Calibration Standards For Electrochemical Gas Sensors

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Gas Sensor Calibration Background and Objectives

Electrochemical gas sensors have evolved significantly since their inception in the early 1950s, initially developed for oxygen detection in medical and industrial applications. The technology has progressively expanded to detect a wide range of gases including carbon monoxide, hydrogen sulfide, nitrogen oxides, and volatile organic compounds. This evolution has been driven by increasing regulatory requirements for workplace safety, environmental monitoring, and industrial process control, creating a growing demand for accurate and reliable gas detection systems.

The fundamental principle of electrochemical gas sensors involves the oxidation or reduction of target gases at an electrode surface, generating an electrical current proportional to the gas concentration. While this principle remains unchanged, sensor designs have advanced considerably, incorporating improvements in electrode materials, electrolyte compositions, and membrane technologies to enhance sensitivity, selectivity, and stability.

Despite these advancements, calibration remains a critical challenge in the practical application of electrochemical gas sensors. Calibration ensures that sensor readings accurately reflect actual gas concentrations, which is essential for safety-critical applications and regulatory compliance. However, the absence of universally accepted calibration standards has led to inconsistencies in sensor performance evaluation and quality assurance across the industry.

Current calibration practices vary widely among manufacturers and end-users, utilizing different reference gases, concentration levels, environmental conditions, and calibration intervals. This variability compromises the comparability of measurements between different sensors and systems, potentially leading to safety risks and compliance issues. Furthermore, the increasing deployment of sensor networks for distributed monitoring applications has highlighted the need for standardized calibration protocols that can be efficiently implemented across multiple devices.

The primary objective of this research is to establish comprehensive calibration standards for electrochemical gas sensors that address these challenges. Specifically, we aim to develop standardized protocols for initial calibration, periodic recalibration, and performance verification that can be universally adopted across the industry. These standards should accommodate various sensor types and target gases while being practical for implementation in both laboratory and field conditions.

Additionally, this research seeks to investigate emerging technologies that could potentially revolutionize calibration practices, such as self-calibrating sensors, remote calibration systems, and artificial intelligence-based calibration algorithms. By establishing robust calibration standards, we anticipate significant improvements in measurement accuracy, cross-platform compatibility, and overall reliability of electrochemical gas sensing systems, ultimately enhancing safety and environmental protection across multiple industries.

The fundamental principle of electrochemical gas sensors involves the oxidation or reduction of target gases at an electrode surface, generating an electrical current proportional to the gas concentration. While this principle remains unchanged, sensor designs have advanced considerably, incorporating improvements in electrode materials, electrolyte compositions, and membrane technologies to enhance sensitivity, selectivity, and stability.

Despite these advancements, calibration remains a critical challenge in the practical application of electrochemical gas sensors. Calibration ensures that sensor readings accurately reflect actual gas concentrations, which is essential for safety-critical applications and regulatory compliance. However, the absence of universally accepted calibration standards has led to inconsistencies in sensor performance evaluation and quality assurance across the industry.

Current calibration practices vary widely among manufacturers and end-users, utilizing different reference gases, concentration levels, environmental conditions, and calibration intervals. This variability compromises the comparability of measurements between different sensors and systems, potentially leading to safety risks and compliance issues. Furthermore, the increasing deployment of sensor networks for distributed monitoring applications has highlighted the need for standardized calibration protocols that can be efficiently implemented across multiple devices.

The primary objective of this research is to establish comprehensive calibration standards for electrochemical gas sensors that address these challenges. Specifically, we aim to develop standardized protocols for initial calibration, periodic recalibration, and performance verification that can be universally adopted across the industry. These standards should accommodate various sensor types and target gases while being practical for implementation in both laboratory and field conditions.

Additionally, this research seeks to investigate emerging technologies that could potentially revolutionize calibration practices, such as self-calibrating sensors, remote calibration systems, and artificial intelligence-based calibration algorithms. By establishing robust calibration standards, we anticipate significant improvements in measurement accuracy, cross-platform compatibility, and overall reliability of electrochemical gas sensing systems, ultimately enhancing safety and environmental protection across multiple industries.

