Research on Composite coatings for advanced structural and functional coatings

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Composite Coating Technology Evolution and Objectives

Composite coating technology has evolved significantly over the past decades, transforming from simple protective layers to sophisticated multifunctional systems. The journey began in the 1950s with basic ceramic and metallic coatings primarily designed for corrosion resistance. By the 1970s, researchers had developed the first generation of composite coatings that combined multiple materials to achieve enhanced properties beyond what single-component coatings could offer.

The 1990s marked a pivotal shift with the emergence of nanocomposite coatings, leveraging nanoscale materials to dramatically improve performance characteristics. This innovation opened new possibilities for tailoring coating properties at the molecular level, enabling unprecedented combinations of hardness, flexibility, and functionality. The early 2000s witnessed the integration of smart materials into composite coating systems, creating responsive surfaces capable of adapting to environmental changes.

Current technological advancements focus on developing multi-layered composite coatings that can simultaneously address multiple challenges in extreme environments. These advanced systems combine ceramic, metallic, polymeric, and carbon-based materials in precisely engineered structures to achieve synergistic effects. The incorporation of self-healing mechanisms represents another significant breakthrough, allowing coatings to repair minor damage autonomously and extend service life dramatically.

The primary objective of contemporary composite coating research is to develop versatile protective systems that can withstand increasingly demanding operational conditions while providing multiple functionalities. This includes resistance to extreme temperatures (both cryogenic and >1000°C), protection against aggressive chemical environments, and the ability to maintain structural integrity under high mechanical stress. Additionally, modern composite coatings aim to deliver functional properties such as electrical conductivity, thermal management, electromagnetic shielding, or catalytic activity without compromising their protective capabilities.

Looking forward, the field is moving toward environmentally sustainable coating technologies that eliminate toxic components while maintaining or exceeding current performance standards. Research objectives increasingly focus on developing bio-inspired composite coatings that mimic natural systems' remarkable properties, such as the self-cleaning capabilities of lotus leaves or the adhesive properties of gecko feet. The ultimate goal is to create multifunctional, adaptive coating systems that can be customized for specific applications across aerospace, energy, biomedical, and advanced manufacturing sectors, while offering extended service life and reduced environmental impact.

The 1990s marked a pivotal shift with the emergence of nanocomposite coatings, leveraging nanoscale materials to dramatically improve performance characteristics. This innovation opened new possibilities for tailoring coating properties at the molecular level, enabling unprecedented combinations of hardness, flexibility, and functionality. The early 2000s witnessed the integration of smart materials into composite coating systems, creating responsive surfaces capable of adapting to environmental changes.

Current technological advancements focus on developing multi-layered composite coatings that can simultaneously address multiple challenges in extreme environments. These advanced systems combine ceramic, metallic, polymeric, and carbon-based materials in precisely engineered structures to achieve synergistic effects. The incorporation of self-healing mechanisms represents another significant breakthrough, allowing coatings to repair minor damage autonomously and extend service life dramatically.

The primary objective of contemporary composite coating research is to develop versatile protective systems that can withstand increasingly demanding operational conditions while providing multiple functionalities. This includes resistance to extreme temperatures (both cryogenic and >1000°C), protection against aggressive chemical environments, and the ability to maintain structural integrity under high mechanical stress. Additionally, modern composite coatings aim to deliver functional properties such as electrical conductivity, thermal management, electromagnetic shielding, or catalytic activity without compromising their protective capabilities.

Looking forward, the field is moving toward environmentally sustainable coating technologies that eliminate toxic components while maintaining or exceeding current performance standards. Research objectives increasingly focus on developing bio-inspired composite coatings that mimic natural systems' remarkable properties, such as the self-cleaning capabilities of lotus leaves or the adhesive properties of gecko feet. The ultimate goal is to create multifunctional, adaptive coating systems that can be customized for specific applications across aerospace, energy, biomedical, and advanced manufacturing sectors, while offering extended service life and reduced environmental impact.

Market Analysis for Advanced Structural and Functional Coatings

The global market for advanced structural and functional coatings is experiencing robust growth, driven by increasing demand across multiple industries including aerospace, automotive, construction, and electronics. Current market valuation stands at approximately 15 billion USD with projections indicating growth to reach 25 billion USD by 2028, representing a compound annual growth rate of 8.7% during the forecast period.

