Flexible And Wearable Electrochemical Gas Sensors Design

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Gas Sensors Background and Objectives

Gas sensing technology has evolved significantly over the past decades, transitioning from bulky laboratory equipment to miniaturized devices. The emergence of flexible and wearable electrochemical gas sensors represents a revolutionary advancement in this field, combining the precision of electrochemical detection with the comfort and convenience of wearable technology. This technological convergence addresses the growing demand for personal environmental monitoring in various contexts including industrial safety, healthcare diagnostics, and ambient air quality assessment.

The historical trajectory of gas sensor development began with conventional rigid sensors primarily used in industrial settings. These early sensors, while effective, lacked portability and user-friendliness. The paradigm shift toward flexible sensors began in the early 2000s, accelerated by advancements in materials science, particularly the development of conductive polymers, carbon nanomaterials, and flexible substrates that maintain electrical properties under mechanical deformation.

Recent technological breakthroughs in nanomaterials and printing technologies have further catalyzed the development of flexible electrochemical gas sensors. Carbon-based materials such as graphene, carbon nanotubes, and conducting polymers have emerged as ideal sensing materials due to their excellent electrical conductivity, high surface area, and mechanical flexibility. Additionally, innovations in microfabrication techniques have enabled the integration of these materials into flexible substrates.

The primary objective of flexible and wearable electrochemical gas sensor design is to create devices that combine high sensitivity, selectivity, and stability with mechanical flexibility and comfort for continuous wear. These sensors aim to provide real-time, accurate gas detection while maintaining performance during bending, stretching, and other mechanical deformations that occur during normal wear.

Another critical goal is to develop low-power consumption sensors compatible with wireless communication technologies, enabling seamless integration with smartphones and other personal devices for data collection and analysis. This connectivity aspect is essential for creating comprehensive personal environmental monitoring systems that can alert users to potential hazards.

Furthermore, the field aims to address challenges related to sensor durability, calibration stability, and cross-sensitivity to interfering gases. Researchers are exploring novel materials and sensor architectures to enhance long-term performance under various environmental conditions, including humidity and temperature fluctuations that typically affect electrochemical sensor readings.

The ultimate vision for this technology extends beyond individual monitoring to creating distributed sensor networks that can map gas concentrations across geographical areas, contributing to smart city initiatives and environmental protection efforts. This broader application potential underscores the transformative impact that flexible and wearable gas sensing technology could have on public health and environmental monitoring.

The historical trajectory of gas sensor development began with conventional rigid sensors primarily used in industrial settings. These early sensors, while effective, lacked portability and user-friendliness. The paradigm shift toward flexible sensors began in the early 2000s, accelerated by advancements in materials science, particularly the development of conductive polymers, carbon nanomaterials, and flexible substrates that maintain electrical properties under mechanical deformation.

Recent technological breakthroughs in nanomaterials and printing technologies have further catalyzed the development of flexible electrochemical gas sensors. Carbon-based materials such as graphene, carbon nanotubes, and conducting polymers have emerged as ideal sensing materials due to their excellent electrical conductivity, high surface area, and mechanical flexibility. Additionally, innovations in microfabrication techniques have enabled the integration of these materials into flexible substrates.

The primary objective of flexible and wearable electrochemical gas sensor design is to create devices that combine high sensitivity, selectivity, and stability with mechanical flexibility and comfort for continuous wear. These sensors aim to provide real-time, accurate gas detection while maintaining performance during bending, stretching, and other mechanical deformations that occur during normal wear.

Another critical goal is to develop low-power consumption sensors compatible with wireless communication technologies, enabling seamless integration with smartphones and other personal devices for data collection and analysis. This connectivity aspect is essential for creating comprehensive personal environmental monitoring systems that can alert users to potential hazards.

Furthermore, the field aims to address challenges related to sensor durability, calibration stability, and cross-sensitivity to interfering gases. Researchers are exploring novel materials and sensor architectures to enhance long-term performance under various environmental conditions, including humidity and temperature fluctuations that typically affect electrochemical sensor readings.

The ultimate vision for this technology extends beyond individual monitoring to creating distributed sensor networks that can map gas concentrations across geographical areas, contributing to smart city initiatives and environmental protection efforts. This broader application potential underscores the transformative impact that flexible and wearable gas sensing technology could have on public health and environmental monitoring.

