Electrochemical Gas Sensor For Fire Detection: Performance Metrics

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Gas Sensor Evolution and Objectives

Electrochemical gas sensors have evolved significantly since their inception in the early 1950s, initially developed for industrial safety applications to detect toxic gases in mining and manufacturing environments. The fundamental operating principle, based on the electrochemical oxidation or reduction of target gases at an electrode surface, has remained consistent while the technology has undergone substantial refinements in sensitivity, selectivity, and reliability.

The 1970s marked a pivotal era with the introduction of amperometric sensors featuring three-electrode configurations, which significantly improved measurement stability and reduced interference. By the 1990s, miniaturization efforts led to the development of compact sensors suitable for portable devices, expanding their application scope beyond industrial settings to residential and commercial environments.

Fire detection represents a critical application domain for electrochemical gas sensors, as they can identify combustion byproducts before visible smoke or flames appear. Early detection of gases such as carbon monoxide (CO), hydrogen (H2), and various volatile organic compounds (VOCs) provides crucial additional response time in fire scenarios, potentially saving lives and reducing property damage.

Current technological objectives for electrochemical gas sensors in fire detection focus on enhancing several key performance metrics. Sensitivity improvements aim to detect gas concentrations in the sub-ppm range, while response time optimization targets detection within seconds of gas presence. Cross-sensitivity reduction seeks to minimize false alarms triggered by non-hazardous gases with similar electrochemical properties.

Longevity represents another critical objective, with research directed toward extending sensor operational life beyond the current 2-5 year average to match the 10-year lifespan of standard smoke detectors. Power consumption reduction remains essential for battery-operated devices, with goals to achieve multi-year operation without battery replacement.

Integration capabilities with IoT systems and smart building infrastructure constitute an emerging priority, enabling remote monitoring, predictive maintenance, and coordinated emergency response. Additionally, environmental resilience development aims to maintain sensor accuracy across varying temperature, humidity, and pressure conditions typical in diverse building environments.

The convergence of these technological objectives with advanced materials science, nanotechnology, and machine learning algorithms is expected to yield next-generation electrochemical gas sensors with unprecedented performance in fire detection applications, ultimately transforming early warning systems and fire safety protocols across residential, commercial, and industrial sectors.

The 1970s marked a pivotal era with the introduction of amperometric sensors featuring three-electrode configurations, which significantly improved measurement stability and reduced interference. By the 1990s, miniaturization efforts led to the development of compact sensors suitable for portable devices, expanding their application scope beyond industrial settings to residential and commercial environments.

Fire detection represents a critical application domain for electrochemical gas sensors, as they can identify combustion byproducts before visible smoke or flames appear. Early detection of gases such as carbon monoxide (CO), hydrogen (H2), and various volatile organic compounds (VOCs) provides crucial additional response time in fire scenarios, potentially saving lives and reducing property damage.

Current technological objectives for electrochemical gas sensors in fire detection focus on enhancing several key performance metrics. Sensitivity improvements aim to detect gas concentrations in the sub-ppm range, while response time optimization targets detection within seconds of gas presence. Cross-sensitivity reduction seeks to minimize false alarms triggered by non-hazardous gases with similar electrochemical properties.

Longevity represents another critical objective, with research directed toward extending sensor operational life beyond the current 2-5 year average to match the 10-year lifespan of standard smoke detectors. Power consumption reduction remains essential for battery-operated devices, with goals to achieve multi-year operation without battery replacement.

Integration capabilities with IoT systems and smart building infrastructure constitute an emerging priority, enabling remote monitoring, predictive maintenance, and coordinated emergency response. Additionally, environmental resilience development aims to maintain sensor accuracy across varying temperature, humidity, and pressure conditions typical in diverse building environments.

The convergence of these technological objectives with advanced materials science, nanotechnology, and machine learning algorithms is expected to yield next-generation electrochemical gas sensors with unprecedented performance in fire detection applications, ultimately transforming early warning systems and fire safety protocols across residential, commercial, and industrial sectors.

Market Analysis for Fire Detection Gas Sensors

The global fire detection market is experiencing robust growth, with electrochemical gas sensors emerging as a critical component in modern fire detection systems. The market size for fire detection equipment reached approximately $62 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 7.8% through 2030. Electrochemical gas sensors specifically account for roughly 24% of this market, representing a significant segment with increasing adoption rates.