Asia-Pacific currently dominates the market share, accounting for nearly 40% of global consumption, with China leading regional demand due to rapid industrialization and infrastructure development. North America and Europe follow with significant market shares of 25% and 22% respectively, primarily driven by technological advancements in aerospace and automotive sectors.

The automotive industry represents the largest end-user segment, consuming roughly 30% of advanced coatings production, as manufacturers seek solutions for lightweighting, corrosion resistance, and enhanced aesthetics. Aerospace applications constitute the fastest-growing segment with 12% annual growth, attributed to increasing aircraft production and stringent performance requirements.

Consumer preference is shifting decisively toward environmentally friendly coating solutions, with water-based and powder coatings gaining market share over traditional solvent-based alternatives. This trend is reinforced by stringent environmental regulations in developed markets, particularly in Europe and North America, which restrict volatile organic compound (VOC) emissions.

Multi-functional coatings that combine several properties—such as corrosion resistance, wear resistance, and self-cleaning capabilities—are experiencing the highest demand growth. The market for smart coatings with self-healing, anti-icing, or sensing capabilities is projected to grow at 15% annually, albeit from a smaller base.

Price sensitivity varies significantly across application segments, with industrial applications demonstrating higher price elasticity compared to specialized aerospace or medical applications where performance requirements take precedence over cost considerations.

Supply chain challenges, including raw material price volatility and availability constraints for certain specialty additives, represent significant market challenges. The recent global disruptions have accelerated regionalization trends, with manufacturers increasingly seeking to establish localized production capabilities to ensure supply security.

Market consolidation continues through strategic acquisitions, with major coating manufacturers expanding their technological portfolios through targeted purchases of specialized coating technology developers. This trend is expected to continue as larger players seek to acquire innovative technologies rather than developing them internally.

Asia-Pacific currently dominates the market share, accounting for nearly 40% of global consumption, with China leading regional demand due to rapid industrialization and infrastructure development. North America and Europe follow with significant market shares of 25% and 22% respectively, primarily driven by technological advancements in aerospace and automotive sectors.

The automotive industry represents the largest end-user segment, consuming roughly 30% of advanced coatings production, as manufacturers seek solutions for lightweighting, corrosion resistance, and enhanced aesthetics. Aerospace applications constitute the fastest-growing segment with 12% annual growth, attributed to increasing aircraft production and stringent performance requirements.

Consumer preference is shifting decisively toward environmentally friendly coating solutions, with water-based and powder coatings gaining market share over traditional solvent-based alternatives. This trend is reinforced by stringent environmental regulations in developed markets, particularly in Europe and North America, which restrict volatile organic compound (VOC) emissions.

Multi-functional coatings that combine several properties—such as corrosion resistance, wear resistance, and self-cleaning capabilities—are experiencing the highest demand growth. The market for smart coatings with self-healing, anti-icing, or sensing capabilities is projected to grow at 15% annually, albeit from a smaller base.

Price sensitivity varies significantly across application segments, with industrial applications demonstrating higher price elasticity compared to specialized aerospace or medical applications where performance requirements take precedence over cost considerations.

Supply chain challenges, including raw material price volatility and availability constraints for certain specialty additives, represent significant market challenges. The recent global disruptions have accelerated regionalization trends, with manufacturers increasingly seeking to establish localized production capabilities to ensure supply security.

Market consolidation continues through strategic acquisitions, with major coating manufacturers expanding their technological portfolios through targeted purchases of specialized coating technology developers. This trend is expected to continue as larger players seek to acquire innovative technologies rather than developing them internally.

Current Challenges in Composite Coating Development

Despite significant advancements in composite coating technologies, several critical challenges continue to impede broader implementation and optimization of these materials for advanced structural and functional applications. One of the most persistent issues is achieving consistent adhesion between the coating and substrate across varying environmental conditions. Temperature fluctuations, chemical exposure, and mechanical stress often lead to delamination or cracking at the interface, particularly in harsh industrial environments where composite coatings are most needed.

Durability remains another significant challenge, with many composite coatings exhibiting premature degradation when exposed to UV radiation, moisture, or chemical agents. This degradation manifests as color changes, surface roughening, or loss of functional properties, substantially reducing the service life of coated components. The multi-phase nature of composite coatings creates inherent vulnerabilities at phase boundaries where environmental factors can accelerate deterioration.

