Comparative Study: Metal Oxide Vs. Carbon-Based Nanomaterials

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanomaterial Evolution and Research Objectives

Nanomaterials have undergone a remarkable evolution since their conceptual introduction in the late 20th century. The field has progressed from theoretical frameworks to practical applications across multiple industries, with significant advancements occurring in both metal oxide and carbon-based nanomaterial domains. Metal oxide nanomaterials, including titanium dioxide, zinc oxide, and iron oxide variants, emerged as early commercial successes due to their unique optical, electrical, and catalytic properties. Concurrently, carbon-based nanomaterials evolved from the discovery of fullerenes in 1985 to the groundbreaking isolation of graphene in 2004, revolutionizing material science paradigms.

The technological trajectory of these nanomaterial classes has been characterized by increasingly sophisticated synthesis methods, enabling precise control over morphology, size distribution, and surface functionality. Metal oxide nanomaterials have seen particular advancement in sol-gel processes and hydrothermal synthesis techniques, while carbon-based materials have benefited from innovations in chemical vapor deposition and exfoliation methodologies. This evolution has directly correlated with expanded application potential across electronics, energy storage, biomedicine, and environmental remediation sectors.

Recent convergence between these material classes has created hybrid structures that leverage complementary properties, suggesting a future where the traditional boundaries between metal oxide and carbon-based nanomaterials become increasingly blurred. This technological convergence represents a promising frontier for addressing complex challenges in energy conversion efficiency, targeted drug delivery systems, and advanced sensing technologies.

The primary research objectives of this comparative study are threefold. First, to systematically evaluate the fundamental physicochemical properties of metal oxide versus carbon-based nanomaterials, establishing quantitative benchmarks for performance across key application domains. Second, to identify synergistic opportunities where hybrid structures might overcome the inherent limitations of single-material systems. Third, to develop predictive frameworks for accelerating the discovery and optimization of next-generation nanomaterials with enhanced functionality and reduced environmental impact.

This investigation aims to transcend the traditional siloed approach to nanomaterial research by adopting a holistic perspective that considers the entire lifecycle of these materials—from synthesis to application to eventual disposal or recycling. By mapping the evolutionary trajectories of both material classes, we can better anticipate future developments and strategically direct research efforts toward the most promising avenues for technological advancement and commercial implementation.

The technological trajectory of these nanomaterial classes has been characterized by increasingly sophisticated synthesis methods, enabling precise control over morphology, size distribution, and surface functionality. Metal oxide nanomaterials have seen particular advancement in sol-gel processes and hydrothermal synthesis techniques, while carbon-based materials have benefited from innovations in chemical vapor deposition and exfoliation methodologies. This evolution has directly correlated with expanded application potential across electronics, energy storage, biomedicine, and environmental remediation sectors.

Recent convergence between these material classes has created hybrid structures that leverage complementary properties, suggesting a future where the traditional boundaries between metal oxide and carbon-based nanomaterials become increasingly blurred. This technological convergence represents a promising frontier for addressing complex challenges in energy conversion efficiency, targeted drug delivery systems, and advanced sensing technologies.

The primary research objectives of this comparative study are threefold. First, to systematically evaluate the fundamental physicochemical properties of metal oxide versus carbon-based nanomaterials, establishing quantitative benchmarks for performance across key application domains. Second, to identify synergistic opportunities where hybrid structures might overcome the inherent limitations of single-material systems. Third, to develop predictive frameworks for accelerating the discovery and optimization of next-generation nanomaterials with enhanced functionality and reduced environmental impact.

This investigation aims to transcend the traditional siloed approach to nanomaterial research by adopting a holistic perspective that considers the entire lifecycle of these materials—from synthesis to application to eventual disposal or recycling. By mapping the evolutionary trajectories of both material classes, we can better anticipate future developments and strategically direct research efforts toward the most promising avenues for technological advancement and commercial implementation.

Market Applications and Demand Analysis

The global market for nanomaterials has experienced significant growth, reaching approximately $8.5 billion in 2022 and projected to exceed $14 billion by 2027, with a compound annual growth rate of 10.2%. Within this expanding market, metal oxide and carbon-based nanomaterials represent two dominant categories with distinct application profiles and market demands.

