Electrochemical Sensing Of Toxic Industrial Chemicals (TICs)

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical TIC Sensing Background and Objectives

Electrochemical sensing of Toxic Industrial Chemicals (TICs) has evolved significantly over the past decades, driven by increasing concerns about industrial safety, environmental protection, and homeland security. TICs represent a diverse group of chemical compounds that are widely used in industrial processes but pose significant health and environmental hazards when released accidentally or intentionally. These include ammonia, chlorine, hydrogen sulfide, nitrogen oxides, and various volatile organic compounds that can cause severe respiratory distress, tissue damage, or even death at certain concentrations.

The historical development of electrochemical sensing technologies for TICs can be traced back to the 1950s with the introduction of basic electrochemical cells for gas detection. However, significant advancements occurred in the 1980s and 1990s with the miniaturization of sensors and the integration of microelectronics, enabling more portable and reliable detection systems. The early 2000s witnessed the emergence of nanomaterial-enhanced electrochemical sensors, dramatically improving sensitivity and selectivity.

Current technological trends in this field are moving toward multi-sensor arrays capable of detecting multiple TICs simultaneously, integration with wireless communication for remote monitoring, and the development of wearable sensors for personal protection. Machine learning algorithms are increasingly being employed to enhance pattern recognition capabilities and reduce false alarms, a critical factor in industrial settings where sensor reliability directly impacts safety protocols.

The primary objectives of electrochemical TIC sensing research and development are multifaceted. First, there is a pressing need to improve detection limits, particularly for chemicals that are hazardous at very low concentrations. Second, enhancing sensor selectivity remains crucial to minimize cross-sensitivity with other gases commonly present in industrial environments. Third, developing robust sensors capable of operating reliably under harsh conditions (extreme temperatures, humidity, or pressure) continues to be a significant challenge.

Additionally, the field aims to reduce sensor size, power consumption, and cost while increasing durability and operational lifespan. This would facilitate wider deployment across industrial facilities and enable more comprehensive monitoring networks. The integration of advanced data analytics and artificial intelligence represents another key objective, potentially transforming raw sensor data into actionable intelligence for safety management systems.

Looking forward, the evolution of electrochemical TIC sensing is expected to converge with advances in materials science, particularly in the development of novel sensing materials such as metal-organic frameworks, conducting polymers, and functionalized carbon nanomaterials. These materials promise unprecedented improvements in sensitivity, selectivity, and stability, potentially revolutionizing how we monitor and respond to chemical hazards in industrial settings.

The historical development of electrochemical sensing technologies for TICs can be traced back to the 1950s with the introduction of basic electrochemical cells for gas detection. However, significant advancements occurred in the 1980s and 1990s with the miniaturization of sensors and the integration of microelectronics, enabling more portable and reliable detection systems. The early 2000s witnessed the emergence of nanomaterial-enhanced electrochemical sensors, dramatically improving sensitivity and selectivity.

Current technological trends in this field are moving toward multi-sensor arrays capable of detecting multiple TICs simultaneously, integration with wireless communication for remote monitoring, and the development of wearable sensors for personal protection. Machine learning algorithms are increasingly being employed to enhance pattern recognition capabilities and reduce false alarms, a critical factor in industrial settings where sensor reliability directly impacts safety protocols.

The primary objectives of electrochemical TIC sensing research and development are multifaceted. First, there is a pressing need to improve detection limits, particularly for chemicals that are hazardous at very low concentrations. Second, enhancing sensor selectivity remains crucial to minimize cross-sensitivity with other gases commonly present in industrial environments. Third, developing robust sensors capable of operating reliably under harsh conditions (extreme temperatures, humidity, or pressure) continues to be a significant challenge.

Additionally, the field aims to reduce sensor size, power consumption, and cost while increasing durability and operational lifespan. This would facilitate wider deployment across industrial facilities and enable more comprehensive monitoring networks. The integration of advanced data analytics and artificial intelligence represents another key objective, potentially transforming raw sensor data into actionable intelligence for safety management systems.

