Miniaturized Potentiostat Designs For Portable Gas Monitors

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Miniaturized Potentiostat Technology Background and Objectives

Potentiostats have evolved significantly since their inception in the early 20th century as laboratory instruments for electrochemical analysis. Initially bulky and confined to specialized laboratories, these devices have undergone remarkable miniaturization over the past few decades, driven by advances in semiconductor technology, microelectronics, and integrated circuit design. This evolution has enabled the transition from bench-top instruments to portable, field-deployable devices capable of real-time gas monitoring in various environments.

The miniaturization trajectory of potentiostats has been accelerated by the growing demand for portable gas monitoring solutions across multiple sectors including industrial safety, environmental monitoring, healthcare, and homeland security. This demand stems from increasing regulatory requirements for workplace safety, growing awareness of air quality impacts on public health, and the need for rapid detection of hazardous gases in emergency response scenarios.

Traditional potentiostat designs typically incorporate high-precision analog components, requiring significant power and space, which limited their portability. The technological breakthrough came with the integration of analog and digital circuits on single chips, allowing for significant size reduction while maintaining or even improving measurement precision. Modern miniaturized potentiostats leverage advanced CMOS technology, enabling the integration of signal processing, data conversion, and control functions into compact form factors.

The primary technical objective in miniaturized potentiostat development is achieving an optimal balance between size reduction and analytical performance. This involves maintaining high sensitivity, selectivity, and stability while reducing power consumption and physical dimensions. Current research focuses on pushing detection limits below parts-per-billion levels while ensuring reliable operation in challenging field conditions with minimal power requirements.

Another critical objective is enhancing the versatility of these devices to detect multiple gas species simultaneously. This multi-gas detection capability requires sophisticated electrode designs, advanced signal processing algorithms, and innovative sensor integration approaches. The goal is to develop platforms that can be easily adapted to different target gases through simple sensor or software modifications.

Connectivity represents another key development focus, with modern miniaturized potentiostats increasingly incorporating wireless communication capabilities (Bluetooth, WiFi, LoRaWAN) to enable real-time data transmission to centralized monitoring systems or cloud platforms. This connectivity facilitates immediate alert generation and data analytics for predictive maintenance and trend analysis.

The ultimate technological vision is to develop ultra-compact, energy-efficient potentiostats that can be integrated into wearable devices, distributed sensor networks, or even smartphone accessories, democratizing access to sophisticated gas monitoring capabilities. This would represent a paradigm shift from centralized monitoring to ubiquitous, continuous environmental sensing with significant implications for public health, industrial safety, and environmental protection.

The miniaturization trajectory of potentiostats has been accelerated by the growing demand for portable gas monitoring solutions across multiple sectors including industrial safety, environmental monitoring, healthcare, and homeland security. This demand stems from increasing regulatory requirements for workplace safety, growing awareness of air quality impacts on public health, and the need for rapid detection of hazardous gases in emergency response scenarios.

Traditional potentiostat designs typically incorporate high-precision analog components, requiring significant power and space, which limited their portability. The technological breakthrough came with the integration of analog and digital circuits on single chips, allowing for significant size reduction while maintaining or even improving measurement precision. Modern miniaturized potentiostats leverage advanced CMOS technology, enabling the integration of signal processing, data conversion, and control functions into compact form factors.

The primary technical objective in miniaturized potentiostat development is achieving an optimal balance between size reduction and analytical performance. This involves maintaining high sensitivity, selectivity, and stability while reducing power consumption and physical dimensions. Current research focuses on pushing detection limits below parts-per-billion levels while ensuring reliable operation in challenging field conditions with minimal power requirements.

Another critical objective is enhancing the versatility of these devices to detect multiple gas species simultaneously. This multi-gas detection capability requires sophisticated electrode designs, advanced signal processing algorithms, and innovative sensor integration approaches. The goal is to develop platforms that can be easily adapted to different target gases through simple sensor or software modifications.

Connectivity represents another key development focus, with modern miniaturized potentiostats increasingly incorporating wireless communication capabilities (Bluetooth, WiFi, LoRaWAN) to enable real-time data transmission to centralized monitoring systems or cloud platforms. This connectivity facilitates immediate alert generation and data analytics for predictive maintenance and trend analysis.

