Cross-Sensitivity Reduction Strategies For Mixed Gas Streams

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gas Sensing Technology Background and Objectives

Gas sensing technology has evolved significantly over the past several decades, transitioning from simple electrochemical sensors to sophisticated multi-gas detection systems. The fundamental challenge in this field has been the accurate detection and quantification of specific gases within complex mixtures. Cross-sensitivity—where a sensor responds to multiple gases rather than just the target analyte—represents one of the most persistent obstacles in gas sensing applications, particularly in industrial environments, environmental monitoring, and medical diagnostics.

The evolution of gas sensing technology began with basic metal oxide semiconductor sensors in the 1960s, followed by electrochemical sensors in the 1970s, and infrared absorption techniques in the 1980s. Recent decades have witnessed the emergence of more advanced technologies including photoacoustic spectroscopy, tunable diode laser absorption spectroscopy (TDLAS), and nanostructured sensing materials. Despite these advancements, cross-sensitivity issues continue to plague practical applications, especially when dealing with mixed gas streams containing multiple interfering compounds.

Current market trends indicate a growing demand for sensors capable of discriminating between similar gases in complex mixtures. This demand is driven by increasingly stringent regulatory requirements for emissions monitoring, workplace safety standards, and the need for more precise medical diagnostic tools. The global gas sensor market, valued at approximately $2.5 billion in 2022, is projected to grow at a CAGR of 7.8% through 2030, with cross-sensitivity reduction technologies representing a significant growth segment.

The primary technical objective in addressing cross-sensitivity is to develop sensing systems that can selectively detect target gases with minimal interference from other components in mixed streams. This involves innovations in sensor materials, signal processing algorithms, and system architectures. Specifically, research aims to achieve selectivity enhancement through various approaches including molecular recognition elements, sensor arrays with pattern recognition, and advanced filtering techniques.

Secondary objectives include improving sensor stability over time, reducing power consumption for portable applications, and developing self-calibration capabilities to maintain accuracy in fluctuating environmental conditions. The ultimate goal is to create "electronic nose" systems that can match or exceed the selectivity of biological olfactory systems while maintaining the robustness required for industrial applications.

The technological trajectory suggests convergence toward integrated sensing platforms that combine multiple sensing modalities with artificial intelligence for real-time analysis and interference compensation. This represents a paradigm shift from single-sensor approaches to intelligent sensing systems capable of adapting to complex and dynamic gas mixtures.

The evolution of gas sensing technology began with basic metal oxide semiconductor sensors in the 1960s, followed by electrochemical sensors in the 1970s, and infrared absorption techniques in the 1980s. Recent decades have witnessed the emergence of more advanced technologies including photoacoustic spectroscopy, tunable diode laser absorption spectroscopy (TDLAS), and nanostructured sensing materials. Despite these advancements, cross-sensitivity issues continue to plague practical applications, especially when dealing with mixed gas streams containing multiple interfering compounds.

Current market trends indicate a growing demand for sensors capable of discriminating between similar gases in complex mixtures. This demand is driven by increasingly stringent regulatory requirements for emissions monitoring, workplace safety standards, and the need for more precise medical diagnostic tools. The global gas sensor market, valued at approximately $2.5 billion in 2022, is projected to grow at a CAGR of 7.8% through 2030, with cross-sensitivity reduction technologies representing a significant growth segment.

The primary technical objective in addressing cross-sensitivity is to develop sensing systems that can selectively detect target gases with minimal interference from other components in mixed streams. This involves innovations in sensor materials, signal processing algorithms, and system architectures. Specifically, research aims to achieve selectivity enhancement through various approaches including molecular recognition elements, sensor arrays with pattern recognition, and advanced filtering techniques.

Secondary objectives include improving sensor stability over time, reducing power consumption for portable applications, and developing self-calibration capabilities to maintain accuracy in fluctuating environmental conditions. The ultimate goal is to create "electronic nose" systems that can match or exceed the selectivity of biological olfactory systems while maintaining the robustness required for industrial applications.

The technological trajectory suggests convergence toward integrated sensing platforms that combine multiple sensing modalities with artificial intelligence for real-time analysis and interference compensation. This represents a paradigm shift from single-sensor approaches to intelligent sensing systems capable of adapting to complex and dynamic gas mixtures.

