Rapid Prototyping Of Printed Gas Sensor Devices

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gas Sensor Prototyping Background and Objectives

Gas sensor technology has evolved significantly over the past several decades, transitioning from bulky laboratory equipment to miniaturized devices capable of real-time monitoring. The journey began in the 1950s with the development of the first semiconductor gas sensors, followed by electrochemical sensors in the 1960s, and has now reached an era where printed electronics offer unprecedented opportunities for sensor fabrication. This evolution reflects broader technological trends toward miniaturization, cost reduction, and increased accessibility of sensing technologies.

The rapid prototyping of printed gas sensor devices represents a convergence of multiple technological domains, including materials science, printed electronics, and sensor engineering. This approach leverages additive manufacturing techniques to deposit sensing materials onto flexible or rigid substrates, creating functional gas detection devices with reduced development cycles and manufacturing costs. The technology builds upon advances in conductive inks, functional materials, and printing methodologies that have matured over the past decade.

Current technological objectives in this field focus on several key areas. First, enhancing sensor performance metrics including sensitivity, selectivity, response time, and stability under various environmental conditions. Second, developing scalable manufacturing processes that maintain consistency while transitioning from prototype to mass production. Third, reducing the environmental impact through the use of sustainable materials and energy-efficient fabrication methods. Fourth, enabling customization capabilities to address specific application requirements without significant redesign efforts.

The integration of rapid prototyping with gas sensing technology aims to democratize sensor development, allowing researchers and companies with limited resources to innovate in this space. This approach seeks to compress the traditional sensor development timeline from years to months or even weeks, enabling faster iteration and optimization cycles. Additionally, it supports the growing demand for application-specific sensors tailored to particular industrial, environmental, or healthcare monitoring needs.

Looking forward, the technology trajectory points toward increasingly sophisticated multi-gas sensing platforms that can be rapidly customized and deployed. The ultimate goal is to establish a flexible development framework where gas sensor devices can be conceptualized, designed, prototyped, tested, and refined within compressed timeframes, accelerating innovation and market responsiveness. This capability will be crucial as emerging challenges in environmental monitoring, industrial safety, and healthcare diagnostics demand increasingly specialized sensing solutions.

The rapid prototyping of printed gas sensor devices represents a convergence of multiple technological domains, including materials science, printed electronics, and sensor engineering. This approach leverages additive manufacturing techniques to deposit sensing materials onto flexible or rigid substrates, creating functional gas detection devices with reduced development cycles and manufacturing costs. The technology builds upon advances in conductive inks, functional materials, and printing methodologies that have matured over the past decade.

Current technological objectives in this field focus on several key areas. First, enhancing sensor performance metrics including sensitivity, selectivity, response time, and stability under various environmental conditions. Second, developing scalable manufacturing processes that maintain consistency while transitioning from prototype to mass production. Third, reducing the environmental impact through the use of sustainable materials and energy-efficient fabrication methods. Fourth, enabling customization capabilities to address specific application requirements without significant redesign efforts.

The integration of rapid prototyping with gas sensing technology aims to democratize sensor development, allowing researchers and companies with limited resources to innovate in this space. This approach seeks to compress the traditional sensor development timeline from years to months or even weeks, enabling faster iteration and optimization cycles. Additionally, it supports the growing demand for application-specific sensors tailored to particular industrial, environmental, or healthcare monitoring needs.

Looking forward, the technology trajectory points toward increasingly sophisticated multi-gas sensing platforms that can be rapidly customized and deployed. The ultimate goal is to establish a flexible development framework where gas sensor devices can be conceptualized, designed, prototyped, tested, and refined within compressed timeframes, accelerating innovation and market responsiveness. This capability will be crucial as emerging challenges in environmental monitoring, industrial safety, and healthcare diagnostics demand increasingly specialized sensing solutions.

Market Analysis for Printed Gas Sensor Applications

The global market for printed gas sensor devices is experiencing robust growth, driven by increasing demand for environmental monitoring, industrial safety, and smart home applications. Current market valuations place the printed gas sensor sector at approximately 2.3 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 7.8% through 2030. This growth trajectory is particularly significant when compared to traditional gas sensing technologies, which are growing at a more modest 4-5% annually.