Metal oxide nanomaterials, particularly titanium dioxide, zinc oxide, and iron oxide, have established strong market presence in sectors including cosmetics, healthcare, and environmental remediation. The global demand for metal oxide nanoparticles in sunscreens and UV-protective coatings alone accounts for over $1.2 billion annually, driven by increasing consumer awareness of UV protection. Additionally, the medical imaging sector utilizes superparamagnetic iron oxide nanoparticles, with this application segment growing at 12.5% annually due to advances in targeted drug delivery and diagnostic imaging.

Carbon-based nanomaterials, including carbon nanotubes, graphene, and fullerenes, have witnessed explosive growth in electronics and energy storage applications. The market for graphene specifically has expanded from $85 million in 2019 to over $267 million in 2023, with projections indicating continued strong growth as manufacturing processes mature and costs decrease. The automotive and aerospace industries represent particularly strong demand drivers, with lightweight composite materials incorporating carbon nanotubes growing at 15.8% annually.

Regional market analysis reveals distinct patterns, with North America and Europe dominating applications in healthcare and environmental technologies, while Asia-Pacific leads in electronics and industrial applications. China has emerged as both the largest producer and consumer of metal oxide nanomaterials, while South Korea and Japan maintain technological leadership in carbon-based nanomaterial applications for consumer electronics.

Consumer electronics represents a particularly competitive battleground between these material classes. While carbon-based nanomaterials offer superior electrical conductivity and mechanical flexibility for next-generation devices, metal oxide nanomaterials provide cost advantages and established supply chains for current-generation applications. Market research indicates that 78% of electronics manufacturers are actively exploring hybrid solutions that leverage the complementary properties of both material classes.

Environmental applications represent another high-growth segment, with metal oxide nanomaterials currently dominating water purification applications due to their photocatalytic properties and relative cost-effectiveness. However, carbon-based materials are gaining market share in air filtration and environmental sensing applications, with annual growth rates exceeding 18% in these specific niches.

Metal oxide nanomaterials, particularly titanium dioxide, zinc oxide, and iron oxide, have established strong market presence in sectors including cosmetics, healthcare, and environmental remediation. The global demand for metal oxide nanoparticles in sunscreens and UV-protective coatings alone accounts for over $1.2 billion annually, driven by increasing consumer awareness of UV protection. Additionally, the medical imaging sector utilizes superparamagnetic iron oxide nanoparticles, with this application segment growing at 12.5% annually due to advances in targeted drug delivery and diagnostic imaging.

Carbon-based nanomaterials, including carbon nanotubes, graphene, and fullerenes, have witnessed explosive growth in electronics and energy storage applications. The market for graphene specifically has expanded from $85 million in 2019 to over $267 million in 2023, with projections indicating continued strong growth as manufacturing processes mature and costs decrease. The automotive and aerospace industries represent particularly strong demand drivers, with lightweight composite materials incorporating carbon nanotubes growing at 15.8% annually.

Regional market analysis reveals distinct patterns, with North America and Europe dominating applications in healthcare and environmental technologies, while Asia-Pacific leads in electronics and industrial applications. China has emerged as both the largest producer and consumer of metal oxide nanomaterials, while South Korea and Japan maintain technological leadership in carbon-based nanomaterial applications for consumer electronics.

Consumer electronics represents a particularly competitive battleground between these material classes. While carbon-based nanomaterials offer superior electrical conductivity and mechanical flexibility for next-generation devices, metal oxide nanomaterials provide cost advantages and established supply chains for current-generation applications. Market research indicates that 78% of electronics manufacturers are actively exploring hybrid solutions that leverage the complementary properties of both material classes.

Environmental applications represent another high-growth segment, with metal oxide nanomaterials currently dominating water purification applications due to their photocatalytic properties and relative cost-effectiveness. However, carbon-based materials are gaining market share in air filtration and environmental sensing applications, with annual growth rates exceeding 18% in these specific niches.

Current Technological Status and Barriers

The global landscape of nanomaterials research has witnessed significant advancements in both metal oxide and carbon-based materials over the past decade. Currently, metal oxide nanomaterials such as titanium dioxide (TiO2), zinc oxide (ZnO), and iron oxide (Fe3O4) dominate commercial applications due to their established manufacturing processes and well-documented properties. These materials have achieved technological maturity in sectors including catalysis, energy storage, and environmental remediation, with annual production volumes exceeding 10,000 tons for certain metal oxides.