Market Analysis for Wearable Gas Sensing Technologies

The global market for wearable gas sensing technologies is experiencing robust growth, driven by increasing awareness of environmental pollution, workplace safety concerns, and personal health monitoring needs. Current market valuations indicate that the flexible and wearable gas sensor segment reached approximately $1.2 billion in 2022, with projections suggesting a compound annual growth rate (CAGR) of 17.5% through 2028. This growth trajectory significantly outpaces traditional fixed gas detection systems, which maintain a more modest 5-7% annual growth rate.

Consumer electronics represents the largest application segment, accounting for nearly 40% of market share, followed by healthcare applications at 25%, industrial safety at 20%, and environmental monitoring at 15%. Geographically, North America leads with 35% market share, followed closely by Europe at 30%, Asia-Pacific at 25% (with the fastest growth rate), and the rest of the world comprising the remaining 10%.

Key market drivers include stringent workplace safety regulations, particularly in chemical, oil and gas, and manufacturing industries, where portable gas detection capabilities offer significant advantages over fixed systems. The healthcare sector shows increasing demand for continuous monitoring of biomarkers through exhaled breath analysis, creating substantial opportunities for non-invasive diagnostic tools.

Consumer demand is primarily fueled by growing air quality concerns in urban environments, with particular interest in detecting pollutants like particulate matter, volatile organic compounds (VOCs), carbon monoxide, and nitrogen dioxide. The fitness and wellness segment has also emerged as a promising market, with devices that can monitor metabolic activity through breath analysis gaining traction.

Market challenges include price sensitivity among consumers, with current high-performance wearable gas sensors typically retailing between $150-300, limiting mass-market adoption. Technical limitations around sensor miniaturization, power consumption, and cross-sensitivity to interfering gases remain significant barriers to widespread commercialization.

The competitive landscape features both established industrial gas detection companies expanding into wearables and startups focused exclusively on flexible sensing technologies. Recent market consolidation has been evident, with several acquisitions of innovative sensor startups by larger industrial players seeking to enhance their technological capabilities in this emerging segment.

Customer expectations are evolving toward multi-gas detection capabilities, longer battery life, seamless smartphone integration, and more sophisticated data analytics. The subscription-based service model is gaining popularity, where hardware is offered at lower initial cost while recurring revenue is generated through data analysis services and calibration.

Consumer electronics represents the largest application segment, accounting for nearly 40% of market share, followed by healthcare applications at 25%, industrial safety at 20%, and environmental monitoring at 15%. Geographically, North America leads with 35% market share, followed closely by Europe at 30%, Asia-Pacific at 25% (with the fastest growth rate), and the rest of the world comprising the remaining 10%.

Key market drivers include stringent workplace safety regulations, particularly in chemical, oil and gas, and manufacturing industries, where portable gas detection capabilities offer significant advantages over fixed systems. The healthcare sector shows increasing demand for continuous monitoring of biomarkers through exhaled breath analysis, creating substantial opportunities for non-invasive diagnostic tools.

Consumer demand is primarily fueled by growing air quality concerns in urban environments, with particular interest in detecting pollutants like particulate matter, volatile organic compounds (VOCs), carbon monoxide, and nitrogen dioxide. The fitness and wellness segment has also emerged as a promising market, with devices that can monitor metabolic activity through breath analysis gaining traction.

Market challenges include price sensitivity among consumers, with current high-performance wearable gas sensors typically retailing between $150-300, limiting mass-market adoption. Technical limitations around sensor miniaturization, power consumption, and cross-sensitivity to interfering gases remain significant barriers to widespread commercialization.

The competitive landscape features both established industrial gas detection companies expanding into wearables and startups focused exclusively on flexible sensing technologies. Recent market consolidation has been evident, with several acquisitions of innovative sensor startups by larger industrial players seeking to enhance their technological capabilities in this emerging segment.

Customer expectations are evolving toward multi-gas detection capabilities, longer battery life, seamless smartphone integration, and more sophisticated data analytics. The subscription-based service model is gaining popularity, where hardware is offered at lower initial cost while recurring revenue is generated through data analysis services and calibration.

Current Challenges in Flexible Electrochemical Gas Sensors

Despite significant advancements in flexible and wearable electrochemical gas sensors, several critical challenges continue to impede their widespread adoption and optimal performance. Material limitations represent a primary obstacle, as traditional sensing materials like metal oxides often lack the necessary flexibility for wearable applications. When these materials are subjected to repeated bending and stretching, they frequently develop microcracks that compromise sensor functionality and reliability over time.

