Electrode Microstructure Characterization Techniques

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrode Microstructure Analysis Background and Objectives

Electrode microstructure characterization has evolved significantly over the past decades, transforming from basic optical microscopy to sophisticated multi-dimensional analytical techniques. This evolution has been driven by the increasing demands for high-performance energy storage and conversion devices, where electrode microstructure plays a critical role in determining device efficiency, durability, and overall performance.

The historical development of electrode characterization began in the 1960s with simple scanning electron microscopy (SEM) observations, providing two-dimensional morphological information. The 1980s witnessed the integration of energy-dispersive X-ray spectroscopy (EDS) with SEM, enabling elemental composition analysis alongside structural observations. A paradigm shift occurred in the early 2000s with the advancement of focused ion beam-scanning electron microscopy (FIB-SEM) and X-ray computed tomography (XCT), which enabled three-dimensional reconstruction of electrode architectures.

Current technological trends are moving toward multi-scale, multi-modal characterization approaches that combine complementary techniques to provide comprehensive insights across different length scales. These approaches aim to bridge the gap between atomic-level phenomena and macroscopic electrode behavior, which is essential for rational electrode design and optimization.

The primary objective of electrode microstructure characterization is to establish quantitative structure-property relationships that can guide the development of next-generation electrodes with enhanced performance metrics. This involves accurate quantification of key microstructural parameters such as porosity, tortuosity, specific surface area, particle size distribution, and phase connectivity.

Another critical goal is to develop in-situ and operando characterization methodologies that can capture dynamic changes in electrode microstructure during device operation. These techniques are particularly valuable for understanding degradation mechanisms and failure modes, which are often related to microstructural evolution under operational conditions.

Furthermore, there is a growing emphasis on correlating experimental characterization with computational modeling to create predictive frameworks for electrode design. This synergistic approach aims to accelerate the development cycle by reducing the reliance on empirical trial-and-error methods.

The ultimate aim of advanced electrode microstructure characterization is to enable precise engineering of electrodes at multiple length scales, from nanometer to millimeter, to achieve optimal performance for specific applications ranging from electric vehicles to grid-scale energy storage systems. This requires not only technological innovation in characterization tools but also sophisticated data analysis methods to extract meaningful insights from increasingly complex datasets.

The historical development of electrode characterization began in the 1960s with simple scanning electron microscopy (SEM) observations, providing two-dimensional morphological information. The 1980s witnessed the integration of energy-dispersive X-ray spectroscopy (EDS) with SEM, enabling elemental composition analysis alongside structural observations. A paradigm shift occurred in the early 2000s with the advancement of focused ion beam-scanning electron microscopy (FIB-SEM) and X-ray computed tomography (XCT), which enabled three-dimensional reconstruction of electrode architectures.

Current technological trends are moving toward multi-scale, multi-modal characterization approaches that combine complementary techniques to provide comprehensive insights across different length scales. These approaches aim to bridge the gap between atomic-level phenomena and macroscopic electrode behavior, which is essential for rational electrode design and optimization.

The primary objective of electrode microstructure characterization is to establish quantitative structure-property relationships that can guide the development of next-generation electrodes with enhanced performance metrics. This involves accurate quantification of key microstructural parameters such as porosity, tortuosity, specific surface area, particle size distribution, and phase connectivity.

Another critical goal is to develop in-situ and operando characterization methodologies that can capture dynamic changes in electrode microstructure during device operation. These techniques are particularly valuable for understanding degradation mechanisms and failure modes, which are often related to microstructural evolution under operational conditions.

Furthermore, there is a growing emphasis on correlating experimental characterization with computational modeling to create predictive frameworks for electrode design. This synergistic approach aims to accelerate the development cycle by reducing the reliance on empirical trial-and-error methods.

The ultimate aim of advanced electrode microstructure characterization is to enable precise engineering of electrodes at multiple length scales, from nanometer to millimeter, to achieve optimal performance for specific applications ranging from electric vehicles to grid-scale energy storage systems. This requires not only technological innovation in characterization tools but also sophisticated data analysis methods to extract meaningful insights from increasingly complex datasets.

Market Demand for Advanced Characterization Methods

The market for advanced electrode microstructure characterization techniques has witnessed substantial growth in recent years, driven primarily by the expanding energy storage sector. With the global push towards electrification and renewable energy integration, battery technologies have become central to numerous industries, creating an unprecedented demand for sophisticated characterization methods that can enhance electrode performance and longevity.

Battery manufacturers are increasingly seeking high-resolution, multi-dimensional characterization techniques that provide comprehensive insights into electrode microstructures. This demand stems from the direct correlation between microstructural properties and battery performance metrics such as capacity, power density, and cycle life. The ability to precisely characterize pore networks, active material distribution, and interfacial phenomena has become a competitive advantage in the industry.

Research institutions and academic laboratories represent another significant market segment, requiring advanced characterization tools for fundamental studies of electrode materials and degradation mechanisms. The growing publication volume in battery research has created sustained demand for cutting-edge analytical capabilities that can reveal previously unobservable microstructural features and their evolution during cycling.