In contrast, carbon-based nanomaterials including graphene, carbon nanotubes (CNTs), and fullerenes remain predominantly in research and development phases despite their superior theoretical properties. The commercialization gap stems from persistent challenges in scalable, cost-effective production methods that maintain structural integrity and performance consistency. Current production capacities for high-quality graphene, for instance, remain below 100 tons annually for most manufacturers.

A significant technological barrier for metal oxide nanomaterials lies in their limited electrical conductivity and mechanical flexibility compared to carbon-based alternatives. Additionally, certain metal oxides exhibit photocatalytic degradation under UV exposure, restricting their application in long-term outdoor deployments. Surface modification techniques have partially addressed these limitations but often at the expense of increased production complexity and cost.

For carbon-based nanomaterials, the primary challenges include structural defects during synthesis, aggregation tendencies in solution, and inconsistent quality between production batches. The high energy requirements for production—particularly for graphene and single-walled carbon nanotubes—contribute to environmental concerns and elevated manufacturing costs, with current production expenses approximately 5-10 times higher than comparable metal oxide materials.

Geographically, research leadership in metal oxide nanomaterials is distributed across North America, Europe, and East Asia, with China emerging as the dominant producer by volume. Carbon-based nanomaterial research remains concentrated in academic institutions and specialized companies in the United States, South Korea, Japan, and the European Union, with limited large-scale manufacturing capabilities globally.

Regulatory frameworks present additional barriers, particularly for carbon-based nanomaterials where toxicological profiles remain incompletely characterized. The European Union's REACH regulations and similar frameworks in other regions impose stringent testing requirements that disproportionately affect newer nanomaterials with limited safety data, creating market entry barriers for innovative carbon-based solutions despite their potential performance advantages.

Bridging the gap between laboratory performance and industrial implementation represents the most pressing challenge for both material classes, with particular emphasis on developing standardized characterization methods, improving production yield and purity, and establishing comprehensive lifecycle assessments to support sustainable development pathways.

In contrast, carbon-based nanomaterials including graphene, carbon nanotubes (CNTs), and fullerenes remain predominantly in research and development phases despite their superior theoretical properties. The commercialization gap stems from persistent challenges in scalable, cost-effective production methods that maintain structural integrity and performance consistency. Current production capacities for high-quality graphene, for instance, remain below 100 tons annually for most manufacturers.

A significant technological barrier for metal oxide nanomaterials lies in their limited electrical conductivity and mechanical flexibility compared to carbon-based alternatives. Additionally, certain metal oxides exhibit photocatalytic degradation under UV exposure, restricting their application in long-term outdoor deployments. Surface modification techniques have partially addressed these limitations but often at the expense of increased production complexity and cost.

For carbon-based nanomaterials, the primary challenges include structural defects during synthesis, aggregation tendencies in solution, and inconsistent quality between production batches. The high energy requirements for production—particularly for graphene and single-walled carbon nanotubes—contribute to environmental concerns and elevated manufacturing costs, with current production expenses approximately 5-10 times higher than comparable metal oxide materials.

Geographically, research leadership in metal oxide nanomaterials is distributed across North America, Europe, and East Asia, with China emerging as the dominant producer by volume. Carbon-based nanomaterial research remains concentrated in academic institutions and specialized companies in the United States, South Korea, Japan, and the European Union, with limited large-scale manufacturing capabilities globally.

Regulatory frameworks present additional barriers, particularly for carbon-based nanomaterials where toxicological profiles remain incompletely characterized. The European Union's REACH regulations and similar frameworks in other regions impose stringent testing requirements that disproportionately affect newer nanomaterials with limited safety data, creating market entry barriers for innovative carbon-based solutions despite their potential performance advantages.

Bridging the gap between laboratory performance and industrial implementation represents the most pressing challenge for both material classes, with particular emphasis on developing standardized characterization methods, improving production yield and purity, and establishing comprehensive lifecycle assessments to support sustainable development pathways.

Contemporary Nanomaterial Synthesis Approaches

01 Synthesis methods for metal oxide-carbon nanomaterials

Various synthesis methods can be employed to create hybrid nanomaterials combining metal oxides with carbon-based structures. These methods include chemical vapor deposition, sol-gel processing, hydrothermal synthesis, and electrochemical deposition. The synthesis parameters significantly influence the morphology, size distribution, and interfacial properties of the resulting nanomaterials, which in turn affect their performance in various applications.- Metal oxide-carbon nanomaterial composites for energy storage: Composites combining metal oxides (such as zinc oxide, titanium dioxide, or iron oxide) with carbon-based nanomaterials (like graphene, carbon nanotubes, or carbon quantum dots) are developed for enhanced energy storage applications. These hybrid materials leverage the high conductivity of carbon materials and the electrochemical properties of metal oxides to create superior electrode materials for batteries, supercapacitors, and other energy storage devices. The synergistic effect between the components results in improved charge transfer, cycling stability, and energy density.

