Temperature And Humidity Compensation Techniques

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Temperature and Humidity Sensing Background and Objectives

Temperature and humidity sensing technologies have evolved significantly over the past several decades, transitioning from rudimentary mechanical hygrometers and thermometers to sophisticated electronic sensors capable of high-precision measurements. The journey began in the early 20th century with basic resistance temperature detectors (RTDs) and evolved through the introduction of thermistors in the 1930s, which offered improved sensitivity and response times.

The development of semiconductor-based sensors in the 1970s marked a pivotal advancement, enabling miniaturization and integration into electronic systems. By the 1990s, capacitive humidity sensors emerged as the industry standard, offering improved accuracy and stability compared to earlier resistive approaches. The early 2000s witnessed the introduction of combined temperature and humidity sensors on single chips, significantly reducing form factors and power requirements.

Today's sensing technologies incorporate MEMS (Micro-Electro-Mechanical Systems) fabrication techniques, resulting in sensors with unprecedented levels of precision, reliability, and energy efficiency. Modern sensors achieve temperature accuracies of ±0.1°C and relative humidity accuracies of ±1%, representing orders of magnitude improvement over early electronic sensors.

The primary objective of temperature and humidity compensation techniques is to mitigate measurement errors caused by environmental factors. These techniques aim to maintain measurement accuracy across wide operating ranges, particularly in applications where sensors experience significant environmental variations. Compensation methods seek to address cross-sensitivity issues, where temperature affects humidity readings and vice versa.

Another critical goal is enhancing long-term stability and reducing drift, ensuring consistent performance throughout a sensor's operational lifetime. This becomes particularly important in applications requiring continuous monitoring over extended periods, such as in industrial process control, environmental monitoring, and medical devices.

The development of these compensation techniques is driven by increasing demands from emerging applications in IoT devices, wearable technology, and precision manufacturing. These applications require not only high accuracy but also minimal power consumption, small form factors, and robust performance in challenging environments.

Looking forward, the field aims to develop self-calibrating sensors capable of maintaining accuracy without manual intervention, as well as sensors that can function reliably in extreme conditions such as high temperatures, corrosive environments, or high-radiation settings. The ultimate objective remains achieving laboratory-grade measurement precision in field-deployable sensors at consumer-friendly price points.

The development of semiconductor-based sensors in the 1970s marked a pivotal advancement, enabling miniaturization and integration into electronic systems. By the 1990s, capacitive humidity sensors emerged as the industry standard, offering improved accuracy and stability compared to earlier resistive approaches. The early 2000s witnessed the introduction of combined temperature and humidity sensors on single chips, significantly reducing form factors and power requirements.

Today's sensing technologies incorporate MEMS (Micro-Electro-Mechanical Systems) fabrication techniques, resulting in sensors with unprecedented levels of precision, reliability, and energy efficiency. Modern sensors achieve temperature accuracies of ±0.1°C and relative humidity accuracies of ±1%, representing orders of magnitude improvement over early electronic sensors.

The primary objective of temperature and humidity compensation techniques is to mitigate measurement errors caused by environmental factors. These techniques aim to maintain measurement accuracy across wide operating ranges, particularly in applications where sensors experience significant environmental variations. Compensation methods seek to address cross-sensitivity issues, where temperature affects humidity readings and vice versa.

Another critical goal is enhancing long-term stability and reducing drift, ensuring consistent performance throughout a sensor's operational lifetime. This becomes particularly important in applications requiring continuous monitoring over extended periods, such as in industrial process control, environmental monitoring, and medical devices.

The development of these compensation techniques is driven by increasing demands from emerging applications in IoT devices, wearable technology, and precision manufacturing. These applications require not only high accuracy but also minimal power consumption, small form factors, and robust performance in challenging environments.

Looking forward, the field aims to develop self-calibrating sensors capable of maintaining accuracy without manual intervention, as well as sensors that can function reliably in extreme conditions such as high temperatures, corrosive environments, or high-radiation settings. The ultimate objective remains achieving laboratory-grade measurement precision in field-deployable sensors at consumer-friendly price points.

Market Demand Analysis for Compensation Solutions

The global market for temperature and humidity compensation solutions has witnessed substantial growth in recent years, driven primarily by increasing demand for high-precision measurement systems across various industries. The market size for environmental sensing technologies, including compensation solutions, reached approximately $8.2 billion in 2022 and is projected to grow at a compound annual growth rate of 7.3% through 2028.

Industrial automation represents the largest market segment, accounting for nearly 32% of the total demand for compensation technologies. Manufacturing processes in semiconductor production, pharmaceutical manufacturing, and precision engineering require extremely accurate environmental control systems to maintain product quality and operational efficiency. In these sectors, even minor deviations in temperature or humidity can result in significant production losses, creating strong economic incentives for advanced compensation solutions.

The automotive industry has emerged as a rapidly growing market for these technologies, particularly with the rise of electric vehicles and autonomous driving systems. Modern automotive sensors require sophisticated compensation mechanisms to ensure reliable operation across diverse environmental conditions. Market research indicates that automotive applications for temperature and humidity compensation are growing at approximately 9.5% annually, outpacing the overall market growth.

