Electrochemical Cell Design For Multi-Gas Detection

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Gas Sensing Technology Evolution and Objectives

Electrochemical gas sensing technology has evolved significantly over the past several decades, transforming from simple single-gas detection systems to sophisticated multi-gas sensing platforms. The journey began in the 1950s with the development of the first commercial electrochemical sensors for oxygen detection, primarily used in industrial safety applications. These early sensors relied on basic redox reactions at metal electrodes to generate electrical signals proportional to gas concentrations.

By the 1970s, advances in electrode materials and electrolyte formulations expanded detection capabilities to toxic gases like carbon monoxide and hydrogen sulfide. The introduction of three-electrode cell designs during this period marked a critical advancement, significantly improving sensor stability and reducing cross-sensitivity issues that plagued earlier models.

The 1990s witnessed the miniaturization of electrochemical cells, enabling their integration into portable gas monitors and expanding their application beyond industrial settings to environmental monitoring and healthcare. This period also saw improvements in sensor selectivity through the development of specialized catalysts and membrane technologies that could filter interfering gases.

Current electrochemical multi-gas detection technology faces increasing demands for higher sensitivity, greater selectivity, and the ability to simultaneously detect multiple gases with a single cell design. The integration of nanomaterials and advanced polymer membranes has pushed detection limits into the parts-per-billion range for many gases, while maintaining reasonable response times and operational lifespans.

The primary objective of modern electrochemical cell design for multi-gas detection is to create versatile platforms capable of accurately measuring complex gas mixtures in real-time with minimal cross-interference. This includes developing cells that can function effectively across varying environmental conditions, including temperature fluctuations and humidity changes that traditionally impact sensor performance.

Another critical goal is reducing power consumption and increasing durability to support deployment in remote monitoring applications and IoT-connected devices. The industry is moving toward electrochemical cells that can operate for years without calibration or replacement, significantly reducing maintenance costs and improving reliability in critical safety applications.

Looking forward, the field aims to develop "universal" electrochemical sensing platforms that can be rapidly reconfigured for different gas detection needs through software adjustments rather than hardware changes. This adaptability would revolutionize applications ranging from industrial safety to medical diagnostics, environmental monitoring, and homeland security.

By the 1970s, advances in electrode materials and electrolyte formulations expanded detection capabilities to toxic gases like carbon monoxide and hydrogen sulfide. The introduction of three-electrode cell designs during this period marked a critical advancement, significantly improving sensor stability and reducing cross-sensitivity issues that plagued earlier models.

The 1990s witnessed the miniaturization of electrochemical cells, enabling their integration into portable gas monitors and expanding their application beyond industrial settings to environmental monitoring and healthcare. This period also saw improvements in sensor selectivity through the development of specialized catalysts and membrane technologies that could filter interfering gases.

Current electrochemical multi-gas detection technology faces increasing demands for higher sensitivity, greater selectivity, and the ability to simultaneously detect multiple gases with a single cell design. The integration of nanomaterials and advanced polymer membranes has pushed detection limits into the parts-per-billion range for many gases, while maintaining reasonable response times and operational lifespans.

The primary objective of modern electrochemical cell design for multi-gas detection is to create versatile platforms capable of accurately measuring complex gas mixtures in real-time with minimal cross-interference. This includes developing cells that can function effectively across varying environmental conditions, including temperature fluctuations and humidity changes that traditionally impact sensor performance.

Another critical goal is reducing power consumption and increasing durability to support deployment in remote monitoring applications and IoT-connected devices. The industry is moving toward electrochemical cells that can operate for years without calibration or replacement, significantly reducing maintenance costs and improving reliability in critical safety applications.

Looking forward, the field aims to develop "universal" electrochemical sensing platforms that can be rapidly reconfigured for different gas detection needs through software adjustments rather than hardware changes. This adaptability would revolutionize applications ranging from industrial safety to medical diagnostics, environmental monitoring, and homeland security.

Market Analysis for Multi-Gas Detection Systems

The multi-gas detection systems market has experienced substantial growth in recent years, driven primarily by increasing safety regulations across industries and growing awareness of workplace hazards. The global market for gas detection equipment was valued at approximately $2.5 billion in 2020 and is projected to reach $3.9 billion by 2027, growing at a CAGR of 6.4% during the forecast period. Multi-gas detection systems specifically represent a significant and rapidly expanding segment within this broader market.

Industrial applications constitute the largest market segment, with oil and gas, mining, chemical manufacturing, and wastewater treatment facilities being the primary end-users. These industries require continuous monitoring of multiple gases simultaneously, including combustible gases, oxygen levels, hydrogen sulfide, carbon monoxide, and volatile organic compounds. The demand for portable multi-gas detectors has seen particularly strong growth, with a market share increase of 8.2% annually since 2018.

Regionally, North America currently dominates the market with approximately 35% share, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years due to rapid industrialization in countries like China and India, coupled with increasingly stringent safety regulations being implemented across the region.