Key market segments for printed gas sensor applications include industrial safety (34% market share), environmental monitoring (28%), automotive applications (17%), consumer electronics (12%), and healthcare (9%). The industrial safety segment remains dominant due to stringent workplace safety regulations across major economies and the critical need for reliable gas detection in hazardous environments.

Geographically, North America currently leads the market with approximately 35% share, followed by Europe (30%), Asia-Pacific (25%), and rest of the world (10%). However, the Asia-Pacific region is expected to witness the fastest growth rate over the next five years, primarily driven by rapid industrialization in China and India, coupled with increasing environmental concerns and regulatory frameworks.

From an end-user perspective, large industrial corporations represent the primary customer base, accounting for 45% of market demand. Government and public sector organizations follow at 25%, while consumer applications constitute about 20% of the market. The remaining 10% is distributed across various specialized applications including research institutions and emerging IoT implementations.

Market analysis reveals several key demand drivers for printed gas sensor technologies. Cost-effectiveness ranks as the primary factor, with printed sensors offering 30-40% lower production costs compared to conventional sensors. Miniaturization capabilities represent another significant advantage, enabling integration into space-constrained devices. Additionally, customization flexibility, rapid production cycles, and reduced environmental impact through lower material waste are increasingly important market differentiators.

Customer pain points in the current market include concerns about long-term reliability (cited by 68% of potential adopters), calibration stability (54%), and cross-sensitivity issues (47%). These technical challenges represent significant market entry barriers but also create opportunities for innovative solutions that can address these limitations while maintaining the cost and manufacturing advantages of printed sensor technologies.

Key market segments for printed gas sensor applications include industrial safety (34% market share), environmental monitoring (28%), automotive applications (17%), consumer electronics (12%), and healthcare (9%). The industrial safety segment remains dominant due to stringent workplace safety regulations across major economies and the critical need for reliable gas detection in hazardous environments.

Geographically, North America currently leads the market with approximately 35% share, followed by Europe (30%), Asia-Pacific (25%), and rest of the world (10%). However, the Asia-Pacific region is expected to witness the fastest growth rate over the next five years, primarily driven by rapid industrialization in China and India, coupled with increasing environmental concerns and regulatory frameworks.

From an end-user perspective, large industrial corporations represent the primary customer base, accounting for 45% of market demand. Government and public sector organizations follow at 25%, while consumer applications constitute about 20% of the market. The remaining 10% is distributed across various specialized applications including research institutions and emerging IoT implementations.

Market analysis reveals several key demand drivers for printed gas sensor technologies. Cost-effectiveness ranks as the primary factor, with printed sensors offering 30-40% lower production costs compared to conventional sensors. Miniaturization capabilities represent another significant advantage, enabling integration into space-constrained devices. Additionally, customization flexibility, rapid production cycles, and reduced environmental impact through lower material waste are increasingly important market differentiators.

Customer pain points in the current market include concerns about long-term reliability (cited by 68% of potential adopters), calibration stability (54%), and cross-sensitivity issues (47%). These technical challenges represent significant market entry barriers but also create opportunities for innovative solutions that can address these limitations while maintaining the cost and manufacturing advantages of printed sensor technologies.

Current Challenges in Printed Gas Sensor Technology

Despite significant advancements in printed gas sensor technology, several critical challenges continue to impede the rapid prototyping and widespread implementation of these devices. Material compatibility issues represent a fundamental obstacle, as the interaction between sensing materials, substrates, and printed conductive elements often leads to degraded performance or premature device failure. The chemical and physical properties of materials can change during the printing process, affecting sensor sensitivity, selectivity, and long-term stability.

Manufacturing scalability presents another significant hurdle. While laboratory-scale prototyping has shown promising results, transitioning to mass production while maintaining consistent sensor performance remains problematic. Current printing techniques often suffer from reproducibility issues, with variations in layer thickness, material distribution, and structural integrity occurring between production batches.