Stability issues present another significant challenge, particularly in real-world environments where sensors must operate under varying humidity, temperature, and mechanical stress conditions. Many current flexible sensors exhibit performance degradation after extended wear periods or exposure to environmental factors such as sweat, which can alter electrode chemistry and sensor response characteristics.

Power management remains problematic for wearable electrochemical gas sensors. Many designs require external power sources or bulky batteries that compromise the form factor and user comfort. While energy harvesting technologies show promise, they currently struggle to provide consistent power for continuous sensing operations, especially for sensors requiring heating elements or complex signal processing.

Sensitivity and selectivity trade-offs continue to challenge researchers. The pursuit of highly flexible substrates and interfaces often comes at the expense of sensing performance. Cross-sensitivity to interferent gases remains particularly problematic in wearable contexts where multiple environmental gases are present simultaneously. Current sensor designs frequently struggle to distinguish between target analytes and similar molecular species.

Manufacturability and scalability issues persist throughout the field. Many laboratory-demonstrated flexible sensors rely on complex fabrication processes that are difficult to scale for mass production. The integration of sensing elements with flexible electronics and data processing components introduces additional manufacturing complexities that impact production costs and commercial viability.

Biocompatibility and user comfort concerns are increasingly important as these sensors move toward direct skin contact applications. Materials that exhibit excellent sensing properties may cause skin irritation or allergic reactions during prolonged wear. Additionally, the mechanical design must balance sensing performance with ergonomic considerations to ensure user acceptance.

Standardization and calibration methodologies remain underdeveloped for flexible electrochemical gas sensors. Unlike their rigid counterparts, flexible sensors often exhibit response variations based on their physical configuration, making universal calibration protocols difficult to establish. This challenge is particularly evident in wearable applications where sensor positioning and body movement introduce additional variables affecting measurement accuracy.

Stability issues present another significant challenge, particularly in real-world environments where sensors must operate under varying humidity, temperature, and mechanical stress conditions. Many current flexible sensors exhibit performance degradation after extended wear periods or exposure to environmental factors such as sweat, which can alter electrode chemistry and sensor response characteristics.

Power management remains problematic for wearable electrochemical gas sensors. Many designs require external power sources or bulky batteries that compromise the form factor and user comfort. While energy harvesting technologies show promise, they currently struggle to provide consistent power for continuous sensing operations, especially for sensors requiring heating elements or complex signal processing.

Sensitivity and selectivity trade-offs continue to challenge researchers. The pursuit of highly flexible substrates and interfaces often comes at the expense of sensing performance. Cross-sensitivity to interferent gases remains particularly problematic in wearable contexts where multiple environmental gases are present simultaneously. Current sensor designs frequently struggle to distinguish between target analytes and similar molecular species.

Manufacturability and scalability issues persist throughout the field. Many laboratory-demonstrated flexible sensors rely on complex fabrication processes that are difficult to scale for mass production. The integration of sensing elements with flexible electronics and data processing components introduces additional manufacturing complexities that impact production costs and commercial viability.

Biocompatibility and user comfort concerns are increasingly important as these sensors move toward direct skin contact applications. Materials that exhibit excellent sensing properties may cause skin irritation or allergic reactions during prolonged wear. Additionally, the mechanical design must balance sensing performance with ergonomic considerations to ensure user acceptance.

Standardization and calibration methodologies remain underdeveloped for flexible electrochemical gas sensors. Unlike their rigid counterparts, flexible sensors often exhibit response variations based on their physical configuration, making universal calibration protocols difficult to establish. This challenge is particularly evident in wearable applications where sensor positioning and body movement introduce additional variables affecting measurement accuracy.

Current Design Approaches for Flexible Electrochemical Gas Sensors

01 Flexible substrate materials for wearable gas sensors

Various flexible substrate materials are used in the development of wearable electrochemical gas sensors to achieve flexibility and comfort. These materials include polymers like polyethylene terephthalate (PET), polyimide, and polydimethylsiloxane (PDMS), which can conform to body contours while maintaining sensor functionality. The flexibility of these substrates allows the sensors to be integrated into clothing, accessories, or directly attached to the skin without causing discomfort during movement.- Flexible substrate materials for wearable gas sensors: Various flexible substrate materials can be used to create wearable electrochemical gas sensors. These include polymers like polyimide, PDMS (polydimethylsiloxane), and PET (polyethylene terephthalate) that provide the necessary flexibility while maintaining structural integrity. These materials allow the sensors to conform to body contours and withstand repeated bending and stretching during normal wear, making them suitable for continuous monitoring applications while maintaining sensor performance.