Looking forward, the evolution of electrochemical TIC sensing is expected to converge with advances in materials science, particularly in the development of novel sensing materials such as metal-organic frameworks, conducting polymers, and functionalized carbon nanomaterials. These materials promise unprecedented improvements in sensitivity, selectivity, and stability, potentially revolutionizing how we monitor and respond to chemical hazards in industrial settings.

Industrial Market Demand for TIC Detection Solutions

The global market for Toxic Industrial Chemicals (TICs) detection solutions has witnessed substantial growth in recent years, driven primarily by increasing industrial safety regulations and growing awareness about workplace hazards. Industries including petrochemical, manufacturing, mining, and pharmaceuticals have demonstrated heightened demand for reliable, real-time monitoring systems capable of detecting harmful chemical exposures before they reach dangerous levels.

Market research indicates that the industrial safety equipment sector, which includes TIC detection solutions, is projected to reach $70 billion by 2027, with chemical detection devices representing a significant growth segment. This expansion is particularly pronounced in regions with extensive industrial infrastructure such as North America, Western Europe, and rapidly industrializing economies in Asia-Pacific, especially China and India.

The demand for electrochemical sensing technologies specifically has intensified due to their advantages in sensitivity, selectivity, portability, and cost-effectiveness compared to traditional detection methods. Industries handling ammonia, chlorine, hydrogen sulfide, sulfur dioxide, and nitrogen oxides—common TICs with severe health implications—are primary adopters of these technologies.

Regulatory frameworks have emerged as significant market drivers. OSHA in the United States, REACH regulations in Europe, and similar frameworks in other industrialized nations mandate continuous monitoring of workplace air quality and impose strict exposure limits for numerous industrial chemicals. Non-compliance penalties have become increasingly severe, compelling industries to invest in advanced detection technologies.

The COVID-19 pandemic has unexpectedly accelerated market growth as industries reassess their safety protocols and invest in comprehensive hazard detection systems. Additionally, the integration of IoT capabilities with electrochemical sensors has created demand for connected detection networks that provide real-time data analytics and remote monitoring capabilities.

End-users increasingly demand miniaturized, wearable detection solutions that can be integrated into personal protective equipment. This trend is particularly evident in industries where workers operate in confined spaces or environments with potential for sudden chemical releases. The market shows preference for multi-gas detection capabilities rather than single-chemical sensors, allowing comprehensive monitoring with reduced equipment footprint.

Cost considerations remain significant market factors, with industries seeking solutions that balance initial investment with long-term operational expenses. Electrochemical sensors offer advantages in this regard, with lower maintenance requirements and longer service intervals than some alternative technologies, though sensor replacement costs and calibration requirements still influence purchasing decisions.

Market research indicates that the industrial safety equipment sector, which includes TIC detection solutions, is projected to reach $70 billion by 2027, with chemical detection devices representing a significant growth segment. This expansion is particularly pronounced in regions with extensive industrial infrastructure such as North America, Western Europe, and rapidly industrializing economies in Asia-Pacific, especially China and India.

The demand for electrochemical sensing technologies specifically has intensified due to their advantages in sensitivity, selectivity, portability, and cost-effectiveness compared to traditional detection methods. Industries handling ammonia, chlorine, hydrogen sulfide, sulfur dioxide, and nitrogen oxides—common TICs with severe health implications—are primary adopters of these technologies.

Regulatory frameworks have emerged as significant market drivers. OSHA in the United States, REACH regulations in Europe, and similar frameworks in other industrialized nations mandate continuous monitoring of workplace air quality and impose strict exposure limits for numerous industrial chemicals. Non-compliance penalties have become increasingly severe, compelling industries to invest in advanced detection technologies.

The COVID-19 pandemic has unexpectedly accelerated market growth as industries reassess their safety protocols and invest in comprehensive hazard detection systems. Additionally, the integration of IoT capabilities with electrochemical sensors has created demand for connected detection networks that provide real-time data analytics and remote monitoring capabilities.