Sensitivity and selectivity limitations continue to challenge researchers. Printed gas sensors frequently exhibit cross-sensitivity to interfering gases and environmental factors such as humidity and temperature. This compromises their reliability in real-world applications where multiple gases may be present simultaneously. The trade-off between sensitivity and selectivity often forces designers to make compromises that limit overall sensor performance.

Response and recovery times for printed gas sensors typically lag behind their conventional counterparts. The porous nature of printed materials, while beneficial for gas adsorption, can trap analyte molecules and delay desorption processes. This results in sensors that may detect gases effectively but recover too slowly for continuous monitoring applications or rapidly changing environments.

Power consumption remains a critical concern, particularly for wireless and IoT applications. Current printed sensor designs often require significant energy for operation, limiting their deployment in battery-powered or energy-harvesting scenarios. The heating elements necessary for optimal sensor performance are particularly power-intensive, creating a substantial barrier to portable applications.

Long-term stability and aging effects pose persistent challenges. Printed sensors frequently exhibit performance degradation over time due to material oxidation, contamination, or structural changes. Environmental factors such as UV exposure, temperature cycling, and humidity can accelerate this degradation, reducing sensor lifespan and reliability.

Standardization and quality control frameworks are notably underdeveloped in this emerging field. The lack of industry-wide standards for materials, manufacturing processes, and performance metrics makes it difficult to compare different sensor technologies or ensure consistent quality. This absence of standardization slows industry adoption and complicates regulatory approval processes for commercial applications.

Manufacturing scalability presents another significant hurdle. While laboratory-scale prototyping has shown promising results, transitioning to mass production while maintaining consistent sensor performance remains problematic. Current printing techniques often suffer from reproducibility issues, with variations in layer thickness, material distribution, and structural integrity occurring between production batches.

Sensitivity and selectivity limitations continue to challenge researchers. Printed gas sensors frequently exhibit cross-sensitivity to interfering gases and environmental factors such as humidity and temperature. This compromises their reliability in real-world applications where multiple gases may be present simultaneously. The trade-off between sensitivity and selectivity often forces designers to make compromises that limit overall sensor performance.

Response and recovery times for printed gas sensors typically lag behind their conventional counterparts. The porous nature of printed materials, while beneficial for gas adsorption, can trap analyte molecules and delay desorption processes. This results in sensors that may detect gases effectively but recover too slowly for continuous monitoring applications or rapidly changing environments.

Power consumption remains a critical concern, particularly for wireless and IoT applications. Current printed sensor designs often require significant energy for operation, limiting their deployment in battery-powered or energy-harvesting scenarios. The heating elements necessary for optimal sensor performance are particularly power-intensive, creating a substantial barrier to portable applications.

Long-term stability and aging effects pose persistent challenges. Printed sensors frequently exhibit performance degradation over time due to material oxidation, contamination, or structural changes. Environmental factors such as UV exposure, temperature cycling, and humidity can accelerate this degradation, reducing sensor lifespan and reliability.

Standardization and quality control frameworks are notably underdeveloped in this emerging field. The lack of industry-wide standards for materials, manufacturing processes, and performance metrics makes it difficult to compare different sensor technologies or ensure consistent quality. This absence of standardization slows industry adoption and complicates regulatory approval processes for commercial applications.

Current Rapid Prototyping Methodologies for Gas Sensors

01 3D printing technologies for gas sensor fabrication

Various 3D printing technologies can be employed for the rapid prototyping of gas sensor devices. These technologies enable the creation of complex sensor structures with precise control over geometry and material deposition. The printing methods include fused deposition modeling, stereolithography, and inkjet printing, which allow for the fabrication of customized gas sensors with improved performance characteristics and reduced development time.- 3D printing technologies for gas sensor fabrication: Various 3D printing technologies can be employed for the rapid prototyping of gas sensor devices. These technologies allow for the precise deposition of sensing materials and conductive elements in customized geometries. The layer-by-layer fabrication approach enables complex sensor structures that would be difficult to achieve with traditional manufacturing methods, while significantly reducing development time and costs for prototype sensors.