- Stretchable electrode configurations: Advanced electrode designs incorporate stretchable configurations to enhance wearability while maintaining electrochemical performance. These include serpentine patterns, mesh structures, and wavy configurations that can accommodate strain without compromising electrical conductivity. Nanomaterials such as carbon nanotubes, graphene, and silver nanowires are commonly used to create these stretchable electrodes, allowing the sensor to maintain functionality during body movement and deformation while ensuring stable signal output.

- Integration with wearable platforms: Electrochemical gas sensors can be integrated into various wearable platforms such as smartwatches, fitness bands, clothing, and patches. This integration requires miniaturization of sensing components and power management systems. Wireless communication modules enable real-time data transmission to smartphones or cloud platforms for continuous monitoring. The integration approach considers user comfort, aesthetic appeal, and practical usability while maintaining accurate gas detection capabilities.

- Energy harvesting and power management: Wearable electrochemical gas sensors incorporate energy harvesting technologies and efficient power management systems to enable long-term operation. These include flexible solar cells, piezoelectric generators, and thermoelectric elements that convert body heat or movement into electrical energy. Low-power microcontrollers and optimized sensing protocols reduce energy consumption, while flexible batteries or supercapacitors provide energy storage solutions that maintain the overall flexibility and comfort of the wearable device.

- Environmental stability and durability enhancements: Techniques to improve the environmental stability and durability of flexible gas sensors include protective coatings, encapsulation methods, and moisture barriers. These enhancements protect sensitive electrochemical components from sweat, humidity, and mechanical stress while maintaining sensor flexibility. Advanced packaging solutions using breathable yet waterproof materials allow gas molecules to reach the sensing elements while preventing contamination. Self-healing materials can repair minor damage, extending the operational lifetime of wearable sensors in real-world conditions.

02 Stretchable electrode designs and materials

Innovative electrode designs and materials are crucial for maintaining electrical conductivity during stretching and bending in wearable gas sensors. These include serpentine patterns, mesh structures, and nanomaterial-based electrodes using carbon nanotubes, graphene, or silver nanowires. Such designs allow the electrodes to withstand mechanical deformation while maintaining electrical performance, enabling reliable gas detection even when the sensor is subjected to movement or strain during wear.Expand Specific Solutions03 Integration with wearable platforms and textiles

Electrochemical gas sensors are being integrated with various wearable platforms including smart textiles, wristbands, patches, and clothing. This integration involves techniques such as screen printing, inkjet printing, or direct deposition of sensing materials onto fabric substrates. The sensors are designed to be lightweight, unobtrusive, and capable of withstanding daily activities while continuously monitoring environmental gases or biomarkers from the wearer's surroundings or body emissions.Expand Specific Solutions04 Power management and wireless connectivity

Efficient power management systems and wireless connectivity are essential components of wearable gas sensors. These include low-power microcontrollers, energy harvesting technologies (such as photovoltaic cells or piezoelectric elements), and wireless communication modules (Bluetooth, NFC, or WiFi). These features enable long-term operation without frequent charging and allow real-time data transmission to smartphones or other devices for immediate analysis and alerts.Expand Specific Solutions05 Novel sensing materials for enhanced sensitivity and selectivity

Advanced sensing materials are being developed to enhance the sensitivity and selectivity of flexible gas sensors. These include metal oxide semiconductors, conducting polymers, carbon-based nanomaterials, and metal-organic frameworks that can be deposited as thin films on flexible substrates. These materials are engineered to maintain their sensing properties under mechanical stress and provide reliable detection of specific gases even at low concentrations, which is crucial for environmental monitoring and health applications.Expand Specific Solutions

Leading Companies and Research Institutions in Flexible Sensors

The flexible and wearable electrochemical gas sensors market is currently in a growth phase, with increasing demand driven by applications in healthcare, environmental monitoring, and industrial safety. The global market size is estimated to reach $1.5 billion by 2025, growing at a CAGR of approximately 8-10%. From a technological maturity perspective, the landscape shows varying degrees of advancement. Industry leaders like Draeger Safety and Drägerwerk AG have established strong positions with mature gas detection technologies, while Robert Bosch GmbH leverages its extensive electronics expertise to develop integrated sensor solutions. Academic institutions such as Huazhong University of Science & Technology and The Johns Hopkins University are driving fundamental research innovations. Companies like Panasonic Electric Works and QUALCOMM are focusing on miniaturization and wireless connectivity aspects, while specialized players such as Gastron Co. and SurExam Bio-Tech are developing application-specific solutions for targeted markets.