Demand for advanced fire detection solutions is being driven by several key factors. Stringent safety regulations across industries, particularly in manufacturing, healthcare, and commercial buildings, have mandated the installation of sophisticated fire detection systems. The insurance industry has also begun offering premium discounts for properties equipped with advanced detection technologies, further incentivizing adoption.

Regional analysis reveals varying market penetration rates. North America and Europe currently dominate the market with approximately 60% combined market share, attributed to their strict regulatory frameworks and higher awareness of fire safety. However, the Asia-Pacific region is witnessing the fastest growth at 9.2% annually, driven by rapid industrialization, urbanization, and increasing safety consciousness in countries like China and India.

Industry-specific demand patterns show notable differences. The oil and gas sector represents the largest vertical market for electrochemical gas sensors due to the high risk of combustible gases, followed by manufacturing and healthcare facilities. The residential sector, while currently underrepresented, shows promising growth potential as smart home technologies become more mainstream.

Customer requirements are evolving toward multi-gas detection capabilities, with particular emphasis on carbon monoxide, hydrogen, and volatile organic compounds (VOCs) detection alongside traditional smoke sensing. Market research indicates that 78% of commercial customers now prefer integrated systems that can detect multiple threat indicators simultaneously.

Price sensitivity varies significantly by market segment. While industrial customers prioritize performance and reliability over cost, the residential and small business segments remain highly price-sensitive. The average price point for commercial-grade electrochemical gas sensors has decreased by approximately 15% over the past five years, making these technologies increasingly accessible to broader market segments.

Competition in this space is intensifying, with over 200 manufacturers globally. Market consolidation is occurring through strategic acquisitions, as larger fire safety companies seek to incorporate advanced gas sensing technologies into their comprehensive offerings.

Demand for advanced fire detection solutions is being driven by several key factors. Stringent safety regulations across industries, particularly in manufacturing, healthcare, and commercial buildings, have mandated the installation of sophisticated fire detection systems. The insurance industry has also begun offering premium discounts for properties equipped with advanced detection technologies, further incentivizing adoption.

Regional analysis reveals varying market penetration rates. North America and Europe currently dominate the market with approximately 60% combined market share, attributed to their strict regulatory frameworks and higher awareness of fire safety. However, the Asia-Pacific region is witnessing the fastest growth at 9.2% annually, driven by rapid industrialization, urbanization, and increasing safety consciousness in countries like China and India.

Industry-specific demand patterns show notable differences. The oil and gas sector represents the largest vertical market for electrochemical gas sensors due to the high risk of combustible gases, followed by manufacturing and healthcare facilities. The residential sector, while currently underrepresented, shows promising growth potential as smart home technologies become more mainstream.

Customer requirements are evolving toward multi-gas detection capabilities, with particular emphasis on carbon monoxide, hydrogen, and volatile organic compounds (VOCs) detection alongside traditional smoke sensing. Market research indicates that 78% of commercial customers now prefer integrated systems that can detect multiple threat indicators simultaneously.

Price sensitivity varies significantly by market segment. While industrial customers prioritize performance and reliability over cost, the residential and small business segments remain highly price-sensitive. The average price point for commercial-grade electrochemical gas sensors has decreased by approximately 15% over the past five years, making these technologies increasingly accessible to broader market segments.

Competition in this space is intensifying, with over 200 manufacturers globally. Market consolidation is occurring through strategic acquisitions, as larger fire safety companies seek to incorporate advanced gas sensing technologies into their comprehensive offerings.

Technical Challenges in Electrochemical Gas Sensing

Despite significant advancements in electrochemical gas sensor technology for fire detection, several technical challenges persist that limit their optimal performance and widespread adoption. Sensor selectivity remains a primary concern, as these devices often struggle to differentiate between target gases and interfering compounds with similar electrochemical properties. This cross-sensitivity issue is particularly problematic in complex fire environments where multiple gases are present simultaneously, potentially leading to false alarms or missed detections.

Sensor stability presents another significant challenge, with many electrochemical sensors exhibiting performance drift over time due to electrode poisoning, electrolyte evaporation, or reference electrode instability. These degradation mechanisms accelerate under the extreme temperature and humidity conditions typical in fire scenarios, compromising long-term reliability and necessitating frequent recalibration or replacement.