Market Analysis of Calibration Standards Demand

The global market for electrochemical gas sensor calibration standards is experiencing robust growth, driven primarily by increasing regulatory requirements for workplace safety and environmental monitoring. Current market valuations indicate that the calibration standards sector represents approximately 15-20% of the overall gas detection equipment market, which was valued at over $2.5 billion in 2022. This specialized segment is projected to grow at a compound annual growth rate of 6.8% through 2028, outpacing the broader sensor market.

Industrial safety applications constitute the largest demand segment, accounting for nearly 40% of calibration standards consumption. This is followed by environmental monitoring (25%), automotive emissions testing (15%), and healthcare applications (10%), with various other sectors comprising the remaining 10%. Regionally, North America and Europe currently dominate market consumption, collectively representing over 60% of global demand, though Asia-Pacific markets are demonstrating the fastest growth rates, particularly in China, India, and South Korea.

Demand patterns reveal distinct customer segments with varying needs. Large industrial operations typically require high-precision, NIST-traceable calibration standards with comprehensive certification documentation. Meanwhile, smaller operations and field service providers often prioritize cost-effectiveness and convenience, driving demand for pre-mixed calibration gas cylinders and portable calibration kits.

Market research indicates that customers increasingly value calibration standards with longer shelf lives and improved stability characteristics. This trend is particularly evident in remote monitoring applications where frequent recalibration presents logistical challenges. Additionally, there is growing demand for calibration standards specifically formulated for emerging sensor technologies, such as those designed for low-concentration detection of volatile organic compounds and specialized industrial gases.

Price sensitivity varies significantly across market segments. While government agencies and regulated industries demonstrate lower price elasticity due to compliance requirements, commercial and industrial users show greater sensitivity to cost factors. This has created market opportunities for tiered product offerings that balance precision requirements against budget constraints.

The competitive landscape features both specialized calibration standard manufacturers and diversified chemical companies. Recent market consolidation has occurred through strategic acquisitions, with larger instrumentation companies vertically integrating calibration capabilities into their service portfolios. This trend reflects recognition of the recurring revenue potential in calibration services and standards provision.

Industrial safety applications constitute the largest demand segment, accounting for nearly 40% of calibration standards consumption. This is followed by environmental monitoring (25%), automotive emissions testing (15%), and healthcare applications (10%), with various other sectors comprising the remaining 10%. Regionally, North America and Europe currently dominate market consumption, collectively representing over 60% of global demand, though Asia-Pacific markets are demonstrating the fastest growth rates, particularly in China, India, and South Korea.

Demand patterns reveal distinct customer segments with varying needs. Large industrial operations typically require high-precision, NIST-traceable calibration standards with comprehensive certification documentation. Meanwhile, smaller operations and field service providers often prioritize cost-effectiveness and convenience, driving demand for pre-mixed calibration gas cylinders and portable calibration kits.

Market research indicates that customers increasingly value calibration standards with longer shelf lives and improved stability characteristics. This trend is particularly evident in remote monitoring applications where frequent recalibration presents logistical challenges. Additionally, there is growing demand for calibration standards specifically formulated for emerging sensor technologies, such as those designed for low-concentration detection of volatile organic compounds and specialized industrial gases.

Price sensitivity varies significantly across market segments. While government agencies and regulated industries demonstrate lower price elasticity due to compliance requirements, commercial and industrial users show greater sensitivity to cost factors. This has created market opportunities for tiered product offerings that balance precision requirements against budget constraints.

The competitive landscape features both specialized calibration standard manufacturers and diversified chemical companies. Recent market consolidation has occurred through strategic acquisitions, with larger instrumentation companies vertically integrating calibration capabilities into their service portfolios. This trend reflects recognition of the recurring revenue potential in calibration services and standards provision.