Key market drivers include stringent occupational safety regulations, particularly in developed economies, which mandate regular gas monitoring in hazardous environments. The International Labour Organization estimates that over 2.3 million workplace fatalities occur annually worldwide, with a significant portion related to toxic gas exposure, creating urgent demand for reliable detection systems.

Technological advancements represent another critical market driver, with customers increasingly demanding systems offering higher sensitivity, selectivity, faster response times, and wireless connectivity. The integration of IoT capabilities and cloud-based monitoring solutions has created a new premium segment growing at 12% annually.

Market challenges include price sensitivity, particularly in emerging economies, and the technical limitations of current electrochemical sensors regarding cross-sensitivity issues and limited lifespans. Additionally, the market faces fragmentation with numerous local and regional players competing alongside global manufacturers.

Customer preferences are shifting toward comprehensive solutions rather than standalone devices, with 68% of procurement managers in a recent industry survey indicating preference for integrated systems that combine detection capabilities with data analytics and predictive maintenance features. This trend suggests significant growth potential for manufacturers who can deliver electrochemical cell designs capable of accurate multi-gas detection while addressing the current limitations in selectivity and longevity.

Industrial applications constitute the largest market segment, with oil and gas, mining, chemical manufacturing, and wastewater treatment facilities being the primary end-users. These industries require continuous monitoring of multiple gases simultaneously, including combustible gases, oxygen levels, hydrogen sulfide, carbon monoxide, and volatile organic compounds. The demand for portable multi-gas detectors has seen particularly strong growth, with a market share increase of 8.2% annually since 2018.

Regionally, North America currently dominates the market with approximately 35% share, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years due to rapid industrialization in countries like China and India, coupled with increasingly stringent safety regulations being implemented across the region.

Key market drivers include stringent occupational safety regulations, particularly in developed economies, which mandate regular gas monitoring in hazardous environments. The International Labour Organization estimates that over 2.3 million workplace fatalities occur annually worldwide, with a significant portion related to toxic gas exposure, creating urgent demand for reliable detection systems.

Technological advancements represent another critical market driver, with customers increasingly demanding systems offering higher sensitivity, selectivity, faster response times, and wireless connectivity. The integration of IoT capabilities and cloud-based monitoring solutions has created a new premium segment growing at 12% annually.

Market challenges include price sensitivity, particularly in emerging economies, and the technical limitations of current electrochemical sensors regarding cross-sensitivity issues and limited lifespans. Additionally, the market faces fragmentation with numerous local and regional players competing alongside global manufacturers.

Customer preferences are shifting toward comprehensive solutions rather than standalone devices, with 68% of procurement managers in a recent industry survey indicating preference for integrated systems that combine detection capabilities with data analytics and predictive maintenance features. This trend suggests significant growth potential for manufacturers who can deliver electrochemical cell designs capable of accurate multi-gas detection while addressing the current limitations in selectivity and longevity.

Current Challenges in Electrochemical Cell Design

Despite significant advancements in electrochemical cell design for gas detection, several critical challenges continue to impede the development of effective multi-gas detection systems. The primary obstacle remains selectivity, as electrochemical cells often struggle to distinguish between gases with similar electrochemical properties. Cross-sensitivity issues frequently arise when multiple target gases generate overlapping electrochemical responses, leading to false readings and compromised reliability in real-world applications.

Sensitivity limitations present another significant challenge, particularly when detecting gases at low concentrations. Current electrochemical cells often fail to achieve the required detection limits for certain toxic gases, which may be harmful even at parts-per-billion levels. This sensitivity constraint becomes more pronounced in multi-gas detection scenarios where performance must be maintained across diverse analytes with varying concentration thresholds.

Stability and longevity of electrochemical cells remain problematic, especially in harsh environmental conditions. Electrode poisoning, reference electrode drift, and electrolyte degradation significantly reduce sensor lifespan and measurement accuracy over time. These issues are exacerbated in multi-gas detection applications where cells are exposed to complex gas mixtures that accelerate degradation processes.

Miniaturization efforts face substantial hurdles as reducing cell dimensions typically compromises performance. The challenge intensifies when designing integrated multi-gas detection systems that require multiple sensing elements within confined spaces. Current microfabrication techniques struggle to maintain electrochemical performance while achieving the necessary size reduction for portable or wearable applications.

Power consumption presents a persistent challenge, particularly for battery-operated devices intended for continuous monitoring. Traditional electrochemical cells often require substantial power for operation, limiting deployment options for remote or long-term monitoring scenarios. This constraint becomes more significant in multi-gas detection systems that incorporate multiple sensing elements.

Response time variations across different target gases complicate data interpretation in multi-gas detection applications. Current designs frequently exhibit inconsistent temporal responses, making it difficult to establish reliable detection algorithms for complex gas mixtures or rapidly changing environments.

Manufacturing scalability and cost-effectiveness remain significant barriers to widespread adoption. Current fabrication processes for high-performance electrochemical cells often involve complex procedures and expensive materials, limiting commercial viability. These challenges are particularly evident when attempting to produce integrated multi-gas detection systems that maintain consistent performance across all sensing elements.