The automotive sector has emerged as a particularly strong driver for advanced characterization methods. Electric vehicle manufacturers are investing heavily in battery technology development, creating demand for techniques that can accelerate the optimization of electrode designs. The push for faster charging capabilities, higher energy densities, and improved safety has intensified the need for sophisticated microstructural analysis.

Regulatory requirements and safety standards have further stimulated market growth. As battery safety becomes increasingly scrutinized, manufacturers must demonstrate comprehensive understanding of their electrode microstructures and potential failure modes. Advanced characterization techniques provide the necessary data to satisfy these requirements and improve quality control processes.

Geographically, the market shows strong concentration in regions with established battery manufacturing ecosystems. East Asia, particularly China, Japan, and South Korea, represents the largest market for advanced characterization technologies, followed by North America and Europe. However, emerging markets are showing accelerated growth as countries invest in domestic battery production capabilities.

The economic value proposition of advanced characterization methods continues to strengthen as battery production scales up. While sophisticated techniques often require significant capital investment, manufacturers increasingly recognize their value in reducing development cycles, improving product consistency, and extending battery lifetimes – all factors that contribute to competitive advantage in a rapidly evolving market.

Battery manufacturers are increasingly seeking high-resolution, multi-dimensional characterization techniques that provide comprehensive insights into electrode microstructures. This demand stems from the direct correlation between microstructural properties and battery performance metrics such as capacity, power density, and cycle life. The ability to precisely characterize pore networks, active material distribution, and interfacial phenomena has become a competitive advantage in the industry.

Research institutions and academic laboratories represent another significant market segment, requiring advanced characterization tools for fundamental studies of electrode materials and degradation mechanisms. The growing publication volume in battery research has created sustained demand for cutting-edge analytical capabilities that can reveal previously unobservable microstructural features and their evolution during cycling.

The automotive sector has emerged as a particularly strong driver for advanced characterization methods. Electric vehicle manufacturers are investing heavily in battery technology development, creating demand for techniques that can accelerate the optimization of electrode designs. The push for faster charging capabilities, higher energy densities, and improved safety has intensified the need for sophisticated microstructural analysis.

Regulatory requirements and safety standards have further stimulated market growth. As battery safety becomes increasingly scrutinized, manufacturers must demonstrate comprehensive understanding of their electrode microstructures and potential failure modes. Advanced characterization techniques provide the necessary data to satisfy these requirements and improve quality control processes.

Geographically, the market shows strong concentration in regions with established battery manufacturing ecosystems. East Asia, particularly China, Japan, and South Korea, represents the largest market for advanced characterization technologies, followed by North America and Europe. However, emerging markets are showing accelerated growth as countries invest in domestic battery production capabilities.

The economic value proposition of advanced characterization methods continues to strengthen as battery production scales up. While sophisticated techniques often require significant capital investment, manufacturers increasingly recognize their value in reducing development cycles, improving product consistency, and extending battery lifetimes – all factors that contribute to competitive advantage in a rapidly evolving market.

Current Challenges in Electrode Microstructure Imaging

Despite significant advancements in electrode microstructure characterization techniques, several critical challenges persist in imaging methodologies that limit our comprehensive understanding of electrode properties and performance. The multi-scale nature of electrode structures presents a fundamental challenge, as relevant features span from nanometers to micrometers, requiring multiple complementary techniques to capture the complete structural hierarchy. This multi-scale characterization often results in data integration difficulties across different resolution regimes.

Resolution limitations remain problematic in many imaging techniques. While scanning electron microscopy (SEM) provides excellent surface morphology information, it struggles with true three-dimensional characterization. Transmission electron microscopy (TEM) offers superior resolution but is limited to extremely thin samples that may not represent bulk electrode properties. Even advanced techniques like focused ion beam-SEM (FIB-SEM) face resolution constraints when attempting to image nanoscale features within larger electrode volumes.

Sample preparation introduces significant challenges that can compromise data integrity. Many characterization techniques require extensive sample processing that may alter the original microstructure. For instance, mechanical polishing can introduce artifacts, while ion beam milling may cause local heating and structural changes. Maintaining the native electrode environment during imaging is particularly challenging for liquid electrolyte systems, where vacuum requirements of electron microscopy necessitate sample drying that alters the original structure.

Dynamic processes occurring during battery operation represent perhaps the most significant imaging challenge. Most characterization techniques provide only static snapshots of electrode structures, failing to capture the dynamic evolution during cycling. While in-situ and operando techniques are emerging, they face substantial technical hurdles including limited spatial resolution, restricted field of view, and compatibility issues with electrochemical cells.

Data processing and quantification present additional challenges. The massive datasets generated by 3D imaging techniques require sophisticated algorithms for segmentation, feature extraction, and quantitative analysis. Distinguishing between different phases with similar imaging contrast remains difficult, particularly for complex composite electrodes containing multiple active materials, conductive additives, and binders.