Drägerwerk AG & Co. KGaA

Technical Solution: Drägerwerk has developed advanced flexible electrochemical gas sensors utilizing polymer-based substrates with printed electrodes that conform to body contours. Their technology incorporates specialized sensing materials like carbon nanotubes and metal oxide semiconductors embedded in flexible polymers to detect gases such as CO, NO2, and VOCs. The company has implemented a multi-layer design approach where the sensing layer, electrode layer, and protective membrane are all engineered to maintain functionality during bending and stretching. Their sensors feature wireless connectivity and low-power operation, with proprietary algorithms for signal processing that compensate for motion artifacts and environmental interferences. Drägerwerk's wearable gas sensors are integrated into personal protective equipment for industrial workers and emergency responders, providing real-time hazard monitoring with minimal impact on user mobility.

Strengths: Superior durability in harsh environments, excellent integration with existing safety equipment, and proven reliability in industrial settings. Weaknesses: Higher cost compared to rigid sensor alternatives, and potential challenges with long-term calibration stability when subjected to repeated mechanical stress.

Korea Institute of Materials Science

Technical Solution: The Korea Institute of Materials Science (KIMS) has developed innovative flexible electrochemical gas sensors using nanofiber-based sensing materials created through electrospinning techniques. Their approach incorporates metal oxide semiconductor nanofibers embedded in flexible polymer matrices that maintain high surface area for gas interaction while allowing mechanical deformation. KIMS has pioneered a unique electrode design using silver nanowires in stretchable configurations that maintain conductivity even at strain levels exceeding 30%. Their sensors feature specialized humidity-resistant coatings that minimize environmental interference while maintaining gas permeability. The institute has also developed low-temperature processing methods that enable direct fabrication on temperature-sensitive flexible substrates. KIMS's wearable gas sensors incorporate energy harvesting elements that utilize body movement to supplement power requirements, extending operational lifetime for continuous environmental monitoring applications.

Strengths: Excellent balance between flexibility and sensing performance, innovative energy harvesting integration, and strong durability under repeated mechanical stress. Weaknesses: Complex manufacturing process that may challenge mass production scaling, and potential signal drift issues under extreme deformation conditions.

Key Materials and Fabrication Techniques Analysis

Electrochemical sensor

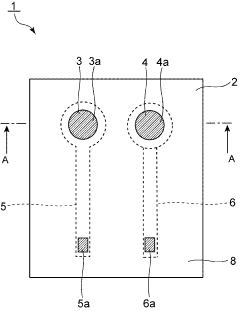

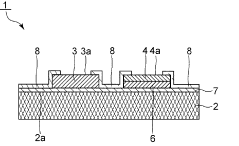

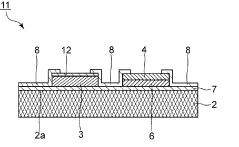

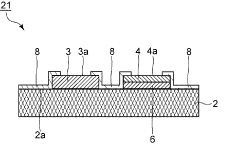

PatentActiveJP2020137671A

Innovation

- The electrochemical sensor employs a base material made of an inorganic fiber sheet, preferably glass cloth, with a working electrode and optional components like a reference electrode, buffer layer, and passivation film, all integrated on a flexible substrate to withstand stress and maintain connectivity.

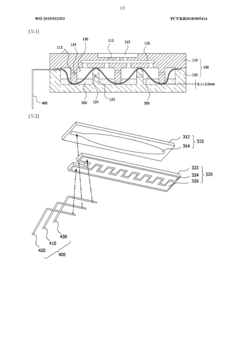

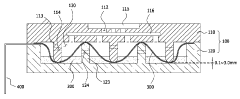

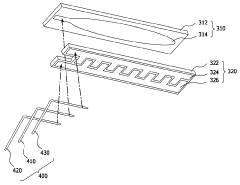

Electrochemical gas sensor having flexible curved electrode

PatentWO2019022353A1

Innovation

- An electrochemical gas sensor with a flexible, curved electrode configuration that increases the electrode area by using protrusions and a receiving space design, allowing for a larger diffusion area and partial immersion of the electrode in the electrolyte, while maintaining electrical connectivity through metal electrodes.