Current Calibration Methodologies and Technical Barriers

Electrochemical gas sensors currently employ several standardized calibration methodologies, each with specific applications and limitations. The most widely adopted approach is the two-point calibration method, which establishes sensor response at zero gas concentration and at a specific span concentration. This method provides reasonable accuracy for linear sensors but becomes problematic when dealing with sensors exhibiting non-linear responses across wider concentration ranges.

Dynamic dilution systems represent another common calibration technique, where calibration gases are precisely mixed with zero air to create various concentration levels. While offering flexibility in generating multiple calibration points, these systems require sophisticated flow controllers and mixing chambers, introducing complexity and potential error sources in field applications.

Permeation tube calibration systems utilize temperature-controlled permeation devices that release target gases at known rates. Though highly precise for certain gases, these systems demand rigorous temperature control and regular verification of permeation rates, making them primarily suitable for laboratory environments rather than field deployments.

Technical barriers in current calibration methodologies present significant challenges. Cross-sensitivity remains a persistent issue, as many electrochemical sensors respond to multiple gases, complicating accurate calibration in complex gas mixtures. Environmental factors such as temperature and humidity significantly impact sensor response, yet many calibration protocols fail to adequately account for these variables across operational ranges.

Calibration gas stability and traceability constitute another major barrier. Reference gases used for calibration may degrade over time, particularly reactive gases like NO2 and H2S, leading to calibration drift. Additionally, establishing traceability to international standards remains challenging for certain specialized gases or low concentration ranges.

The lack of standardization across manufacturers creates interoperability issues, as calibration procedures optimized for one sensor model may not transfer effectively to another. This fragmentation impedes the development of universal calibration protocols and increases calibration complexity in multi-sensor networks.

Field calibration presents unique challenges compared to laboratory settings. Portable calibration equipment often sacrifices precision for convenience, while environmental conditions during field calibration may differ significantly from operational conditions. The time constraints of field operations frequently lead to abbreviated calibration procedures that compromise accuracy.

Emerging sensor technologies, particularly miniaturized and low-cost sensors, introduce new calibration challenges. These sensors often exhibit greater variability in manufacturing, shorter lifespans, and different response characteristics compared to traditional sensors, necessitating novel calibration approaches that balance practicality with performance requirements.

Dynamic dilution systems represent another common calibration technique, where calibration gases are precisely mixed with zero air to create various concentration levels. While offering flexibility in generating multiple calibration points, these systems require sophisticated flow controllers and mixing chambers, introducing complexity and potential error sources in field applications.

Permeation tube calibration systems utilize temperature-controlled permeation devices that release target gases at known rates. Though highly precise for certain gases, these systems demand rigorous temperature control and regular verification of permeation rates, making them primarily suitable for laboratory environments rather than field deployments.

Technical barriers in current calibration methodologies present significant challenges. Cross-sensitivity remains a persistent issue, as many electrochemical sensors respond to multiple gases, complicating accurate calibration in complex gas mixtures. Environmental factors such as temperature and humidity significantly impact sensor response, yet many calibration protocols fail to adequately account for these variables across operational ranges.

Calibration gas stability and traceability constitute another major barrier. Reference gases used for calibration may degrade over time, particularly reactive gases like NO2 and H2S, leading to calibration drift. Additionally, establishing traceability to international standards remains challenging for certain specialized gases or low concentration ranges.

The lack of standardization across manufacturers creates interoperability issues, as calibration procedures optimized for one sensor model may not transfer effectively to another. This fragmentation impedes the development of universal calibration protocols and increases calibration complexity in multi-sensor networks.

Field calibration presents unique challenges compared to laboratory settings. Portable calibration equipment often sacrifices precision for convenience, while environmental conditions during field calibration may differ significantly from operational conditions. The time constraints of field operations frequently lead to abbreviated calibration procedures that compromise accuracy.

Emerging sensor technologies, particularly miniaturized and low-cost sensors, introduce new calibration challenges. These sensors often exhibit greater variability in manufacturing, shorter lifespans, and different response characteristics compared to traditional sensors, necessitating novel calibration approaches that balance practicality with performance requirements.