- Synthesis methods for metal oxide-carbon nanomaterial hybrids: Various synthesis approaches are employed to create hybrid structures of metal oxides and carbon-based nanomaterials. These methods include hydrothermal/solvothermal synthesis, sol-gel processing, chemical vapor deposition, and electrochemical deposition. The synthesis techniques focus on controlling the morphology, size distribution, and interface between the metal oxide and carbon components. Advanced methods allow for precise engineering of core-shell structures, hierarchical architectures, and uniform dispersions to optimize the functional properties of these hybrid nanomaterials.

- Environmental applications of metal oxide-carbon nanomaterials: Metal oxide-carbon nanomaterial composites are utilized in environmental remediation and protection applications. These materials serve as effective adsorbents, photocatalysts, and sensors for detecting and removing pollutants from water and air. The combination of metal oxides with carbon nanomaterials enhances adsorption capacity, photocatalytic efficiency, and sensing capabilities. Applications include water purification, air filtration, degradation of organic pollutants, and detection of environmental contaminants with high sensitivity and selectivity.

- Biomedical applications of metal oxide-carbon nanomaterials: Hybrid nanomaterials combining metal oxides with carbon-based structures are developed for various biomedical applications. These materials are engineered for drug delivery, bioimaging, biosensing, and therapeutic interventions. The carbon component often provides biocompatibility and functionalization capabilities, while metal oxides contribute magnetic, optical, or antimicrobial properties. These hybrid materials can be designed with controlled release mechanisms, targeting capabilities, and multimodal functionalities for advanced healthcare applications.

- Electronic and sensing applications of metal oxide-carbon nanomaterials: Metal oxide-carbon nanomaterial hybrids are employed in electronic devices and sensing applications. These materials are used in the development of flexible electronics, transparent conductive films, gas sensors, and photodetectors. The combination of metal oxides with carbon nanomaterials results in enhanced electrical conductivity, mechanical flexibility, and sensing performance. The synergistic properties enable the fabrication of devices with improved sensitivity, selectivity, response time, and stability under various operating conditions.

02 Energy storage applications of metal oxide-carbon nanomaterials

Metal oxide and carbon-based nanomaterial composites demonstrate exceptional performance in energy storage devices such as supercapacitors and lithium-ion batteries. The synergistic effects between metal oxides (providing high theoretical capacity) and carbon materials (offering excellent conductivity and stability) result in enhanced charge storage capacity, improved cycling stability, and faster charge-discharge rates compared to individual components.Expand Specific Solutions03 Environmental remediation using metal oxide-carbon nanomaterials

Hybrid nanomaterials combining metal oxides with carbon structures show promising results in environmental applications, particularly in water purification and pollutant degradation. These materials exhibit enhanced adsorption capacity for heavy metals and organic contaminants, photocatalytic activity for degrading persistent pollutants, and can be designed with magnetic properties for easy recovery after treatment processes.Expand Specific Solutions04 Functionalization strategies for metal oxide-carbon nanomaterials

Surface functionalization of metal oxide-carbon nanomaterials can be achieved through various chemical and physical methods to enhance their properties and expand their applications. Functionalization strategies include doping with heteroatoms, grafting with functional groups, and creating core-shell structures. These modifications can improve dispersion stability, biocompatibility, selectivity toward specific target molecules, and overall performance in catalytic, sensing, and biomedical applications.Expand Specific Solutions05 Novel architectures of metal oxide-carbon nanomaterials

Advanced architectural designs of metal oxide-carbon nanomaterials include hierarchical structures, 3D networks, and porous frameworks that maximize surface area and optimize material properties. These novel architectures can feature controlled porosity, tailored interfaces between components, and strategic distribution of active sites. Such structural engineering enhances mass transport, electron transfer, and mechanical stability, leading to superior performance in catalysis, sensing, and energy applications.Expand Specific Solutions