Market Analysis for Cross-Sensitivity Solutions

The cross-sensitivity reduction market for mixed gas sensing solutions is experiencing robust growth, driven by increasing demands across multiple industries. Current market valuation stands at approximately 3.2 billion USD with projected annual growth rates of 8.7% through 2028, significantly outpacing the broader sensor market's 5.4% growth rate. This acceleration stems from stringent regulatory requirements for environmental monitoring and workplace safety across industrial sectors.

Industrial applications represent the largest market segment, accounting for 42% of total demand. This includes chemical processing, oil and gas, and manufacturing facilities where accurate gas discrimination is critical for both safety and process optimization. The environmental monitoring sector follows at 27%, with applications in air quality management, emissions control, and climate research requiring increasingly precise multi-gas detection capabilities.

Healthcare applications constitute a rapidly expanding segment growing at 11.3% annually, particularly for breath analysis diagnostics and anesthesia monitoring systems where cross-sensitivity issues have traditionally limited clinical adoption. The automotive sector represents another high-growth area at 9.8% annual growth, driven by requirements for cabin air quality monitoring and emissions systems.

Regionally, North America leads with 34% market share, followed by Europe (29%) and Asia-Pacific (27%). However, the Asia-Pacific region demonstrates the highest growth trajectory at 10.2% annually, fueled by rapid industrialization and strengthening environmental regulations in China and India.

Customer pain points consistently highlight reliability concerns in complex gas environments, with 78% of industrial users reporting false positives as their primary challenge with current sensing technologies. Cost remains a significant barrier, particularly for solutions employing advanced materials or sophisticated algorithms, with premium cross-sensitivity reduction features commanding 40-60% price premiums over standard sensors.

The competitive landscape features established instrumentation companies like Honeywell, Siemens, and Dräger holding 47% combined market share, while specialized sensor manufacturers like Alphasense, Figaro, and SGX Sensortech control approximately 31%. The remaining market comprises emerging technology startups focused on novel materials and AI-enhanced signal processing approaches.

Market adoption barriers include integration challenges with existing systems, calibration complexity, and total cost of ownership concerns. However, the value proposition of reduced false alarms, extended sensor lifetimes, and improved measurement accuracy continues to drive market expansion across all segments.

Industrial applications represent the largest market segment, accounting for 42% of total demand. This includes chemical processing, oil and gas, and manufacturing facilities where accurate gas discrimination is critical for both safety and process optimization. The environmental monitoring sector follows at 27%, with applications in air quality management, emissions control, and climate research requiring increasingly precise multi-gas detection capabilities.

Healthcare applications constitute a rapidly expanding segment growing at 11.3% annually, particularly for breath analysis diagnostics and anesthesia monitoring systems where cross-sensitivity issues have traditionally limited clinical adoption. The automotive sector represents another high-growth area at 9.8% annual growth, driven by requirements for cabin air quality monitoring and emissions systems.

Regionally, North America leads with 34% market share, followed by Europe (29%) and Asia-Pacific (27%). However, the Asia-Pacific region demonstrates the highest growth trajectory at 10.2% annually, fueled by rapid industrialization and strengthening environmental regulations in China and India.

Customer pain points consistently highlight reliability concerns in complex gas environments, with 78% of industrial users reporting false positives as their primary challenge with current sensing technologies. Cost remains a significant barrier, particularly for solutions employing advanced materials or sophisticated algorithms, with premium cross-sensitivity reduction features commanding 40-60% price premiums over standard sensors.

The competitive landscape features established instrumentation companies like Honeywell, Siemens, and Dräger holding 47% combined market share, while specialized sensor manufacturers like Alphasense, Figaro, and SGX Sensortech control approximately 31%. The remaining market comprises emerging technology startups focused on novel materials and AI-enhanced signal processing approaches.

Market adoption barriers include integration challenges with existing systems, calibration complexity, and total cost of ownership concerns. However, the value proposition of reduced false alarms, extended sensor lifetimes, and improved measurement accuracy continues to drive market expansion across all segments.