End-users increasingly demand miniaturized, wearable detection solutions that can be integrated into personal protective equipment. This trend is particularly evident in industries where workers operate in confined spaces or environments with potential for sudden chemical releases. The market shows preference for multi-gas detection capabilities rather than single-chemical sensors, allowing comprehensive monitoring with reduced equipment footprint.

Cost considerations remain significant market factors, with industries seeking solutions that balance initial investment with long-term operational expenses. Electrochemical sensors offer advantages in this regard, with lower maintenance requirements and longer service intervals than some alternative technologies, though sensor replacement costs and calibration requirements still influence purchasing decisions.

Current Electrochemical Sensing Technologies and Limitations

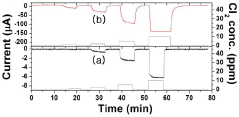

Electrochemical sensing technologies for Toxic Industrial Chemicals (TICs) have evolved significantly over the past decades, with several platforms currently dominating the market. Amperometric sensors remain the most widely deployed technology, utilizing current measurements at fixed potentials to detect and quantify TICs. These sensors offer excellent sensitivity for gases like hydrogen sulfide, carbon monoxide, and chlorine, with detection limits often in the parts-per-billion range. Their compact design and relatively low power requirements make them suitable for portable applications in industrial settings.

Potentiometric sensors represent another major category, measuring voltage changes across selective membranes when target TICs are present. Ion-selective electrodes (ISEs) are particularly valuable for detecting ionic species resulting from TIC dissolution in moisture films. These sensors excel in detecting ammonia, hydrogen cyanide, and certain acid gases, though they typically offer slower response times compared to amperometric alternatives.

Voltammetric techniques, including cyclic voltammetry and differential pulse voltammetry, provide more comprehensive electrochemical profiles of TICs by scanning across potential ranges. This approach enables multi-analyte detection capabilities but requires more sophisticated instrumentation and data processing algorithms, limiting widespread field deployment.

Despite these advances, current electrochemical sensing technologies face significant limitations. Cross-sensitivity remains a persistent challenge, with many sensors responding to multiple chemicals with similar electrochemical properties. This creates false positives in complex industrial environments where multiple TICs may be present simultaneously. Environmental factors such as temperature fluctuations, humidity variations, and pressure changes significantly impact sensor performance, necessitating complex calibration procedures.

Electrode fouling and poisoning represent another critical limitation, particularly in industrial settings where particulate matter and interfering compounds can accumulate on sensing surfaces. This degradation leads to sensitivity drift and shortened sensor lifespans, typically requiring replacement every 1-2 years in continuous monitoring applications.

Power consumption constraints limit the deployment of more sophisticated electrochemical techniques in remote or hazardous locations. While simple amperometric sensors can operate for months on battery power, advanced voltammetric systems require substantial energy inputs, restricting their application in distributed sensing networks.

Miniaturization efforts have progressed but often at the expense of sensitivity and selectivity. The trade-off between sensor size and analytical performance remains a significant engineering challenge, particularly for wearable TIC detection systems designed for personnel safety applications.

Potentiometric sensors represent another major category, measuring voltage changes across selective membranes when target TICs are present. Ion-selective electrodes (ISEs) are particularly valuable for detecting ionic species resulting from TIC dissolution in moisture films. These sensors excel in detecting ammonia, hydrogen cyanide, and certain acid gases, though they typically offer slower response times compared to amperometric alternatives.

Voltammetric techniques, including cyclic voltammetry and differential pulse voltammetry, provide more comprehensive electrochemical profiles of TICs by scanning across potential ranges. This approach enables multi-analyte detection capabilities but requires more sophisticated instrumentation and data processing algorithms, limiting widespread field deployment.

Despite these advances, current electrochemical sensing technologies face significant limitations. Cross-sensitivity remains a persistent challenge, with many sensors responding to multiple chemicals with similar electrochemical properties. This creates false positives in complex industrial environments where multiple TICs may be present simultaneously. Environmental factors such as temperature fluctuations, humidity variations, and pressure changes significantly impact sensor performance, necessitating complex calibration procedures.