Sensitivity limitations present another significant challenge, particularly when detecting gases at low concentrations. Current electrochemical cells often fail to achieve the required detection limits for certain toxic gases, which may be harmful even at parts-per-billion levels. This sensitivity constraint becomes more pronounced in multi-gas detection scenarios where performance must be maintained across diverse analytes with varying concentration thresholds.

Stability and longevity of electrochemical cells remain problematic, especially in harsh environmental conditions. Electrode poisoning, reference electrode drift, and electrolyte degradation significantly reduce sensor lifespan and measurement accuracy over time. These issues are exacerbated in multi-gas detection applications where cells are exposed to complex gas mixtures that accelerate degradation processes.

Miniaturization efforts face substantial hurdles as reducing cell dimensions typically compromises performance. The challenge intensifies when designing integrated multi-gas detection systems that require multiple sensing elements within confined spaces. Current microfabrication techniques struggle to maintain electrochemical performance while achieving the necessary size reduction for portable or wearable applications.

Power consumption presents a persistent challenge, particularly for battery-operated devices intended for continuous monitoring. Traditional electrochemical cells often require substantial power for operation, limiting deployment options for remote or long-term monitoring scenarios. This constraint becomes more significant in multi-gas detection systems that incorporate multiple sensing elements.

Response time variations across different target gases complicate data interpretation in multi-gas detection applications. Current designs frequently exhibit inconsistent temporal responses, making it difficult to establish reliable detection algorithms for complex gas mixtures or rapidly changing environments.

Manufacturing scalability and cost-effectiveness remain significant barriers to widespread adoption. Current fabrication processes for high-performance electrochemical cells often involve complex procedures and expensive materials, limiting commercial viability. These challenges are particularly evident when attempting to produce integrated multi-gas detection systems that maintain consistent performance across all sensing elements.