The ultimate technological vision is to develop ultra-compact, energy-efficient potentiostats that can be integrated into wearable devices, distributed sensor networks, or even smartphone accessories, democratizing access to sophisticated gas monitoring capabilities. This would represent a paradigm shift from centralized monitoring to ubiquitous, continuous environmental sensing with significant implications for public health, industrial safety, and environmental protection.

Market Analysis for Portable Gas Detection Solutions

The global market for portable gas detection solutions has experienced significant growth in recent years, driven by increasing awareness of workplace safety, stringent regulatory requirements, and technological advancements in sensor miniaturization. The market was valued at approximately $2.3 billion in 2022 and is projected to reach $3.5 billion by 2028, representing a compound annual growth rate (CAGR) of 7.2% during the forecast period.

Industrial safety applications currently dominate the market, accounting for nearly 45% of the total market share. This segment includes oil and gas, mining, chemical manufacturing, and other heavy industries where gas leaks pose significant safety hazards. The demand for portable gas monitors in these sectors is primarily driven by occupational health and safety regulations that mandate continuous monitoring of toxic and combustible gases in workplace environments.

Environmental monitoring represents the fastest-growing segment, with an estimated CAGR of 9.5%. This growth is attributed to increasing environmental concerns, stricter emission standards, and growing investments in air quality monitoring infrastructure across urban areas. Portable gas detection solutions equipped with miniaturized potentiostats offer significant advantages in this segment due to their ability to provide real-time, on-site analysis of multiple gas species.

Geographically, North America and Europe currently lead the market, collectively accounting for approximately 60% of global revenue. However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years, driven by rapid industrialization, increasing safety awareness, and strengthening regulatory frameworks in countries like China, India, and South Korea.

The consumer segment for portable gas detection solutions remains relatively small but shows promising growth potential. This includes applications in smart homes, personal safety devices, and wearable air quality monitors. The integration of miniaturized potentiostats into consumer electronics represents an emerging opportunity, particularly as costs decrease and public awareness of indoor air quality increases.

Key customer requirements driving market demand include enhanced sensitivity and selectivity, longer battery life, reduced form factor, wireless connectivity, and data analytics capabilities. Miniaturized potentiostat designs address several of these requirements by enabling more compact, energy-efficient devices capable of detecting multiple gas species with high accuracy.

Price sensitivity varies significantly across market segments. While industrial customers prioritize reliability and certification compliance over cost, the consumer and small business segments remain highly price-sensitive, creating demand for cost-effective solutions that maintain adequate performance standards.

Industrial safety applications currently dominate the market, accounting for nearly 45% of the total market share. This segment includes oil and gas, mining, chemical manufacturing, and other heavy industries where gas leaks pose significant safety hazards. The demand for portable gas monitors in these sectors is primarily driven by occupational health and safety regulations that mandate continuous monitoring of toxic and combustible gases in workplace environments.

Environmental monitoring represents the fastest-growing segment, with an estimated CAGR of 9.5%. This growth is attributed to increasing environmental concerns, stricter emission standards, and growing investments in air quality monitoring infrastructure across urban areas. Portable gas detection solutions equipped with miniaturized potentiostats offer significant advantages in this segment due to their ability to provide real-time, on-site analysis of multiple gas species.

Geographically, North America and Europe currently lead the market, collectively accounting for approximately 60% of global revenue. However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years, driven by rapid industrialization, increasing safety awareness, and strengthening regulatory frameworks in countries like China, India, and South Korea.

The consumer segment for portable gas detection solutions remains relatively small but shows promising growth potential. This includes applications in smart homes, personal safety devices, and wearable air quality monitors. The integration of miniaturized potentiostats into consumer electronics represents an emerging opportunity, particularly as costs decrease and public awareness of indoor air quality increases.

Key customer requirements driving market demand include enhanced sensitivity and selectivity, longer battery life, reduced form factor, wireless connectivity, and data analytics capabilities. Miniaturized potentiostat designs address several of these requirements by enabling more compact, energy-efficient devices capable of detecting multiple gas species with high accuracy.

Price sensitivity varies significantly across market segments. While industrial customers prioritize reliability and certification compliance over cost, the consumer and small business segments remain highly price-sensitive, creating demand for cost-effective solutions that maintain adequate performance standards.

Current Challenges in Potentiostat Miniaturization

Despite significant advancements in potentiostat miniaturization for portable gas monitoring applications, several critical challenges continue to impede further progress in this field. The primary obstacle remains the fundamental trade-off between size reduction and analytical performance. As potentiostats are scaled down, maintaining signal integrity becomes increasingly difficult due to increased susceptibility to electronic noise and interference, which can severely compromise measurement accuracy and reliability in field conditions.