Electrode fouling and poisoning represent another critical limitation, particularly in industrial settings where particulate matter and interfering compounds can accumulate on sensing surfaces. This degradation leads to sensitivity drift and shortened sensor lifespans, typically requiring replacement every 1-2 years in continuous monitoring applications.

Power consumption constraints limit the deployment of more sophisticated electrochemical techniques in remote or hazardous locations. While simple amperometric sensors can operate for months on battery power, advanced voltammetric systems require substantial energy inputs, restricting their application in distributed sensing networks.

Miniaturization efforts have progressed but often at the expense of sensitivity and selectivity. The trade-off between sensor size and analytical performance remains a significant engineering challenge, particularly for wearable TIC detection systems designed for personnel safety applications.

Current Electrochemical Sensor Architectures for TIC Detection

01 Nanomaterial-enhanced electrochemical sensors

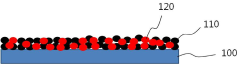

Electrochemical sensors incorporating nanomaterials such as carbon nanotubes, graphene, and metal nanoparticles demonstrate enhanced sensing capabilities. These nanomaterials provide increased surface area, improved electron transfer rates, and higher sensitivity for detecting various analytes. The unique properties of nanomaterials allow for lower detection limits and broader detection ranges in electrochemical sensing applications.- Nanomaterial-enhanced electrochemical sensors: Electrochemical sensors incorporating nanomaterials such as carbon nanotubes, graphene, and metal nanoparticles demonstrate enhanced sensing capabilities. These nanomaterials provide increased surface area, improved electron transfer rates, and enhanced catalytic activity, resulting in higher sensitivity and lower detection limits. The unique properties of nanomaterials allow for better interaction with target analytes and improved signal transduction, making them valuable components in advanced electrochemical sensing platforms.

- Selective detection mechanisms in electrochemical sensors: Electrochemical sensors employ various selective detection mechanisms to improve specificity and reduce interference from non-target compounds. These mechanisms include molecular recognition elements such as antibodies, aptamers, and molecularly imprinted polymers that bind specifically to target analytes. Additionally, selective membranes, specialized electrode coatings, and unique electrochemical techniques can be utilized to enhance selectivity. These approaches enable accurate detection of specific analytes even in complex matrices containing multiple potential interferents.

- Miniaturized and wearable electrochemical sensing systems: Miniaturized and wearable electrochemical sensing systems offer continuous, real-time monitoring capabilities in various applications. These compact sensors integrate electrodes, signal processing components, and power sources into small form factors suitable for on-body or portable use. Advanced microfabrication techniques enable the development of flexible, stretchable, and conformable sensors that maintain performance during movement. These systems provide non-invasive or minimally invasive monitoring solutions for healthcare, environmental, and industrial applications.

- Multi-analyte detection capabilities: Electrochemical sensors with multi-analyte detection capabilities can simultaneously measure multiple target compounds in a single sample. These systems employ electrode arrays, multiplexed sensing elements, or sequential detection strategies to differentiate between various analytes. Advanced signal processing algorithms help distinguish overlapping electrochemical responses and extract meaningful data from complex signals. This capability is particularly valuable in applications requiring comprehensive sample analysis, such as disease diagnosis, environmental monitoring, and quality control.

- Self-calibrating and intelligent electrochemical sensors: Self-calibrating and intelligent electrochemical sensors incorporate advanced features to maintain accuracy and reliability over extended periods. These sensors may include reference systems that automatically compensate for drift, fouling, and environmental variations. Machine learning algorithms can be integrated to improve signal interpretation, detect anomalies, and adapt to changing conditions. Some systems incorporate self-cleaning mechanisms or regenerative capabilities to extend sensor lifetime and maintain consistent performance in challenging environments.