Beam damage constitutes another significant concern, particularly for electron microscopy techniques. Electron beam exposure can induce structural changes, especially in sensitive electrode materials like organic components or lithium-containing compounds, potentially leading to misinterpretation of the original microstructure.

Resolution limitations remain problematic in many imaging techniques. While scanning electron microscopy (SEM) provides excellent surface morphology information, it struggles with true three-dimensional characterization. Transmission electron microscopy (TEM) offers superior resolution but is limited to extremely thin samples that may not represent bulk electrode properties. Even advanced techniques like focused ion beam-SEM (FIB-SEM) face resolution constraints when attempting to image nanoscale features within larger electrode volumes.

Sample preparation introduces significant challenges that can compromise data integrity. Many characterization techniques require extensive sample processing that may alter the original microstructure. For instance, mechanical polishing can introduce artifacts, while ion beam milling may cause local heating and structural changes. Maintaining the native electrode environment during imaging is particularly challenging for liquid electrolyte systems, where vacuum requirements of electron microscopy necessitate sample drying that alters the original structure.

Dynamic processes occurring during battery operation represent perhaps the most significant imaging challenge. Most characterization techniques provide only static snapshots of electrode structures, failing to capture the dynamic evolution during cycling. While in-situ and operando techniques are emerging, they face substantial technical hurdles including limited spatial resolution, restricted field of view, and compatibility issues with electrochemical cells.

Data processing and quantification present additional challenges. The massive datasets generated by 3D imaging techniques require sophisticated algorithms for segmentation, feature extraction, and quantitative analysis. Distinguishing between different phases with similar imaging contrast remains difficult, particularly for complex composite electrodes containing multiple active materials, conductive additives, and binders.

Beam damage constitutes another significant concern, particularly for electron microscopy techniques. Electron beam exposure can induce structural changes, especially in sensitive electrode materials like organic components or lithium-containing compounds, potentially leading to misinterpretation of the original microstructure.

State-of-the-Art Characterization Methodologies

01 Microscopy techniques for electrode characterization

Various microscopy techniques are employed to characterize the microstructure of electrodes. These include scanning electron microscopy (SEM), transmission electron microscopy (TEM), and atomic force microscopy (AFM). These techniques allow for high-resolution imaging of electrode surfaces and internal structures, providing valuable information about morphology, particle size, distribution, and interface characteristics. Advanced microscopy methods enable researchers to visualize electrode components at nano and micro scales, which is crucial for understanding performance characteristics.- Microscopy techniques for electrode microstructure analysis: Various microscopy techniques are employed to characterize electrode microstructures, including scanning electron microscopy (SEM), transmission electron microscopy (TEM), and focused ion beam (FIB) microscopy. These techniques allow for high-resolution imaging of electrode surfaces and cross-sections, revealing critical features such as porosity, particle size distribution, and interfacial properties. Advanced microscopy methods enable researchers to visualize the three-dimensional architecture of electrodes and identify structural changes during cycling.

- Spectroscopic methods for electrode material characterization: Spectroscopic techniques provide valuable information about the chemical composition and bonding states of electrode materials. X-ray photoelectron spectroscopy (XPS), Raman spectroscopy, and Fourier transform infrared spectroscopy (FTIR) are commonly used to analyze surface chemistry and structural changes in electrode materials. These methods help identify chemical transformations during electrode operation and aging, offering insights into degradation mechanisms and performance limitations.

- X-ray based characterization techniques: X-ray diffraction (XRD), X-ray computed tomography (CT), and X-ray absorption spectroscopy are powerful tools for analyzing electrode microstructures. These techniques provide information about crystalline phases, particle orientation, porosity distribution, and elemental composition. X-ray methods can be used for both ex-situ and in-situ characterization, allowing researchers to monitor structural changes during electrode operation and identify factors affecting performance and durability.

- Electrochemical characterization methods: Electrochemical techniques such as impedance spectroscopy, cyclic voltammetry, and galvanostatic cycling are essential for correlating microstructural features with electrode performance. These methods provide information about reaction kinetics, charge transfer resistance, and diffusion processes within the electrode. By combining electrochemical measurements with microstructural analysis, researchers can establish structure-property relationships and optimize electrode designs for specific applications.

- Advanced computational and modeling approaches: Computational methods, including finite element modeling, molecular dynamics simulations, and machine learning algorithms, are increasingly used to analyze and predict electrode microstructural properties. These approaches enable the reconstruction of three-dimensional electrode architectures from two-dimensional images, simulation of transport phenomena, and prediction of performance characteristics. Computational techniques complement experimental methods by providing insights into processes that are difficult to observe directly and facilitating the design of optimized electrode structures.