Power management represents another significant hurdle in miniaturization efforts. Portable gas monitors require efficient power utilization to enable extended operation periods without recharging or battery replacement. Current miniaturized designs struggle to balance power consumption with performance requirements, particularly when implementing advanced electrochemical techniques that demand precise control of potential and current measurements at microamp and nanovolt levels.

Thermal management challenges intensify as components are packed more densely within smaller form factors. Heat dissipation becomes problematic in compact designs, potentially affecting both electronic stability and sensor performance. This is particularly critical for gas sensing applications where temperature fluctuations can significantly impact measurement accuracy and sensor response characteristics.

Integration complexity presents substantial difficulties as designers attempt to incorporate multiple functional components—including signal processing circuits, data conversion systems, wireless communication modules, and user interfaces—into increasingly constrained spaces. The challenge extends beyond mere physical accommodation to addressing electromagnetic compatibility issues that arise from placing sensitive analog measurement circuits in close proximity to digital and RF components.

Manufacturing constraints also pose significant barriers to further miniaturization. As dimensions decrease, production tolerances become more critical, and specialized fabrication techniques may be required. This increases production costs and can limit scalability, particularly for technologies intended for widespread deployment in environmental monitoring networks or personal safety devices.

Material limitations further complicate miniaturization efforts. Conventional printed circuit board materials and traditional packaging approaches may be inadequate for ultra-compact designs, necessitating exploration of alternative substrates, interconnect technologies, and packaging solutions that can withstand environmental stressors while maintaining dimensional stability and electrical performance.

Calibration and standardization remain persistent challenges for miniaturized potentiostats. Ensuring measurement consistency across devices becomes more difficult as component variations have proportionally larger effects in smaller systems. This impacts both manufacturing quality control and field reliability, potentially undermining confidence in measurement results from portable gas monitoring systems.

Power management represents another significant hurdle in miniaturization efforts. Portable gas monitors require efficient power utilization to enable extended operation periods without recharging or battery replacement. Current miniaturized designs struggle to balance power consumption with performance requirements, particularly when implementing advanced electrochemical techniques that demand precise control of potential and current measurements at microamp and nanovolt levels.

Thermal management challenges intensify as components are packed more densely within smaller form factors. Heat dissipation becomes problematic in compact designs, potentially affecting both electronic stability and sensor performance. This is particularly critical for gas sensing applications where temperature fluctuations can significantly impact measurement accuracy and sensor response characteristics.

Integration complexity presents substantial difficulties as designers attempt to incorporate multiple functional components—including signal processing circuits, data conversion systems, wireless communication modules, and user interfaces—into increasingly constrained spaces. The challenge extends beyond mere physical accommodation to addressing electromagnetic compatibility issues that arise from placing sensitive analog measurement circuits in close proximity to digital and RF components.

Manufacturing constraints also pose significant barriers to further miniaturization. As dimensions decrease, production tolerances become more critical, and specialized fabrication techniques may be required. This increases production costs and can limit scalability, particularly for technologies intended for widespread deployment in environmental monitoring networks or personal safety devices.

Material limitations further complicate miniaturization efforts. Conventional printed circuit board materials and traditional packaging approaches may be inadequate for ultra-compact designs, necessitating exploration of alternative substrates, interconnect technologies, and packaging solutions that can withstand environmental stressors while maintaining dimensional stability and electrical performance.

Calibration and standardization remain persistent challenges for miniaturized potentiostats. Ensuring measurement consistency across devices becomes more difficult as component variations have proportionally larger effects in smaller systems. This impacts both manufacturing quality control and field reliability, potentially undermining confidence in measurement results from portable gas monitoring systems.

Current Miniaturization Approaches and Architectures

01 Miniaturized potentiostat design techniques

Various design techniques are employed to miniaturize potentiostats, including integrated circuit technology, system-on-chip approaches, and advanced electronic component integration. These techniques focus on reducing the overall size while maintaining or improving the analytical performance. Miniaturized designs often incorporate specialized circuit layouts and component arrangements to optimize space utilization while ensuring accurate electrochemical measurements.- Miniaturized potentiostat design techniques: Various design techniques are employed to miniaturize potentiostats, including integrated circuit technology, system-on-chip approaches, and advanced fabrication methods. These techniques focus on reducing the overall size while maintaining or improving performance characteristics. Miniaturized designs often incorporate specialized components and circuit layouts to achieve compact form factors suitable for portable applications.