Contemporary Multi-Gas Detection Cell Architectures

01 Electrochemical cell designs for multi-gas detection

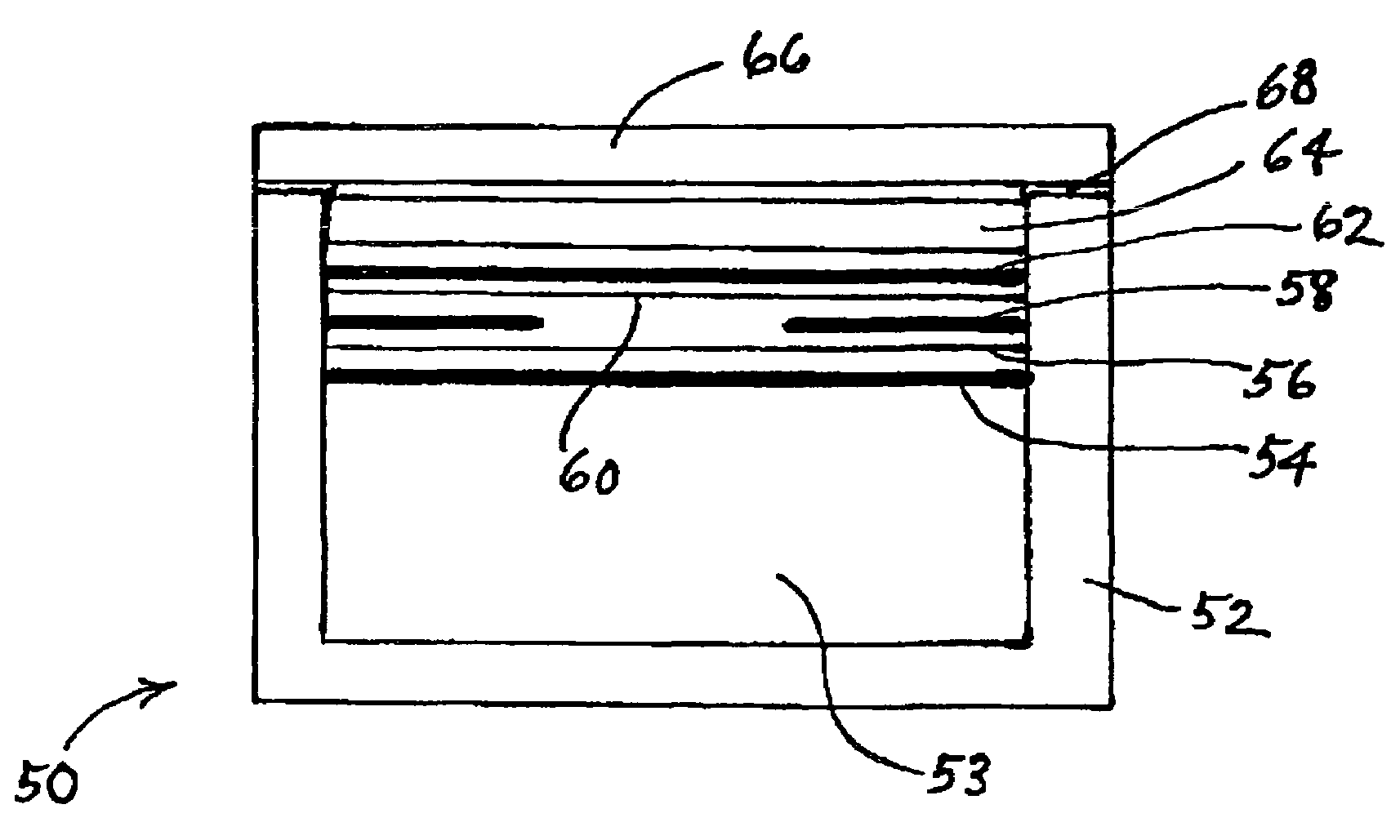

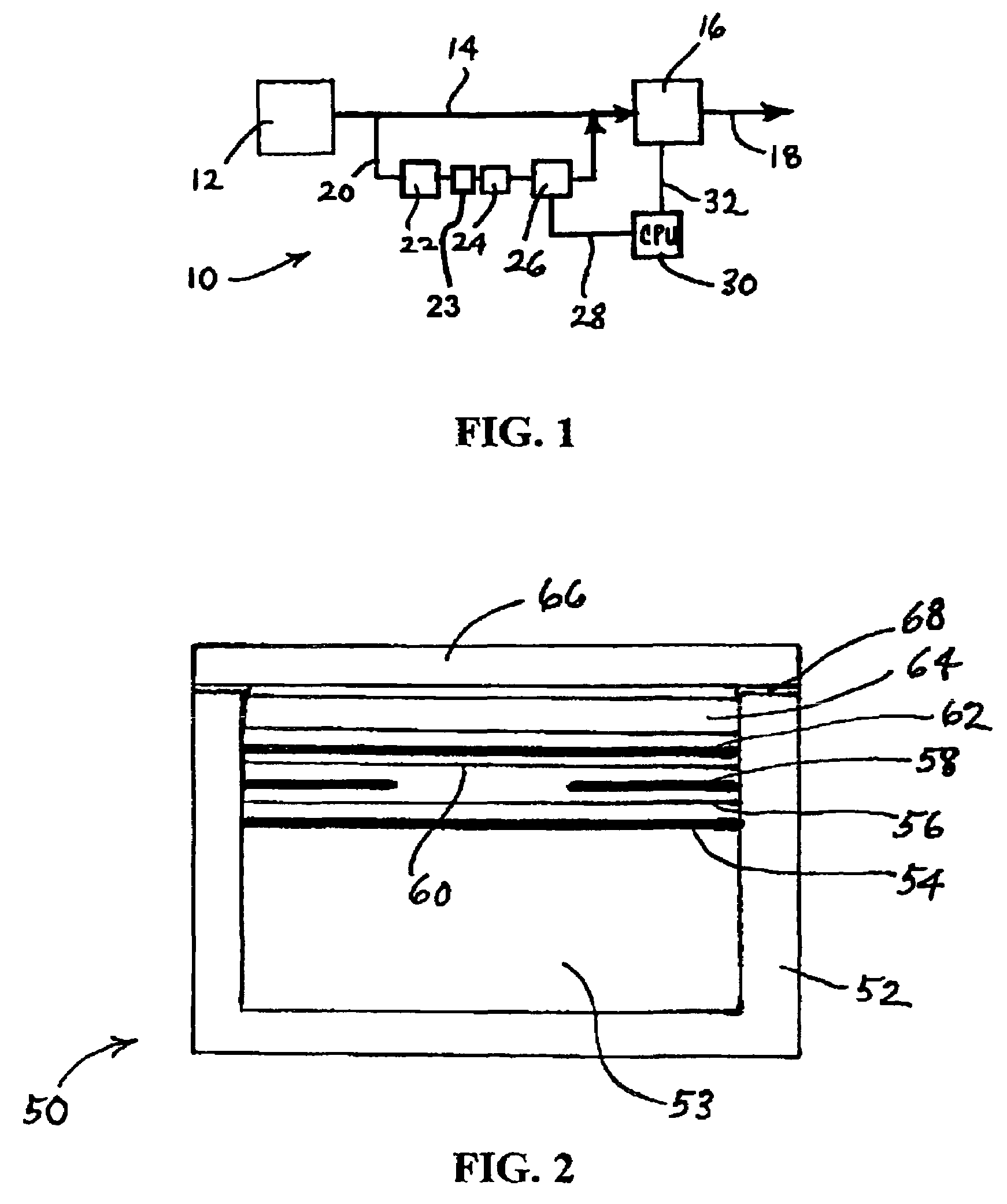

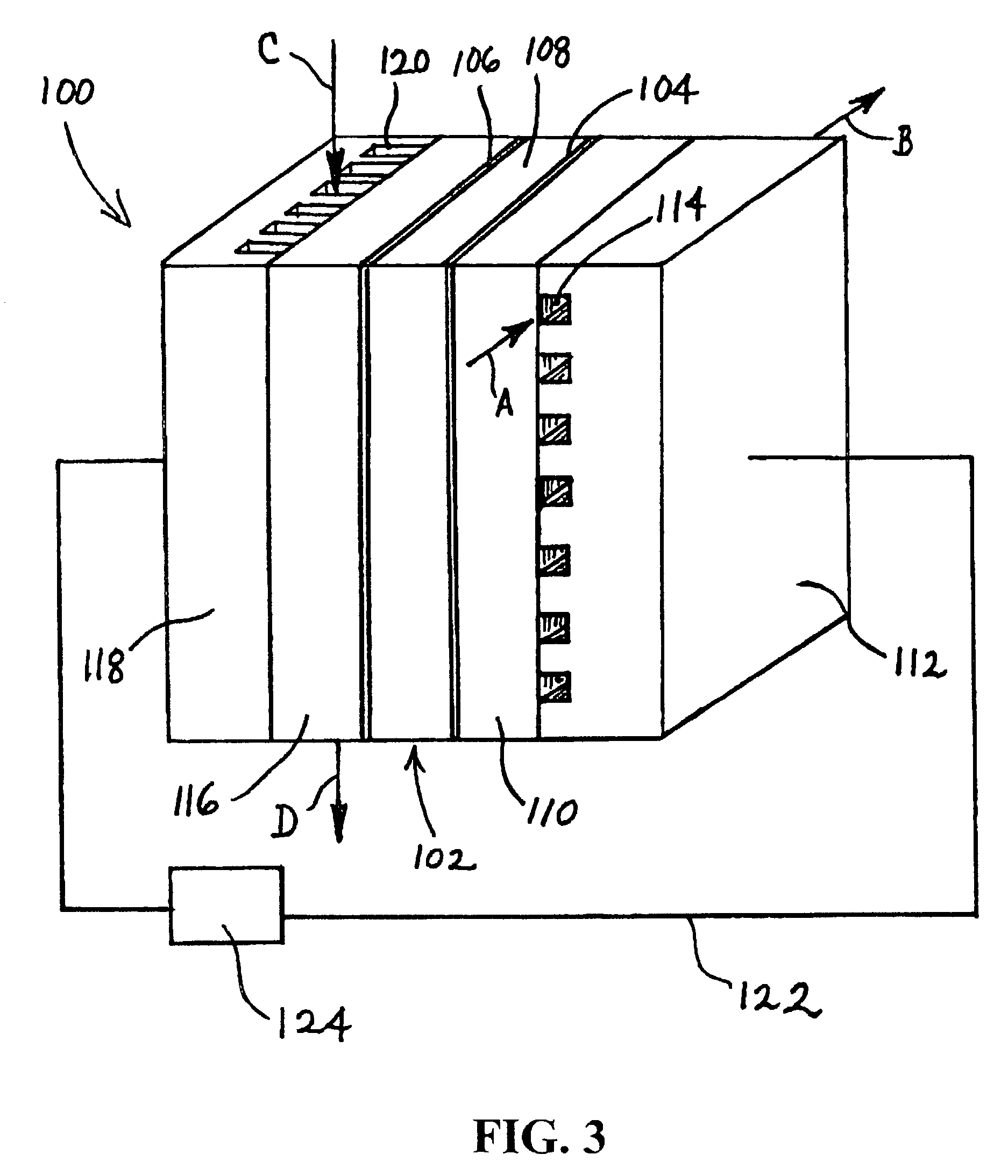

Various electrochemical cell designs have been developed specifically for multi-gas detection applications. These designs focus on optimizing electrode configurations, membrane structures, and electrolyte compositions to enable simultaneous or sequential detection of multiple gas species. The cells incorporate specialized sensing elements that can respond to different target gases with high selectivity and sensitivity, while maintaining stability over extended periods of operation.- Electrochemical cell designs for multi-gas detection: Various electrochemical cell designs have been developed specifically for multi-gas detection applications. These designs focus on optimizing electrode configurations, membrane structures, and electrolyte compositions to enable simultaneous detection of multiple gas species. The cells typically incorporate multiple working electrodes with different catalytic properties to selectively respond to different target gases, while maintaining stability and sensitivity across varying environmental conditions.

- Sensor arrays and integrated systems: Integrated sensor array systems combine multiple electrochemical cells or sensing elements into a unified detection platform. These systems often feature miniaturized cell arrays with shared reference electrodes and integrated signal processing capabilities. The arrays can be configured to detect a wide spectrum of gases simultaneously, with advanced algorithms to compensate for cross-sensitivity issues. Such integrated approaches enable comprehensive gas monitoring in complex environments while reducing overall system size and power requirements.

- Novel electrode materials and catalysts: Advanced electrode materials and catalysts significantly enhance the performance of multi-gas detection electrochemical cells. These materials include nanostructured metals, carbon-based composites, and specialized alloys designed to improve selectivity, sensitivity, and stability. Catalyst modifications can tune electrodes to respond preferentially to specific gas species while minimizing interference from others. These material innovations enable lower detection limits and extended operational lifetimes in challenging environments.

