Sensor Lifetime Testing: Accelerated Aging Protocols

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sensor Aging Mechanisms and Testing Objectives

Sensors are critical components in modern technological systems, with applications ranging from consumer electronics to industrial monitoring and healthcare devices. Understanding the mechanisms that lead to sensor degradation and establishing clear testing objectives are fundamental to developing effective accelerated aging protocols. Sensor aging is a complex process influenced by multiple factors that can significantly impact performance, reliability, and accuracy over time.

Physical degradation represents one of the primary aging mechanisms affecting sensors. This includes material fatigue, corrosion of metallic components, degradation of polymer-based elements, and mechanical wear of moving parts. For instance, MEMS (Micro-Electro-Mechanical Systems) sensors are particularly susceptible to mechanical fatigue and stiction issues that develop gradually during their operational lifetime.

Chemical deterioration constitutes another significant aging pathway. Exposure to environmental contaminants, humidity, and reactive gases can lead to oxidation, hydrolysis, or other chemical reactions that alter sensor materials and interfaces. Chemical aging is especially pronounced in electrochemical sensors where electrode poisoning and electrolyte degradation directly impact measurement capabilities.

Thermal effects accelerate numerous aging processes through mechanisms such as diffusion, phase changes, and thermal expansion/contraction cycles. Repeated thermal cycling can induce mechanical stress, leading to microcracks and delamination in sensor packaging and sensing elements. Additionally, elevated temperatures often catalyze chemical reactions that would otherwise progress more slowly under normal operating conditions.

Electrical stress represents a fourth major aging mechanism, particularly relevant for semiconductor-based sensors. Phenomena such as electromigration, hot carrier injection, and dielectric breakdown progressively degrade sensor performance. Constant electrical biasing or frequent power cycling can exacerbate these effects, leading to drift in calibration parameters and reduced sensitivity.

The primary objective of accelerated aging testing is to predict real-world sensor lifetime within a compressed timeframe. This requires establishing correlations between accelerated test conditions and normal operating environments, enabling the development of mathematical models that accurately translate accelerated aging results to expected field performance.

Another critical objective is identifying dominant failure modes and their progression patterns. By understanding which aging mechanisms are most likely to cause sensor failure, manufacturers can implement targeted design improvements and appropriate mitigation strategies. This knowledge also supports the development of more effective maintenance schedules and replacement policies for deployed sensors.

Quantifying reliability metrics represents a third key objective, including mean time between failures (MTBF), failure rates under various conditions, and statistical distributions of sensor lifespans. These metrics provide essential inputs for system-level reliability analyses and warranty planning, while also informing quality control processes during manufacturing.

Physical degradation represents one of the primary aging mechanisms affecting sensors. This includes material fatigue, corrosion of metallic components, degradation of polymer-based elements, and mechanical wear of moving parts. For instance, MEMS (Micro-Electro-Mechanical Systems) sensors are particularly susceptible to mechanical fatigue and stiction issues that develop gradually during their operational lifetime.

Chemical deterioration constitutes another significant aging pathway. Exposure to environmental contaminants, humidity, and reactive gases can lead to oxidation, hydrolysis, or other chemical reactions that alter sensor materials and interfaces. Chemical aging is especially pronounced in electrochemical sensors where electrode poisoning and electrolyte degradation directly impact measurement capabilities.

Thermal effects accelerate numerous aging processes through mechanisms such as diffusion, phase changes, and thermal expansion/contraction cycles. Repeated thermal cycling can induce mechanical stress, leading to microcracks and delamination in sensor packaging and sensing elements. Additionally, elevated temperatures often catalyze chemical reactions that would otherwise progress more slowly under normal operating conditions.

Electrical stress represents a fourth major aging mechanism, particularly relevant for semiconductor-based sensors. Phenomena such as electromigration, hot carrier injection, and dielectric breakdown progressively degrade sensor performance. Constant electrical biasing or frequent power cycling can exacerbate these effects, leading to drift in calibration parameters and reduced sensitivity.