Healthcare and life sciences constitute another significant market segment, with applications in medical devices, laboratory equipment, and pharmaceutical storage. The COVID-19 pandemic has further accelerated demand in this sector, as temperature-sensitive vaccine storage and distribution highlighted the critical importance of precise environmental control systems.

Geographically, North America and Europe currently dominate the market, collectively accounting for approximately 58% of global demand. However, the Asia-Pacific region is experiencing the fastest growth rate at 10.2% annually, driven by rapid industrialization in China, India, and Southeast Asian countries. The expansion of electronics manufacturing and increasing adoption of IoT devices in these regions are creating substantial new opportunities for compensation technology providers.

Consumer electronics represents an emerging market with significant potential, as manufacturers increasingly incorporate environmental sensors in smartphones, wearables, and smart home devices. This segment is expected to grow at 11.7% annually through 2028, creating new requirements for miniaturized, low-power compensation solutions.

Market analysis reveals a clear trend toward integrated compensation systems that combine hardware and software solutions, with cloud-based calibration and machine learning algorithms gaining particular traction. End-users increasingly demand solutions that not only compensate for environmental variations but also provide predictive maintenance capabilities and seamless integration with existing industrial control systems.

Industrial automation represents the largest market segment, accounting for nearly 32% of the total demand for compensation technologies. Manufacturing processes in semiconductor production, pharmaceutical manufacturing, and precision engineering require extremely accurate environmental control systems to maintain product quality and operational efficiency. In these sectors, even minor deviations in temperature or humidity can result in significant production losses, creating strong economic incentives for advanced compensation solutions.

The automotive industry has emerged as a rapidly growing market for these technologies, particularly with the rise of electric vehicles and autonomous driving systems. Modern automotive sensors require sophisticated compensation mechanisms to ensure reliable operation across diverse environmental conditions. Market research indicates that automotive applications for temperature and humidity compensation are growing at approximately 9.5% annually, outpacing the overall market growth.

Healthcare and life sciences constitute another significant market segment, with applications in medical devices, laboratory equipment, and pharmaceutical storage. The COVID-19 pandemic has further accelerated demand in this sector, as temperature-sensitive vaccine storage and distribution highlighted the critical importance of precise environmental control systems.

Geographically, North America and Europe currently dominate the market, collectively accounting for approximately 58% of global demand. However, the Asia-Pacific region is experiencing the fastest growth rate at 10.2% annually, driven by rapid industrialization in China, India, and Southeast Asian countries. The expansion of electronics manufacturing and increasing adoption of IoT devices in these regions are creating substantial new opportunities for compensation technology providers.

Consumer electronics represents an emerging market with significant potential, as manufacturers increasingly incorporate environmental sensors in smartphones, wearables, and smart home devices. This segment is expected to grow at 11.7% annually through 2028, creating new requirements for miniaturized, low-power compensation solutions.

Market analysis reveals a clear trend toward integrated compensation systems that combine hardware and software solutions, with cloud-based calibration and machine learning algorithms gaining particular traction. End-users increasingly demand solutions that not only compensate for environmental variations but also provide predictive maintenance capabilities and seamless integration with existing industrial control systems.

Current Challenges in Sensor Accuracy

Despite significant advancements in sensor technology, achieving high accuracy in temperature and humidity measurements remains challenging due to several persistent issues. Modern sensors still struggle with cross-sensitivity problems, where humidity sensors respond to temperature variations and vice versa, creating complex interdependencies that compromise measurement integrity. This phenomenon is particularly problematic in environments with rapid fluctuations in both parameters, such as industrial processes or meteorological applications.

Material limitations present another significant obstacle. Current sensor materials exhibit non-linear responses across their operational range, with sensitivity often decreasing at extreme values. For instance, capacitive humidity sensors typically show reduced accuracy above 90% relative humidity, while resistive temperature sensors may drift at high temperatures due to material degradation or structural changes.

Calibration drift represents a persistent challenge that undermines long-term measurement reliability. Environmental factors, aging processes, and chemical contamination gradually alter sensor characteristics, necessitating recalibration. However, field recalibration procedures are often impractical or prohibitively expensive, especially for deployed sensor networks or inaccessible installations.

Response time disparities between temperature and humidity sensors further complicate compensation techniques. Humidity sensors generally respond more slowly than temperature sensors, creating temporal misalignment in measurements that must be addressed through sophisticated algorithms. This discrepancy becomes particularly problematic in dynamic environments where conditions change rapidly.

Power consumption constraints in battery-operated or energy-harvesting systems limit the implementation of complex compensation algorithms. While advanced mathematical models could theoretically improve accuracy, they often require computational resources incompatible with low-power applications, forcing compromises between measurement accuracy and operational longevity.