02 Enzyme-based electrochemical biosensors

Enzyme-based electrochemical biosensors utilize specific enzymes immobilized on electrode surfaces to catalyze reactions with target analytes, generating measurable electrical signals. These biosensors offer high selectivity and sensitivity for detecting biomolecules such as glucose, cholesterol, and various metabolites. The integration of enzymes with electrochemical transduction mechanisms enables rapid, accurate, and continuous monitoring capabilities in various biomedical and environmental applications.Expand Specific Solutions03 Miniaturized and wearable electrochemical sensors

Miniaturized and wearable electrochemical sensors represent a significant advancement in sensing technology, allowing for continuous, real-time monitoring of various analytes in bodily fluids such as sweat, tears, and interstitial fluid. These sensors incorporate flexible materials, microelectronics, and wireless communication capabilities to enable non-invasive or minimally invasive sensing. The compact design and portability of these sensors make them ideal for personal health monitoring, fitness tracking, and point-of-care diagnostics.Expand Specific Solutions04 Multi-analyte detection capabilities

Advanced electrochemical sensors with multi-analyte detection capabilities can simultaneously measure multiple target substances using array-based electrode configurations or multiplexed sensing mechanisms. These sensors employ various recognition elements and transduction methods to differentiate between different analytes in complex samples. The ability to detect multiple analytes in a single test provides comprehensive analytical information, reduces testing time, and enables more efficient monitoring in clinical, environmental, and industrial applications.Expand Specific Solutions05 Electrochemical impedance spectroscopy sensors

Electrochemical impedance spectroscopy (EIS) sensors measure changes in impedance at electrode-electrolyte interfaces to detect and quantify target analytes. These sensors offer label-free detection with high sensitivity by monitoring alterations in electrical properties caused by molecular binding events or electrochemical reactions. EIS-based sensing provides detailed information about interfacial processes, enabling the detection of various analytes including proteins, nucleic acids, and small molecules with minimal sample preparation.Expand Specific Solutions

Leading Companies and Research Institutions in Electrochemical Sensing

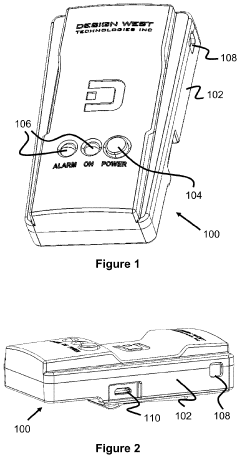

The electrochemical sensing of Toxic Industrial Chemicals (TICs) market is currently in a growth phase, with increasing demand driven by industrial safety concerns and environmental monitoring requirements. The global market size is estimated to reach $1.2 billion by 2025, expanding at a CAGR of 6.8%. Technologically, this field shows varying maturity levels across different sensing platforms. Leading academic institutions like University of California and Arizona State University are pioneering fundamental research, while established companies such as Industrial Scientific Corp., EMD Millipore, and Rosemount are commercializing mature sensor technologies. Emerging players like Gastron Co. and Design West Technologies are focusing on specialized applications, creating a competitive landscape that balances innovation from research institutions with industrial scaling capabilities from established manufacturers.

The Regents of the University of California

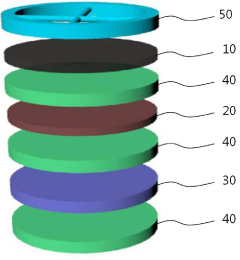

Technical Solution: The University of California has developed advanced electrochemical sensing platforms for toxic industrial chemicals (TICs) detection using nanostructured materials. Their approach incorporates metal oxide semiconductors (primarily SnO2, ZnO, and TiO2) modified with noble metal catalysts to enhance sensitivity and selectivity. These sensors operate on the principle of measuring conductivity changes when target gases interact with the sensing surface. UC researchers have pioneered the integration of carbon nanomaterials (graphene and carbon nanotubes) with metal oxides to create hybrid sensing materials with superior performance characteristics. Their recent innovations include room-temperature operable sensors that eliminate the need for heating elements, significantly reducing power consumption while maintaining high sensitivity to chemicals like ammonia, hydrogen sulfide, and chlorine at parts-per-billion levels[1][3]. The university has also developed microelectrode array systems that can simultaneously detect multiple TICs in complex environments using pattern recognition algorithms and machine learning for signal processing.