- Portable electrochemical sensing systems: Miniaturized potentiostats enable the development of portable electrochemical sensing systems for field applications. These systems integrate the potentiostat with sensors, power management, and data processing components in a compact package. The portability allows for on-site analysis in environmental monitoring, healthcare diagnostics, and industrial quality control, eliminating the need for laboratory-based testing.

- Microfluidic integration with potentiostats: Integration of miniaturized potentiostats with microfluidic platforms creates comprehensive lab-on-chip devices. These systems combine sample handling, preparation, and electrochemical detection in a single miniaturized platform. The integration enables precise control of fluid volumes and electrochemical measurements, making them suitable for point-of-care diagnostics and automated analytical procedures.

- Low-power consumption designs: Energy-efficient designs are crucial for miniaturized potentiostats, particularly for battery-operated and wearable applications. These designs incorporate power management techniques, sleep modes, and optimized circuit architectures to reduce energy consumption. Low-power consumption enables extended operation time in field applications and integration with energy harvesting technologies for self-powered operation.

- Wireless connectivity for potentiostats: Modern miniaturized potentiostats incorporate wireless communication capabilities for data transmission and remote control. These systems use Bluetooth, Wi-Fi, or other wireless protocols to connect with smartphones, tablets, or cloud platforms. Wireless connectivity enables real-time data analysis, remote monitoring, and integration with Internet of Things (IoT) networks, expanding the functionality of miniaturized electrochemical systems.

02 Portable and wearable potentiostat applications

Miniaturized potentiostats enable portable and wearable applications for point-of-care diagnostics and continuous health monitoring. These compact devices can be integrated into wearable platforms or handheld devices, allowing for real-time electrochemical measurements outside laboratory settings. The miniaturization facilitates on-body sensing and remote monitoring capabilities while maintaining measurement accuracy and reliability.Expand Specific Solutions03 Microfluidic integration with miniaturized potentiostats

Integration of miniaturized potentiostats with microfluidic systems creates compact analytical platforms for various applications. These integrated systems combine sample handling, preparation, and electrochemical detection in a single miniaturized device. The combination enables precise control of fluid volumes and electrochemical measurements, making them suitable for applications requiring minimal sample volumes and rapid analysis times.Expand Specific Solutions04 Power management in miniaturized potentiostats

Efficient power management is crucial for miniaturized potentiostats, particularly for battery-operated portable devices. Advanced power optimization techniques include low-power circuit designs, sleep modes, and energy harvesting capabilities. These approaches extend battery life while maintaining measurement accuracy, making the devices suitable for long-term deployment in remote or wearable applications where frequent battery replacement is impractical.Expand Specific Solutions05 Electrode configurations for miniaturized potentiostats

Specialized electrode configurations are developed to complement miniaturized potentiostat systems. These include screen-printed electrodes, microfabricated electrode arrays, and nanostructured sensing surfaces. The electrode designs focus on miniaturization while enhancing sensitivity, selectivity, and stability of electrochemical measurements. Advanced manufacturing techniques enable the production of highly reproducible electrode systems suitable for integration with miniaturized potentiostats.Expand Specific Solutions

Key Industry Players in Portable Gas Monitoring

The miniaturized potentiostat market for portable gas monitors is currently in a growth phase, with increasing demand driven by workplace safety regulations and environmental monitoring needs. The market size is expanding as industries adopt more sophisticated gas detection technologies, estimated to reach several billion dollars globally by 2025. Technologically, the field shows varying maturity levels, with established players like Honeywell, Siemens, and Robert Bosch leading with comprehensive solutions, while specialized manufacturers such as Riken Keiki, Industrial Scientific, and New Cosmos Electric focus on industry-specific applications. Academic institutions including University of Electronic Science & Technology of China and Czech Technical University are advancing novel sensor designs, while emerging companies like MicroJet Technology and Yang-Ming Quantum Tech are introducing innovative miniaturization approaches, creating a competitive landscape balanced between established industrial giants and specialized innovators.

Riken Keiki Co., Ltd.