The primary objective of accelerated aging testing is to predict real-world sensor lifetime within a compressed timeframe. This requires establishing correlations between accelerated test conditions and normal operating environments, enabling the development of mathematical models that accurately translate accelerated aging results to expected field performance.

Another critical objective is identifying dominant failure modes and their progression patterns. By understanding which aging mechanisms are most likely to cause sensor failure, manufacturers can implement targeted design improvements and appropriate mitigation strategies. This knowledge also supports the development of more effective maintenance schedules and replacement policies for deployed sensors.

Quantifying reliability metrics represents a third key objective, including mean time between failures (MTBF), failure rates under various conditions, and statistical distributions of sensor lifespans. These metrics provide essential inputs for system-level reliability analyses and warranty planning, while also informing quality control processes during manufacturing.

Market Demand for Reliable Sensor Lifetime Prediction

The global sensor market is experiencing unprecedented growth, with reliable lifetime prediction becoming a critical factor in sensor selection and deployment. According to recent market analyses, the global sensor market is projected to reach $287 billion by 2025, with a compound annual growth rate of approximately 9.5%. This growth is primarily driven by the increasing adoption of sensors across various industries including automotive, healthcare, industrial automation, and consumer electronics.

Reliable sensor lifetime prediction has emerged as a key differentiator in this competitive landscape. End-users across industries are increasingly demanding sensors with well-documented and predictable operational lifespans. This demand stems from the critical role sensors play in modern systems where unexpected failures can lead to significant operational disruptions, safety hazards, and financial losses.

In the automotive sector, the rise of advanced driver-assistance systems (ADAS) and autonomous vehicles has intensified the need for sensors with precisely characterized lifetimes. Vehicle manufacturers require sensors that can maintain performance throughout the vehicle's operational life, typically 10-15 years, under varying environmental conditions. Similar requirements exist in industrial automation, where unplanned downtime due to sensor failure can cost manufacturers thousands of dollars per minute.

The healthcare industry presents another significant market for reliable sensor lifetime prediction. Medical devices incorporating sensors for patient monitoring and diagnostics must maintain accuracy and reliability throughout their intended use period. Regulatory bodies such as the FDA increasingly require comprehensive lifetime testing data as part of approval processes for medical devices.

Consumer electronics manufacturers are also driving demand for better sensor lifetime characterization. As devices become more sensor-rich, manufacturers seek to balance performance, cost, and durability. Accurate lifetime predictions allow for optimized design decisions and appropriate warranty periods.

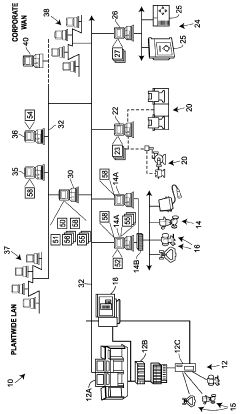

The Internet of Things (IoT) represents perhaps the largest emerging market for sensors with well-characterized lifetimes. With billions of connected devices being deployed in remote or difficult-to-access locations, replacement costs for failed sensors extend far beyond the component cost to include service visits and system downtime. This has created strong market pull for sensors with predictable, long operational lives and for accelerated aging protocols that can reliably predict real-world performance.

Energy efficiency considerations further amplify market demand for lifetime prediction. In battery-powered applications, sensor power consumption directly impacts overall system lifetime. Accurate characterization of how sensor performance and power requirements change over time enables better system design and more accurate battery life predictions.

Reliable sensor lifetime prediction has emerged as a key differentiator in this competitive landscape. End-users across industries are increasingly demanding sensors with well-documented and predictable operational lifespans. This demand stems from the critical role sensors play in modern systems where unexpected failures can lead to significant operational disruptions, safety hazards, and financial losses.