Current Challenges in Mixed Gas Detection

The detection of mixed gas streams presents significant technical challenges that continue to impede the development of reliable and accurate sensing systems. Current gas sensors often exhibit cross-sensitivity issues when exposed to complex gas mixtures, leading to false readings and compromised measurement accuracy. This fundamental limitation stems from the inherent difficulty in distinguishing between similar gas molecules, particularly those with comparable chemical properties or molecular structures.

Traditional metal oxide semiconductor (MOS) sensors, while cost-effective and widely deployed, suffer from poor selectivity in mixed environments. These sensors typically respond to a broad range of reducing or oxidizing gases, making specific target gas identification problematic when multiple gases are present simultaneously. Temperature and humidity variations further exacerbate these issues, causing baseline drift and sensitivity fluctuations that complicate data interpretation.

Electrochemical sensors face similar challenges, with cross-interference from gases that undergo similar redox reactions at the sensing electrode. For instance, carbon monoxide sensors often show false positive responses to hydrogen, ethanol, and other volatile organic compounds (VOCs), limiting their reliability in industrial environments where multiple gases coexist.

Optical sensing technologies, including non-dispersive infrared (NDIR) and tunable diode laser absorption spectroscopy (TDLAS), offer improved selectivity but encounter difficulties with overlapping absorption spectra in complex mixtures. Gas species with similar absorption bands can interfere with target gas measurements, necessitating sophisticated algorithms for spectral deconvolution that increase computational demands and system complexity.

Miniaturization efforts for portable and wearable gas detection systems introduce additional constraints on sensor performance. The reduced surface area available for sensing elements often results in diminished sensitivity and selectivity, further complicating the cross-sensitivity challenge in field applications where multiple gases are typically present.

Data processing approaches such as pattern recognition and machine learning algorithms show promise but remain limited by the quality and representativeness of training datasets. Current algorithms struggle to generalize across varying environmental conditions and gas concentration ranges, particularly when confronted with previously unencountered gas combinations.

Calibration maintenance represents another significant hurdle, as sensors deployed in mixed gas environments often experience accelerated drift and degradation due to complex chemical interactions at the sensing surface. This necessitates frequent recalibration, increasing operational costs and reducing system reliability in continuous monitoring applications.

The development of standardized testing protocols for evaluating cross-sensitivity performance remains inadequate, hampering meaningful comparison between different sensing technologies and slowing industry-wide progress toward more selective detection solutions for mixed gas streams.

Traditional metal oxide semiconductor (MOS) sensors, while cost-effective and widely deployed, suffer from poor selectivity in mixed environments. These sensors typically respond to a broad range of reducing or oxidizing gases, making specific target gas identification problematic when multiple gases are present simultaneously. Temperature and humidity variations further exacerbate these issues, causing baseline drift and sensitivity fluctuations that complicate data interpretation.

Electrochemical sensors face similar challenges, with cross-interference from gases that undergo similar redox reactions at the sensing electrode. For instance, carbon monoxide sensors often show false positive responses to hydrogen, ethanol, and other volatile organic compounds (VOCs), limiting their reliability in industrial environments where multiple gases coexist.

Optical sensing technologies, including non-dispersive infrared (NDIR) and tunable diode laser absorption spectroscopy (TDLAS), offer improved selectivity but encounter difficulties with overlapping absorption spectra in complex mixtures. Gas species with similar absorption bands can interfere with target gas measurements, necessitating sophisticated algorithms for spectral deconvolution that increase computational demands and system complexity.

Miniaturization efforts for portable and wearable gas detection systems introduce additional constraints on sensor performance. The reduced surface area available for sensing elements often results in diminished sensitivity and selectivity, further complicating the cross-sensitivity challenge in field applications where multiple gases are typically present.

Data processing approaches such as pattern recognition and machine learning algorithms show promise but remain limited by the quality and representativeness of training datasets. Current algorithms struggle to generalize across varying environmental conditions and gas concentration ranges, particularly when confronted with previously unencountered gas combinations.

Calibration maintenance represents another significant hurdle, as sensors deployed in mixed gas environments often experience accelerated drift and degradation due to complex chemical interactions at the sensing surface. This necessitates frequent recalibration, increasing operational costs and reducing system reliability in continuous monitoring applications.