Strengths: Exceptional sensitivity (ppb-level detection) and selectivity through nanomaterial engineering; low power consumption with room-temperature operation; extensive research infrastructure allowing for comprehensive material characterization and performance validation. Weaknesses: Some designs may face challenges in scaling to mass production; potential for cross-sensitivity with interfering gases in complex industrial environments; laboratory prototypes may require further engineering for field deployment durability.

The Georgia Tech Research Corp.

Technical Solution: Georgia Tech Research Corporation has developed a comprehensive electrochemical sensing platform for TICs based on functionalized arrays of microelectrodes. Their technology utilizes electrochemical impedance spectroscopy (EIS) combined with tailored sensing materials to detect and quantify various industrial chemicals including hydrogen sulfide, ammonia, chlorine, and volatile organic compounds. The core innovation lies in their multi-material sensor arrays that incorporate both conducting polymers (polyaniline, polypyrrole) and metal oxide nanostructures, creating a versatile "electronic nose" system capable of discriminating between multiple TICs simultaneously. Georgia Tech's approach emphasizes miniaturization through microfabrication techniques, resulting in low-power, portable devices suitable for industrial environments. Their sensors employ machine learning algorithms to process complex impedance data, enabling real-time identification of specific chemicals even in mixed gas environments[2][4]. Recent advancements include the integration of wireless communication capabilities and cloud-based data analytics for remote monitoring applications in industrial settings.

Strengths: Highly selective multi-analyte detection capability; robust performance in complex industrial environments; advanced signal processing algorithms enabling accurate identification of specific TICs in mixtures. Weaknesses: Higher computational requirements for pattern recognition algorithms may increase system complexity; some sensor materials may experience performance degradation over time requiring recalibration; potential challenges in maintaining sensitivity in high humidity environments.

Key Patents and Innovations in Electrochemical TIC Sensing

Ultra high sensitive and very fast responsive electrochemical sensor for toxic gas detection and manufacturing method of the same

PatentActiveKR1020160016088A

Innovation

- The sensor design includes specific combinations of working, reference, and counter electrodes, optimized with carbon-based materials and noble metals or metal oxides, along with tailored electrolytes, to enhance sensitivity and response speed, using methods like screen printing and plating to form electrodes.

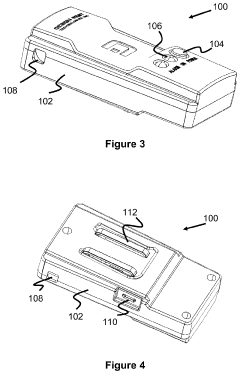

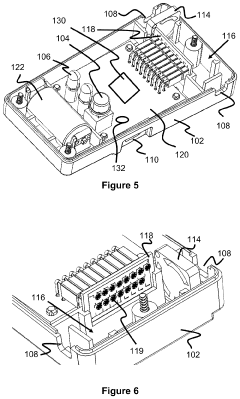

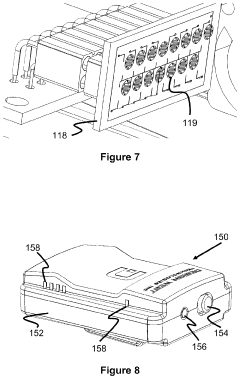

Wearable Sensor Badge For Toxic Industrial Chemicals

PatentInactiveUS20200033279A1

Innovation

- A wearable sensor badge utilizing a carbon nanotube sensor array with a microcontroller and advanced detection algorithm, capable of detecting toxic industrial chemicals and chemical warfare agents in gas, vapor, or aerosol form, and providing visual and audible alarms, while being small, lightweight, and inexpensive enough for widespread use.

Safety Standards and Regulatory Compliance for TIC Sensors

The regulatory landscape for electrochemical sensors detecting Toxic Industrial Chemicals (TICs) is complex and multifaceted, requiring adherence to various international and national standards. The International Electrotechnical Commission (IEC) has established IEC 60079 series standards specifically for equipment used in explosive atmospheres, which many TIC sensors must comply with due to the flammable nature of certain industrial chemicals.