Existing Calibration Standard Protocols and Implementations

01 Gas calibration standards and reference materials

Calibration standards and reference materials are essential for accurate electrochemical gas sensor calibration. These standards provide known concentrations of target gases that serve as reference points for sensor calibration. The use of certified reference materials ensures traceability to international standards and improves measurement accuracy. Various types of reference materials, including gas mixtures in cylinders and permeation tubes, can be used depending on the specific gas being measured and the required accuracy level.- Gas calibration standards and reference materials: Calibration standards and reference materials are essential for accurate calibration of electrochemical gas sensors. These standards provide known concentrations of target gases that can be used to establish calibration curves and verify sensor performance. Reference materials with certified gas concentrations ensure traceability to international standards and improve measurement accuracy across different laboratories and testing environments.

- Calibration methods and procedures: Specific methods and procedures for calibrating electrochemical gas sensors involve systematic approaches to ensure accuracy and reliability. These include multi-point calibration techniques, zero-point calibration, span calibration, and automated calibration systems. Proper calibration procedures account for environmental factors such as temperature, pressure, and humidity that can affect sensor response, and establish protocols for calibration frequency based on sensor drift characteristics.

- Calibration equipment and systems: Specialized equipment and systems are used for calibrating electrochemical gas sensors, including gas mixing systems, flow controllers, calibration chambers, and automated calibration stations. These systems can generate precise gas mixtures, control environmental conditions, and automate the calibration process to improve repeatability and reduce human error. Advanced calibration systems may incorporate data logging capabilities and software for calibration management and documentation.

- Temperature compensation and environmental factors: Temperature significantly affects electrochemical gas sensor performance, necessitating compensation methods during calibration. Calibration standards account for temperature effects by providing correction factors or by performing calibration at multiple temperatures. Other environmental factors such as humidity, pressure, and interfering gases are also addressed in comprehensive calibration standards to ensure sensor accuracy across varying operating conditions.

- Traceability and validation of calibration standards: Ensuring traceability of calibration standards to national or international reference materials is crucial for electrochemical gas sensor calibration. Validation procedures verify the accuracy and stability of calibration standards over time. This includes regular verification against primary standards, uncertainty analysis, and documentation of calibration standard preparation and certification. Proper validation ensures that calibration results are comparable across different laboratories and time periods.

02 Calibration methods and procedures

Specific methods and procedures for calibrating electrochemical gas sensors ensure accuracy and reliability. These include multi-point calibration techniques, zero and span calibration procedures, and automated calibration systems. Proper calibration frequency and documentation are critical for maintaining sensor performance over time. Calibration procedures may vary depending on the sensor type, target gas, and environmental conditions in which the sensor operates.Expand Specific Solutions03 Temperature compensation and environmental factors

Environmental factors significantly impact electrochemical gas sensor performance and calibration. Temperature compensation techniques are employed to adjust sensor readings based on ambient temperature variations. Humidity, pressure, and interfering gases can also affect sensor response and must be accounted for during calibration. Advanced calibration standards incorporate methods to compensate for these environmental factors, ensuring accurate measurements across varying conditions.Expand Specific Solutions04 Calibration equipment and systems

Specialized equipment and systems are used for electrochemical gas sensor calibration. These include gas dilution systems, flow controllers, calibration chambers, and automated calibration stations. Modern calibration systems often incorporate digital interfaces and software for precise control of gas concentrations and documentation of calibration results. Portable calibration equipment allows for field calibration of sensors in their operational environment.Expand Specific Solutions05 Traceability and validation of calibration standards

Ensuring traceability and validation of calibration standards is crucial for reliable electrochemical gas sensor measurements. This involves regular verification of calibration gases against primary standards, documentation of calibration procedures, and uncertainty analysis. Quality assurance protocols help maintain the integrity of calibration standards over time. International standards and guidelines provide frameworks for establishing and maintaining traceability in gas sensor calibration.Expand Specific Solutions

