite coatings derived from renewable resources such as plant oils and cellulose are showing promising performance characteristics while significantly reducing carbon footprints.

The end-of-life management of composite coatings presents both challenges and opportunities. Current recycling technologies often struggle with the complex multi-material nature of these coatings, particularly those containing nanomaterials or specialized polymers. Research into advanced separation techniques and designed-for-recycling approaches is ongoing, with thermal and chemical recovery methods showing potential for material reclamation from coated components.

Energy consumption during coating application and curing represents another significant environmental consideration. Conventional thermal curing methods can account for up to 70% of the total energy consumption in coating processes. Alternative technologies such as UV-curing, electron beam processing, and room-temperature curing catalysts are being developed to reduce energy requirements while maintaining or enhancing coating performance properties.

The sustainability benefits of composite coatings must be evaluated holistically, considering their contribution to overall system efficiency. For instance, coatings that reduce friction in EV drivetrains can improve vehicle range by 5-8%, potentially offsetting their production impacts through operational energy savings. Similarly, erosion-resistant coatings on wind turbine blades can extend service life by 15-20%, reducing the environmental burden of replacement and maintenance activities.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of coating technologies. The European Union's REACH regulations, California's VOC restrictions, and various global initiatives to reduce hazardous substances are driving innovation toward greener coating solutions. Industry leaders are responding by developing comprehensive environmental product declarations (EPDs) and adopting circular economy principles in their coating development strategies.

Recent advancements have focused on developing more sustainable coating formulations that reduce or eliminate volatile organic compounds (VOCs) and heavy metals. Water-based composite coating systems have emerged as environmentally preferable alternatives to traditional solvent-based systems, reducing harmful emissions by up to 80% during application processes. Additionally, bio-based composite coatings derived from renewable resources such as plant oils and cellulose are showing promising performance characteristics while significantly reducing carbon footprints.

The end-of-life management of composite coatings presents both challenges and opportunities. Current recycling technologies often struggle with the complex multi-material nature of these coatings, particularly those containing nanomaterials or specialized polymers. Research into advanced separation techniques and designed-for-recycling approaches is ongoing, with thermal and chemical recovery methods showing potential for material reclamation from coated components.

Energy consumption during coating application and curing represents another significant environmental consideration. Conventional thermal curing methods can account for up to 70% of the total energy consumption in coating processes. Alternative technologies such as UV-curing, electron beam processing, and room-temperature curing catalysts are being developed to reduce energy requirements while maintaining or enhancing coating performance properties.

The sustainability benefits of composite coatings must be evaluated holistically, considering their contribution to overall system efficiency. For instance, coatings that reduce friction in EV drivetrains can improve vehicle range by 5-8%, potentially offsetting their production impacts through operational energy savings. Similarly, erosion-resistant coatings on wind turbine blades can extend service life by 15-20%, reducing the environmental burden of replacement and maintenance activities.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of coating technologies. The European Union's REACH regulations, California's VOC restrictions, and various global initiatives to reduce hazardous substances are driving innovation toward greener coating solutions. Industry leaders are responding by developing comprehensive environmental product declarations (EPDs) and adopting circular economy principles in their coating development strategies.

Cost-Benefit Analysis of Advanced Coating Implementation

Implementing advanced composite coatings for electric vehicle (EV) and renewable energy components requires thorough cost-benefit analysis to justify investment decisions. Initial implementation costs typically range from $50,000 to $500,000 depending on production scale, coating complexity, and application method. These costs encompass equipment acquisition, facility modifications, staff training, and initial material purchases.

When evaluating return on investment, performance enhancement coatings demonstrate compelling financial benefits. For EV components, advanced ceramic-polymer composite coatings can extend battery pack lifespan by 15-25%, representing potential savings of $1,500-3,000 per vehicle over its operational life. Similarly, thermal management coatings reduce cooling system requirements by up to 30%, decreasing both manufacturing and operational costs.

In renewable energy applications, anti-corrosion composite coatings extend wind turbine component lifespans by 5-8 years, reducing maintenance frequency by approximately 40%. Solar panel efficiency improvements of 3-7% through specialized anti-reflective and self-cleaning coatings translate to substantial energy generation increases over installation lifetimes.

Operational cost reductions present another significant benefit category. Enhanced wear resistance in EV drivetrain components reduces maintenance requirements by 30-50%, while specialized coatings for renewable energy systems decrease cleaning and maintenance expenses by 25-35% annually. These improvements directly impact total cost of ownership calculations.

Implementation timelines affect cost-benefit projections significantly. Full integration typically requires 6-18 months, with ROI breakeven points occurring between 14-36 months depending on application scale and specific coating technology. Organizations implementing phased approaches often experience faster returns on initial investments while distributing costs over longer periods.

Environmental and regulatory considerations also factor into comprehensive cost-benefit analysis. Advanced coatings that reduce hazardous material usage can decrease compliance costs by 15-20%, while contributing to sustainability goals. Additionally, components with extended operational lifespans reduce waste management expenses and support circular economy initiatives.

Market differentiation represents an often-overlooked benefit. Products featuring performance-enhanced components command premium pricing of 5-15% in both EV and renewable energy sectors, particularly when performance improvements are quantifiable and marketable to end users.

When evaluating return on investment, performance enhancement coatings demonstrate compelling financial benefits. For EV components, advanced ceramic-polymer composite coatings can extend battery pack lifespan by 15-25%, representing potential savings of $1,500-3,000 per vehicle over its operational life. Similarly, thermal management coatings reduce cooling system requirements by up to 30%, decreasing both manufacturing and operational costs.

In renewable energy applications, anti-corrosion composite coatings extend wind turbine component lifespans by 5-8 years, reducing maintenance frequency by approximately 40%. Solar panel efficiency improvements of 3-7% through specialized anti-reflective and self-cleaning coatings translate to substantial energy generation increases over installation lifetimes.

Operational cost reductions present another significant benefit category. Enhanced wear resistance in EV drivetrain components reduces maintenance requirements by 30-50%, while specialized coatings for renewable energy systems decrease cleaning and maintenance expenses by 25-35% annually. These improvements directly impact total cost of ownership calculations.

Implementation timelines affect cost-benefit projections significantly. Full integration typically requires 6-18 months, with ROI breakeven points occurring between 14-36 months depending on application scale and specific coating technology. Organizations implementing phased approaches often experience faster returns on initial investments while distributing costs over longer periods.

Environmental and regulatory considerations also factor into comprehensive cost-benefit analysis. Advanced coatings that reduce hazardous material usage can decrease compliance costs by 15-20%, while contributing to sustainability goals. Additionally, components with extended operational lifespans reduce waste management expenses and support circular economy initiatives.

Market differentiation represents an often-overlooked benefit. Products featuring performance-enhanced components command premium pricing of 5-15% in both EV and renewable energy sectors, particularly when performance improvements are quantifiable and marketable to end users.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!