02 Spectroscopic methods for electrode analysis

Spectroscopic techniques are widely used for analyzing the chemical composition and structure of electrode materials. These include X-ray diffraction (XRD), X-ray photoelectron spectroscopy (XPS), Raman spectroscopy, and energy-dispersive X-ray spectroscopy (EDX). These methods provide information about crystalline phases, chemical bonding, elemental composition, and oxidation states of electrode materials. Spectroscopic analysis helps in understanding the relationship between electrode microstructure and electrochemical performance.Expand Specific Solutions03 Tomography and 3D reconstruction techniques

Advanced tomography techniques enable three-dimensional reconstruction of electrode microstructures. Methods such as X-ray computed tomography (CT), focused ion beam-scanning electron microscopy (FIB-SEM), and neutron tomography allow researchers to visualize and quantify the internal structure of electrodes in three dimensions. These techniques provide insights into porosity, tortuosity, and connectivity of electrode components, which are critical parameters affecting electrode performance and degradation mechanisms.Expand Specific Solutions04 In-situ and operando characterization methods

In-situ and operando characterization techniques allow for real-time observation of electrode microstructural changes during operation. These methods include in-situ XRD, in-situ TEM, and operando spectroscopy. By monitoring electrodes under actual operating conditions, researchers can observe dynamic processes such as phase transformations, interface evolution, and degradation mechanisms. These techniques provide crucial information for understanding electrode behavior during cycling and for developing strategies to improve electrode durability and performance.Expand Specific Solutions05 Quantitative analysis and modeling of electrode microstructures

Quantitative analysis and modeling techniques are employed to extract meaningful metrics from electrode microstructure data. These include digital image analysis, statistical methods, and computational modeling approaches. Parameters such as particle size distribution, porosity, specific surface area, and phase connectivity can be quantified and correlated with electrode performance. Advanced algorithms and machine learning techniques are increasingly being used to process large datasets from microstructural characterization, enabling more comprehensive understanding of structure-property relationships in electrode materials.Expand Specific Solutions

Leading Research Groups and Equipment Manufacturers

Electrode Microstructure Characterization Techniques market is in a growth phase, with increasing demand driven by advancements in energy storage, electronics, and materials science. The competitive landscape features academic institutions (Caltech, MIT, Tsinghua University) pioneering fundamental research alongside industrial players developing commercial applications. Leading companies like Applied Materials, LG Chem, and Toyota are investing in advanced characterization technologies to optimize battery performance. Research organizations such as AIST, CNRS, and CEA are bridging the gap between theoretical understanding and practical applications. The market is characterized by collaborative efforts between academia and industry, with Asian companies (particularly from China, Japan, and South Korea) showing strong growth in patent filings and technology development, reflecting the strategic importance of electrode microstructure characterization in next-generation energy and electronic devices.

California Institute of Technology

Technical Solution: Caltech has developed advanced electrode microstructure characterization techniques focusing on multi-scale 3D imaging and quantification. Their approach combines X-ray nano-computed tomography (nano-CT) with focused ion beam-scanning electron microscopy (FIB-SEM) to create detailed 3D reconstructions of electrode architectures across multiple length scales. This multi-modal imaging strategy allows researchers to quantitatively analyze critical microstructural parameters including porosity, tortuosity, and particle size distributions with nanometer resolution. Caltech researchers have pioneered machine learning algorithms that automate the segmentation and analysis of these complex 3D datasets, significantly reducing processing time while improving accuracy. Their techniques have been particularly valuable for understanding degradation mechanisms in lithium-ion battery electrodes, where they've correlated microstructural evolution with electrochemical performance through in-situ and operando characterization methods.

Strengths: Superior resolution capabilities combining multiple imaging modalities; advanced machine learning integration for automated analysis; established protocols for in-situ characterization. Weaknesses: Techniques require specialized equipment with high capital costs; sample preparation can be destructive; computational analysis demands significant expertise and resources.

The Regents of the University of California

Technical Solution: The University of California system has developed comprehensive electrode microstructure characterization techniques centered around synchrotron-based X-ray tomography and advanced spectroscopic methods. Their approach utilizes the Advanced Light Source (ALS) and other national laboratory facilities to perform high-resolution, non-destructive 3D imaging of electrode materials. UC researchers have pioneered techniques combining X-ray absorption spectroscopy (XAS) with tomographic imaging to simultaneously map chemical states and structural features within electrodes. This allows correlation between local chemistry and microstructural evolution during cycling. Their characterization suite includes in-operando cells designed specifically for real-time observation of dynamic processes occurring within electrodes during charge-discharge cycles. UC Berkeley and UC San Diego groups have developed specialized algorithms for quantitative analysis of tortuosity factors, effective transport properties, and heterogeneity metrics from the 3D reconstructions, enabling direct connections between manufacturing parameters, resulting microstructures, and device performance.

Strengths: Access to world-class synchrotron facilities enabling non-destructive analysis; well-established protocols for operando measurements; strong computational modeling capabilities to interpret experimental data. Weaknesses: Reliance on limited-access national laboratory facilities; complex data processing workflows; challenges in achieving highest spatial resolution for nanoscale features.