Leading Organizations in Calibration Standards Development

The electrochemical gas sensor calibration standards market is currently in a growth phase, with increasing demand driven by stringent safety regulations across industries. The global market size is estimated to exceed $1.5 billion, expanding at a CAGR of approximately 6-7%. Leading players include established safety equipment manufacturers like Draeger Safety, MSA Technology, and Industrial Scientific, who possess mature calibration technologies. Honeywell Analytics and Robert Bosch represent technological innovators with advanced sensor integration capabilities. The competitive landscape is diversifying with specialized entrants like Sunvou Medical Electronics and Shanghai Leimi focusing on niche applications. Academic institutions such as The Regents of the University of California are contributing fundamental research, while regional players from China (Gree Electric, GL Tech) are rapidly gaining market share through cost-effective solutions and manufacturing advantages.

Draeger Safety, Inc.

Technical Solution: Draeger has developed a comprehensive calibration system for electrochemical gas sensors that includes traceable calibration gases with precise concentrations and automated calibration stations. Their DrägerSensor technology incorporates advanced calibration algorithms that compensate for environmental factors such as temperature, pressure, and humidity. The company has pioneered multi-gas calibration techniques that allow simultaneous calibration of multiple sensors, reducing maintenance time and improving accuracy. Their Sensor Diagnostic System continuously monitors sensor performance between calibrations, providing real-time data on sensor health and calibration status. Draeger's calibration standards are compliant with international regulations including NIST, ISO 17025, and EN 45001, ensuring traceability and reliability across different jurisdictions.

Strengths: Industry-leading traceability of calibration gases to international standards; automated calibration systems reduce human error; comprehensive sensor diagnostics. Weaknesses: Proprietary calibration systems can be expensive; requires specialized training for maintenance personnel; some calibration procedures are time-consuming for complex multi-gas systems.

Endress+Hauser Conducta GmbH+Co. KG

Technical Solution: Endress+Hauser has developed the Memosens calibration technology for electrochemical sensors that digitizes the calibration data and stores it directly in the sensor head. This revolutionary approach allows sensors to be calibrated in optimal laboratory conditions and then installed in the field without signal degradation. Their Memocheck calibration verification tools provide standardized testing procedures that verify sensor performance against traceable standards. Endress+Hauser's Heartbeat Technology continuously monitors sensor health between calibrations, providing predictive diagnostics on calibration status. Their research has established mathematical models for sensor drift compensation that extend calibration intervals while maintaining measurement accuracy. The company has also pioneered the development of automated cleaning procedures integrated with calibration cycles to eliminate contamination effects on calibration accuracy.

Strengths: Digital calibration data storage eliminates signal degradation during sensor transport; predictive diagnostics optimize calibration scheduling; integrated cleaning procedures improve calibration accuracy. Weaknesses: Requires investment in compatible infrastructure; proprietary technology creates potential vendor lock-in; higher initial cost compared to traditional calibration methods.

Critical Patents and Research in Sensor Calibration Technology

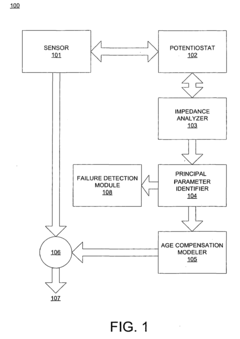

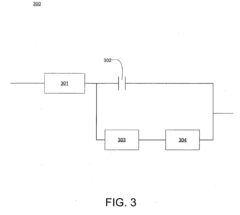

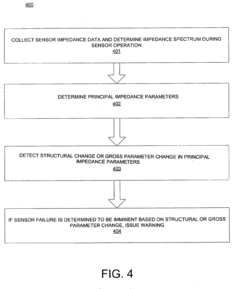

Gas sensor age compensation and failure detection

PatentInactiveEP2365322A1

Innovation

- A method and system for age compensation using impedance spectrum analysis to determine principal parameters, constructing an age compensation model, and applying it to the sensor output to automatically correct for drift and detect impending failure.

Gas sensor calibration device and its calibration method

PatentActiveZA202300853A

Innovation

- Precise control of valve opening time in a constant volume gas distribution device to achieve different gas concentrations for calibration.

- Use of gas chromatograph or pre-calibrated sensors to determine real gas concentrations, improving overall calibration accuracy.