In the automotive sector, the rise of advanced driver-assistance systems (ADAS) and autonomous vehicles has intensified the need for sensors with precisely characterized lifetimes. Vehicle manufacturers require sensors that can maintain performance throughout the vehicle's operational life, typically 10-15 years, under varying environmental conditions. Similar requirements exist in industrial automation, where unplanned downtime due to sensor failure can cost manufacturers thousands of dollars per minute.

The healthcare industry presents another significant market for reliable sensor lifetime prediction. Medical devices incorporating sensors for patient monitoring and diagnostics must maintain accuracy and reliability throughout their intended use period. Regulatory bodies such as the FDA increasingly require comprehensive lifetime testing data as part of approval processes for medical devices.

Consumer electronics manufacturers are also driving demand for better sensor lifetime characterization. As devices become more sensor-rich, manufacturers seek to balance performance, cost, and durability. Accurate lifetime predictions allow for optimized design decisions and appropriate warranty periods.

The Internet of Things (IoT) represents perhaps the largest emerging market for sensors with well-characterized lifetimes. With billions of connected devices being deployed in remote or difficult-to-access locations, replacement costs for failed sensors extend far beyond the component cost to include service visits and system downtime. This has created strong market pull for sensors with predictable, long operational lives and for accelerated aging protocols that can reliably predict real-world performance.

Energy efficiency considerations further amplify market demand for lifetime prediction. In battery-powered applications, sensor power consumption directly impacts overall system lifetime. Accurate characterization of how sensor performance and power requirements change over time enables better system design and more accurate battery life predictions.

Current Challenges in Accelerated Aging Methodologies

Despite significant advancements in accelerated aging methodologies for sensor lifetime testing, several critical challenges persist that limit the accuracy and reliability of these protocols. One fundamental issue is the establishment of valid acceleration factors that accurately correlate accelerated test conditions with real-world degradation patterns. Current models often fail to account for complex interaction effects between multiple stressors, leading to inaccurate lifetime predictions when sensors are exposed to combinations of environmental factors simultaneously.

The non-linear degradation pathways present another significant challenge. Many sensors exhibit threshold effects or sudden failure modes that are difficult to capture in accelerated testing. This is particularly problematic for modern multi-component sensors where different elements may degrade at varying rates under accelerated conditions, creating failure mechanisms that would not occur during normal operation.

Statistical validation remains problematic due to the limited sample sizes typically used in accelerated testing. The high costs associated with comprehensive testing often force compromises in experimental design, resulting in insufficient data for robust statistical analysis. This challenge is compounded by the inherent variability in sensor manufacturing, where slight differences in components or assembly can significantly impact aging characteristics.

The development of standardized protocols across different sensor types represents another major hurdle. Current methodologies are often highly specialized for specific sensor categories, making cross-comparison between different technologies difficult. This lack of standardization impedes industry-wide benchmarking and complicates the integration of multiple sensor types in complex systems.

For emerging sensor technologies, particularly those incorporating novel materials or nanoscale components, existing accelerated aging models may be fundamentally inadequate. These new technologies often exhibit unique degradation mechanisms that are not well-represented in traditional testing frameworks, necessitating the development of entirely new approaches to lifetime prediction.

Real-time monitoring during accelerated aging tests presents technical difficulties that can compromise data quality. The measurement systems themselves may be affected by the harsh test conditions, introducing artifacts or measurement drift that confounds the actual sensor degradation data. This creates a paradoxical situation where the tools used to evaluate sensor performance may themselves be unreliable under test conditions.

Finally, there is a growing recognition that accelerated aging protocols often fail to account for the complex software-hardware interactions in modern smart sensors. As sensors increasingly incorporate sophisticated signal processing and self-calibration algorithms, the degradation of performance becomes a function not only of hardware deterioration but also of how software compensates for these changes over time.

The non-linear degradation pathways present another significant challenge. Many sensors exhibit threshold effects or sudden failure modes that are difficult to capture in accelerated testing. This is particularly problematic for modern multi-component sensors where different elements may degrade at varying rates under accelerated conditions, creating failure mechanisms that would not occur during normal operation.