Key Innovations in 3D Microstructure Reconstruction

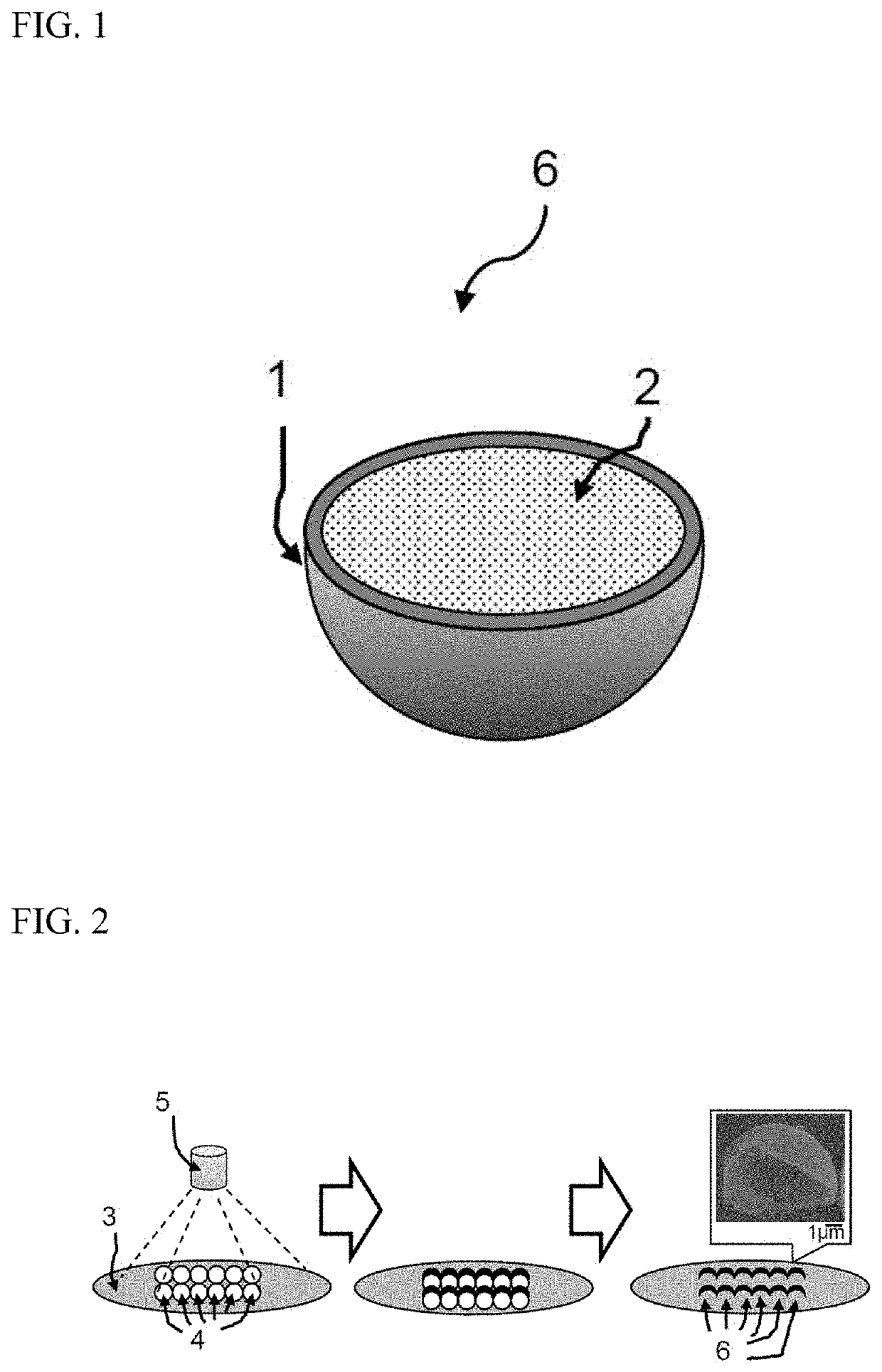

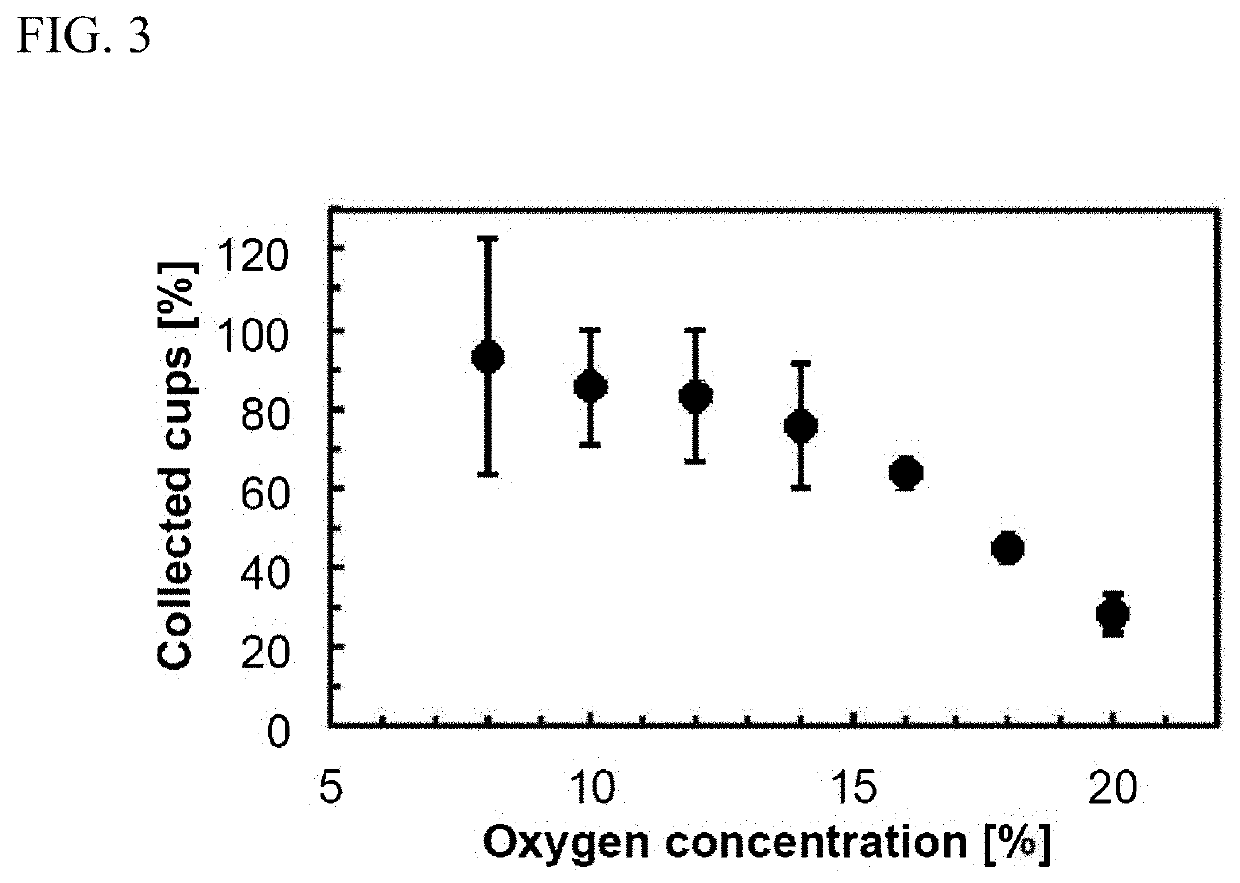

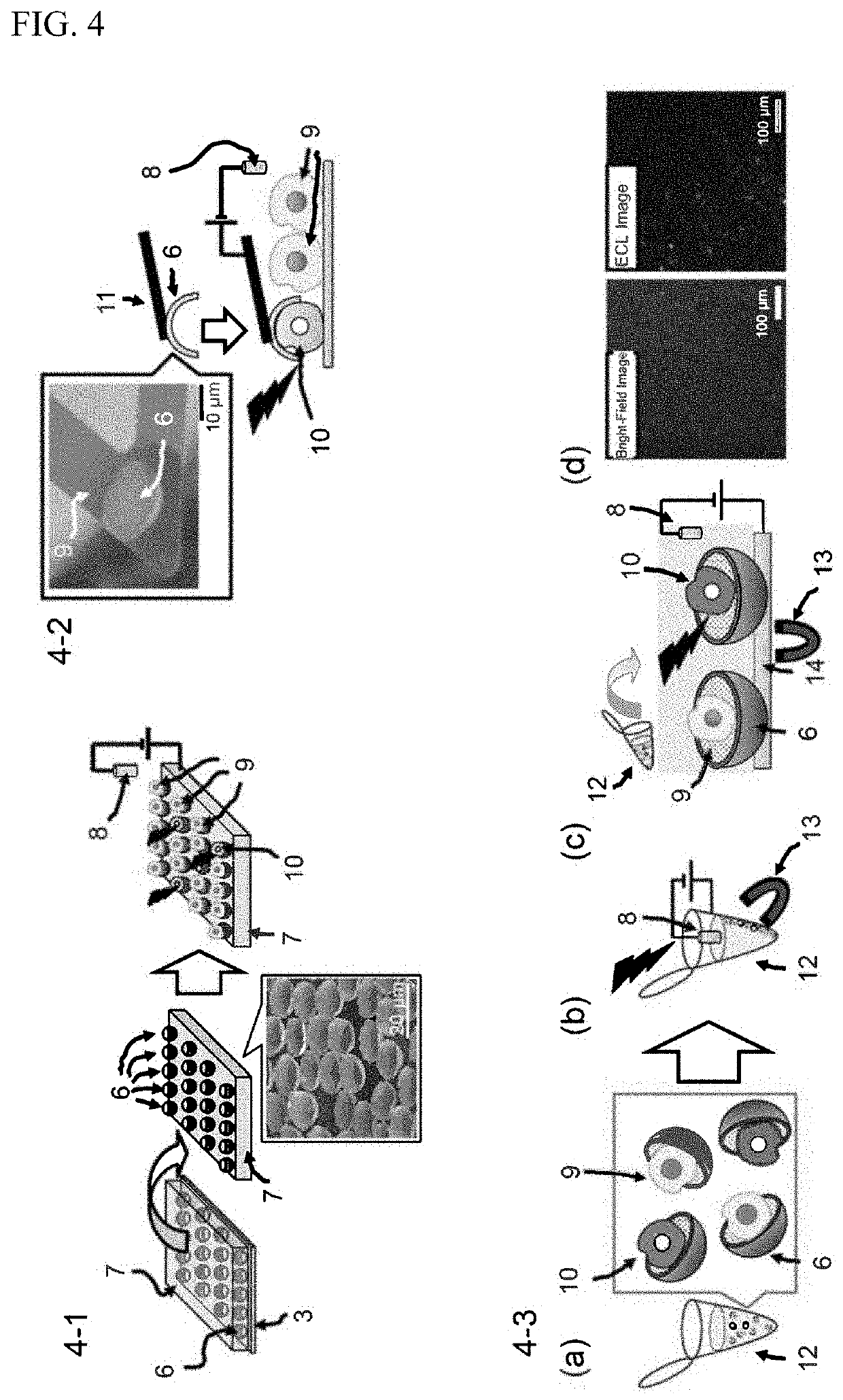

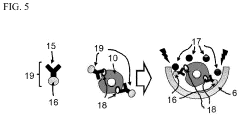

Microstructure, method for manufacturing same, and molecule detection method using same

PatentPendingUS20220026424A1

Innovation

- A microstructure with a nearly hemispherical shell-shaped structure made of a magnetic material and an electrode layer of nanocarbon thin film on the concave side, capable of receiving cells, allowing for electrochemiluminescence-based detection without excitation light, and an external magnetic field for orientation control.

Data Processing and Machine Learning Applications

The integration of advanced data processing techniques and machine learning algorithms has revolutionized electrode microstructure characterization. Traditional image analysis methods often struggle with the complex, heterogeneous nature of electrode materials, but computational approaches now enable researchers to extract meaningful information from large datasets with unprecedented accuracy and efficiency.

Machine learning applications in electrode characterization have evolved from simple classification algorithms to sophisticated deep learning networks. Convolutional Neural Networks (CNNs) have proven particularly effective for image segmentation tasks, automatically distinguishing between active materials, binders, and pore spaces with accuracy rates exceeding 95% in optimal conditions. These algorithms can process thousands of tomographic slices in minutes, compared to days required for manual analysis.