- Electrolyte formulations for multi-gas applications: Specialized electrolyte formulations play a crucial role in multi-gas detection capabilities. These formulations are designed to maintain ionic conductivity while facilitating the selective transport of target gas molecules to the sensing electrodes. Advanced electrolytes incorporate additives that enhance stability across temperature variations and prevent electrode poisoning. Some formulations feature ionic liquids or polymer-based systems that extend sensor lifetime and improve performance in varying humidity conditions.

- Signal processing and interference compensation techniques: Advanced signal processing methods are essential for accurate multi-gas detection using electrochemical cells. These techniques include adaptive filtering algorithms, machine learning approaches, and real-time calibration systems that compensate for cross-sensitivity between gases. Signal processing innovations enable the extraction of meaningful data from complex electrochemical responses, improving detection accuracy in mixed-gas environments. These methods often incorporate temperature and humidity compensation to maintain measurement reliability under varying ambient conditions.

02 Advanced electrode materials for multi-gas sensing

Novel electrode materials have been developed to enhance the performance of electrochemical cells for multi-gas detection. These materials include specialized catalysts, nanostructured surfaces, and composite materials that improve selectivity, sensitivity, and response time. By tailoring the electrode composition and structure, these innovations enable detection of multiple gases with reduced cross-sensitivity and improved signal-to-noise ratios.Expand Specific Solutions03 Integrated multi-gas detection systems

Integrated systems combine multiple electrochemical cells or sensing elements within a single device to detect various gases simultaneously. These systems incorporate advanced signal processing, microcontrollers, and data analysis algorithms to differentiate between gas species and quantify their concentrations. The integration enables compact, portable multi-gas detection solutions with improved reliability and reduced power consumption.Expand Specific Solutions04 Electrolyte formulations for multi-gas detection

Specialized electrolyte formulations have been developed to optimize the performance of electrochemical cells for multi-gas detection. These formulations include specific ionic compounds, buffers, and additives that enhance conductivity, stability, and selectivity for target gases. The electrolyte composition plays a crucial role in determining which gases can be detected and the sensitivity of the measurement, allowing for customization based on specific application requirements.Expand Specific Solutions05 Miniaturized electrochemical sensors for portable multi-gas detection

Miniaturized electrochemical sensor technologies enable portable and wearable multi-gas detection devices. These compact sensors utilize microfabrication techniques, thin-film electrodes, and microfluidic designs to achieve small form factors while maintaining detection capabilities. The miniaturization allows for integration into personal safety equipment, environmental monitoring networks, and mobile devices, expanding the applications for multi-gas detection.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The electrochemical multi-gas detection cell design market is in a growth phase, with increasing demand driven by environmental monitoring, industrial safety, and healthcare applications. The market is projected to reach significant scale as IoT and smart sensing technologies proliferate. Technologically, the field shows varying maturity levels across different gas detection applications. Leading players include established industrial giants like Honeywell, Bosch, and Toyota, who leverage their manufacturing expertise and R&D capabilities, alongside specialized sensor companies such as Sensirion and FREDsense. Research institutions like AIST and CNRS contribute fundamental innovations, while battery technology leaders including CATL and LG Energy Solution are expanding into this space, applying their electrochemical expertise to develop next-generation detection solutions.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced electrochemical cell designs for multi-gas detection utilizing a proprietary three-electrode system with optimized electrolyte formulations. Their technology employs nanostructured sensing electrodes with tailored catalysts that can selectively detect multiple gases simultaneously. The design incorporates a patented membrane technology that allows for controlled gas diffusion while filtering out interfering compounds. Honeywell's electrochemical cells feature integrated temperature compensation mechanisms and advanced signal processing algorithms to maintain accuracy across varying environmental conditions. Their multi-gas detection systems utilize amperometric and potentiometric measurement techniques with specialized reference electrodes to ensure long-term stability and minimal drift. The cells are designed with redundant sensing elements to improve reliability and extend operational lifetimes in industrial environments.

Strengths: Superior selectivity and sensitivity for multiple gas detection in complex environments; robust design with excellent long-term stability and minimal drift; comprehensive temperature compensation for reliable operation across wide environmental conditions. Weaknesses: Higher manufacturing costs compared to simpler single-gas sensors; requires more complex calibration procedures; power consumption may be higher than simpler alternatives.

Sensirion AG

Technical Solution: Sensirion has developed a novel electrochemical cell platform for multi-gas detection that combines electrochemical sensing with digital signal processing. Their design features microfabricated electrode arrays with specialized catalyst materials deposited using precision techniques. The electrochemical cells incorporate a unique microfluidic structure that controls gas diffusion pathways, enabling selective detection of multiple gases with minimal cross-interference. Sensirion's technology utilizes a proprietary solid polymer electrolyte that offers improved stability and longer operational life compared to traditional liquid electrolytes. Their cells feature integrated temperature and humidity compensation, with on-chip reference electrodes for continuous baseline monitoring. The design includes a digital interface with embedded algorithms for real-time signal processing and gas identification. Sensirion's approach also incorporates machine learning techniques to improve selectivity and adapt to changing environmental conditions over time, with self-diagnostic capabilities to monitor sensor health and predict maintenance needs.