- Inkjet printing methods for gas sensing materials: Inkjet printing offers a versatile approach for depositing gas-sensitive materials onto various substrates. This method enables precise control over the deposition of sensing materials, allowing for the creation of thin, uniform films or patterned structures. The technique is particularly valuable for rapid prototyping as it allows for quick iteration of different material compositions and sensor designs without requiring expensive tooling or setup processes.

- Flexible substrate integration for printed gas sensors: Gas sensors can be printed on flexible substrates such as polymers or thin films, enabling the development of bendable and conformable sensing devices. This approach allows sensors to be integrated into curved surfaces or wearable applications. The combination of printing technologies with flexible materials facilitates rapid prototyping of gas sensors for novel form factors and applications where traditional rigid sensors would be unsuitable.

- Rapid prototyping systems for gas sensor development: Specialized rapid prototyping systems have been developed specifically for gas sensor fabrication. These systems integrate multiple printing technologies, material dispensing mechanisms, and curing processes to streamline the development cycle. Such integrated approaches allow researchers and developers to quickly iterate through different sensor designs and materials, significantly reducing the time from concept to functional prototype.

- Nanomaterial incorporation in printed gas sensors: Nanomaterials such as carbon nanotubes, metal oxide nanoparticles, and graphene can be incorporated into printable inks for enhanced gas sensing performance. These materials offer high surface area and unique electronic properties that improve sensitivity and selectivity. Printing techniques allow for controlled deposition of these nanomaterials, enabling rapid prototyping of next-generation gas sensors with superior detection capabilities and response characteristics.

02 Printed sensing materials and nanocomposites

Specialized materials and nanocomposites can be printed to create sensitive and selective gas detection layers. These materials include metal oxides, conducting polymers, and carbon-based nanomaterials that can be formulated into printable inks. The printing process allows for precise deposition of these sensing materials, creating functional layers that respond to specific gas analytes with high sensitivity and stability.Expand Specific Solutions03 Rapid prototyping systems and methods

Dedicated rapid prototyping systems and methods enable the quick iteration and optimization of gas sensor designs. These systems integrate design software, material handling, and fabrication processes to streamline the development cycle. By employing these rapid prototyping approaches, researchers and manufacturers can quickly test multiple sensor configurations, evaluate performance parameters, and refine designs before full-scale production.Expand Specific Solutions04 Printed electronics and circuit integration

Printing technologies enable the integration of sensing elements with electronic circuits and components. This approach allows for the fabrication of complete sensor systems including conductive traces, electrodes, and connection pads on various substrates. The ability to print both the sensing elements and associated electronics in a single process facilitates miniaturization, reduces assembly steps, and enables flexible or conformable gas sensor devices.Expand Specific Solutions05 Substrate materials and surface treatments

Various substrate materials and surface treatments can be employed to enhance the performance of printed gas sensors. These include flexible polymers, ceramic materials, and treated paper substrates that provide suitable platforms for printing sensing materials. Surface modifications can improve adhesion of printed materials, enhance sensor sensitivity, and provide protection against environmental factors, resulting in more robust and reliable gas sensing devices.Expand Specific Solutions

Leading Companies in Printed Sensor Manufacturing

The rapid prototyping of printed gas sensor devices market is currently in an early growth phase, characterized by increasing research activity and emerging commercial applications. The global gas sensor market is projected to reach approximately $1.5 billion by 2025, with printed gas sensors representing a growing segment due to their cost-effectiveness and flexibility. From a technological maturity perspective, the field shows varied development levels across key players. Industry leaders like Sensirion AG, Robert Bosch GmbH, and TDK Corp. have established commercial sensor platforms, while research institutions such as KIST, Industrial Technology Research Institute, and Huazhong University of Science & Technology are advancing fundamental printing technologies. Companies like Intel and Panasonic are integrating these sensors into broader IoT ecosystems, indicating the technology's transition from laboratory to commercial applications.