Scalability of production processes presents substantial technical hurdles. Laboratory-scale successes often fail to translate to industrial-scale manufacturing due to difficulties in maintaining homogeneous dispersion of reinforcement materials throughout the matrix. This challenge is particularly pronounced with nanomaterial-enhanced composite coatings, where agglomeration frequently occurs during scale-up, compromising the enhanced properties observed in smaller batches.

Cost-effectiveness continues to be a significant barrier to widespread adoption. Many advanced composite coating formulations incorporate expensive materials such as rare earth elements, specialized polymers, or precisely engineered nanoparticles. The complex processing techniques required, including specialized curing methods or controlled atmosphere deposition, further increase production costs, limiting commercial viability for many potential applications.

Multifunctionality integration represents perhaps the most sophisticated challenge. Modern applications increasingly demand coatings that simultaneously provide multiple functions—such as corrosion resistance, thermal management, electrical conductivity, and self-healing capabilities. Engineering composite coatings that can deliver this suite of properties without compromising performance in any single area requires sophisticated material design approaches that are still evolving.

Regulatory compliance and environmental considerations add another layer of complexity. Traditional composite coating formulations often contain volatile organic compounds (VOCs), heavy metals, or other environmentally problematic substances. Developing "green" alternatives that maintain performance standards while meeting increasingly stringent environmental regulations requires fundamental reformulation of many established coating systems.

Durability remains another significant challenge, with many composite coatings exhibiting premature degradation when exposed to UV radiation, moisture, or chemical agents. This degradation manifests as color changes, surface roughening, or loss of functional properties, substantially reducing the service life of coated components. The multi-phase nature of composite coatings creates inherent vulnerabilities at phase boundaries where environmental factors can accelerate deterioration.

Scalability of production processes presents substantial technical hurdles. Laboratory-scale successes often fail to translate to industrial-scale manufacturing due to difficulties in maintaining homogeneous dispersion of reinforcement materials throughout the matrix. This challenge is particularly pronounced with nanomaterial-enhanced composite coatings, where agglomeration frequently occurs during scale-up, compromising the enhanced properties observed in smaller batches.

Cost-effectiveness continues to be a significant barrier to widespread adoption. Many advanced composite coating formulations incorporate expensive materials such as rare earth elements, specialized polymers, or precisely engineered nanoparticles. The complex processing techniques required, including specialized curing methods or controlled atmosphere deposition, further increase production costs, limiting commercial viability for many potential applications.

Multifunctionality integration represents perhaps the most sophisticated challenge. Modern applications increasingly demand coatings that simultaneously provide multiple functions—such as corrosion resistance, thermal management, electrical conductivity, and self-healing capabilities. Engineering composite coatings that can deliver this suite of properties without compromising performance in any single area requires sophisticated material design approaches that are still evolving.

Regulatory compliance and environmental considerations add another layer of complexity. Traditional composite coating formulations often contain volatile organic compounds (VOCs), heavy metals, or other environmentally problematic substances. Developing "green" alternatives that maintain performance standards while meeting increasingly stringent environmental regulations requires fundamental reformulation of many established coating systems.

State-of-the-Art Composite Coating Solutions

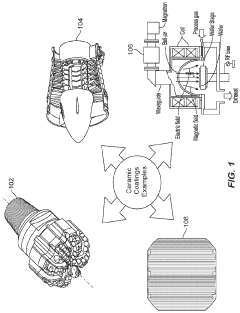

01 Metal-based composite coatings

Metal-based composite coatings involve the application of metallic materials combined with other substances to create protective layers with enhanced properties. These coatings typically incorporate metals such as aluminum, zinc, or nickel with various additives to improve corrosion resistance, wear resistance, and durability. The metal components provide structural integrity while the additives contribute specific functional properties, resulting in coatings suitable for industrial applications requiring high performance under harsh conditions.- Metal-based composite coatings: Metal-based composite coatings involve the application of metallic materials combined with other substances to create protective layers with enhanced properties. These coatings typically incorporate metals such as aluminum, zinc, or nickel with various additives to improve corrosion resistance, wear resistance, and durability. The metal components provide structural integrity while the additives contribute specific functional properties, resulting in coatings suitable for industrial applications requiring high performance under harsh conditions.