- Implementation of curve fitting between sensor detection values at multiple concentrations and real concentration values to address sensor nonlinearity issues.

Regulatory Framework for Gas Sensor Calibration

The regulatory landscape for electrochemical gas sensor calibration is governed by a complex framework of international standards, national regulations, and industry-specific guidelines. At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) have established foundational standards that define calibration methodologies, traceability requirements, and performance criteria for gas sensors across various applications.

In the United States, the National Institute of Standards and Technology (NIST) provides reference materials and calibration services that serve as the basis for gas sensor calibration. The Occupational Safety and Health Administration (OSHA) enforces specific calibration requirements for workplace gas detection systems, particularly for toxic gases and oxygen monitoring. Similarly, the Environmental Protection Agency (EPA) mandates calibration protocols for environmental monitoring applications through methods such as EPA Method TO-15 for volatile organic compounds.

European regulations are primarily governed by the European Committee for Standardization (CEN), which has developed standards like EN 45544 for direct-reading toxic gas detectors. The ATEX Directive further regulates equipment used in potentially explosive atmospheres, imposing additional calibration requirements for sensors deployed in hazardous environments. The Measuring Instruments Directive (MID) establishes legal metrology requirements that impact gas sensor calibration for commercial transactions.

In Asia, countries like Japan and China have established their own regulatory frameworks. Japan's Industrial Safety and Health Law sets forth calibration requirements for workplace monitoring, while China's national standards (GB standards) define calibration procedures for various industrial applications. The global harmonization of these standards remains an ongoing challenge for manufacturers operating across multiple jurisdictions.

Industry-specific regulations add another layer of complexity. For instance, the semiconductor industry follows SEMI guidelines, while pharmaceutical manufacturing adheres to Good Manufacturing Practice (GMP) regulations that include specific calibration requirements. The oil and gas sector typically follows standards set by organizations like the American Petroleum Institute (API).

Recent regulatory trends indicate a move toward more frequent calibration verification, particularly for critical safety applications. There is also increasing emphasis on digital calibration certificates and remote calibration capabilities, reflecting the industry's shift toward IoT-enabled sensor networks. Regulatory bodies are beginning to acknowledge these technological advances, though formal standards for digital calibration processes are still evolving.

In the United States, the National Institute of Standards and Technology (NIST) provides reference materials and calibration services that serve as the basis for gas sensor calibration. The Occupational Safety and Health Administration (OSHA) enforces specific calibration requirements for workplace gas detection systems, particularly for toxic gases and oxygen monitoring. Similarly, the Environmental Protection Agency (EPA) mandates calibration protocols for environmental monitoring applications through methods such as EPA Method TO-15 for volatile organic compounds.

European regulations are primarily governed by the European Committee for Standardization (CEN), which has developed standards like EN 45544 for direct-reading toxic gas detectors. The ATEX Directive further regulates equipment used in potentially explosive atmospheres, imposing additional calibration requirements for sensors deployed in hazardous environments. The Measuring Instruments Directive (MID) establishes legal metrology requirements that impact gas sensor calibration for commercial transactions.

In Asia, countries like Japan and China have established their own regulatory frameworks. Japan's Industrial Safety and Health Law sets forth calibration requirements for workplace monitoring, while China's national standards (GB standards) define calibration procedures for various industrial applications. The global harmonization of these standards remains an ongoing challenge for manufacturers operating across multiple jurisdictions.

Industry-specific regulations add another layer of complexity. For instance, the semiconductor industry follows SEMI guidelines, while pharmaceutical manufacturing adheres to Good Manufacturing Practice (GMP) regulations that include specific calibration requirements. The oil and gas sector typically follows standards set by organizations like the American Petroleum Institute (API).

Recent regulatory trends indicate a move toward more frequent calibration verification, particularly for critical safety applications. There is also increasing emphasis on digital calibration certificates and remote calibration capabilities, reflecting the industry's shift toward IoT-enabled sensor networks. Regulatory bodies are beginning to acknowledge these technological advances, though formal standards for digital calibration processes are still evolving.