Manufacturing variations introduce additional complexity, as sensors from the same production batch may exhibit slightly different characteristics. These variations necessitate individual calibration procedures that increase production costs and complexity. Even with initial calibration, the long-term stability of these calibration parameters remains uncertain.

Environmental contaminants pose another significant challenge, particularly for humidity sensors. Exposure to dust, oils, chemicals, or particulate matter can alter sensor surface properties, affecting measurement accuracy and response characteristics. While protective filters can mitigate some contamination effects, they often introduce their own measurement delays and maintenance requirements.

These challenges collectively highlight the need for more robust compensation techniques that can address the multifaceted nature of measurement errors in temperature and humidity sensing applications.

Material limitations present another significant obstacle. Current sensor materials exhibit non-linear responses across their operational range, with sensitivity often decreasing at extreme values. For instance, capacitive humidity sensors typically show reduced accuracy above 90% relative humidity, while resistive temperature sensors may drift at high temperatures due to material degradation or structural changes.

Calibration drift represents a persistent challenge that undermines long-term measurement reliability. Environmental factors, aging processes, and chemical contamination gradually alter sensor characteristics, necessitating recalibration. However, field recalibration procedures are often impractical or prohibitively expensive, especially for deployed sensor networks or inaccessible installations.

Response time disparities between temperature and humidity sensors further complicate compensation techniques. Humidity sensors generally respond more slowly than temperature sensors, creating temporal misalignment in measurements that must be addressed through sophisticated algorithms. This discrepancy becomes particularly problematic in dynamic environments where conditions change rapidly.

Power consumption constraints in battery-operated or energy-harvesting systems limit the implementation of complex compensation algorithms. While advanced mathematical models could theoretically improve accuracy, they often require computational resources incompatible with low-power applications, forcing compromises between measurement accuracy and operational longevity.

Manufacturing variations introduce additional complexity, as sensors from the same production batch may exhibit slightly different characteristics. These variations necessitate individual calibration procedures that increase production costs and complexity. Even with initial calibration, the long-term stability of these calibration parameters remains uncertain.

Environmental contaminants pose another significant challenge, particularly for humidity sensors. Exposure to dust, oils, chemicals, or particulate matter can alter sensor surface properties, affecting measurement accuracy and response characteristics. While protective filters can mitigate some contamination effects, they often introduce their own measurement delays and maintenance requirements.

These challenges collectively highlight the need for more robust compensation techniques that can address the multifaceted nature of measurement errors in temperature and humidity sensing applications.