Technical Solution: Riken Keiki has developed advanced miniaturized potentiostat designs for portable gas monitors utilizing electrochemical sensing technology. Their approach integrates custom application-specific integrated circuits (ASICs) with low-power microcontrollers to achieve significant size reduction while maintaining detection accuracy. The company's proprietary three-electrode sensor system employs a working electrode, counter electrode, and reference electrode configuration that enables precise measurement of target gases at parts-per-million (ppm) levels. Their design incorporates digital signal processing algorithms that compensate for temperature and humidity variations, ensuring reliable performance across diverse environmental conditions. Riken Keiki's potentiostats feature auto-ranging capabilities that dynamically adjust measurement sensitivity based on gas concentration levels, extending the effective detection range while optimizing power consumption.

Strengths: Superior noise rejection capabilities and environmental compensation algorithms provide exceptional measurement stability in field conditions. Their miniaturized designs achieve up to 70% size reduction compared to conventional potentiostats without compromising performance. Weaknesses: Higher production costs compared to simpler designs and relatively complex calibration requirements that may necessitate specialized training for maintenance personnel.

Robert Bosch GmbH

Technical Solution: Bosch has pioneered miniaturized potentiostat technology for portable gas monitors through their innovative System-in-Package (SiP) approach. Their design integrates the potentiostat circuit, microcontroller, and wireless communication components into a single compact package measuring just 5mm × 7mm. The company's solution employs a proprietary low-noise analog front-end that achieves sub-nanoamp current resolution, enabling detection of trace gas concentrations with high precision. Bosch's potentiostats utilize adaptive power management techniques that dynamically adjust operating parameters based on measurement requirements, reducing average power consumption to below 1mW during continuous operation. Their design incorporates built-in self-test and calibration features that ensure measurement accuracy over the device lifetime while minimizing maintenance requirements. The potentiostat architecture supports multiple electrochemical measurement techniques including cyclic voltammetry, square wave voltammetry, and amperometry, providing versatility for different gas detection applications.

Strengths: Exceptional miniaturization with industry-leading power efficiency makes their solution ideal for wearable gas monitors with extended battery life. Their integrated self-diagnostic capabilities significantly reduce maintenance costs and improve reliability. Weaknesses: Higher initial component cost compared to discrete implementations and proprietary interfaces that may limit compatibility with third-party sensors.

Critical Patents and Innovations in Potentiostat Design

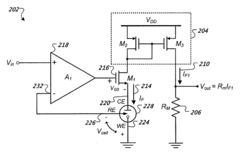

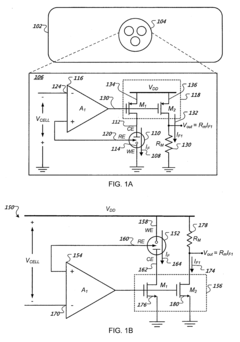

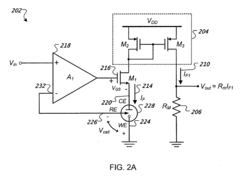

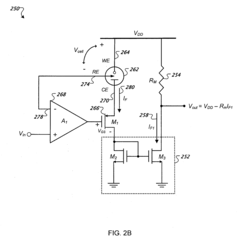

Current Mirror Potentiostat

PatentInactiveUS20100066378A1

Innovation

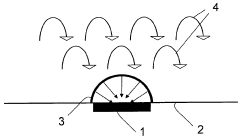

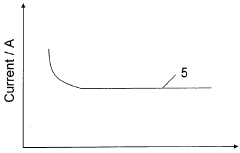

- A potentiostat circuit with a voltage controller and current copier is introduced to control the voltage difference between electrodes in a three-electrode electrochemical cell, replicating the sensor current to measure it without disturbing the original current flow, thereby maintaining precise control of the interfacial potential difference.

Miniaturised biosensor with optimized amperometric detection

PatentWO2007115694A2

Innovation

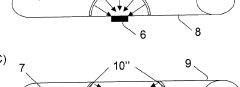

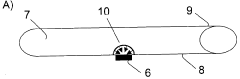

- The development of microchip-based electrochemical sensors with optimized geometry and amperometric detection methods, including precise sizing and positioning of working electrodes within microchannels to maintain a hemispherical or cylindrical diffusion regime, allowing for maximum depletion of analytes within the microstructure without establishing a linear diffusion regime along the channel length, thereby maximizing measurable currents and sensitivity.

Power Optimization Strategies for Extended Field Operation

Power optimization represents a critical challenge in the development of miniaturized potentiostats for portable gas monitors. Field operations often require extended deployment periods where access to power sources may be limited or unavailable. Addressing this constraint demands a multi-faceted approach to energy management that balances performance requirements with power consumption.