Statistical validation remains problematic due to the limited sample sizes typically used in accelerated testing. The high costs associated with comprehensive testing often force compromises in experimental design, resulting in insufficient data for robust statistical analysis. This challenge is compounded by the inherent variability in sensor manufacturing, where slight differences in components or assembly can significantly impact aging characteristics.

The development of standardized protocols across different sensor types represents another major hurdle. Current methodologies are often highly specialized for specific sensor categories, making cross-comparison between different technologies difficult. This lack of standardization impedes industry-wide benchmarking and complicates the integration of multiple sensor types in complex systems.

For emerging sensor technologies, particularly those incorporating novel materials or nanoscale components, existing accelerated aging models may be fundamentally inadequate. These new technologies often exhibit unique degradation mechanisms that are not well-represented in traditional testing frameworks, necessitating the development of entirely new approaches to lifetime prediction.

Real-time monitoring during accelerated aging tests presents technical difficulties that can compromise data quality. The measurement systems themselves may be affected by the harsh test conditions, introducing artifacts or measurement drift that confounds the actual sensor degradation data. This creates a paradoxical situation where the tools used to evaluate sensor performance may themselves be unreliable under test conditions.

Finally, there is a growing recognition that accelerated aging protocols often fail to account for the complex software-hardware interactions in modern smart sensors. As sensors increasingly incorporate sophisticated signal processing and self-calibration algorithms, the degradation of performance becomes a function not only of hardware deterioration but also of how software compensates for these changes over time.

Standard Accelerated Aging Protocols and Frameworks

01 Energy optimization techniques for sensor lifetime extension

Various energy optimization techniques can be employed to extend the lifetime of sensors. These include power management algorithms, energy harvesting methods, and adaptive duty cycling. By optimizing the energy consumption of sensors, their operational lifetime can be significantly increased, making them more suitable for long-term deployments in various applications including environmental monitoring and industrial settings.- Energy optimization techniques for extending sensor lifetime: Various energy optimization techniques can be employed to extend the lifetime of sensors. These include power management algorithms, sleep/wake scheduling, and energy-efficient data processing methods. By minimizing unnecessary power consumption and optimizing operational cycles, sensors can operate for longer periods without battery replacement or recharging. These techniques are particularly important for remote or difficult-to-access sensor deployments where maintenance is challenging.

- Battery and power source innovations for sensors: Advancements in battery technology and alternative power sources significantly impact sensor lifetime. These innovations include high-capacity batteries, energy harvesting technologies (solar, vibration, thermal), and low-power circuit designs. Some sensors incorporate hybrid power systems that combine multiple energy sources to ensure continuous operation. These power solutions are designed to match the specific energy requirements and environmental conditions of different sensor applications.

- Environmental adaptation and protective measures: Sensors can be designed with features that protect against environmental factors that typically reduce lifetime. These include protective coatings against moisture and corrosion, temperature compensation mechanisms, and physical shields against mechanical damage. Some sensors incorporate self-diagnostic capabilities to detect environmental stressors and adjust operation accordingly. These protective measures help maintain sensor accuracy and functionality over extended periods in harsh or variable conditions.

- Predictive maintenance and self-calibration systems: Advanced sensors incorporate predictive maintenance algorithms and self-calibration capabilities to extend operational lifetime. These systems can detect early signs of degradation, automatically adjust parameters to compensate for drift, and notify operators when maintenance is required. Some sensors use machine learning techniques to adapt to changing conditions and optimize their own performance over time. These features help prevent premature failure and ensure consistent measurement accuracy throughout the sensor's lifetime.

- Medical and biological sensor lifetime enhancement: Medical and biological sensors face unique challenges related to biocompatibility, sterilization requirements, and interaction with bodily fluids. Techniques to extend their lifetime include biocompatible coatings, anti-fouling surfaces, and materials that resist protein adsorption. Some implantable sensors incorporate drug-eluting components to prevent tissue encapsulation or inflammation. These specialized approaches help maintain sensor functionality in biological environments while ensuring patient safety and comfort over extended periods.