Response time limitations further constrain the effectiveness of electrochemical sensors in fire detection applications. Current technologies typically exhibit response times ranging from 30 seconds to several minutes, which may be inadequate for early fire detection where rapid response is critical. This delay is often attributed to gas diffusion barriers and the kinetics of electrochemical reactions at the sensing interface.

Power consumption requirements pose challenges for battery-operated or remote sensing applications. While electrochemical sensors generally consume less power than optical or semiconductor alternatives, the need for signal conditioning circuitry, temperature compensation, and data processing increases the overall energy demand, limiting deployment options in resource-constrained environments.

Miniaturization efforts face obstacles related to maintaining sensitivity and stability while reducing sensor dimensions. As sensor size decreases, the active electrode area diminishes, resulting in lower signal-to-noise ratios and decreased sensitivity. Additionally, smaller electrolyte volumes are more susceptible to evaporation and contamination effects, potentially shortening sensor lifespan.

Environmental robustness remains problematic, with many electrochemical sensors showing performance variations under fluctuating temperature, humidity, and pressure conditions. These environmental factors affect reaction kinetics, gas solubility in the electrolyte, and diffusion rates, complicating the interpretation of sensor signals in real-world fire detection scenarios.

Manufacturing consistency and cost-effectiveness present additional challenges, particularly for sensors requiring precious metal catalysts or specialized membranes. Variations in electrode deposition, electrolyte composition, and membrane characteristics can lead to sensor-to-sensor performance differences, necessitating individual calibration and increasing production costs.

Sensor stability presents another significant challenge, with many electrochemical sensors exhibiting performance drift over time due to electrode poisoning, electrolyte evaporation, or reference electrode instability. These degradation mechanisms accelerate under the extreme temperature and humidity conditions typical in fire scenarios, compromising long-term reliability and necessitating frequent recalibration or replacement.

Response time limitations further constrain the effectiveness of electrochemical sensors in fire detection applications. Current technologies typically exhibit response times ranging from 30 seconds to several minutes, which may be inadequate for early fire detection where rapid response is critical. This delay is often attributed to gas diffusion barriers and the kinetics of electrochemical reactions at the sensing interface.

Power consumption requirements pose challenges for battery-operated or remote sensing applications. While electrochemical sensors generally consume less power than optical or semiconductor alternatives, the need for signal conditioning circuitry, temperature compensation, and data processing increases the overall energy demand, limiting deployment options in resource-constrained environments.

Miniaturization efforts face obstacles related to maintaining sensitivity and stability while reducing sensor dimensions. As sensor size decreases, the active electrode area diminishes, resulting in lower signal-to-noise ratios and decreased sensitivity. Additionally, smaller electrolyte volumes are more susceptible to evaporation and contamination effects, potentially shortening sensor lifespan.

Environmental robustness remains problematic, with many electrochemical sensors showing performance variations under fluctuating temperature, humidity, and pressure conditions. These environmental factors affect reaction kinetics, gas solubility in the electrolyte, and diffusion rates, complicating the interpretation of sensor signals in real-world fire detection scenarios.

Manufacturing consistency and cost-effectiveness present additional challenges, particularly for sensors requiring precious metal catalysts or specialized membranes. Variations in electrode deposition, electrolyte composition, and membrane characteristics can lead to sensor-to-sensor performance differences, necessitating individual calibration and increasing production costs.

Current Electrochemical Sensor Performance Metrics

01 Sensitivity and detection limits in electrochemical gas sensors

Electrochemical gas sensors are evaluated based on their sensitivity to target gases and their detection limits. These metrics determine the minimum concentration of gas that can be reliably detected and the sensor's ability to respond to small changes in gas concentration. Factors affecting sensitivity include electrode material, electrolyte composition, and operating temperature. Advanced sensor designs incorporate novel materials and optimized geometries to achieve lower detection limits and higher sensitivity across a wide range of gas concentrations.- Sensitivity and detection limits in electrochemical gas sensors: Electrochemical gas sensors can be evaluated based on their sensitivity to target gases and their detection limits. These metrics determine the minimum concentration of gas that can be reliably detected and the sensor's ability to respond to small changes in gas concentration. Performance metrics in this category include limit of detection (LOD), sensitivity slope, and signal-to-noise ratio. Optimizing these parameters is crucial for applications requiring detection of trace amounts of gases or precise concentration measurements.