Current Compensation Algorithms and Methods

01 Mathematical compensation algorithms for temperature and humidity

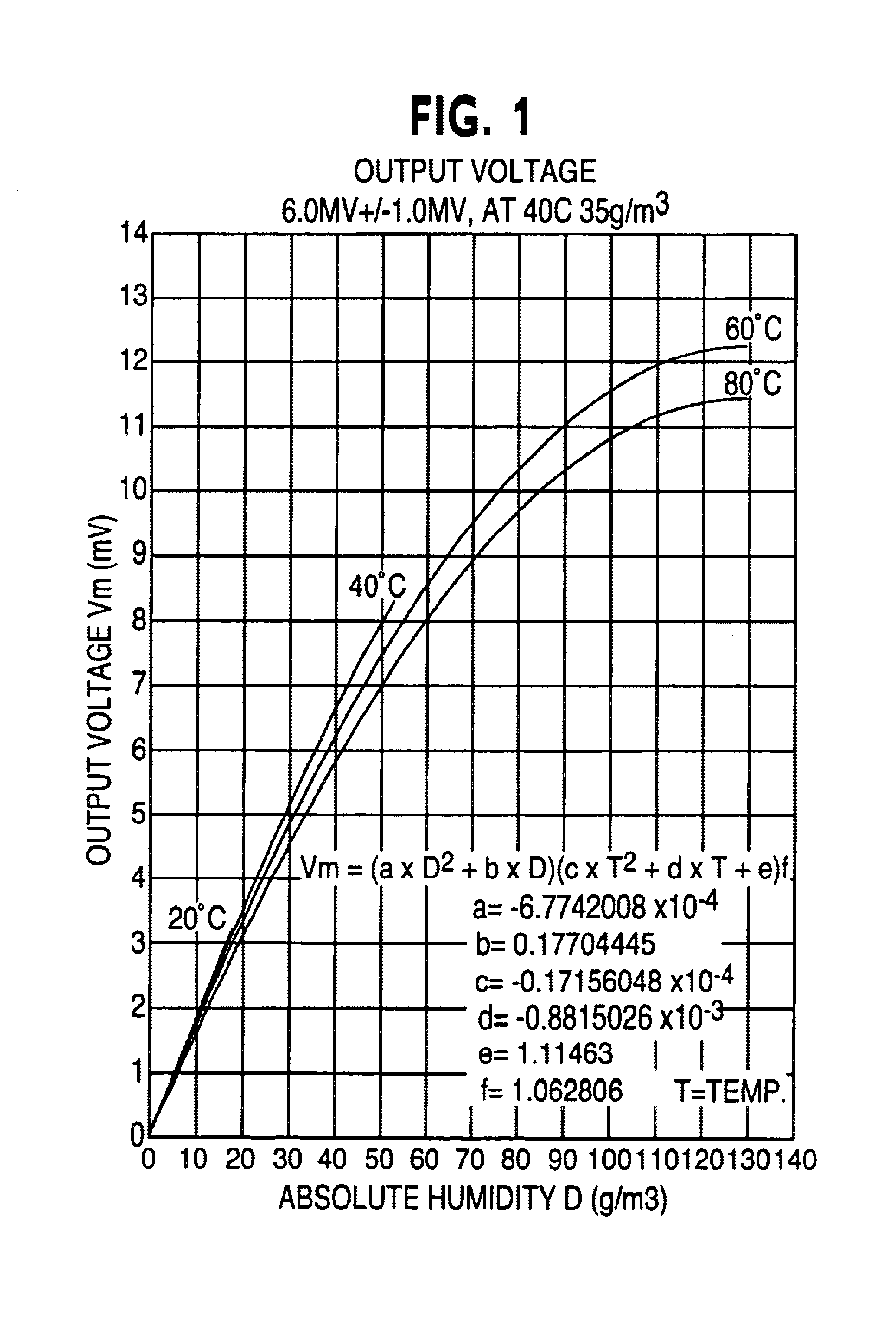

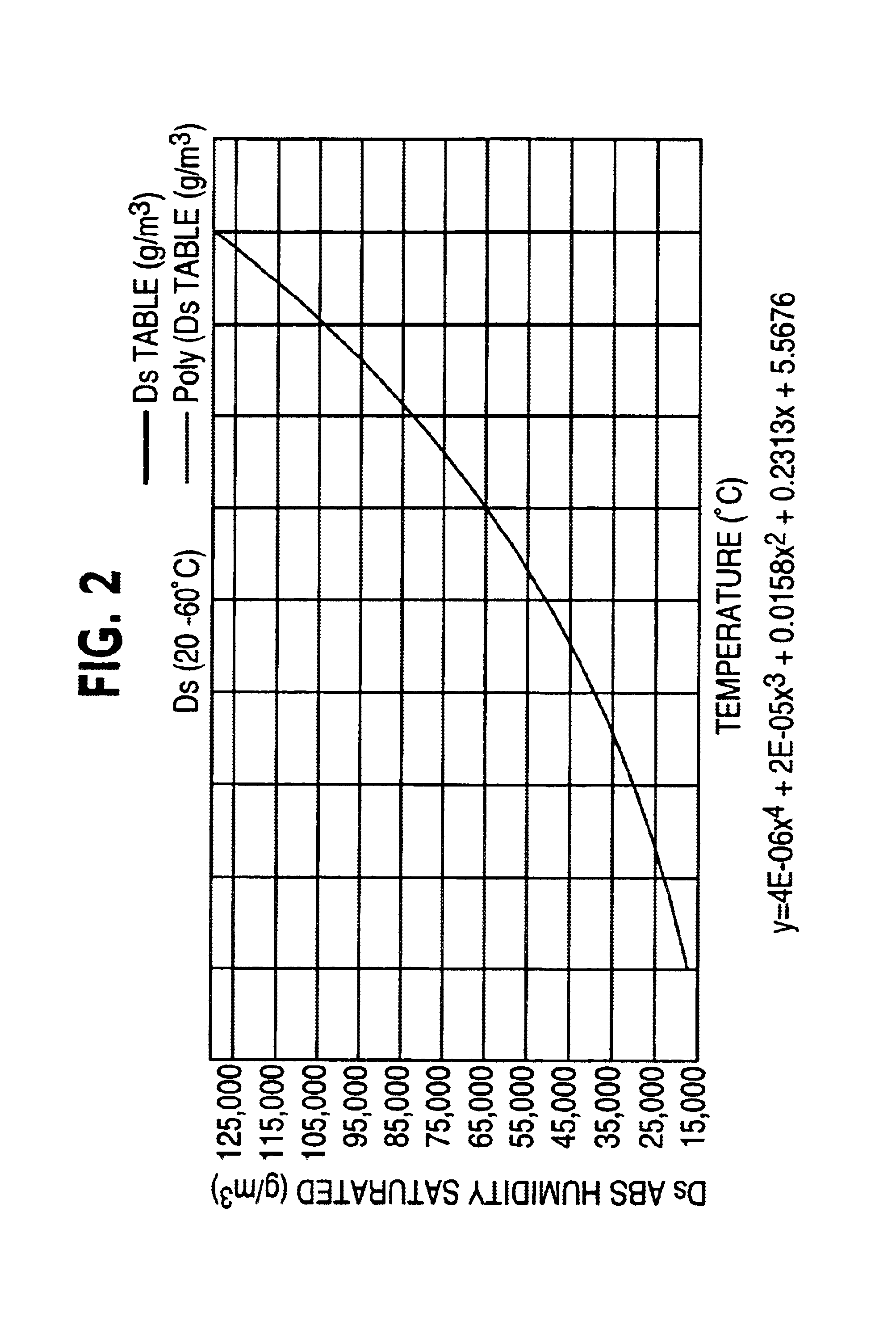

Various mathematical algorithms are employed to compensate for temperature and humidity effects on sensor readings. These include polynomial regression models, neural networks, and adaptive filtering techniques that process raw sensor data to correct for environmental variations. These algorithms analyze the relationship between environmental conditions and measurement errors, applying correction factors to improve accuracy across different operating conditions.- Mathematical modeling for temperature and humidity compensation: Mathematical models are developed to compensate for temperature and humidity effects on sensor readings. These models use algorithms that account for the relationship between environmental conditions and measurement