Miniaturization and Power Optimization Strategies

Miniaturization and power optimization represent critical challenges in the development of flexible and wearable electrochemical gas sensors. The evolution of these technologies has been driven by the need for portable, unobtrusive sensing solutions that can operate continuously without frequent charging or replacement.

Current miniaturization strategies focus on innovative substrate materials and fabrication techniques. Ultrathin polymeric substrates such as polyimide and polyethylene terephthalate (PET) have enabled the development of sensors with thicknesses below 100 μm. Advanced microfabrication techniques including photolithography, screen printing, and inkjet printing have facilitated the precise deposition of sensing materials at microscale dimensions, significantly reducing the overall sensor footprint.

Power optimization approaches have evolved along two primary pathways: reducing power consumption and implementing energy harvesting technologies. Low-power circuit designs utilizing sleep modes and duty cycling have decreased energy requirements by up to 80% compared to traditional sensing systems. The integration of ultra-low-power microcontrollers and application-specific integrated circuits (ASICs) has further enhanced energy efficiency, with some systems achieving operational power consumption below 100 μW.

Energy harvesting technologies have emerged as complementary solutions to extend operational lifetimes. Flexible photovoltaic cells integrated directly onto sensor platforms can generate 1-10 mW/cm² under ambient lighting conditions. Thermoelectric generators leveraging body heat differentials typically produce 10-100 μW/cm² when placed on skin surfaces. Piezoelectric and triboelectric nanogenerators harvesting energy from body movement have demonstrated power densities of 1-5 mW/cm² during normal physical activity.

System-level optimization strategies have focused on intelligent power management. Adaptive sampling rates that adjust based on environmental conditions or user activity patterns can reduce average power consumption by 30-60%. Edge computing implementations that process sensor data locally minimize power-intensive wireless data transmission, resulting in energy savings of up to 70% compared to continuous transmission architectures.

Recent innovations include the development of self-powered sensing systems that combine multiple energy harvesting modalities with ultra-low-power sensing elements. These integrated platforms have demonstrated continuous operation for periods exceeding six months without external charging, representing a significant advancement toward truly wearable, maintenance-free gas sensing solutions.

The miniaturization and power optimization landscape continues to evolve rapidly, with emerging technologies such as atomic layer deposition, 3D printing of functional materials, and novel nanomaterials promising further reductions in size and power requirements while maintaining or improving sensing performance.

Current miniaturization strategies focus on innovative substrate materials and fabrication techniques. Ultrathin polymeric substrates such as polyimide and polyethylene terephthalate (PET) have enabled the development of sensors with thicknesses below 100 μm. Advanced microfabrication techniques including photolithography, screen printing, and inkjet printing have facilitated the precise deposition of sensing materials at microscale dimensions, significantly reducing the overall sensor footprint.

Power optimization approaches have evolved along two primary pathways: reducing power consumption and implementing energy harvesting technologies. Low-power circuit designs utilizing sleep modes and duty cycling have decreased energy requirements by up to 80% compared to traditional sensing systems. The integration of ultra-low-power microcontrollers and application-specific integrated circuits (ASICs) has further enhanced energy efficiency, with some systems achieving operational power consumption below 100 μW.

Energy harvesting technologies have emerged as complementary solutions to extend operational lifetimes. Flexible photovoltaic cells integrated directly onto sensor platforms can generate 1-10 mW/cm² under ambient lighting conditions. Thermoelectric generators leveraging body heat differentials typically produce 10-100 μW/cm² when placed on skin surfaces. Piezoelectric and triboelectric nanogenerators harvesting energy from body movement have demonstrated power densities of 1-5 mW/cm² during normal physical activity.

System-level optimization strategies have focused on intelligent power management. Adaptive sampling rates that adjust based on environmental conditions or user activity patterns can reduce average power consumption by 30-60%. Edge computing implementations that process sensor data locally minimize power-intensive wireless data transmission, resulting in energy savings of up to 70% compared to continuous transmission architectures.