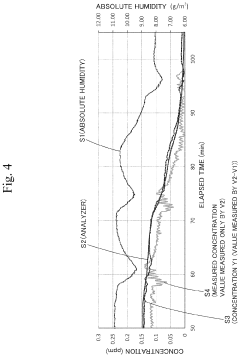

- Response time and recovery characteristics: The temporal performance of electrochemical gas sensors is characterized by metrics such as response time (T90), recovery time, and drift rate. These metrics measure how quickly a sensor responds to the presence of a target gas, how rapidly it returns to baseline after gas removal, and how stable the signal remains over time. Fast response and recovery times are essential for real-time monitoring applications, while minimal drift ensures reliable long-term operation without frequent recalibration.

- Cross-sensitivity and selectivity evaluation: Selectivity metrics quantify an electrochemical gas sensor's ability to distinguish the target gas from interfering substances. Cross-sensitivity factors measure the sensor's response to non-target gases relative to the target gas. Selectivity coefficients and interference rejection ratios help evaluate a sensor's performance in complex gas mixtures. These metrics are particularly important in applications where multiple gases may be present simultaneously, such as industrial environments or air quality monitoring.

- Environmental stability and robustness: Environmental performance metrics assess how sensor accuracy and reliability are maintained under varying conditions. These include temperature coefficient, humidity dependence, pressure effects, and long-term stability. Robustness metrics evaluate sensor performance under extreme conditions and include parameters such as shock resistance, vibration tolerance, and chemical resistance. These metrics are critical for sensors deployed in harsh or variable environments where maintaining accuracy despite changing conditions is essential.

- Power consumption and operational lifetime: Operational efficiency metrics for electrochemical gas sensors include power consumption, energy efficiency, battery life for portable devices, and overall operational lifetime. These metrics are particularly important for battery-powered or energy-constrained applications. The sensor's duty cycle, warm-up time, and power management capabilities also factor into these performance assessments. Optimizing these parameters enables longer deployment periods without maintenance and makes sensors suitable for remote or energy-limited applications.

02 Response time and recovery characteristics

The speed at which electrochemical gas sensors respond to the presence of target gases and return to baseline after gas removal are critical performance metrics. Fast response times are essential for safety applications where immediate detection of hazardous gases is required. Recovery characteristics determine how quickly the sensor can detect subsequent gas events. These parameters are influenced by diffusion rates, electrode porosity, and electrolyte properties. Optimization techniques include membrane modifications and signal processing algorithms to improve temporal performance.Expand Specific Solutions03 Selectivity and cross-sensitivity analysis

Selectivity refers to an electrochemical gas sensor's ability to respond specifically to the target gas while minimizing interference from other gases. Cross-sensitivity analysis evaluates how the sensor responds to potential interferents. High selectivity is achieved through specialized electrode catalysts, selective membranes, and operating temperature optimization. Advanced sensors employ multi-electrode arrays and pattern recognition algorithms to differentiate between similar gas species and compensate for cross-sensitivity effects, improving measurement accuracy in complex gas mixtures.Expand Specific Solutions04 Long-term stability and calibration requirements

The performance stability of electrochemical gas sensors over extended periods is a critical metric for industrial and environmental monitoring applications. Factors affecting long-term stability include electrode poisoning, electrolyte evaporation, and reference electrode drift. Calibration requirements determine maintenance schedules and operational costs. Advanced sensor designs incorporate self-diagnostic capabilities, drift compensation algorithms, and improved sealing techniques to extend calibration intervals and service life while maintaining measurement accuracy under varying environmental conditions.Expand Specific Solutions05 Environmental robustness and operating conditions