Strengths: Excellent long-term stability with solid polymer electrolyte; highly miniaturized design suitable for portable applications; sophisticated digital processing with machine learning capabilities for improved selectivity. Weaknesses: Higher power consumption during data processing operations; more complex calibration requirements; potentially higher cost due to advanced materials and processing.

Key Patents and Innovations in Electrode Materials

Multiple gas detection device

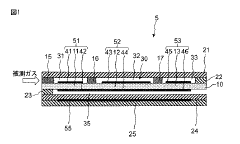

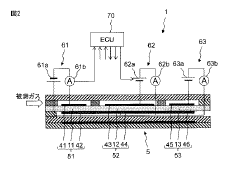

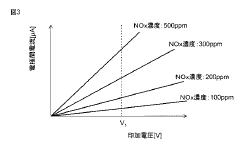

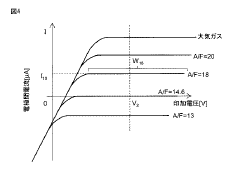

PatentInactiveJP2017072502A

Innovation

- A multi-gas detection apparatus with a configuration of solid electrolyte bodies, electrodes, and diffusion barriers that separate gas chambers to allow for precise detection of NOx, ammonia, and oxygen concentrations using electrochemical cells with controlled diffusion rates and selective detection mechanisms.

Electrochemical cell for gas sensor

PatentInactiveUS7060169B2

Innovation

- The use of ionic liquids as electrolytes in electrochemical cells, which are stable at low temperatures, have negligible vapor pressure, and provide high electrical conductivity, allowing for the construction of smaller, more durable gas sensors and fuel cells that can operate across a broader range of humidity and temperature conditions.

Miniaturization and Power Optimization Strategies

The miniaturization of electrochemical cells for multi-gas detection represents a critical advancement pathway that addresses the growing demand for portable, energy-efficient sensing technologies. Current design approaches focus on reducing the physical dimensions of sensing elements while maintaining or enhancing detection capabilities through innovative material selection and fabrication techniques.

Microfabrication technologies, particularly MEMS (Micro-Electro-Mechanical Systems), have enabled significant reductions in electrochemical cell sizes. These techniques allow for precise patterning of electrode arrays with feature sizes in the micrometer range, dramatically decreasing the overall footprint of sensing devices. The integration of multiple sensing electrodes on a single chip facilitates simultaneous detection of various gases while minimizing space requirements.

Power optimization strategies have evolved along two primary trajectories: reducing operational power requirements and improving energy harvesting capabilities. Advanced electrode materials with high catalytic activity, such as nanostructured noble metals and metal oxides, enable lower operating potentials while maintaining sensitivity. This approach directly translates to reduced power consumption during sensing operations.

Circuit design innovations have further contributed to power efficiency through implementation of low-power operational modes. Intermittent sampling techniques, where the sensor operates in sleep mode between measurements, can reduce average power consumption by up to 90% compared to continuous operation. Additionally, adaptive sampling rates that adjust based on detected concentration levels optimize power usage during extended deployment periods.

Energy harvesting technologies present promising solutions for self-powered electrochemical gas sensors. Photovoltaic cells integrated with sensing platforms can provide sustainable power in outdoor or well-lit environments. Thermoelectric generators utilizing temperature gradients and piezoelectric elements harvesting mechanical vibrations offer alternative energy sources for specific deployment scenarios.

Miniaturized power management systems incorporating supercapacitors or thin-film batteries provide efficient energy storage solutions with rapid charging capabilities. These components are increasingly being integrated directly into sensor packages, creating truly autonomous sensing systems with minimal maintenance requirements.

The convergence of these miniaturization and power optimization strategies has enabled the development of wearable gas sensors and IoT-compatible devices with operational lifetimes extending from months to years on a single charge or with energy harvesting capabilities. This evolution supports the growing deployment of distributed sensor networks for environmental monitoring, industrial safety, and smart city applications.

Microfabrication technologies, particularly MEMS (Micro-Electro-Mechanical Systems), have enabled significant reductions in electrochemical cell sizes. These techniques allow for precise patterning of electrode arrays with feature sizes in the micrometer range, dramatically decreasing the overall footprint of sensing devices. The integration of multiple sensing electrodes on a single chip facilitates simultaneous detection of various gases while minimizing space requirements.

Power optimization strategies have evolved along two primary trajectories: reducing operational power requirements and improving energy harvesting capabilities. Advanced electrode materials with high catalytic activity, such as nanostructured noble metals and metal oxides, enable lower operating potentials while maintaining sensitivity. This approach directly translates to reduced power consumption during sensing operations.

Circuit design innovations have further contributed to power efficiency through implementation of low-power operational modes. Intermittent sampling techniques, where the sensor operates in sleep mode between measurements, can reduce average power consumption by up to 90% compared to continuous operation. Additionally, adaptive sampling rates that adjust based on detected concentration levels optimize power usage during extended deployment periods.