The development of standardized testing protocols for evaluating cross-sensitivity performance remains inadequate, hampering meaningful comparison between different sensing technologies and slowing industry-wide progress toward more selective detection solutions for mixed gas streams.

Current Cross-Sensitivity Reduction Methods

01 Cross-sensitivity compensation methods

Various methods are employed to compensate for cross-sensitivity in gas sensors. These include algorithmic approaches, machine learning techniques, and signal processing methods that can distinguish between target gases and interfering substances. By implementing these compensation methods, the accuracy and reliability of gas measurements can be significantly improved even in the presence of multiple gases.- Cross-sensitivity reduction techniques in gas sensors: Various techniques can be employed to reduce cross-sensitivity in gas sensors, including the use of selective filtering materials, specialized coatings, and advanced sensor designs. These approaches help to minimize interference from non-target gases, improving the accuracy and reliability of gas detection. Selective materials can be incorporated into sensor structures to preferentially interact with target gases while blocking interfering compounds.

- Algorithmic compensation for cross-sensitivity: Advanced algorithms and data processing techniques can be used to compensate for cross-sensitivity issues in gas sensors. These methods involve mathematical models that account for known interference patterns and correct sensor readings accordingly. Machine learning approaches can analyze sensor response patterns to differentiate between target gases and interferents, enabling more accurate gas concentration measurements even in complex gas mixtures.

- Multi-sensor array systems for addressing cross-sensitivity: Multi-sensor array systems utilize multiple different sensing elements with varying selectivity profiles to overcome cross-sensitivity limitations. By analyzing the combined response pattern from multiple sensors, these systems can distinguish between different gases even when individual sensors exhibit cross-sensitivity. This approach, sometimes called an electronic nose, uses pattern recognition techniques to identify specific gas signatures in complex environments.

- Temperature and humidity compensation in gas sensing: Environmental factors such as temperature and humidity can significantly affect gas sensor performance and exacerbate cross-sensitivity issues. Specialized designs incorporate temperature and humidity sensors alongside gas sensing elements to enable real-time compensation for these environmental variables. Some advanced sensors include integrated heating elements that maintain optimal operating temperatures to minimize cross-sensitivity effects.

- Novel materials for selective gas detection: Research into novel sensing materials focuses on developing compounds with high selectivity for specific gases to inherently reduce cross-sensitivity problems. These materials include specialized metal oxides, polymers, and nanostructured composites designed to interact preferentially with target gas molecules. Some approaches utilize molecularly imprinted polymers or functionalized nanomaterials that can recognize specific gas molecules based on their size, shape, and chemical properties.

02 Selective gas sensor materials and coatings

Specialized materials and coatings are developed to enhance the selectivity of gas sensors. These materials can include modified metal oxides, polymers, and nanomaterials that preferentially interact with specific target gases while minimizing responses to interfering gases. The selective nature of these materials helps reduce cross-sensitivity issues in gas detection applications.Expand Specific Solutions03 Multi-sensor array systems

Multi-sensor array systems utilize multiple different sensors with varying selectivity patterns to detect and differentiate between gases. By analyzing the combined response pattern from these sensor arrays, it becomes possible to identify specific gases even in complex mixtures. This approach, sometimes called an electronic nose, can effectively address cross-sensitivity challenges through pattern recognition techniques.Expand Specific Solutions04 Temperature modulation techniques

Temperature modulation techniques involve operating gas sensors at different temperatures to create distinctive response patterns for various gases. Since different gases react optimally at different temperatures, cycling through temperature profiles can generate unique signatures for each gas. This approach helps distinguish between target gases and interferents, thereby reducing cross-sensitivity issues.Expand Specific Solutions05 Filtering and pre-treatment methods

Physical and chemical filtering methods can be employed to selectively remove or reduce interfering gases before they reach the sensing element. These pre-treatment approaches include selective membranes, catalytic filters, and scrubbers that can block or transform interfering gases while allowing target gases to pass through. Such methods effectively reduce cross-sensitivity by controlling the composition of the gas mixture that reaches the sensor.Expand Specific Solutions