Electrochemical gas sensors must maintain performance across varying environmental conditions including temperature, humidity, and pressure fluctuations. Performance metrics in this category evaluate sensor accuracy and reliability under extreme conditions. Temperature compensation algorithms, humidity-resistant membranes, and pressure-equalization mechanisms are employed to minimize environmental effects. Testing protocols assess sensor performance across specified operating ranges and during rapid environmental transitions to ensure consistent measurement quality in real-world applications.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The electrochemical gas sensor market for fire detection is currently in a growth phase, with increasing adoption across commercial and residential applications. The market is projected to expand significantly due to stringent safety regulations and growing awareness of fire safety. Leading players include established industrial giants like Robert Bosch GmbH, Honeywell International, and Draeger Safety, who leverage their extensive R&D capabilities and global distribution networks. The technology maturity varies, with companies like Figaro Technology and Riken Keiki demonstrating advanced sensor technologies, while newer entrants such as Cubic Sensor & Instrument and Aeroqual are introducing innovative approaches. Academic institutions like North China Electric Power University and Case Western Reserve University are contributing to technological advancements through research partnerships with industry players.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced electrochemical gas sensors for fire detection that utilize multi-gas sensing arrays combined with intelligent signal processing algorithms. Their technology employs amperometric and potentiometric sensing principles with noble metal electrodes and specialized electrolytes to detect combustion products like CO, H2, and NOx at sub-ppm levels. Bosch's sensors feature temperature compensation mechanisms and integrated humidity correction to maintain accuracy across varying environmental conditions. Their latest generation incorporates MEMS fabrication techniques to achieve miniaturization while maintaining sensitivity, with response times under 30 seconds for early fire detection. The sensors employ proprietary electrode catalyst formulations that enhance selectivity and reduce cross-sensitivity to common interferents. Bosch's approach integrates these sensors into comprehensive fire detection systems with self-diagnostic capabilities and predictive maintenance algorithms to ensure reliable operation throughout the sensor lifecycle.

Strengths: Superior manufacturing consistency and quality control; extensive integration capabilities with building management systems; strong resistance to poisoning agents. Weaknesses: Higher cost compared to semiconductor sensors; requires periodic calibration; limited effectiveness in extremely low humidity environments.

Draeger Safety, Inc.

Technical Solution: Draeger has pioneered electrochemical gas sensor technology for fire detection with their DrägerSensor® series specifically designed for early fire detection applications. Their sensors utilize a three-electrode design with a working electrode, counter electrode, and reference electrode immersed in an electrolyte solution optimized for detecting combustion gases. The technology employs proprietary catalyst formulations on the working electrode that enable selective detection of gases like CO, H2S, and NO2 at concentrations below 1 ppm. Draeger's sensors feature temperature-compensated measurement circuits and pressure-equalization membranes that maintain accuracy across varying environmental conditions. Their XS series incorporates digital signal processing directly at the sensor level to filter noise and improve detection reliability. Draeger's sensors are characterized by long operational lifespans (3-5 years) and maintain calibration stability through proprietary electrolyte formulations that resist evaporation and contamination. The sensors integrate with Draeger's comprehensive fire detection systems that employ multi-criteria alarm algorithms to minimize false alarms.

Strengths: Exceptional long-term stability; highly selective gas detection with minimal cross-sensitivity; comprehensive temperature and environmental compensation. Weaknesses: Higher power consumption compared to some competing technologies; performance degradation in extremely dry conditions; requires more frequent replacement in harsh industrial environments.

Key Patents and Research in Gas Sensor Technology

Electrochemical gas sensor, ozone generator, and humidifier

PatentInactiveUS20240102957A1

Innovation

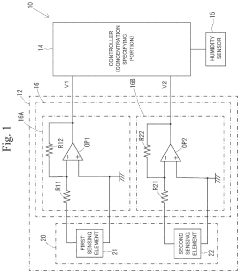

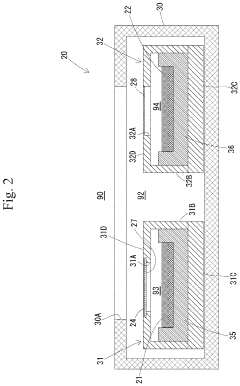

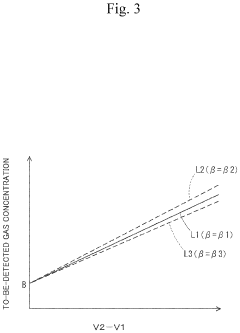

- An electrochemical gas sensor design incorporating a first sensing element and a second sensing element, along with a moisture permeable film, which allows water vapor permeation while preventing the target gas from entering, enabling the cancellation of water vapor influence and accurate detection of gas concentrations as low as 0 or more and 1 ppm or less.