errors. By applying these mathematical corrections, the accuracy of sensors can be significantly improved across varying environmental conditions. The compensation techniques often involve polynomial equations or lookup tables that adjust raw sensor data based on current temperature and humidity values.

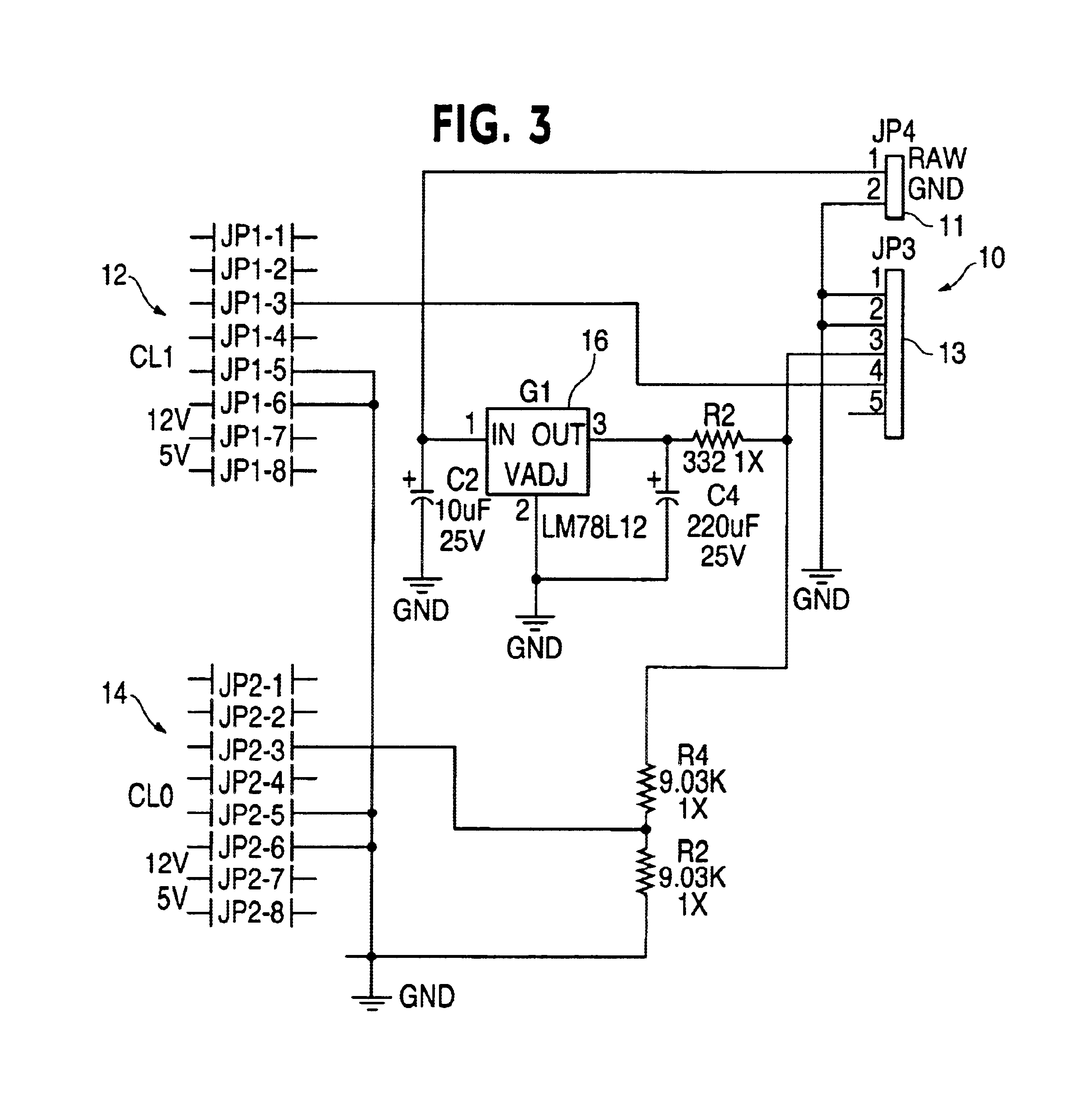

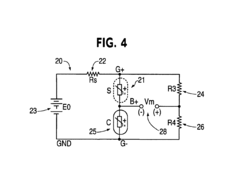

- Hardware-based compensation techniques: Hardware solutions for temperature and humidity compensation involve specialized circuit designs and components that automatically adjust for environmental variations. These include thermistors, humidity-sensitive resistors, and dedicated compensation circuits that work in real-time to maintain measurement accuracy. Some designs incorporate reference sensors that provide baseline measurements for comparison, while others use specialized integrated circuits specifically designed for environmental compensation.