Leading Companies in Gas Sensor Industry

The cross-sensitivity reduction market for mixed gas streams is currently in a growth phase, with increasing demand driven by industrial automation, environmental monitoring, and safety applications. The market size is expanding steadily as industries face stricter regulatory requirements for gas detection accuracy. Technologically, the field shows varying maturity levels, with established players like Siemens AG, Robert Bosch GmbH, and Infineon Technologies AG leading innovation through advanced sensor technologies and signal processing algorithms. Specialized companies such as Drägerwerk and TDK-Micronas are developing application-specific solutions, while automotive manufacturers like BMW and Mercedes-Benz are integrating these technologies for emissions monitoring and cabin air quality. The competitive landscape features collaboration between semiconductor manufacturers, sensor specialists, and end-application developers to overcome the fundamental challenge of selective gas detection in complex environments.

Robert Bosch GmbH

Technical Solution: Robert Bosch has developed advanced cross-sensitivity reduction strategies for mixed gas streams through their multi-sensor array technology. Their approach combines selective gas sensors with sophisticated signal processing algorithms to differentiate between various gases in complex mixtures. The company employs micro-electromechanical systems (MEMS) with specialized coatings that respond differently to various gas components, creating unique response patterns. These patterns are then processed using machine learning algorithms to identify and quantify individual gases within mixed streams. Bosch's technology incorporates temperature cycling techniques where sensors operate at different temperature profiles to exploit the temperature-dependent response characteristics of various gases, further enhancing selectivity. Their systems also utilize dynamic baseline correction methods to compensate for environmental factors like humidity and temperature variations that can affect sensor readings[1][3].

Strengths: Highly integrated MEMS technology allows for miniaturization and mass production capabilities, making solutions cost-effective for automotive and industrial applications. Their extensive experience in automotive emissions monitoring provides practical implementation knowledge. Weaknesses: Higher power consumption due to temperature cycling techniques, and system complexity requires sophisticated calibration procedures that must be maintained over the sensor lifetime.

Siemens AG

Technical Solution: Siemens AG has pioneered cross-sensitivity reduction strategies through their differential measurement approach for mixed gas streams. Their technology utilizes paired sensor arrays where one set is selectively exposed to target gases while reference sensors are protected by specialized filtering membranes. This differential measurement technique effectively cancels out common environmental interferences. Siemens has also developed proprietary catalytic filters that selectively convert interfering gases before they reach the sensing elements. Their gas analysis systems incorporate multi-wavelength infrared spectroscopy that can identify specific gas absorption patterns even in complex mixtures. For industrial applications, Siemens employs a combination of electrochemical and optical sensing technologies with cross-validation algorithms to verify measurements across different sensing principles, significantly reducing false readings caused by cross-sensitivity issues. Their systems also feature adaptive calibration routines that continuously optimize sensor performance based on historical data patterns and known gas behaviors[2][5].

Strengths: Comprehensive system integration capabilities allow Siemens to implement solutions across entire industrial processes rather than just point measurements. Their multi-principle approach provides redundancy and higher reliability in critical applications. Weaknesses: Higher initial implementation costs compared to simpler solutions, and their systems often require more frequent maintenance due to the complexity of the filtering and reference components.

Key Innovations in Selective Gas Detection

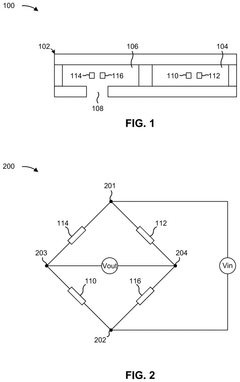

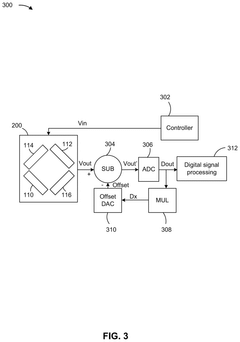

Enhanced offset compensation technique for thermal conductivity sensing of a gas concentration sensor

PatentPendingUS20250093288A1

Innovation

- A gas concentration sensor design featuring a reference chamber and a measurement chamber, with a measurement circuit that operates in both calibration and operational modes. The circuit includes a full-bridge or resistive bridge configuration with piezoresistive wires exposed to reference and target gases, allowing for offset compensation and improved sensitivity to thermal conductivity.