- Polymer-based composite coatings: Polymer-based composite coatings combine organic polymers with various fillers, additives, or reinforcing materials to create versatile protective layers. These coatings offer advantages such as flexibility, chemical resistance, and ease of application. By incorporating different additives into the polymer matrix, properties such as adhesion, weatherability, and impact resistance can be tailored for specific applications. These coatings are widely used in automotive, construction, and consumer goods industries where a combination of protection and aesthetic appeal is required.

- Ceramic and inorganic composite coatings: Ceramic and inorganic composite coatings utilize non-metallic inorganic materials to create highly durable protective layers with exceptional thermal and chemical resistance. These coatings typically incorporate materials such as silicon carbide, aluminum oxide, or zirconium oxide, often combined with binding agents to enhance adhesion and flexibility. The resulting coatings offer superior performance in high-temperature environments, resistance to abrasion, and protection against aggressive chemical exposure, making them suitable for aerospace, energy, and heavy industrial applications.

- Nanocomposite coatings: Nanocomposite coatings incorporate nanoscale particles or structures within a coating matrix to achieve enhanced properties not possible with conventional materials. By dispersing nanoparticles such as carbon nanotubes, graphene, or metal oxide nanoparticles throughout the coating, significant improvements in hardness, scratch resistance, and barrier properties can be achieved. These advanced coatings can also provide additional functionalities such as self-cleaning, antimicrobial properties, or electrical conductivity while maintaining optical clarity and thin film characteristics.

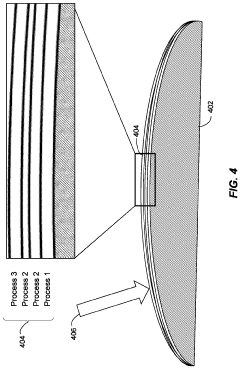

- Multi-layer composite coating systems: Multi-layer composite coating systems consist of strategically applied sequential layers, each serving a specific function to create an integrated protective system. These systems typically include primer layers for adhesion, intermediate layers for barrier properties, and topcoats for aesthetic and weathering resistance. By combining different coating technologies in a layered approach, these systems can provide comprehensive protection against multiple degradation mechanisms simultaneously, extending the service life of the coated substrate while maintaining appearance and functionality over time.

02 Polymer-based composite coatings

Polymer-based composite coatings combine organic polymers with various fillers, reinforcements, or functional additives to create versatile protective layers. These coatings offer advantages such as flexibility, chemical resistance, and ease of application. By incorporating different additives into the polymer matrix, properties such as adhesion, durability, and specific functionalities can be tailored for applications ranging from automotive finishes to architectural coatings. The polymer matrix provides a continuous phase while the additives enhance specific performance characteristics.Expand Specific Solutions03 Ceramic and inorganic composite coatings

Ceramic and inorganic composite coatings utilize non-metallic inorganic materials to create highly durable protective layers with exceptional thermal and chemical resistance. These coatings typically incorporate materials such as silicon carbide, aluminum oxide, or zirconium oxide, often combined with binding agents to enhance adhesion and performance. The resulting coatings offer superior hardness, wear resistance, and stability at high temperatures, making them suitable for applications in aerospace, manufacturing, and other industries requiring extreme performance conditions.Expand Specific Solutions04 Nanocomposite coating technologies

Nanocomposite coatings incorporate nanoscale particles or structures within a coating matrix to achieve enhanced properties not possible with conventional materials. By dispersing nanoparticles throughout the coating, properties such as hardness, scratch resistance, and barrier performance can be significantly improved while maintaining other desirable characteristics. These advanced coatings utilize the unique properties of nanomaterials to create multifunctional surfaces with applications in electronics, automotive, and consumer products where conventional coatings would be insufficient.Expand Specific Solutions05 Environmentally friendly composite coating formulations

Environmentally friendly composite coating formulations focus on reducing environmental impact through the use of sustainable materials, low-VOC compositions, and water-based systems. These coatings incorporate renewable resources, bio-based polymers, and non-toxic additives while maintaining performance comparable to conventional alternatives. By eliminating harmful substances and reducing energy requirements during application and curing, these coatings address growing regulatory requirements and market demand for sustainable solutions across industries including construction, automotive, and consumer goods.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The composite coatings market for advanced structural and functional applications is in a growth phase, driven by increasing demand across aerospace, automotive, and industrial sectors. The market size is expanding rapidly due to the need for materials with enhanced properties like corrosion resistance, thermal stability, and mechanical strength. Technologically, the field shows varying maturity levels, with companies like PPG Industries, BASF, and Nippon Paint leading commercial applications through established product lines. Research institutions such as MIT and University of Houston are advancing fundamental innovations, while specialized players like Castagra Products and CeramTec-Etec focus on niche applications. Companies including Boeing and Northrop Grumman represent end-users driving requirements for next-generation coatings with multi-functional capabilities, particularly in high-performance sectors.