Recent innovations include the development of self-powered sensing systems that combine multiple energy harvesting modalities with ultra-low-power sensing elements. These integrated platforms have demonstrated continuous operation for periods exceeding six months without external charging, representing a significant advancement toward truly wearable, maintenance-free gas sensing solutions.

The miniaturization and power optimization landscape continues to evolve rapidly, with emerging technologies such as atomic layer deposition, 3D printing of functional materials, and novel nanomaterials promising further reductions in size and power requirements while maintaining or improving sensing performance.

Environmental and Health Safety Considerations

The development of flexible and wearable electrochemical gas sensors brings significant environmental and health safety considerations that must be addressed throughout their lifecycle. These devices, while offering substantial benefits for personal health monitoring and environmental sensing, introduce potential risks related to material toxicity, disposal challenges, and user safety concerns.

Material selection represents a critical environmental consideration in sensor design. Many conventional gas sensors incorporate heavy metals, rare earth elements, and potentially hazardous chemicals that pose environmental risks during extraction, processing, and disposal. Advanced flexible sensors increasingly utilize biodegradable substrates, non-toxic conductive polymers, and environmentally benign nanomaterials to minimize ecological impact while maintaining sensing performance.

Manufacturing processes for these sensors require careful environmental management. Traditional fabrication techniques often involve hazardous solvents, high-temperature processing, and chemical etching that generate toxic waste streams. Emerging green manufacturing approaches emphasize aqueous processing, reduced energy consumption, and minimal waste generation through techniques like inkjet printing and roll-to-roll fabrication, significantly reducing the environmental footprint.

User safety considerations are paramount for wearable gas sensors that maintain prolonged contact with skin. Potential risks include skin irritation, allergic reactions, and chemical leaching from sensor components. Biocompatibility testing protocols must be rigorously implemented to ensure materials in direct contact with users meet medical-grade safety standards. Additionally, electrical safety measures must prevent potential thermal incidents or electrical shocks, particularly when sensors are exposed to moisture or mechanical stress.

End-of-life management presents substantial challenges for these hybrid electronic-chemical devices. The integration of multiple materials in compact, flexible formats often complicates recycling efforts. Design strategies increasingly incorporate modular approaches that facilitate component separation, material recovery, and responsible disposal. Extended producer responsibility programs are emerging to ensure manufacturers address the full lifecycle environmental impact of their sensor products.

Regulatory frameworks governing these technologies continue to evolve across different regions. Compliance with standards such as RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), and medical device regulations requires comprehensive material documentation and safety testing. Forward-thinking manufacturers are adopting precautionary approaches that anticipate stricter future regulations while maintaining innovation momentum.

Material selection represents a critical environmental consideration in sensor design. Many conventional gas sensors incorporate heavy metals, rare earth elements, and potentially hazardous chemicals that pose environmental risks during extraction, processing, and disposal. Advanced flexible sensors increasingly utilize biodegradable substrates, non-toxic conductive polymers, and environmentally benign nanomaterials to minimize ecological impact while maintaining sensing performance.

Manufacturing processes for these sensors require careful environmental management. Traditional fabrication techniques often involve hazardous solvents, high-temperature processing, and chemical etching that generate toxic waste streams. Emerging green manufacturing approaches emphasize aqueous processing, reduced energy consumption, and minimal waste generation through techniques like inkjet printing and roll-to-roll fabrication, significantly reducing the environmental footprint.

User safety considerations are paramount for wearable gas sensors that maintain prolonged contact with skin. Potential risks include skin irritation, allergic reactions, and chemical leaching from sensor components. Biocompatibility testing protocols must be rigorously implemented to ensure materials in direct contact with users meet medical-grade safety standards. Additionally, electrical safety measures must prevent potential thermal incidents or electrical shocks, particularly when sensors are exposed to moisture or mechanical stress.

End-of-life management presents substantial challenges for these hybrid electronic-chemical devices. The integration of multiple materials in compact, flexible formats often complicates recycling efforts. Design strategies increasingly incorporate modular approaches that facilitate component separation, material recovery, and responsible disposal. Extended producer responsibility programs are emerging to ensure manufacturers address the full lifecycle environmental impact of their sensor products.

Regulatory frameworks governing these technologies continue to evolve across different regions. Compliance with standards such as RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), and medical device regulations requires comprehensive material documentation and safety testing. Forward-thinking manufacturers are adopting precautionary approaches that anticipate stricter future regulations while maintaining innovation momentum.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!