Low-power microcontrollers form the foundation of modern power optimization strategies. The selection of microcontrollers with advanced sleep modes and peripheral management capabilities allows for significant power savings during inactive periods. Texas Instruments' MSP430 series and ARM Cortex-M0+ based controllers have demonstrated particular efficacy in potentiostat applications, offering power consumption as low as 100μA/MHz during active operation and sub-1μA during deep sleep modes.

Adaptive sampling techniques further enhance power efficiency by dynamically adjusting measurement frequency based on environmental conditions or detected gas concentration changes. Rather than continuous high-frequency sampling, intelligent algorithms can implement event-triggered measurements that activate full-power operation only when necessary. Research indicates this approach can reduce average power consumption by 60-85% compared to fixed-interval sampling.

Energy harvesting technologies present promising supplementary power sources for extended field operation. Recent developments in photovoltaic, thermoelectric, and piezoelectric energy harvesting have enabled self-sustaining operation in certain environments. Notably, integration of dye-sensitized solar cells with power management circuits has achieved energy autonomy in outdoor deployments, while thermoelectric generators utilizing temperature gradients have shown viability in industrial monitoring scenarios.

Battery chemistry selection significantly impacts field longevity. Lithium thionyl chloride (Li-SOCl₂) batteries offer high energy density (up to 500 Wh/kg) and extremely low self-discharge rates (less than 1% annually), making them ideal for long-term deployments. Alternatively, lithium-ion polymer batteries paired with efficient charging circuits provide a rechargeable solution for applications where periodic maintenance is feasible.

Circuit-level optimizations, including the implementation of switched-capacitor designs and chopper-stabilized amplifiers, have demonstrated power reductions of 30-50% compared to traditional operational amplifier configurations. These approaches minimize quiescent current while maintaining measurement precision. Additionally, the strategic use of analog front-end components with ultra-low power consumption characteristics can significantly extend operational lifetimes.

Wireless communication represents a major power drain in networked systems. Implementing low-power protocols such as BLE 5.0, LoRaWAN, or Zigbee, combined with optimized transmission scheduling and data compression algorithms, can reduce communication-related power consumption by up to 75% compared to continuous transmission approaches.

Low-power microcontrollers form the foundation of modern power optimization strategies. The selection of microcontrollers with advanced sleep modes and peripheral management capabilities allows for significant power savings during inactive periods. Texas Instruments' MSP430 series and ARM Cortex-M0+ based controllers have demonstrated particular efficacy in potentiostat applications, offering power consumption as low as 100μA/MHz during active operation and sub-1μA during deep sleep modes.

Adaptive sampling techniques further enhance power efficiency by dynamically adjusting measurement frequency based on environmental conditions or detected gas concentration changes. Rather than continuous high-frequency sampling, intelligent algorithms can implement event-triggered measurements that activate full-power operation only when necessary. Research indicates this approach can reduce average power consumption by 60-85% compared to fixed-interval sampling.

Energy harvesting technologies present promising supplementary power sources for extended field operation. Recent developments in photovoltaic, thermoelectric, and piezoelectric energy harvesting have enabled self-sustaining operation in certain environments. Notably, integration of dye-sensitized solar cells with power management circuits has achieved energy autonomy in outdoor deployments, while thermoelectric generators utilizing temperature gradients have shown viability in industrial monitoring scenarios.

Battery chemistry selection significantly impacts field longevity. Lithium thionyl chloride (Li-SOCl₂) batteries offer high energy density (up to 500 Wh/kg) and extremely low self-discharge rates (less than 1% annually), making them ideal for long-term deployments. Alternatively, lithium-ion polymer batteries paired with efficient charging circuits provide a rechargeable solution for applications where periodic maintenance is feasible.

Circuit-level optimizations, including the implementation of switched-capacitor designs and chopper-stabilized amplifiers, have demonstrated power reductions of 30-50% compared to traditional operational amplifier configurations. These approaches minimize quiescent current while maintaining measurement precision. Additionally, the strategic use of analog front-end components with ultra-low power consumption characteristics can significantly extend operational lifetimes.

Wireless communication represents a major power drain in networked systems. Implementing low-power protocols such as BLE 5.0, LoRaWAN, or Zigbee, combined with optimized transmission scheduling and data compression algorithms, can reduce communication-related power consumption by up to 75% compared to continuous transmission approaches.