PPG Industries Ohio, Inc.

Technical Solution: PPG has developed advanced nanocomposite coatings that combine ceramic nanoparticles with polymer matrices to create multifunctional protective layers. Their proprietary technology incorporates silica, alumina, and zirconia nanoparticles into resin systems to enhance mechanical properties while maintaining flexibility. PPG's electrodeposition coating process enables uniform application of these composite materials on complex geometries, achieving consistent thickness and performance. Their recent innovations include self-healing composite coatings that incorporate microcapsules containing healing agents that are released upon mechanical damage, automatically repairing scratches and preventing corrosion propagation. PPG has also pioneered thermally conductive composite coatings that maintain electrical insulation properties, addressing thermal management challenges in electronics and automotive applications.

Strengths: Industry-leading expertise in large-scale manufacturing of composite coatings; extensive distribution network; strong R&D capabilities with over 100 years of coating experience. Weaknesses: Higher production costs compared to conventional coatings; some formulations require specialized application equipment; environmental regulations may limit certain chemical components.

BASF SE

Technical Solution: BASF has developed an innovative platform of composite coatings utilizing their proprietary nanoparticle dispersion technology. Their approach combines ceramic nanoparticles with specialized polymer matrices to create multifunctional coatings with enhanced mechanical, thermal, and chemical resistance properties. BASF's composite coatings incorporate graphene and carbon nanotubes to improve electrical conductivity while maintaining corrosion protection. Their water-based composite formulations achieve VOC reductions of up to 80% compared to traditional solvent-based systems while maintaining performance characteristics. BASF has pioneered self-stratifying composite coatings that automatically form multiple functional layers during the curing process, eliminating the need for multiple application steps. Their recent developments include bio-based composite coatings that incorporate renewable materials while maintaining industrial performance standards.

Strengths: Vertical integration allowing control of raw material quality; extensive global research network with specialized coating technology centers; strong patent portfolio in composite materials. Weaknesses: Complex formulations can present manufacturing challenges; higher initial costs compared to conventional coatings; some advanced composites require specialized application techniques.

Key Patents and Scientific Breakthroughs

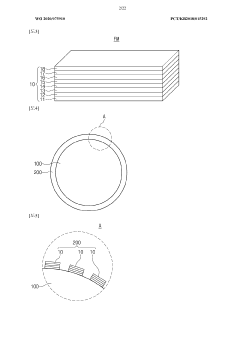

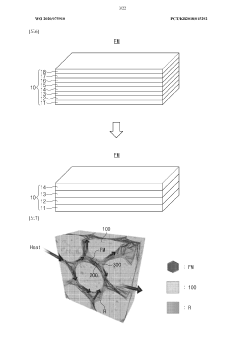

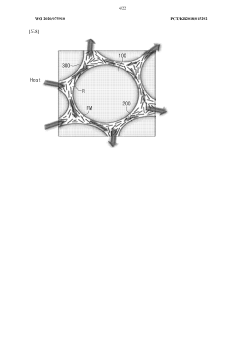

Composite material obtained by surface coating functional material, and method for producing same

PatentWO2020075910A1

Innovation

- A composite powder is developed with a base core coated by a functional material featuring a carbon layer, where the carbon to oxygen ratio is optimized, and a method involving vibration is used to apply the carbon laminate structure, allowing for improved conductivity and resistance properties, and enabling coating on various substrates, including curved surfaces.