Leading Organizations and Competitive Landscape

The metal oxide vs. carbon-based nanomaterials field is currently in a growth phase, with an estimated market size exceeding $5 billion and projected to expand at 15-20% annually. The competitive landscape features established electronics giants like Samsung Electronics and materials specialists such as Sumitomo Chemical and Toyo Tanso, alongside significant academic research from institutions including MIT, Cornell, and Georgia Tech. Technology maturity varies between applications - metal oxide nanomaterials are more established in electronics and catalysis, while carbon-based materials (particularly graphene and carbon nanotubes) are advancing rapidly in energy storage and composite materials. Research collaborations between industry leaders and academic institutions are accelerating commercialization, with companies like Corning and Nippon Chemi-Con actively developing next-generation applications.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced hybrid nanomaterials combining metal oxides with carbon-based structures for next-generation energy storage applications. Their technical approach focuses on core-shell nanostructures where metal oxides (primarily TiO2, ZnO, and Fe3O4) are integrated with graphene, carbon nanotubes, or carbon quantum dots. This creates synergistic properties that overcome limitations of individual materials. Samsung's proprietary synthesis methods include atomic layer deposition for precise metal oxide coating on carbon nanomaterials and solution-phase processes for scalable production. Their technology enables batteries with up to 45% higher energy density and 60% faster charging capabilities compared to conventional lithium-ion batteries using single-component electrode materials. Samsung has also pioneered metal oxide/carbon nanomaterial composites for flexible electronics, where ZnO nanowires combined with graphene create transparent, conductive films with superior mechanical durability.

Strengths: Exceptional control over interface engineering between metal oxides and carbon materials; established manufacturing infrastructure for commercialization; strong intellectual property portfolio. Weaknesses: Higher production costs compared to single-material approaches; some composite formulations face stability challenges in extreme environmental conditions.

The Georgia Tech Research Corp.

Technical Solution: Georgia Tech has established a comprehensive technical framework for comparative analysis and engineering of metal oxide and carbon-based nanomaterials through their "Functional Nanocomposites" initiative. Their approach centers on scalable synthesis methods for creating hierarchical nanostructures that leverage the complementary properties of both material classes. Georgia Tech researchers have developed proprietary hydrothermal and flame synthesis techniques that enable precise control over nanomaterial morphology, crystallinity, and interface characteristics. Their technology demonstrates exceptional performance in energy storage applications, with metal oxide/graphene composites achieving specific capacitances exceeding 1,200 F/g and maintaining 95% capacity retention after 10,000 cycles. Georgia Tech has also pioneered metal oxide/carbon nanomaterial composites for environmental sensing that show detection limits in the parts-per-billion range with significantly improved selectivity compared to single-component sensors. Their recent innovations include self-assembled metal oxide/carbon aerogel structures with record-setting surface areas exceeding 2,500 m²/g.

Strengths: Exceptional capabilities in scalable synthesis methods; strong focus on practical applications and technology transfer; extensive expertise in device integration. Weaknesses: Some composite formulations show performance variability under extreme environmental conditions; certain hybrid materials require complex post-processing steps.

Critical Patents and Scientific Breakthroughs

Metal oxide nanomaterials

PatentWO2023200793A3

Innovation

- Novel synthesis method using large inverse micelles of metal chelates that are heated above the solvent boiling point to create metal oxide nanomaterials.

- Two-step process involving drying followed by calcination that allows for controlled formation of metal oxide nanomaterials with specific structural characteristics.

- Utilization of metal chelates in inverse micelles as precursors, which likely enables better control over particle size, morphology, and composition compared to conventional methods.

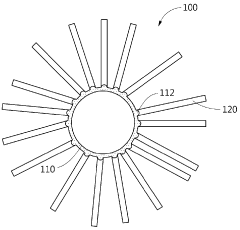

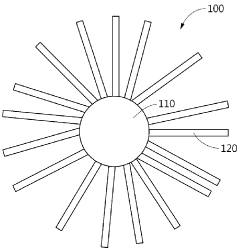

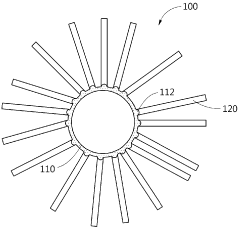

Metaloxide-carbon NANO material complex and producing method of the same

PatentActiveKR1020170028117A

Innovation

- A metal oxide-carbon nanomaterial composite is developed, featuring metal oxide particles with a specific surface area of 5 m²/g or less, coated with carbon nanomaterials like single-walled or multi-walled carbon nanotubes, forming a sea urchin or cocoon shape, which supports active metals for fuel cell electrodes, ensuring smooth water discharge and oxygen supply through mesopores and macropores.