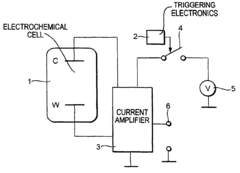

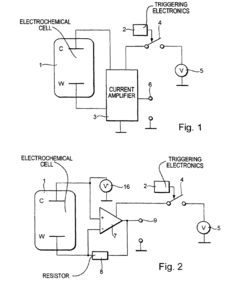

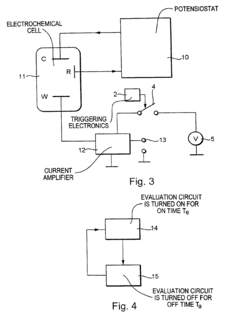

Method for the operation of an analytical circuit for an electromechanical cell

PatentInactiveUS7276912B2

Innovation

- Operating the evaluation circuit in a pulsed manner, where the OFF time is longer than the ON time, allowing for reduced power consumption and increased gas sensitivity by utilizing a high-consumption current amplifier and maintaining charge equilibrium between ON and OFF periods.

Reliability and Durability Assessment Methods

Reliability and durability assessment of electrochemical gas sensors for fire detection requires systematic methodologies to ensure consistent performance throughout their operational lifetime. The primary assessment framework involves accelerated aging tests where sensors are exposed to elevated temperatures, humidity levels, and gas concentrations exceeding normal operating conditions. These tests typically follow standardized protocols such as ASTM E595 for outgassing characteristics and MIL-STD-810 for environmental stress screening.

Long-term stability testing constitutes another critical evaluation method, involving continuous operation of sensors over extended periods (typically 1-3 years) with regular calibration checks to monitor sensitivity drift. Data collected from these tests enables the calculation of Mean Time Between Failures (MTBF) and Mean Time To Failure (MTTF) metrics, essential for reliability engineering and maintenance scheduling in fire detection systems.

Environmental resistance testing evaluates sensor performance under various challenging conditions including temperature cycling (-40°C to +85°C), humidity extremes (10-95% RH), and exposure to common interfering gases. Cross-sensitivity analysis identifies potential false alarm triggers by exposing sensors to non-target gases such as cleaning agents, cooking fumes, and industrial chemicals that may be present in the monitored environment.

Vibration and mechanical shock testing follows standards like IEC 60068 to ensure sensors maintain calibration and functionality when subjected to physical stresses. This is particularly important for fire detection systems in industrial settings, transportation applications, or areas prone to seismic activity.

Chemical poisoning resistance assessment examines sensor performance after exposure to silicon compounds, sulfur-containing gases, and other contaminants known to degrade electrochemical cells. Recovery time and sensitivity retention post-exposure provide valuable insights into sensor resilience against common poisoning agents.

Field validation complements laboratory testing by deploying sensors in actual operating environments with continuous monitoring systems. This approach captures real-world performance data including response to seasonal variations, building material outgassing effects, and maintenance requirements under practical conditions.

Statistical reliability modeling using Weibull analysis and Monte Carlo simulations helps predict failure rates and establish confidence intervals for sensor lifespans. These probabilistic models inform warranty periods, replacement schedules, and total cost of ownership calculations for end users implementing electrochemical gas sensors in fire detection systems.

Long-term stability testing constitutes another critical evaluation method, involving continuous operation of sensors over extended periods (typically 1-3 years) with regular calibration checks to monitor sensitivity drift. Data collected from these tests enables the calculation of Mean Time Between Failures (MTBF) and Mean Time To Failure (MTTF) metrics, essential for reliability engineering and maintenance scheduling in fire detection systems.

Environmental resistance testing evaluates sensor performance under various challenging conditions including temperature cycling (-40°C to +85°C), humidity extremes (10-95% RH), and exposure to common interfering gases. Cross-sensitivity analysis identifies potential false alarm triggers by exposing sensors to non-target gases such as cleaning agents, cooking fumes, and industrial chemicals that may be present in the monitored environment.

Vibration and mechanical shock testing follows standards like IEC 60068 to ensure sensors maintain calibration and functionality when subjected to physical stresses. This is particularly important for fire detection systems in industrial settings, transportation applications, or areas prone to seismic activity.