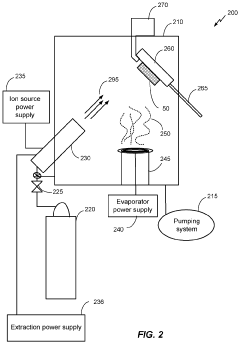

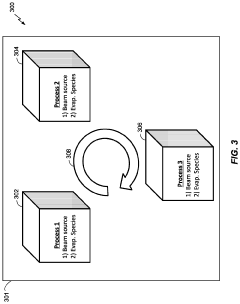

Functionally integrated coating structures

PatentActiveUS20200131619A1

Innovation

- A multi-process ion beam assisted deposition system with multiple zones, each using specific evaporator species like Aluminum Oxide, Yttrium Oxide, and Zirconium Oxide, and ion beams with controlled energy and current density, allows for sequential and adjustable deposition of coatings, enabling the creation of functionally integrated coating structures.

Environmental Impact and Sustainability Considerations

The environmental impact of composite coatings has become increasingly significant as industries adopt more sustainable practices. Traditional coating processes often involve volatile organic compounds (VOCs), heavy metals, and other environmentally harmful substances that contribute to air pollution, water contamination, and soil degradation. Recent regulatory frameworks, including the European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and various national environmental protection policies, have accelerated the transition toward greener coating technologies.

Sustainable composite coatings are being developed through several innovative approaches. Water-based formulations have emerged as viable alternatives to solvent-based systems, reducing VOC emissions by up to 80% while maintaining comparable performance characteristics. Additionally, bio-based raw materials derived from renewable resources such as plant oils, cellulose, and chitosan are increasingly incorporated into coating formulations, decreasing dependence on petroleum-derived components.

Life cycle assessment (LCA) studies reveal that advanced composite coatings can significantly reduce environmental footprints through extended service life and reduced maintenance requirements. For instance, thermal barrier coatings in aerospace applications can improve fuel efficiency by 1-2%, translating to substantial reductions in carbon emissions over an aircraft's operational lifetime. Similarly, anti-corrosion composite coatings can extend infrastructure lifespan by 15-20 years, reducing resource consumption associated with replacement and repair.

Energy-efficient deposition methods represent another frontier in sustainable coating technology. Techniques such as cold spray, electrophoretic deposition, and UV-curing processes consume significantly less energy compared to conventional thermal spray or chemical vapor deposition methods. These approaches not only reduce carbon footprints but also minimize waste generation during application processes.

End-of-life considerations are increasingly integrated into composite coating design. Recyclability and biodegradability have become important performance metrics alongside traditional parameters like durability and functionality. Self-healing coatings that can repair minor damage autonomously extend service life while reducing maintenance-related environmental impacts. Additionally, coating systems designed for easy removal and recovery of valuable components facilitate material reclamation at end-of-life.

The economic implications of environmentally sustainable coatings are compelling. Though initial implementation costs may be higher, the total cost of ownership analysis typically favors sustainable solutions when accounting for reduced maintenance, extended service life, and avoidance of regulatory compliance penalties. Market trends indicate growing consumer preference for environmentally responsible products, creating additional economic incentives for industries to adopt sustainable coating technologies.

Sustainable composite coatings are being developed through several innovative approaches. Water-based formulations have emerged as viable alternatives to solvent-based systems, reducing VOC emissions by up to 80% while maintaining comparable performance characteristics. Additionally, bio-based raw materials derived from renewable resources such as plant oils, cellulose, and chitosan are increasingly incorporated into coating formulations, decreasing dependence on petroleum-derived components.

Life cycle assessment (LCA) studies reveal that advanced composite coatings can significantly reduce environmental footprints through extended service life and reduced maintenance requirements. For instance, thermal barrier coatings in aerospace applications can improve fuel efficiency by 1-2%, translating to substantial reductions in carbon emissions over an aircraft's operational lifetime. Similarly, anti-corrosion composite coatings can extend infrastructure lifespan by 15-20 years, reducing resource consumption associated with replacement and repair.

Energy-efficient deposition methods represent another frontier in sustainable coating technology. Techniques such as cold spray, electrophoretic deposition, and UV-curing processes consume significantly less energy compared to conventional thermal spray or chemical vapor deposition methods. These approaches not only reduce carbon footprints but also minimize waste generation during application processes.

End-of-life considerations are increasingly integrated into composite coating design. Recyclability and biodegradability have become important performance metrics alongside traditional parameters like durability and functionality. Self-healing coatings that can repair minor damage autonomously extend service life while reducing maintenance-related environmental impacts. Additionally, coating systems designed for easy removal and recovery of valuable components facilitate material reclamation at end-of-life.