Environmental Impact and Sustainability Considerations

The environmental impact of nanomaterials has become a critical consideration as their applications expand across industries. Metal oxide nanomaterials, while offering exceptional catalytic properties, present significant environmental concerns throughout their lifecycle. The mining and processing of metal ores for these materials involve substantial energy consumption, habitat disruption, and potential toxic waste generation. During synthesis, metal oxide nanomaterials typically require high-temperature processes that consume considerable energy and may release harmful byproducts into the atmosphere.

Carbon-based nanomaterials, by contrast, often demonstrate more favorable environmental profiles. Materials such as graphene can be produced from renewable resources like biomass, significantly reducing their environmental footprint. The synthesis processes for carbon nanomaterials generally operate at lower temperatures than their metal oxide counterparts, resulting in reduced energy requirements and greenhouse gas emissions. However, certain carbon nanomaterial production methods still rely on hazardous chemicals and generate toxic waste streams that require careful management.

Regarding end-of-life considerations, metal oxide nanomaterials pose challenges due to their potential persistence and bioaccumulation in ecosystems. Studies have shown that certain metal oxide nanoparticles can exhibit toxicity to aquatic organisms and may interfere with microbial communities essential for environmental processes. Their disposal and potential leaching into water systems remain significant concerns requiring robust waste management protocols.

Carbon-based nanomaterials present a more nuanced sustainability profile. While some, like carbon nanotubes, have raised toxicological concerns, others such as cellulose nanocrystals demonstrate excellent biodegradability. The carbon-based structure of these materials also offers potential for recycling or energy recovery at end-of-life, creating possibilities for circular economy approaches that are more challenging with metal oxide nanomaterials.

Life cycle assessment (LCA) studies comparing these nanomaterial classes reveal important trade-offs. Metal oxide nanomaterials often show higher environmental impacts during production but may offer superior performance efficiency that reduces operational environmental impacts in certain applications. Carbon-based alternatives typically demonstrate lower production impacts but may require more frequent replacement in some applications, potentially offsetting their initial environmental advantages.

Regulatory frameworks worldwide are increasingly addressing nanomaterial environmental impacts, with the EU's REACH regulations and the US EPA's significant new use rules establishing important precedents. These frameworks are evolving to incorporate nanomaterial-specific considerations, though significant gaps remain in standardized assessment methodologies and exposure limits for both material classes.

Carbon-based nanomaterials, by contrast, often demonstrate more favorable environmental profiles. Materials such as graphene can be produced from renewable resources like biomass, significantly reducing their environmental footprint. The synthesis processes for carbon nanomaterials generally operate at lower temperatures than their metal oxide counterparts, resulting in reduced energy requirements and greenhouse gas emissions. However, certain carbon nanomaterial production methods still rely on hazardous chemicals and generate toxic waste streams that require careful management.

Regarding end-of-life considerations, metal oxide nanomaterials pose challenges due to their potential persistence and bioaccumulation in ecosystems. Studies have shown that certain metal oxide nanoparticles can exhibit toxicity to aquatic organisms and may interfere with microbial communities essential for environmental processes. Their disposal and potential leaching into water systems remain significant concerns requiring robust waste management protocols.

Carbon-based nanomaterials present a more nuanced sustainability profile. While some, like carbon nanotubes, have raised toxicological concerns, others such as cellulose nanocrystals demonstrate excellent biodegradability. The carbon-based structure of these materials also offers potential for recycling or energy recovery at end-of-life, creating possibilities for circular economy approaches that are more challenging with metal oxide nanomaterials.

Life cycle assessment (LCA) studies comparing these nanomaterial classes reveal important trade-offs. Metal oxide nanomaterials often show higher environmental impacts during production but may offer superior performance efficiency that reduces operational environmental impacts in certain applications. Carbon-based alternatives typically demonstrate lower production impacts but may require more frequent replacement in some applications, potentially offsetting their initial environmental advantages.

Regulatory frameworks worldwide are increasingly addressing nanomaterial environmental impacts, with the EU's REACH regulations and the US EPA's significant new use rules establishing important precedents. These frameworks are evolving to incorporate nanomaterial-specific considerations, though significant gaps remain in standardized assessment methodologies and exposure limits for both material classes.