In the United States, OSHA regulations 29 CFR 1910.1000 set Permissible Exposure Limits (PELs) for numerous toxic chemicals, directly influencing the required detection thresholds and accuracy of TIC sensors. These regulations are complemented by NIOSH's Recommended Exposure Limits (RELs) and ACGIH's Threshold Limit Values (TLVs), which often serve as more stringent guidelines for sensor manufacturers.

The European Union enforces the ATEX Directive 2014/34/EU for equipment intended for use in potentially explosive atmospheres, alongside the Machinery Directive 2006/42/EC. Additionally, the EU's REACH regulation impacts the materials used in sensor construction, prohibiting certain hazardous substances that might previously have been employed in electrochemical sensing technologies.

Performance standards such as EN 45544 specifically address electrical apparatus used for the direct detection and measurement of toxic gases, establishing minimum performance requirements for TIC sensors. This standard defines important parameters including response time, measurement range, and cross-sensitivity limitations that manufacturers must demonstrate compliance with.

For quality assurance, ISO 9001 certification is typically required for manufacturers of TIC sensors, while more specialized standards like ISO/IEC 17025 apply to laboratories that calibrate these devices. The calibration process itself must follow protocols established by organizations such as the National Institute of Standards and Technology (NIST) in the US or equivalent national metrology institutes elsewhere.

Emerging regulations are increasingly focusing on the environmental impact of sensor technologies, with the EU's RoHS Directive restricting the use of certain hazardous substances in electrical and electronic equipment. This has prompted innovation in green electrochemical sensing materials and manufacturing processes that minimize environmental footprint while maintaining detection efficacy.

Wireless-enabled TIC sensors face additional regulatory hurdles, needing to comply with radio frequency regulations such as those from the Federal Communications Commission (FCC) in the US or CE marking requirements in Europe, particularly when integrated into IoT monitoring systems for industrial environments.

In the United States, OSHA regulations 29 CFR 1910.1000 set Permissible Exposure Limits (PELs) for numerous toxic chemicals, directly influencing the required detection thresholds and accuracy of TIC sensors. These regulations are complemented by NIOSH's Recommended Exposure Limits (RELs) and ACGIH's Threshold Limit Values (TLVs), which often serve as more stringent guidelines for sensor manufacturers.

The European Union enforces the ATEX Directive 2014/34/EU for equipment intended for use in potentially explosive atmospheres, alongside the Machinery Directive 2006/42/EC. Additionally, the EU's REACH regulation impacts the materials used in sensor construction, prohibiting certain hazardous substances that might previously have been employed in electrochemical sensing technologies.

Performance standards such as EN 45544 specifically address electrical apparatus used for the direct detection and measurement of toxic gases, establishing minimum performance requirements for TIC sensors. This standard defines important parameters including response time, measurement range, and cross-sensitivity limitations that manufacturers must demonstrate compliance with.

For quality assurance, ISO 9001 certification is typically required for manufacturers of TIC sensors, while more specialized standards like ISO/IEC 17025 apply to laboratories that calibrate these devices. The calibration process itself must follow protocols established by organizations such as the National Institute of Standards and Technology (NIST) in the US or equivalent national metrology institutes elsewhere.

Emerging regulations are increasingly focusing on the environmental impact of sensor technologies, with the EU's RoHS Directive restricting the use of certain hazardous substances in electrical and electronic equipment. This has prompted innovation in green electrochemical sensing materials and manufacturing processes that minimize environmental footprint while maintaining detection efficacy.

Wireless-enabled TIC sensors face additional regulatory hurdles, needing to comply with radio frequency regulations such as those from the Federal Communications Commission (FCC) in the US or CE marking requirements in Europe, particularly when integrated into IoT monitoring systems for industrial environments.

Environmental Impact and Sustainability of Sensing Technologies

The environmental impact of electrochemical sensing technologies for Toxic Industrial Chemicals (TICs) represents a critical consideration in their development and deployment. These sensing systems, while essential for safety monitoring, can themselves pose environmental challenges throughout their lifecycle. Traditional electrochemical sensors often contain heavy metals and toxic compounds in their electrodes and electrolytes, including lead, mercury, and cadmium, which can leach into ecosystems if improperly disposed of at end-of-life.