- Calibration methods for improved accuracy: Calibration procedures are essential for achieving high accuracy in temperature and humidity compensation. These methods involve testing sensors under controlled environmental conditions to establish correction factors. Multi-point calibration techniques that sample performance across a range of temperatures and humidity levels provide more accurate compensation than single-point methods. Regular recalibration helps maintain accuracy over time as sensor characteristics may drift due to aging or environmental exposure.

- Real-time adaptive compensation systems: Adaptive systems continuously monitor environmental conditions and dynamically adjust compensation parameters in real-time. These systems use feedback mechanisms to learn from measurement errors and improve accuracy over time. Machine learning algorithms can be employed to recognize patterns in environmental effects and optimize compensation strategies accordingly. This approach is particularly effective in applications where environmental conditions change rapidly or unpredictably.

- Integrated sensor fusion for enhanced compensation: Sensor fusion techniques combine data from multiple sensors to achieve more accurate temperature and humidity compensation. By integrating readings from different sensor types, systematic errors can be identified and corrected. This approach often uses complementary sensors with different error characteristics to provide redundancy and cross-validation. Advanced signal processing algorithms then merge these multiple data streams to produce highly accurate compensated measurements that are more reliable than those from any single sensor.

02 Hardware-based compensation techniques

Hardware solutions for temperature and humidity compensation involve specialized circuit designs and components that automatically adjust for environmental variations. These include thermistors, humidity-sensitive resistors, and reference circuits that provide real-time correction signals. Some designs incorporate dedicated compensation chips or modules that work alongside the primary sensing elements to maintain accuracy across varying conditions.Expand Specific Solutions03 Calibration methods for improved compensation accuracy

Advanced calibration techniques are essential for effective temperature and humidity compensation. These methods involve characterizing sensors across their full operating range under controlled conditions, creating detailed correction maps or lookup tables. Multi-point calibration approaches capture non-linear responses, while some systems implement automatic recalibration routines that periodically adjust compensation parameters to maintain accuracy over time.Expand Specific Solutions04 Real-time dynamic compensation systems

Real-time compensation systems continuously monitor environmental conditions and adjust measurements accordingly. These systems use feedback loops that sample temperature and humidity at high frequencies, applying instantaneous corrections to sensor outputs. Some implementations utilize predictive models that anticipate environmental changes and preemptively adjust compensation parameters, reducing lag in correction response and improving overall accuracy.Expand Specific Solutions05 Integrated sensor fusion for enhanced compensation

Sensor fusion approaches combine data from multiple sensor types to achieve more robust temperature and humidity compensation. By integrating readings from different sensor technologies with complementary characteristics, these systems can cross-validate measurements and apply more sophisticated compensation algorithms. This approach reduces dependency on individual sensor calibration and provides redundancy that improves overall system reliability and accuracy under varying environmental conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The temperature and humidity compensation techniques market is in a growth phase, characterized by increasing demand for precise environmental control across industries. The market is expanding due to rising applications in HVAC systems, industrial processes, and smart home technologies. Leading players include established HVAC manufacturers like Gree Electric Appliances and Haier Smart Home from China, alongside global industrial giants such as Honeywell International, Mitsubishi Electric, and Siemens AG. Technological maturity varies, with companies like Vaisala and Fluke Corporation offering advanced sensor solutions, while Carrier and Dwyer Instruments focus on integrated systems. Innovation is driven by semiconductor advancements from companies like Tokyo Electron and Nexchip Semiconductor, creating more precise and energy-efficient compensation technologies for diverse environmental conditions.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced temperature and humidity compensation techniques utilizing multi-point calibration systems that dynamically adjust sensor readings based on environmental conditions. Their approach incorporates proprietary algorithms that analyze historical sensor data patterns to predict and compensate for drift over time. Honeywell's solution employs dual-sensor technology with cross-verification mechanisms to ensure accuracy across wide operating ranges (-40°C to 85°C) with humidity compensation from 0-100% RH. The system features automatic temperature coefficient adjustment that recalibrates in real-time as ambient conditions change, maintaining accuracy within ±0.5°C and ±2% RH even in rapidly fluctuating environments. Their digital signal processing techniques filter out noise and environmental interference, while self-diagnostic capabilities continuously monitor sensor health and performance degradation.