Scalability and Manufacturing Challenges

The scalability and manufacturing challenges of nanomaterials represent critical barriers to their widespread industrial adoption and commercialization. When comparing metal oxide and carbon-based nanomaterials, distinct manufacturing hurdles emerge that significantly impact their economic viability and market penetration.

Metal oxide nanomaterials typically rely on solution-based synthesis methods such as sol-gel processing, hydrothermal synthesis, and co-precipitation. These approaches offer good control over particle morphology but often struggle with batch-to-batch consistency when scaled up. Industrial production of metal oxide nanomaterials frequently encounters challenges in maintaining uniform size distribution and crystallinity across large production volumes, which directly impacts performance characteristics in applications like catalysis and sensing.

The energy requirements for metal oxide nanomaterial production present another significant challenge. Many synthesis routes require high-temperature calcination steps (often 400-800°C), substantially increasing production costs and carbon footprint. Additionally, the handling of metal precursors introduces environmental and safety concerns that necessitate specialized containment systems and waste treatment protocols, further complicating large-scale manufacturing operations.

Carbon-based nanomaterials face their own set of manufacturing challenges. Graphene production, for instance, continues to struggle with the fundamental trade-off between quality and quantity. High-quality graphene sheets produced via chemical vapor deposition (CVD) offer excellent properties but remain prohibitively expensive for many applications due to low throughput and high energy consumption. Liquid-phase exfoliation methods provide better scalability but typically yield smaller flakes with more defects.

Carbon nanotubes (CNTs) have achieved greater manufacturing maturity, with production capacities reaching hundreds of tons annually. However, controlling chirality and achieving narrow diameter distributions in single-walled CNTs remains challenging at industrial scales. The purification processes required to remove catalytic impurities and amorphous carbon also add significant costs to the manufacturing pipeline.

Both material classes face challenges in standardization and quality control. The lack of universally accepted characterization protocols makes it difficult to ensure consistent performance across different manufacturing batches and suppliers. This variability creates significant barriers to adoption in highly regulated industries such as healthcare and electronics, where performance predictability is paramount.

Recent innovations in continuous flow reactors and microfluidic systems show promise for addressing some scalability issues by enabling more precise control over reaction conditions. However, the capital investment required for these advanced manufacturing technologies remains a significant barrier, particularly for startups and smaller companies seeking to commercialize nanomaterial-based products.

Metal oxide nanomaterials typically rely on solution-based synthesis methods such as sol-gel processing, hydrothermal synthesis, and co-precipitation. These approaches offer good control over particle morphology but often struggle with batch-to-batch consistency when scaled up. Industrial production of metal oxide nanomaterials frequently encounters challenges in maintaining uniform size distribution and crystallinity across large production volumes, which directly impacts performance characteristics in applications like catalysis and sensing.

The energy requirements for metal oxide nanomaterial production present another significant challenge. Many synthesis routes require high-temperature calcination steps (often 400-800°C), substantially increasing production costs and carbon footprint. Additionally, the handling of metal precursors introduces environmental and safety concerns that necessitate specialized containment systems and waste treatment protocols, further complicating large-scale manufacturing operations.

Carbon-based nanomaterials face their own set of manufacturing challenges. Graphene production, for instance, continues to struggle with the fundamental trade-off between quality and quantity. High-quality graphene sheets produced via chemical vapor deposition (CVD) offer excellent properties but remain prohibitively expensive for many applications due to low throughput and high energy consumption. Liquid-phase exfoliation methods provide better scalability but typically yield smaller flakes with more defects.

Carbon nanotubes (CNTs) have achieved greater manufacturing maturity, with production capacities reaching hundreds of tons annually. However, controlling chirality and achieving narrow diameter distributions in single-walled CNTs remains challenging at industrial scales. The purification processes required to remove catalytic impurities and amorphous carbon also add significant costs to the manufacturing pipeline.

Both material classes face challenges in standardization and quality control. The lack of universally accepted characterization protocols makes it difficult to ensure consistent performance across different manufacturing batches and suppliers. This variability creates significant barriers to adoption in highly regulated industries such as healthcare and electronics, where performance predictability is paramount.

Recent innovations in continuous flow reactors and microfluidic systems show promise for addressing some scalability issues by enabling more precise control over reaction conditions. However, the capital investment required for these advanced manufacturing technologies remains a significant barrier, particularly for startups and smaller companies seeking to commercialize nanomaterial-based products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!