Transfer learning techniques have emerged as a powerful approach for electrode microstructure analysis, allowing models trained on large datasets to be fine-tuned for specific electrode materials with minimal additional training data. This has democratized advanced characterization capabilities, enabling smaller research groups to leverage sophisticated analysis tools previously accessible only to major institutions with extensive computational resources.

Unsupervised learning methods, particularly autoencoders and clustering algorithms, have demonstrated remarkable capabilities in identifying hidden patterns within electrode microstructures. These techniques have revealed previously unrecognized relationships between manufacturing parameters and resulting microstructural features, guiding optimization efforts for enhanced battery performance.

Real-time data processing pipelines now enable in-situ characterization during electrode fabrication or battery operation. By combining edge computing with streamlined machine learning models, researchers can monitor microstructural evolution dynamically, providing crucial feedback for process control and quality assurance. This capability has reduced manufacturing defects by up to 40% in pilot production environments.

Generative adversarial networks (GANs) represent the cutting edge in this field, creating synthetic but realistic electrode microstructures that can be used for virtual testing and optimization. These AI-generated structures allow researchers to explore theoretical material configurations before committing resources to physical prototyping, accelerating innovation cycles by 30-50% according to recent industry reports.

The integration of physics-informed neural networks with microstructural data has enabled more accurate prediction of electrode performance characteristics, bridging the gap between observed microstructure and functional properties. These hybrid models incorporate fundamental electrochemical principles into their architecture, resulting in predictions that respect physical constraints while leveraging the pattern recognition capabilities of machine learning.

Machine learning applications in electrode characterization have evolved from simple classification algorithms to sophisticated deep learning networks. Convolutional Neural Networks (CNNs) have proven particularly effective for image segmentation tasks, automatically distinguishing between active materials, binders, and pore spaces with accuracy rates exceeding 95% in optimal conditions. These algorithms can process thousands of tomographic slices in minutes, compared to days required for manual analysis.

Transfer learning techniques have emerged as a powerful approach for electrode microstructure analysis, allowing models trained on large datasets to be fine-tuned for specific electrode materials with minimal additional training data. This has democratized advanced characterization capabilities, enabling smaller research groups to leverage sophisticated analysis tools previously accessible only to major institutions with extensive computational resources.