Strengths: Industry-leading accuracy across extreme temperature and humidity ranges; robust self-calibration capabilities reduce maintenance requirements; extensive field-proven reliability in industrial applications. Weaknesses: Higher implementation cost compared to simpler solutions; requires more processing power for complex algorithms; some configurations have higher power consumption requirements.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has pioneered temperature and humidity compensation techniques through their Dual Sensing Control system that utilizes multiple sensor arrays strategically positioned throughout their HVAC equipment. Their approach incorporates machine learning algorithms that continuously analyze the relationship between temperature, humidity, and equipment performance to optimize compensation parameters. Mitsubishi's system employs a three-dimensional sensing grid that creates thermal mapping of spaces to identify microclimates and adjust accordingly. Their compensation technique includes predictive modeling that anticipates environmental changes based on historical patterns and external weather data inputs. The system features automatic sensor cross-calibration that compares readings across multiple points to eliminate individual sensor bias, achieving temperature accuracy within ±0.1°C and humidity precision of ±1.5% RH across their operating range.

Strengths: Exceptional precision in varied environmental conditions; integrated AI capabilities enable adaptive compensation that improves over time; comprehensive system approach rather than just sensor-level compensation. Weaknesses: Complex implementation requiring specialized technical knowledge; higher initial cost compared to conventional systems; proprietary nature limits integration with third-party equipment.

Key Patents and Technical Innovations

Thermal conductivity measurement of carbon dioxide gas with relative humidity and temperature compensation

PatentInactiveUS6843100B2

Innovation

- A method and system that compensates for humidity and temperature variations using a humidity sensor, a temperature sensor, and a carbon dioxide adjustment control circuit, employing a mathematical expression to isolate and quantify carbon dioxide levels by measuring absolute humidity and temperature, and adjusting CO2 levels accordingly.

Measurement system and apparatus, and measurement method and temperature and humidity compensation method therefor

PatentWO2022141475A1

Innovation

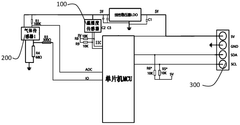

- Design a detection system, including a microcontroller, temperature and humidity sensor and gas sensor. By obtaining temperature and humidity information, the VOC concentration compensation operation is performed, and the heating resistor and voltage dividing circuit are used to optimize the operating environment of the gas-sensitive resistor and improve the measurement accuracy.

Environmental Impact and Sustainability Considerations

The implementation of temperature and humidity compensation techniques carries significant environmental implications that must be considered in their development and deployment. These technologies, while solving critical measurement challenges, can contribute to both positive and negative environmental outcomes. Energy consumption represents a primary concern, as many compensation systems require continuous power for operation, particularly in IoT sensor networks and industrial monitoring applications. The environmental footprint of these systems extends beyond operational energy to include the resources consumed during manufacturing and eventual disposal of electronic components.

Advanced compensation techniques are increasingly being designed with sustainability principles in mind. Low-power microcontrollers and energy-efficient algorithms have emerged as solutions that maintain accuracy while reducing power requirements by up to 60% compared to traditional approaches. These improvements directly translate to extended battery life and reduced electronic waste generation. Furthermore, the development of energy harvesting technologies that power compensation circuits through ambient temperature differentials or vibration represents a promising frontier for self-sustaining sensor systems.

Material selection for sensors and compensation circuits also presents environmental considerations. Traditional manufacturing often relies on rare earth elements and potentially toxic compounds that pose extraction and disposal challenges. Recent innovations have focused on biodegradable substrates and environmentally benign materials that maintain performance while reducing environmental impact. These advances align with circular economy principles and extended producer responsibility frameworks being adopted globally.

The environmental benefits of precise temperature and humidity compensation extend to numerous applications. In HVAC systems, accurate compensation enables optimal climate control that can reduce energy consumption by 15-25% in commercial buildings. Similarly, in agricultural settings, properly compensated environmental monitoring supports precision farming practices that minimize water usage and fertilizer application, reducing resource consumption and preventing groundwater contamination.

Climate change adaptation represents another dimension where these technologies contribute positively. As weather patterns become more extreme and unpredictable, robust compensation techniques ensure reliable environmental monitoring essential for early warning systems, climate research, and adaptation planning. The resilience of these systems under varying conditions directly supports sustainable development goals related to climate action and environmental protection.

Lifecycle assessment studies indicate that while the production phase of compensation technologies carries environmental costs, these are typically offset by efficiency gains during operation. However, end-of-life management remains challenging, with electronic components often entering waste streams without proper recycling. Industry initiatives focusing on modular design and recoverable materials are beginning to address these concerns, though significant progress is still needed to close the sustainability loop.

Advanced compensation techniques are increasingly being designed with sustainability principles in mind. Low-power microcontrollers and energy-efficient algorithms have emerged as solutions that maintain accuracy while reducing power requirements by up to 60% compared to traditional approaches. These improvements directly translate to extended battery life and reduced electronic waste generation. Furthermore, the development of energy harvesting technologies that power compensation circuits through ambient temperature differentials or vibration represents a promising frontier for self-sustaining sensor systems.

Material selection for sensors and compensation circuits also presents environmental considerations. Traditional manufacturing often relies on rare earth elements and potentially toxic compounds that pose extraction and disposal challenges. Recent innovations have focused on biodegradable substrates and environmentally benign materials that maintain performance while reducing environmental impact. These advances align with circular economy principles and extended producer responsibility frameworks being adopted globally.