02 Battery technology and power management for sensors

Advanced battery technologies and power management systems play a crucial role in extending sensor lifetimes. This includes the development of high-capacity batteries, low-power consumption circuits, and intelligent power distribution systems. Effective power management can monitor and control energy usage, putting sensors into sleep modes when not in use and optimizing wake-up schedules based on application requirements.Expand Specific Solutions03 Predictive maintenance and sensor health monitoring

Predictive maintenance systems can monitor sensor health and performance to anticipate failures before they occur. By analyzing sensor data patterns, degradation trends, and performance metrics, these systems can predict when sensors might fail and schedule maintenance accordingly. This approach extends the effective lifetime of sensor networks by preventing unexpected failures and optimizing replacement schedules.Expand Specific Solutions04 Environmental protection and ruggedization of sensors

Protecting sensors from environmental factors such as moisture, temperature extremes, vibration, and corrosive substances can significantly extend their operational lifetime. This includes the development of specialized enclosures, protective coatings, and ruggedized designs that shield sensitive components from harsh conditions while maintaining measurement accuracy and reliability in challenging environments.Expand Specific Solutions05 Self-calibration and adaptive sensing techniques

Self-calibration mechanisms and adaptive sensing techniques can extend sensor lifetime by maintaining accuracy over time and reducing unnecessary operations. These approaches allow sensors to adjust their parameters based on changing conditions, compensate for drift, and optimize their sampling rates according to the dynamics of the measured phenomena. By reducing the need for manual recalibration and minimizing unnecessary measurements, these techniques can significantly extend the functional lifetime of sensor systems.Expand Specific Solutions

Leading Organizations in Sensor Reliability Testing

The sensor lifetime testing market is currently in a growth phase, with accelerated aging protocols becoming increasingly critical for industries requiring high reliability. The market is expanding due to demand from medical device companies like DexCom, Medtronic MiniMed, and Abbott Diabetes Care, who need to validate long-term sensor performance for continuous glucose monitoring systems. Power grid operators including Guangdong Power Grid and State Grid Shaanxi are driving adoption for infrastructure monitoring applications. Technology maturity varies significantly across sectors, with semiconductor leaders (Intel, Micron) and research institutions (IMEC, EPFL) advancing standardized methodologies, while medical device manufacturers focus on application-specific protocols. Companies like Bosch, AVL List, and Thales are developing proprietary testing frameworks to address reliability challenges in automotive and aerospace applications.

Medtronic MiniMed, Inc.

Technical Solution: Medtronic MiniMed has developed comprehensive accelerated aging protocols specifically for implantable medical sensors and insulin delivery systems. Their approach combines multiple stress factors including temperature cycling (between -20°C to 55°C), humidity variation (20-95% RH), and mechanical vibration to simulate years of wear in weeks. They employ a proprietary "Environmental Stress Screening" methodology that incorporates both static and dynamic testing phases. For their glucose sensors, they utilize electrochemical impedance spectroscopy to track sensor degradation patterns during accelerated aging, allowing for precise lifetime prediction models. Their protocols include specialized testing for biofouling resistance, which simulates the body's foreign body response to implanted sensors. Medtronic's testing includes real-time monitoring of sensor performance metrics during aging, rather than just end-point analysis, providing deeper insights into failure mechanisms.

Strengths: Highly specialized for medical implantable devices with validated correlation between accelerated and real-world performance. Their protocols account for biological interactions specific to implantable sensors. Weaknesses: Methodology is highly specialized for medical applications and may not translate well to industrial sensors. The testing protocols require expensive specialized equipment and significant expertise in biomedical engineering.

Abbott Diabetes Care, Inc.