Environmental and Safety Standards Compliance

Compliance with environmental and safety standards is a critical consideration in the development and deployment of miniaturized potentiostats for portable gas monitors. These devices must adhere to a complex framework of international, regional, and local regulations that govern both their operational safety and environmental impact throughout their lifecycle.

The International Electrotechnical Commission (IEC) provides several standards relevant to portable electronic measurement devices, including IEC 61010 for safety requirements and IEC 60079 for equipment used in explosive atmospheres. Specifically, portable gas monitors often need to comply with ATEX directives in Europe or equivalent standards in other regions when deployed in potentially explosive environments such as mining operations or chemical processing facilities.

For environmental considerations, the Restriction of Hazardous Substances (RoHS) directive limits the use of certain hazardous materials in electronic equipment, while the Waste Electrical and Electronic Equipment (WEEE) directive establishes collection, recycling, and recovery targets. Miniaturized potentiostats must be designed with these regulations in mind, particularly regarding the selection of materials for sensors, circuit boards, and enclosures.

Performance standards such as EN 50104 for oxygen detectors and EN 45544 for toxic gas detectors establish minimum requirements for detection accuracy, response time, and reliability. These standards ensure that portable gas monitors provide consistent and reliable measurements across varying environmental conditions, which is essential for safety-critical applications.

Intrinsic safety certification (IS) represents another crucial compliance area for portable gas monitors used in hazardous locations. Standards like UL 913 in North America or IEC 60079-11 globally define requirements for equipment designed to limit electrical and thermal energy to levels that cannot ignite flammable gas-air mixtures.

Electromagnetic compatibility (EMC) standards, including IEC 61326, address the device's ability to function correctly in its intended electromagnetic environment without introducing electromagnetic disturbances. This is particularly important for miniaturized potentiostats, as their compact design can make them more susceptible to electromagnetic interference.

Ingress protection (IP) ratings defined by IEC 60529 specify the environmental protection provided by the device enclosure. Portable gas monitors typically require ratings such as IP65 or IP67 to ensure protection against dust and water ingress in field conditions.

Calibration and measurement accuracy standards, such as ISO/IEC 17025, establish requirements for testing and calibration laboratories. Manufacturers must ensure their miniaturized potentiostats can be calibrated according to these standards to maintain measurement traceability and reliability throughout the device's operational life.

The International Electrotechnical Commission (IEC) provides several standards relevant to portable electronic measurement devices, including IEC 61010 for safety requirements and IEC 60079 for equipment used in explosive atmospheres. Specifically, portable gas monitors often need to comply with ATEX directives in Europe or equivalent standards in other regions when deployed in potentially explosive environments such as mining operations or chemical processing facilities.

For environmental considerations, the Restriction of Hazardous Substances (RoHS) directive limits the use of certain hazardous materials in electronic equipment, while the Waste Electrical and Electronic Equipment (WEEE) directive establishes collection, recycling, and recovery targets. Miniaturized potentiostats must be designed with these regulations in mind, particularly regarding the selection of materials for sensors, circuit boards, and enclosures.

Performance standards such as EN 50104 for oxygen detectors and EN 45544 for toxic gas detectors establish minimum requirements for detection accuracy, response time, and reliability. These standards ensure that portable gas monitors provide consistent and reliable measurements across varying environmental conditions, which is essential for safety-critical applications.

Intrinsic safety certification (IS) represents another crucial compliance area for portable gas monitors used in hazardous locations. Standards like UL 913 in North America or IEC 60079-11 globally define requirements for equipment designed to limit electrical and thermal energy to levels that cannot ignite flammable gas-air mixtures.

Electromagnetic compatibility (EMC) standards, including IEC 61326, address the device's ability to function correctly in its intended electromagnetic environment without introducing electromagnetic disturbances. This is particularly important for miniaturized potentiostats, as their compact design can make them more susceptible to electromagnetic interference.

Ingress protection (IP) ratings defined by IEC 60529 specify the environmental protection provided by the device enclosure. Portable gas monitors typically require ratings such as IP65 or IP67 to ensure protection against dust and water ingress in field conditions.

Calibration and measurement accuracy standards, such as ISO/IEC 17025, establish requirements for testing and calibration laboratories. Manufacturers must ensure their miniaturized potentiostats can be calibrated according to these standards to maintain measurement traceability and reliability throughout the device's operational life.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!