Cross-Industry Applications and Implementation Challenges

Electrochemical gas sensors have demonstrated remarkable versatility across multiple industries, though their implementation faces distinct challenges in each sector. In healthcare, these sensors are increasingly deployed for breath analysis to detect biomarkers for conditions like diabetes and lung cancer. However, the implementation requires addressing the complex matrix of human breath and establishing reliable calibration protocols that account for physiological variations among patients. The sensitivity requirements in medical applications often exceed those in industrial settings, necessitating more stringent calibration standards.

The automotive industry has embraced electrochemical sensors for emissions monitoring and cabin air quality assessment. Implementation challenges include developing calibration standards that remain accurate under extreme temperature fluctuations and vibration conditions typical in vehicles. Additionally, sensors must maintain calibration integrity despite exposure to multiple interfering gases simultaneously, a scenario rarely addressed in current standardization efforts.

Environmental monitoring networks represent another significant application domain, where sensors are deployed in urban, rural, and remote locations. The implementation challenge lies in developing field-calibration methodologies that can be performed without transporting sensors to specialized laboratories. Weather conditions, particularly humidity variations, significantly impact sensor performance, requiring calibration standards that incorporate environmental compensation algorithms.

In industrial safety applications, electrochemical sensors serve as critical components in toxic gas detection systems. The implementation challenge centers on developing calibration standards that account for cross-sensitivity with other industrial gases and maintaining accuracy during rapid concentration changes. Many industrial environments also contain particulate matter that can contaminate sensor membranes, gradually altering calibration parameters over time.

Smart city initiatives increasingly incorporate electrochemical sensor networks for air quality monitoring, creating unique challenges in maintaining calibration across distributed sensor arrays. The cost constraints of large-scale deployments often preclude frequent manual calibration, necessitating the development of remote calibration standards and self-diagnostic capabilities. Additionally, the integration of these sensors with IoT platforms requires standardized digital calibration certificates that can be automatically processed and updated.

Agriculture and food storage facilities utilize electrochemical sensors for monitoring ethylene, ammonia, and other gases critical to crop ripening and preservation. The implementation challenge involves developing calibration standards suitable for the high-humidity environments typical in these applications, while accounting for the presence of biological volatiles that may interfere with sensor performance.

The automotive industry has embraced electrochemical sensors for emissions monitoring and cabin air quality assessment. Implementation challenges include developing calibration standards that remain accurate under extreme temperature fluctuations and vibration conditions typical in vehicles. Additionally, sensors must maintain calibration integrity despite exposure to multiple interfering gases simultaneously, a scenario rarely addressed in current standardization efforts.

Environmental monitoring networks represent another significant application domain, where sensors are deployed in urban, rural, and remote locations. The implementation challenge lies in developing field-calibration methodologies that can be performed without transporting sensors to specialized laboratories. Weather conditions, particularly humidity variations, significantly impact sensor performance, requiring calibration standards that incorporate environmental compensation algorithms.

In industrial safety applications, electrochemical sensors serve as critical components in toxic gas detection systems. The implementation challenge centers on developing calibration standards that account for cross-sensitivity with other industrial gases and maintaining accuracy during rapid concentration changes. Many industrial environments also contain particulate matter that can contaminate sensor membranes, gradually altering calibration parameters over time.

Smart city initiatives increasingly incorporate electrochemical sensor networks for air quality monitoring, creating unique challenges in maintaining calibration across distributed sensor arrays. The cost constraints of large-scale deployments often preclude frequent manual calibration, necessitating the development of remote calibration standards and self-diagnostic capabilities. Additionally, the integration of these sensors with IoT platforms requires standardized digital calibration certificates that can be automatically processed and updated.

Agriculture and food storage facilities utilize electrochemical sensors for monitoring ethylene, ammonia, and other gases critical to crop ripening and preservation. The implementation challenge involves developing calibration standards suitable for the high-humidity environments typical in these applications, while accounting for the presence of biological volatiles that may interfere with sensor performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!