Technical Solution: Abbott Diabetes Care has pioneered accelerated aging protocols specifically designed for continuous glucose monitoring sensors. Their approach utilizes a multi-tiered testing framework that combines environmental stressors with simulated biological conditions. The company employs a "step-stress" methodology where sensors are exposed to progressively increasing stress levels (temperature, humidity, mechanical stress) until failure, allowing for the development of precise Weibull reliability models. Abbott's protocols include specialized chemical exposure tests that simulate the oxidative environment of subcutaneous tissue, providing more realistic aging conditions than standard protocols. They have developed proprietary algorithms that correlate accelerated aging results with real-world clinical data from their extensive user base, enabling highly accurate lifetime predictions. Their testing includes both functional performance metrics (accuracy, response time) and physical/chemical degradation analysis using techniques such as scanning electron microscopy and Fourier-transform infrared spectroscopy to identify failure mechanisms at the molecular level.

Strengths: Their protocols demonstrate excellent correlation between accelerated testing and real-world performance data from millions of users. The methodology incorporates both functional and structural analysis for comprehensive understanding of sensor degradation. Weaknesses: Highly specialized for wearable medical sensors with limited applicability to other sensor types. The protocols require sophisticated analytical equipment and expertise in both materials science and biomedical engineering.

Key Research in Correlation Models for Accelerated Testing

Valve prognostics for polymeric components based on accelerated aging techniques

PatentActiveCA2904081C

Innovation

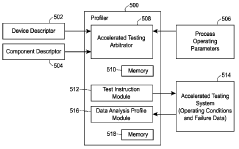

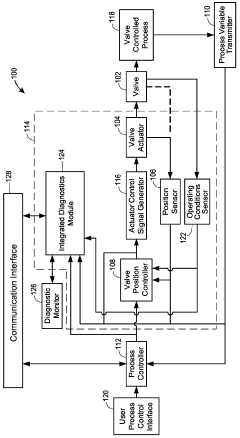

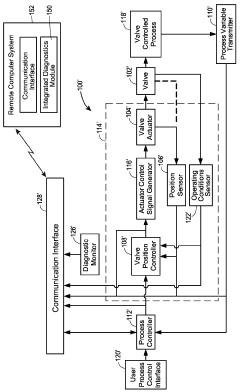

- A method involving an accelerated aging test protocol is developed to simulate in-service conditions, using a profiler to receive operating parameters and sensed data, and an integrated diagnostics module to determine a projected lifetime profile, accounting for mechanical wear and fatigue, and providing notification for maintenance scheduling.

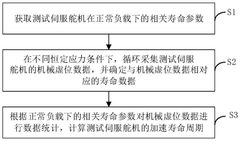

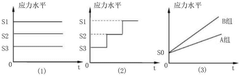

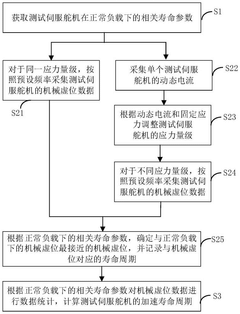

Accelerated aging test method, test device, test system and storage medium

PatentPendingCN118671582A

Innovation

- An accelerated aging test method is proposed. By cyclically collecting the mechanical virtual position data of the servo servo under different constant stress conditions, the accelerated life cycle is calculated based on the life parameters under normal load, simplifying the data statistics and calculation process, eliminating the need to consider temperature, Factors such as humidity and vibration.

Environmental Factors Impact on Sensor Reliability

Environmental factors play a critical role in determining sensor reliability and longevity during accelerated aging tests. Temperature variations represent one of the most significant stressors, with most sensors experiencing exponential degradation rates as temperatures increase according to the Arrhenius relationship. For every 10°C rise in temperature, chemical reaction rates typically double, accelerating aging mechanisms such as material oxidation, diffusion processes, and thermal expansion/contraction cycles that can compromise sensor integrity.