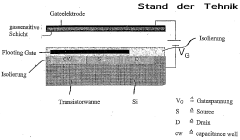

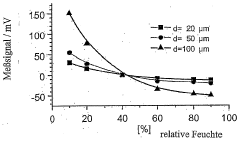

Method for measuring gases and/or minimizing cross sensitivity in FET-based gas sensors

PatentWO2005103668A1

Innovation

- Evaluating both the change in work function and capacitance of the sensitive layer in FET-based gas sensors, generating two independent signals that differentiate between target and interfering gases, allowing for compensation of interfering gas influence and determination of target gas concentration without the need for a second sensor.

Environmental Impact and Sustainability Considerations

The implementation of cross-sensitivity reduction strategies in mixed gas sensing systems carries significant environmental implications that must be carefully considered. Traditional gas sensing technologies often rely on materials and processes that generate substantial environmental footprints, including rare earth elements, precious metals, and energy-intensive manufacturing procedures. By developing more selective and efficient sensing technologies, we can dramatically reduce resource consumption while enhancing monitoring capabilities for environmental pollutants.

Advanced cross-sensitivity reduction approaches frequently incorporate nanomaterials and specialized coatings that may present novel environmental challenges. The lifecycle assessment of these materials reveals potential concerns regarding their production, use, and disposal. Particularly, nanoparticle leaching from sensor components could introduce persistent environmental contaminants if not properly managed. Implementing closed-loop manufacturing systems and developing biodegradable sensing elements represents a promising direction for mitigating these impacts.

Energy efficiency constitutes another critical environmental consideration in gas sensing applications. Conventional gas analyzers typically require substantial power inputs, limiting their deployment in remote environmental monitoring scenarios. Cross-sensitivity reduction strategies that incorporate low-power operation principles, such as passive sampling techniques and ambient energy harvesting, can significantly extend sensor lifespans while reducing battery waste and energy consumption. These improvements directly translate to smaller carbon footprints across monitoring networks.

The sustainability benefits of improved gas sensing selectivity extend beyond the sensors themselves. By enabling more accurate detection of greenhouse gases, air pollutants, and industrial emissions, these technologies support enhanced environmental compliance monitoring and emissions reduction initiatives. This capability proves particularly valuable in developing regions where traditional laboratory infrastructure may be limited, allowing for distributed monitoring networks that provide real-time environmental data.

Circular economy principles are increasingly being applied to sensor design, with modular architectures allowing for component replacement rather than complete system disposal. Materials selection for cross-sensitivity reduction components now frequently prioritizes recyclability and reduced toxicity. Furthermore, the extended calibration intervals achieved through improved selectivity reduce maintenance requirements and associated transportation emissions, contributing to overall sustainability improvements in environmental monitoring programs.

Advanced cross-sensitivity reduction approaches frequently incorporate nanomaterials and specialized coatings that may present novel environmental challenges. The lifecycle assessment of these materials reveals potential concerns regarding their production, use, and disposal. Particularly, nanoparticle leaching from sensor components could introduce persistent environmental contaminants if not properly managed. Implementing closed-loop manufacturing systems and developing biodegradable sensing elements represents a promising direction for mitigating these impacts.

Energy efficiency constitutes another critical environmental consideration in gas sensing applications. Conventional gas analyzers typically require substantial power inputs, limiting their deployment in remote environmental monitoring scenarios. Cross-sensitivity reduction strategies that incorporate low-power operation principles, such as passive sampling techniques and ambient energy harvesting, can significantly extend sensor lifespans while reducing battery waste and energy consumption. These improvements directly translate to smaller carbon footprints across monitoring networks.

The sustainability benefits of improved gas sensing selectivity extend beyond the sensors themselves. By enabling more accurate detection of greenhouse gases, air pollutants, and industrial emissions, these technologies support enhanced environmental compliance monitoring and emissions reduction initiatives. This capability proves particularly valuable in developing regions where traditional laboratory infrastructure may be limited, allowing for distributed monitoring networks that provide real-time environmental data.

Circular economy principles are increasingly being applied to sensor design, with modular architectures allowing for component replacement rather than complete system disposal. Materials selection for cross-sensitivity reduction components now frequently prioritizes recyclability and reduced toxicity. Furthermore, the extended calibration intervals achieved through improved selectivity reduce maintenance requirements and associated transportation emissions, contributing to overall sustainability improvements in environmental monitoring programs.