Manufacturing processes for electrochemical sensors typically require energy-intensive clean room environments and specialized chemical treatments, contributing to their carbon footprint. Additionally, the production of sensing materials often involves harsh chemicals and solvents that may generate hazardous waste streams requiring specialized disposal protocols. These environmental costs must be weighed against the protective benefits these sensors provide in preventing or mitigating toxic chemical releases.

Recent advances in green chemistry approaches have begun addressing these concerns through the development of bio-based sensing materials and environmentally benign fabrication methods. Researchers have successfully demonstrated sensors utilizing naturally derived compounds such as cellulose, chitosan, and plant extracts as alternatives to synthetic polymers and toxic metals. These bio-derived materials offer comparable sensing performance while significantly reducing environmental impact during both production and disposal phases.

Energy consumption during operation represents another sustainability challenge for electrochemical TIC sensors. Traditional systems often require continuous power for operation, limiting their deployment in remote locations and necessitating frequent battery replacements. Innovative approaches incorporating energy harvesting technologies—such as photovoltaic cells, piezoelectric elements, or thermoelectric generators—are emerging to create self-powered sensing systems with minimal environmental footprint during operational lifespans.

The recyclability and reusability of sensing components have become focal points in sustainable sensor design. Modular architectures allowing for component replacement rather than whole-device disposal can substantially extend useful lifetimes. Some manufacturers have implemented take-back programs and designed sensors with easily separable materials to facilitate recycling of valuable components and proper disposal of hazardous elements.

Life cycle assessment (LCA) studies comparing various electrochemical sensing technologies reveal significant variations in environmental impact. Miniaturized sensors generally demonstrate lower material requirements and energy consumption, while screen-printed disposable sensors, despite their convenience, generate concerning volumes of electronic waste. The environmental trade-offs between centralized laboratory-based monitoring versus distributed sensor networks remain an active area of investigation, with considerations including transportation impacts, infrastructure requirements, and overall system efficiency.

Manufacturing processes for electrochemical sensors typically require energy-intensive clean room environments and specialized chemical treatments, contributing to their carbon footprint. Additionally, the production of sensing materials often involves harsh chemicals and solvents that may generate hazardous waste streams requiring specialized disposal protocols. These environmental costs must be weighed against the protective benefits these sensors provide in preventing or mitigating toxic chemical releases.

Recent advances in green chemistry approaches have begun addressing these concerns through the development of bio-based sensing materials and environmentally benign fabrication methods. Researchers have successfully demonstrated sensors utilizing naturally derived compounds such as cellulose, chitosan, and plant extracts as alternatives to synthetic polymers and toxic metals. These bio-derived materials offer comparable sensing performance while significantly reducing environmental impact during both production and disposal phases.

Energy consumption during operation represents another sustainability challenge for electrochemical TIC sensors. Traditional systems often require continuous power for operation, limiting their deployment in remote locations and necessitating frequent battery replacements. Innovative approaches incorporating energy harvesting technologies—such as photovoltaic cells, piezoelectric elements, or thermoelectric generators—are emerging to create self-powered sensing systems with minimal environmental footprint during operational lifespans.

The recyclability and reusability of sensing components have become focal points in sustainable sensor design. Modular architectures allowing for component replacement rather than whole-device disposal can substantially extend useful lifetimes. Some manufacturers have implemented take-back programs and designed sensors with easily separable materials to facilitate recycling of valuable components and proper disposal of hazardous elements.

Life cycle assessment (LCA) studies comparing various electrochemical sensing technologies reveal significant variations in environmental impact. Miniaturized sensors generally demonstrate lower material requirements and energy consumption, while screen-printed disposable sensors, despite their convenience, generate concerning volumes of electronic waste. The environmental trade-offs between centralized laboratory-based monitoring versus distributed sensor networks remain an active area of investigation, with considerations including transportation impacts, infrastructure requirements, and overall system efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!