Humidity presents another crucial environmental variable affecting sensor performance, particularly for electrochemical and capacitive sensors. High humidity environments (>80% RH) can induce moisture ingress into sensor housings, leading to corrosion of metallic components, electrical shorts, and degradation of polymer-based sensing elements. Conversely, extremely low humidity can cause desiccation of certain sensing materials, resulting in cracking and sensitivity drift.

Ultraviolet radiation exposure significantly impacts optical sensors and those with polymer components. UV radiation breaks chemical bonds in organic materials, leading to photodegradation that manifests as yellowing, embrittlement, and eventual failure. Studies indicate that 1000 hours of accelerated UV exposure can simulate years of natural outdoor aging for many sensor types.

Mechanical vibration and shock testing reveal vulnerabilities in sensor mounting systems and internal components. Continuous vibration at resonant frequencies can induce fatigue failures in solder joints and wire bonds, while sudden shock events may cause immediate catastrophic failures. Industry standards typically require sensors to withstand 10-2000 Hz vibration ranges and shock impacts of 50-1500g depending on application environments.

Chemical exposure represents a particularly challenging environmental factor to simulate accurately. Accelerated testing protocols often employ concentrated chemical solutions to replicate years of exposure in weeks. Gaseous pollutants (SO2, NOx, O3) at 5-10x ambient concentrations can rapidly degrade sensor surfaces, while salt spray tests (5% NaCl solution at 35°C) effectively simulate maritime or roadside environments where deicing chemicals are present.

Pressure cycling affects sensor accuracy and longevity, particularly for pressure-sensitive devices. Rapid cycling between pressure extremes can induce mechanical fatigue in diaphragms and sensing elements. Testing protocols typically apply 10,000-100,000 pressure cycles to identify potential failure modes that might emerge after years of field operation.

The combined effect of multiple environmental stressors often produces synergistic degradation mechanisms that exceed the sum of individual factors. For instance, high temperature combined with humidity accelerates corrosion rates exponentially compared to either factor alone. Effective accelerated aging protocols must therefore incorporate multiple stressors in carefully designed sequences to accurately predict real-world sensor reliability.

Humidity presents another crucial environmental variable affecting sensor performance, particularly for electrochemical and capacitive sensors. High humidity environments (>80% RH) can induce moisture ingress into sensor housings, leading to corrosion of metallic components, electrical shorts, and degradation of polymer-based sensing elements. Conversely, extremely low humidity can cause desiccation of certain sensing materials, resulting in cracking and sensitivity drift.

Ultraviolet radiation exposure significantly impacts optical sensors and those with polymer components. UV radiation breaks chemical bonds in organic materials, leading to photodegradation that manifests as yellowing, embrittlement, and eventual failure. Studies indicate that 1000 hours of accelerated UV exposure can simulate years of natural outdoor aging for many sensor types.

Mechanical vibration and shock testing reveal vulnerabilities in sensor mounting systems and internal components. Continuous vibration at resonant frequencies can induce fatigue failures in solder joints and wire bonds, while sudden shock events may cause immediate catastrophic failures. Industry standards typically require sensors to withstand 10-2000 Hz vibration ranges and shock impacts of 50-1500g depending on application environments.

Chemical exposure represents a particularly challenging environmental factor to simulate accurately. Accelerated testing protocols often employ concentrated chemical solutions to replicate years of exposure in weeks. Gaseous pollutants (SO2, NOx, O3) at 5-10x ambient concentrations can rapidly degrade sensor surfaces, while salt spray tests (5% NaCl solution at 35°C) effectively simulate maritime or roadside environments where deicing chemicals are present.

Pressure cycling affects sensor accuracy and longevity, particularly for pressure-sensitive devices. Rapid cycling between pressure extremes can induce mechanical fatigue in diaphragms and sensing elements. Testing protocols typically apply 10,000-100,000 pressure cycles to identify potential failure modes that might emerge after years of field operation.

The combined effect of multiple environmental stressors often produces synergistic degradation mechanisms that exceed the sum of individual factors. For instance, high temperature combined with humidity accelerates corrosion rates exponentially compared to either factor alone. Effective accelerated aging protocols must therefore incorporate multiple stressors in carefully designed sequences to accurately predict real-world sensor reliability.