Standardization and Calibration Protocols

Standardization and calibration protocols represent a critical foundation for addressing cross-sensitivity challenges in mixed gas sensing environments. The establishment of robust protocols ensures measurement consistency, reliability, and comparability across different sensor systems and operational conditions. Current standardization efforts primarily focus on single-gas calibration procedures, which prove inadequate when applied to complex multi-gas environments where cross-interference effects significantly impact measurement accuracy.

Industry-leading calibration protocols now incorporate multi-point calibration matrices that account for the non-linear responses observed when multiple target gases interact simultaneously with sensing elements. These protocols typically employ statistical modeling techniques such as multivariate regression analysis and machine learning algorithms to develop comprehensive calibration models that can effectively compensate for cross-sensitivity effects.

The International Organization for Standardization (ISO) has developed several standards specifically addressing gas sensor calibration, including ISO 16000-29 for indoor air quality monitoring and ISO 14912 for gas analysis. However, these standards require significant adaptation when applied to mixed gas environments. Recent collaborative efforts between industry stakeholders and regulatory bodies have focused on developing specialized protocols for sectors where mixed gas detection is particularly critical, such as industrial safety monitoring and environmental compliance.

Calibration frequency represents another crucial aspect of standardization protocols. Research indicates that sensors exposed to complex gas mixtures often experience accelerated drift and sensitivity changes compared to those in single-gas environments. Consequently, calibration intervals must be optimized based on exposure history, environmental conditions, and application requirements. Advanced protocols now incorporate adaptive calibration scheduling based on statistical analysis of sensor performance degradation patterns.

Reference gas preparation standards constitute a fundamental component of effective calibration protocols. The accuracy of mixed gas calibration depends heavily on the precision and stability of reference gas mixtures. Current best practices involve the use of certified reference materials with traceability to national metrology institutes, coupled with rigorous uncertainty analysis to quantify calibration confidence levels.

Interlaboratory comparison programs have emerged as valuable tools for validating calibration protocols across different facilities and equipment configurations. These programs enable the identification of systematic biases and procedural inconsistencies that might otherwise compromise measurement comparability. The development of shared databases containing cross-sensitivity coefficients for common gas combinations further enhances standardization efforts by providing reference data for calibration model development and validation.

Industry-leading calibration protocols now incorporate multi-point calibration matrices that account for the non-linear responses observed when multiple target gases interact simultaneously with sensing elements. These protocols typically employ statistical modeling techniques such as multivariate regression analysis and machine learning algorithms to develop comprehensive calibration models that can effectively compensate for cross-sensitivity effects.

The International Organization for Standardization (ISO) has developed several standards specifically addressing gas sensor calibration, including ISO 16000-29 for indoor air quality monitoring and ISO 14912 for gas analysis. However, these standards require significant adaptation when applied to mixed gas environments. Recent collaborative efforts between industry stakeholders and regulatory bodies have focused on developing specialized protocols for sectors where mixed gas detection is particularly critical, such as industrial safety monitoring and environmental compliance.

Calibration frequency represents another crucial aspect of standardization protocols. Research indicates that sensors exposed to complex gas mixtures often experience accelerated drift and sensitivity changes compared to those in single-gas environments. Consequently, calibration intervals must be optimized based on exposure history, environmental conditions, and application requirements. Advanced protocols now incorporate adaptive calibration scheduling based on statistical analysis of sensor performance degradation patterns.

Reference gas preparation standards constitute a fundamental component of effective calibration protocols. The accuracy of mixed gas calibration depends heavily on the precision and stability of reference gas mixtures. Current best practices involve the use of certified reference materials with traceability to national metrology institutes, coupled with rigorous uncertainty analysis to quantify calibration confidence levels.

Interlaboratory comparison programs have emerged as valuable tools for validating calibration protocols across different facilities and equipment configurations. These programs enable the identification of systematic biases and procedural inconsistencies that might otherwise compromise measurement comparability. The development of shared databases containing cross-sensitivity coefficients for common gas combinations further enhances standardization efforts by providing reference data for calibration model development and validation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!