The economic implications of environmentally sustainable coatings are compelling. Though initial implementation costs may be higher, the total cost of ownership analysis typically favors sustainable solutions when accounting for reduced maintenance, extended service life, and avoidance of regulatory compliance penalties. Market trends indicate growing consumer preference for environmentally responsible products, creating additional economic incentives for industries to adopt sustainable coating technologies.

Industrial Application Case Studies

Composite coatings have revolutionized numerous industries by providing enhanced protection, functionality, and performance to various components and structures. The aerospace industry has been at the forefront of adopting advanced composite coatings, particularly thermal barrier coatings (TBCs) for jet engine components. These coatings enable turbine blades to operate at temperatures exceeding 1200°C, significantly improving fuel efficiency and engine durability. Companies like General Electric and Rolls-Royce have reported 15-20% improvements in engine performance through the implementation of ceramic-metal composite coatings on critical components.

In the automotive sector, composite coatings have transformed both functional and aesthetic aspects of vehicle manufacturing. Hard chrome replacement coatings based on nickel-tungsten-carbide composites have demonstrated superior wear resistance, extending component life by up to 300% compared to traditional chrome plating. Tesla and BMW have pioneered the use of self-healing composite coatings that incorporate microcapsules with repair agents, reducing maintenance costs and extending vehicle lifespans.

The energy sector presents another compelling application area, particularly in renewable energy systems. Wind turbine blades coated with graphene-reinforced polymer composites have shown 40% improved erosion resistance and 25% extended service life in harsh offshore environments. Similarly, solar panel manufacturers have implemented anti-reflective composite coatings that increase energy absorption efficiency by 3-5%, translating to significant performance gains over panel lifetimes.

Marine applications demonstrate the versatility of composite coatings in extreme environments. Ships equipped with copper-polymer composite antifouling coatings have reported fuel savings of up to 8% due to reduced hull friction, while simultaneously decreasing maintenance frequency by 50%. The offshore oil and gas industry utilizes ceramic-polymer composites for platform structures, providing corrosion protection that extends asset life by 10-15 years in highly corrosive saltwater environments.

The medical device industry represents one of the most sophisticated applications of functional composite coatings. Hydroxyapatite-silver composite coatings on orthopedic implants promote bone integration while providing antimicrobial properties, reducing infection rates by up to 70% in clinical trials. Similarly, cardiovascular stents coated with drug-eluting polymer composites have revolutionized treatment outcomes, with major manufacturers reporting restenosis rate reductions from 30% to under 5% compared to uncoated alternatives.

In the automotive sector, composite coatings have transformed both functional and aesthetic aspects of vehicle manufacturing. Hard chrome replacement coatings based on nickel-tungsten-carbide composites have demonstrated superior wear resistance, extending component life by up to 300% compared to traditional chrome plating. Tesla and BMW have pioneered the use of self-healing composite coatings that incorporate microcapsules with repair agents, reducing maintenance costs and extending vehicle lifespans.

The energy sector presents another compelling application area, particularly in renewable energy systems. Wind turbine blades coated with graphene-reinforced polymer composites have shown 40% improved erosion resistance and 25% extended service life in harsh offshore environments. Similarly, solar panel manufacturers have implemented anti-reflective composite coatings that increase energy absorption efficiency by 3-5%, translating to significant performance gains over panel lifetimes.

Marine applications demonstrate the versatility of composite coatings in extreme environments. Ships equipped with copper-polymer composite antifouling coatings have reported fuel savings of up to 8% due to reduced hull friction, while simultaneously decreasing maintenance frequency by 50%. The offshore oil and gas industry utilizes ceramic-polymer composites for platform structures, providing corrosion protection that extends asset life by 10-15 years in highly corrosive saltwater environments.

The medical device industry represents one of the most sophisticated applications of functional composite coatings. Hydroxyapatite-silver composite coatings on orthopedic implants promote bone integration while providing antimicrobial properties, reducing infection rates by up to 70% in clinical trials. Similarly, cardiovascular stents coated with drug-eluting polymer composites have revolutionized treatment outcomes, with major manufacturers reporting restenosis rate reductions from 30% to under 5% compared to uncoated alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!