Cost-Benefit Analysis of Advanced Testing Methods

When evaluating advanced sensor lifetime testing methods, a comprehensive cost-benefit analysis reveals significant economic implications for organizations. Traditional testing methods typically require extended timeframes—often months or years—resulting in delayed product launches and increased labor costs. Advanced accelerated aging protocols, while requiring higher initial investment, demonstrate substantial long-term financial advantages.

The implementation of environmental stress screening chambers for accelerated testing represents a capital expenditure ranging from $50,000 to $250,000, depending on sophistication and capacity. Additionally, specialized testing equipment for thermal cycling, humidity variation, and electrical stress application may require investments of $30,000-$100,000 per testing station. Organizations must also consider costs associated with staff training, which typically ranges from $5,000-$15,000 per technical employee.

Despite these upfront costs, the financial benefits of advanced testing methods are compelling. Market analysis indicates that accelerated aging protocols can reduce time-to-market by 40-60%, translating to approximately $100,000-$500,000 in additional revenue per month for typical sensing products. Furthermore, early detection of failure modes through advanced testing reduces warranty claim expenses by an estimated 25-35%, representing significant cost avoidance.

The return on investment timeline varies by industry and application. Medical device manufacturers implementing advanced sensor testing methods typically achieve ROI within 12-18 months, while industrial sensor producers may see returns in 8-14 months. Consumer electronics companies often experience the fastest returns, frequently within 6-10 months due to higher production volumes and competitive market pressures.

Risk mitigation represents another crucial benefit that, while difficult to quantify precisely, carries substantial financial implications. Advanced testing methods reduce the probability of costly field failures by an estimated 30-50%, protecting brand reputation and avoiding potential regulatory penalties that could reach millions of dollars in regulated industries.

Organizations should consider scalability factors when evaluating testing investments. Modular testing systems that can accommodate multiple sensor types offer better long-term value despite higher initial costs. Additionally, the development of in-house testing capabilities versus outsourcing to specialized laboratories presents different cost structures—outsourcing typically costs $5,000-$20,000 per test series but eliminates capital expenditure requirements.

The implementation of environmental stress screening chambers for accelerated testing represents a capital expenditure ranging from $50,000 to $250,000, depending on sophistication and capacity. Additionally, specialized testing equipment for thermal cycling, humidity variation, and electrical stress application may require investments of $30,000-$100,000 per testing station. Organizations must also consider costs associated with staff training, which typically ranges from $5,000-$15,000 per technical employee.

Despite these upfront costs, the financial benefits of advanced testing methods are compelling. Market analysis indicates that accelerated aging protocols can reduce time-to-market by 40-60%, translating to approximately $100,000-$500,000 in additional revenue per month for typical sensing products. Furthermore, early detection of failure modes through advanced testing reduces warranty claim expenses by an estimated 25-35%, representing significant cost avoidance.

The return on investment timeline varies by industry and application. Medical device manufacturers implementing advanced sensor testing methods typically achieve ROI within 12-18 months, while industrial sensor producers may see returns in 8-14 months. Consumer electronics companies often experience the fastest returns, frequently within 6-10 months due to higher production volumes and competitive market pressures.

Risk mitigation represents another crucial benefit that, while difficult to quantify precisely, carries substantial financial implications. Advanced testing methods reduce the probability of costly field failures by an estimated 30-50%, protecting brand reputation and avoiding potential regulatory penalties that could reach millions of dollars in regulated industries.

Organizations should consider scalability factors when evaluating testing investments. Modular testing systems that can accommodate multiple sensor types offer better long-term value despite higher initial costs. Additionally, the development of in-house testing capabilities versus outsourcing to specialized laboratories presents different cost structures—outsourcing typically costs $5,000-$20,000 per test series but eliminates capital expenditure requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!