Energy harvesting technologies present promising solutions for self-powered electrochemical gas sensors. Photovoltaic cells integrated with sensing platforms can provide sustainable power in outdoor or well-lit environments. Thermoelectric generators utilizing temperature gradients and piezoelectric elements harvesting mechanical vibrations offer alternative energy sources for specific deployment scenarios.

Miniaturized power management systems incorporating supercapacitors or thin-film batteries provide efficient energy storage solutions with rapid charging capabilities. These components are increasingly being integrated directly into sensor packages, creating truly autonomous sensing systems with minimal maintenance requirements.

The convergence of these miniaturization and power optimization strategies has enabled the development of wearable gas sensors and IoT-compatible devices with operational lifetimes extending from months to years on a single charge or with energy harvesting capabilities. This evolution supports the growing deployment of distributed sensor networks for environmental monitoring, industrial safety, and smart city applications.

Environmental and Safety Standards Compliance

Electrochemical cell designs for multi-gas detection must adhere to stringent environmental and safety standards across various jurisdictions. The International Electrotechnical Commission (IEC) has established the IEC 60079 series specifically for equipment used in explosive atmospheres, with IEC 60079-29 focusing on gas detectors. These standards mandate specific performance requirements, including response time, accuracy, and cross-sensitivity limitations that directly impact cell design parameters.

In the United States, OSHA regulations (29 CFR 1910.1000) establish permissible exposure limits (PELs) for various gases, requiring detection systems to provide accurate measurements at these threshold levels. The National Institute for Occupational Safety and Health (NIOSH) further recommends exposure limits that often influence electrochemical cell sensitivity requirements. Similarly, the European Union's ATEX Directive 2014/34/EU governs equipment intended for use in potentially explosive atmospheres, imposing additional design constraints on electrochemical cells.

Environmental compliance extends beyond operational safety to include manufacturing and disposal considerations. The Restriction of Hazardous Substances (RoHS) Directive restricts the use of certain hazardous materials in electrical and electronic equipment, affecting electrode material selection and electrolyte composition. Many electrochemical cells contain heavy metals or corrosive electrolytes that require careful handling throughout the product lifecycle.

Temperature and humidity performance requirements are specified in standards such as EN 50104 for oxygen detectors and EN 45544 for toxic gas detectors. These standards require electrochemical cells to maintain accuracy across defined environmental conditions, necessitating robust design approaches that can compensate for environmental variations without compromising detection capabilities.

Certification processes for electrochemical gas detection systems involve rigorous testing by recognized bodies such as UL (Underwriters Laboratories), CSA (Canadian Standards Association), or European Notified Bodies. These certification procedures evaluate not only detection performance but also electrical safety, electromagnetic compatibility, and mechanical robustness. The IECEx scheme provides an international certification framework that facilitates global market access while ensuring compliance with safety standards.

Recent regulatory trends show increasing emphasis on long-term stability and reduced calibration frequency requirements. This shift drives innovation in electrochemical cell design toward more stable reference electrodes and counter electrode systems that maintain performance over extended periods. Additionally, emerging standards are beginning to address cybersecurity concerns for networked detection systems, introducing new compliance considerations for digital interfaces connected to electrochemical sensing elements.

In the United States, OSHA regulations (29 CFR 1910.1000) establish permissible exposure limits (PELs) for various gases, requiring detection systems to provide accurate measurements at these threshold levels. The National Institute for Occupational Safety and Health (NIOSH) further recommends exposure limits that often influence electrochemical cell sensitivity requirements. Similarly, the European Union's ATEX Directive 2014/34/EU governs equipment intended for use in potentially explosive atmospheres, imposing additional design constraints on electrochemical cells.

Environmental compliance extends beyond operational safety to include manufacturing and disposal considerations. The Restriction of Hazardous Substances (RoHS) Directive restricts the use of certain hazardous materials in electrical and electronic equipment, affecting electrode material selection and electrolyte composition. Many electrochemical cells contain heavy metals or corrosive electrolytes that require careful handling throughout the product lifecycle.

Temperature and humidity performance requirements are specified in standards such as EN 50104 for oxygen detectors and EN 45544 for toxic gas detectors. These standards require electrochemical cells to maintain accuracy across defined environmental conditions, necessitating robust design approaches that can compensate for environmental variations without compromising detection capabilities.

Certification processes for electrochemical gas detection systems involve rigorous testing by recognized bodies such as UL (Underwriters Laboratories), CSA (Canadian Standards Association), or European Notified Bodies. These certification procedures evaluate not only detection performance but also electrical safety, electromagnetic compatibility, and mechanical robustness. The IECEx scheme provides an international certification framework that facilitates global market access while ensuring compliance with safety standards.

Recent regulatory trends show increasing emphasis on long-term stability and reduced calibration frequency requirements. This shift drives innovation in electrochemical cell design toward more stable reference electrodes and counter electrode systems that maintain performance over extended periods. Additionally, emerging standards are beginning to address cybersecurity concerns for networked detection systems, introducing new compliance considerations for digital interfaces connected to electrochemical sensing elements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!