The environmental benefits of precise temperature and humidity compensation extend to numerous applications. In HVAC systems, accurate compensation enables optimal climate control that can reduce energy consumption by 15-25% in commercial buildings. Similarly, in agricultural settings, properly compensated environmental monitoring supports precision farming practices that minimize water usage and fertilizer application, reducing resource consumption and preventing groundwater contamination.

Climate change adaptation represents another dimension where these technologies contribute positively. As weather patterns become more extreme and unpredictable, robust compensation techniques ensure reliable environmental monitoring essential for early warning systems, climate research, and adaptation planning. The resilience of these systems under varying conditions directly supports sustainable development goals related to climate action and environmental protection.

Lifecycle assessment studies indicate that while the production phase of compensation technologies carries environmental costs, these are typically offset by efficiency gains during operation. However, end-of-life management remains challenging, with electronic components often entering waste streams without proper recycling. Industry initiatives focusing on modular design and recoverable materials are beginning to address these concerns, though significant progress is still needed to close the sustainability loop.

Cross-Industry Applications and Use Cases

Temperature and humidity compensation techniques have found widespread applications across numerous industries, demonstrating their versatility and critical importance in various operational contexts. In manufacturing sectors, these techniques are extensively utilized in semiconductor fabrication where precise environmental control directly impacts product quality and yield rates. Production facilities implement advanced compensation algorithms to maintain optimal conditions during sensitive processes such as wafer etching and photolithography.

The agricultural industry has embraced these technologies for greenhouse management and crop storage facilities. Smart farming systems incorporate temperature and humidity compensation to create ideal growing conditions for different crop varieties, resulting in increased yields and reduced resource consumption. Similarly, these techniques are vital in post-harvest storage to prevent spoilage and maintain product quality.

In pharmaceutical manufacturing and storage, compensation techniques ensure compliance with strict regulatory requirements. Vaccine production facilities and medication storage systems rely on precise environmental control to maintain product efficacy and safety. The implementation of real-time compensation algorithms has significantly reduced product loss and improved quality assurance metrics.

The transportation and logistics sector utilizes these techniques for cold chain management when shipping temperature-sensitive goods. Advanced sensor networks with compensation capabilities monitor and adjust conditions during transit, ensuring products remain within specified environmental parameters regardless of external conditions.

In the energy sector, HVAC system efficiency has been dramatically improved through the implementation of temperature and humidity compensation. Smart building management systems continuously adjust operations based on compensated sensor readings, resulting in energy savings of 15-30% compared to traditional systems. These techniques also extend equipment lifespan by preventing condensation damage and optimizing operational parameters.

Cultural heritage preservation represents another critical application area. Museums and archives employ sophisticated compensation systems to protect irreplaceable artifacts from environmental damage. These systems account for seasonal variations, visitor traffic patterns, and building envelope characteristics to maintain stable preservation conditions.

The healthcare industry implements these techniques in operating rooms, laboratories, and patient care environments where precise environmental control impacts both diagnostic accuracy and patient outcomes. Modern hospital designs incorporate zoned environmental control systems with compensation capabilities tailored to the specific requirements of different medical procedures and equipment.

The agricultural industry has embraced these technologies for greenhouse management and crop storage facilities. Smart farming systems incorporate temperature and humidity compensation to create ideal growing conditions for different crop varieties, resulting in increased yields and reduced resource consumption. Similarly, these techniques are vital in post-harvest storage to prevent spoilage and maintain product quality.

In pharmaceutical manufacturing and storage, compensation techniques ensure compliance with strict regulatory requirements. Vaccine production facilities and medication storage systems rely on precise environmental control to maintain product efficacy and safety. The implementation of real-time compensation algorithms has significantly reduced product loss and improved quality assurance metrics.

The transportation and logistics sector utilizes these techniques for cold chain management when shipping temperature-sensitive goods. Advanced sensor networks with compensation capabilities monitor and adjust conditions during transit, ensuring products remain within specified environmental parameters regardless of external conditions.

In the energy sector, HVAC system efficiency has been dramatically improved through the implementation of temperature and humidity compensation. Smart building management systems continuously adjust operations based on compensated sensor readings, resulting in energy savings of 15-30% compared to traditional systems. These techniques also extend equipment lifespan by preventing condensation damage and optimizing operational parameters.

Cultural heritage preservation represents another critical application area. Museums and archives employ sophisticated compensation systems to protect irreplaceable artifacts from environmental damage. These systems account for seasonal variations, visitor traffic patterns, and building envelope characteristics to maintain stable preservation conditions.

The healthcare industry implements these techniques in operating rooms, laboratories, and patient care environments where precise environmental control impacts both diagnostic accuracy and patient outcomes. Modern hospital designs incorporate zoned environmental control systems with compensation capabilities tailored to the specific requirements of different medical procedures and equipment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!