Chemical poisoning resistance assessment examines sensor performance after exposure to silicon compounds, sulfur-containing gases, and other contaminants known to degrade electrochemical cells. Recovery time and sensitivity retention post-exposure provide valuable insights into sensor resilience against common poisoning agents.

Field validation complements laboratory testing by deploying sensors in actual operating environments with continuous monitoring systems. This approach captures real-world performance data including response to seasonal variations, building material outgassing effects, and maintenance requirements under practical conditions.

Statistical reliability modeling using Weibull analysis and Monte Carlo simulations helps predict failure rates and establish confidence intervals for sensor lifespans. These probabilistic models inform warranty periods, replacement schedules, and total cost of ownership calculations for end users implementing electrochemical gas sensors in fire detection systems.

Environmental Impact and Sustainability Considerations

The environmental impact of electrochemical gas sensors for fire detection extends beyond their primary safety function, encompassing their entire lifecycle from production to disposal. Manufacturing processes for these sensors involve the use of precious metals like platinum, gold, and silver as catalysts and electrodes, raising concerns about resource depletion and mining impacts. However, compared to traditional fire detection methods, electrochemical sensors require significantly smaller quantities of these materials, resulting in a reduced environmental footprint.

Energy consumption represents another critical environmental consideration. Modern electrochemical gas sensors are designed with low power requirements, typically operating in the microwatt to milliwatt range during standby mode. This energy efficiency makes them suitable for battery-powered and energy-harvesting applications, reducing the need for frequent battery replacements and associated waste. When integrated into smart building systems, these sensors can contribute to overall energy optimization by providing data for more efficient HVAC and ventilation control.

The disposal and end-of-life management of electrochemical sensors present notable environmental challenges. These devices contain electronic components, small amounts of potentially hazardous chemicals, and heavy metals that require proper handling. Implementing effective recycling programs for these sensors is essential to recover valuable materials and prevent environmental contamination. Several manufacturers have begun developing take-back programs and designing sensors with easier disassembly to facilitate recycling.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of electronic devices, including gas sensors. The European Union's Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives have prompted manufacturers to reduce or eliminate hazardous materials in sensor design. Similarly, initiatives like the Electronic Product Environmental Assessment Tool (EPEAT) encourage the development of more environmentally friendly electronic products, including detection systems.

Looking toward future developments, research is focusing on creating more sustainable electrochemical gas sensors. Innovations include bio-based electrolytes, reduced reliance on rare earth elements, and designs that facilitate easier recycling. Some manufacturers are exploring biodegradable components for non-critical parts of the sensors, potentially reducing landfill impact. Additionally, extending sensor lifespan through improved durability and self-calibration features represents another approach to enhancing sustainability by reducing replacement frequency and associated resource consumption.

Energy consumption represents another critical environmental consideration. Modern electrochemical gas sensors are designed with low power requirements, typically operating in the microwatt to milliwatt range during standby mode. This energy efficiency makes them suitable for battery-powered and energy-harvesting applications, reducing the need for frequent battery replacements and associated waste. When integrated into smart building systems, these sensors can contribute to overall energy optimization by providing data for more efficient HVAC and ventilation control.

The disposal and end-of-life management of electrochemical sensors present notable environmental challenges. These devices contain electronic components, small amounts of potentially hazardous chemicals, and heavy metals that require proper handling. Implementing effective recycling programs for these sensors is essential to recover valuable materials and prevent environmental contamination. Several manufacturers have begun developing take-back programs and designing sensors with easier disassembly to facilitate recycling.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of electronic devices, including gas sensors. The European Union's Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives have prompted manufacturers to reduce or eliminate hazardous materials in sensor design. Similarly, initiatives like the Electronic Product Environmental Assessment Tool (EPEAT) encourage the development of more environmentally friendly electronic products, including detection systems.

Looking toward future developments, research is focusing on creating more sustainable electrochemical gas sensors. Innovations include bio-based electrolytes, reduced reliance on rare earth elements, and designs that facilitate easier recycling. Some manufacturers are exploring biodegradable components for non-critical parts of the sensors, potentially reducing landfill impact. Additionally, extending sensor lifespan through improved durability and self-calibration features represents another approach to enhancing sustainability by reducing replacement frequency and associated resource consumption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!