Unsupervised learning methods, particularly autoencoders and clustering algorithms, have demonstrated remarkable capabilities in identifying hidden patterns within electrode microstructures. These techniques have revealed previously unrecognized relationships between manufacturing parameters and resulting microstructural features, guiding optimization efforts for enhanced battery performance.

Real-time data processing pipelines now enable in-situ characterization during electrode fabrication or battery operation. By combining edge computing with streamlined machine learning models, researchers can monitor microstructural evolution dynamically, providing crucial feedback for process control and quality assurance. This capability has reduced manufacturing defects by up to 40% in pilot production environments.

Generative adversarial networks (GANs) represent the cutting edge in this field, creating synthetic but realistic electrode microstructures that can be used for virtual testing and optimization. These AI-generated structures allow researchers to explore theoretical material configurations before committing resources to physical prototyping, accelerating innovation cycles by 30-50% according to recent industry reports.

The integration of physics-informed neural networks with microstructural data has enabled more accurate prediction of electrode performance characteristics, bridging the gap between observed microstructure and functional properties. These hybrid models incorporate fundamental electrochemical principles into their architecture, resulting in predictions that respect physical constraints while leveraging the pattern recognition capabilities of machine learning.

Standardization and Validation Protocols

The development of standardized protocols for electrode microstructure characterization represents a critical frontier in advancing battery technology. Current characterization methods suffer from significant variability across laboratories, making direct comparison of results challenging and hindering scientific progress. Establishing robust standardization frameworks requires collaborative efforts between academic institutions, industry stakeholders, and regulatory bodies to define common metrics, sample preparation procedures, and data reporting formats.

Key validation protocols must address multiple dimensions of characterization reliability. Round-robin testing programs involving multiple laboratories analyzing identical samples have emerged as an essential approach for establishing measurement reproducibility. These programs have revealed significant variations in reported microstructural parameters, highlighting the urgent need for standardized procedures. Recent initiatives by organizations such as ASTM International and the International Electrotechnical Commission (IEC) have begun developing specific standards for electrode characterization techniques.

Sample preparation standardization represents a fundamental component of these protocols. Variations in sectioning methods, polishing procedures, and environmental exposure conditions can dramatically alter observed microstructural features. Emerging best practices include detailed documentation of sample history, controlled environmental conditions during preparation, and the use of reference materials with known microstructural parameters for calibration purposes.

Data validation frameworks must incorporate statistical analysis methods appropriate for three-dimensional microstructural data. Representative volume element (RVE) analysis has become increasingly important for ensuring that characterized regions adequately represent the overall electrode structure. Quantitative metrics for assessing data quality, such as signal-to-noise ratios for tomographic techniques and resolution verification standards, are being integrated into emerging protocols.

Interlaboratory comparison studies have demonstrated that even with identical equipment, variations in operator procedures and data processing algorithms can lead to significantly different results. This has prompted the development of automated analysis workflows and open-source software tools that implement standardized processing methods. The battery research community has increasingly embraced open data initiatives, with repositories like the Battery Microstructure Library facilitating the sharing of raw characterization data alongside processing parameters.

Traceability to physical standards represents another crucial aspect of validation protocols. Reference materials with certified microstructural parameters are being developed to enable calibration across different characterization platforms. These materials must exhibit long-term stability and contain features relevant to electrode structures at appropriate length scales.

Key validation protocols must address multiple dimensions of characterization reliability. Round-robin testing programs involving multiple laboratories analyzing identical samples have emerged as an essential approach for establishing measurement reproducibility. These programs have revealed significant variations in reported microstructural parameters, highlighting the urgent need for standardized procedures. Recent initiatives by organizations such as ASTM International and the International Electrotechnical Commission (IEC) have begun developing specific standards for electrode characterization techniques.

Sample preparation standardization represents a fundamental component of these protocols. Variations in sectioning methods, polishing procedures, and environmental exposure conditions can dramatically alter observed microstructural features. Emerging best practices include detailed documentation of sample history, controlled environmental conditions during preparation, and the use of reference materials with known microstructural parameters for calibration purposes.

Data validation frameworks must incorporate statistical analysis methods appropriate for three-dimensional microstructural data. Representative volume element (RVE) analysis has become increasingly important for ensuring that characterized regions adequately represent the overall electrode structure. Quantitative metrics for assessing data quality, such as signal-to-noise ratios for tomographic techniques and resolution verification standards, are being integrated into emerging protocols.

Interlaboratory comparison studies have demonstrated that even with identical equipment, variations in operator procedures and data processing algorithms can lead to significantly different results. This has prompted the development of automated analysis workflows and open-source software tools that implement standardized processing methods. The battery research community has increasingly embraced open data initiatives, with repositories like the Battery Microstructure Library facilitating the sharing of raw characterization data alongside processing parameters.

Traceability to physical standards represents another crucial aspect of validation protocols. Reference materials with certified microstructural parameters are being developed to enable calibration across different characterization platforms. These materials must exhibit long-term stability and contain features relevant to electrode structures at appropriate length scales.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!