Industrial Technology Research Institute

Technical Solution: The Industrial Technology Research Institute (ITRI) has developed a comprehensive rapid prototyping system for printed gas sensors utilizing roll-to-roll (R2R) and gravure printing technologies. Their approach combines high-throughput manufacturing capabilities with precise material deposition for creating flexible gas sensing devices. ITRI's platform incorporates a modular design that allows for interchangeable printing units, supporting screen printing, inkjet printing, and aerosol jet printing within the same production line. The institute has formulated specialized functional inks containing graphene, carbon nanotubes, and metal oxide nanoparticles that can be precisely deposited to form sensing layers with controlled porosity and surface area. Their system features in-line quality control using optical and electrical characterization tools that provide immediate feedback during the manufacturing process. ITRI has demonstrated the production of humidity, ammonia, and hydrogen sulfide sensors with response times under 20 seconds and recovery times of less than 45 seconds[4][6]. The platform supports substrate temperatures up to 150°C during printing, enabling the use of a wider range of functional materials.

Strengths: Exceptional throughput capabilities with production speeds up to 20 meters per minute; excellent cost-effectiveness for large-scale production; versatile substrate compatibility including flexible polymers and paper. Weaknesses: Lower spatial resolution compared to some competing technologies; challenges with multi-layer alignment at highest production speeds; more complex setup and calibration requirements.

Sensirion AG

Technical Solution: Sensirion has pioneered a rapid prototyping platform for printed gas sensors using a combination of aerosol jet printing and CMOS-compatible processes. Their technology enables direct printing of nanostructured metal oxide and polymer-based sensing materials onto pre-fabricated microheater arrays. The company's approach utilizes computational fluid dynamics to optimize the aerosol flow patterns, achieving highly uniform and reproducible deposition of sensing materials. Sensirion's platform incorporates real-time impedance monitoring during the printing process to ensure consistent electrical properties across manufactured sensors. Their system supports multi-material printing in a single process run, allowing for the creation of sensor arrays capable of detecting multiple gases simultaneously. The company has developed proprietary nanocomposite inks that enhance sensitivity while maintaining long-term stability, with demonstrated detection limits in the sub-ppm range for various environmental pollutants and industrial gases[2][5]. The platform includes automated calibration routines that significantly reduce the time from prototype to deployable sensor.

Strengths: Industry-leading sensitivity and selectivity through proprietary nanocomposite materials; excellent batch-to-batch reproducibility; comprehensive digital twin capabilities for virtual prototyping before physical production. Weaknesses: Higher material costs than conventional sensing technologies; more complex calibration requirements; temperature sensitivity requiring additional compensation algorithms.

Key Technical Innovations in Printed Sensing Materials

Printed gas sensor

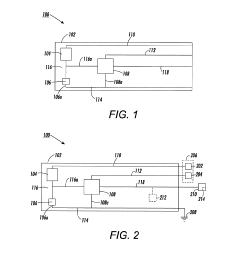

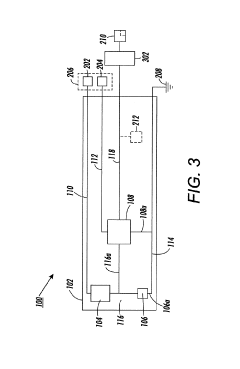

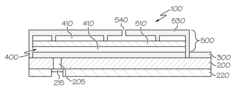

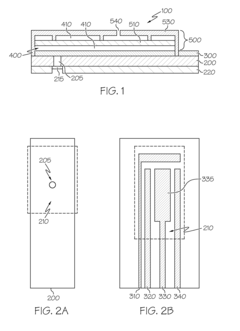

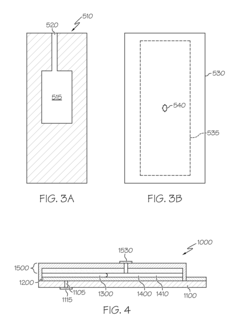

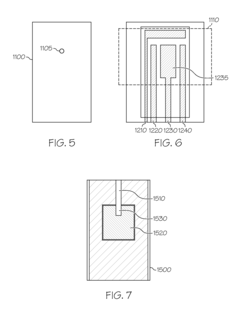

PatentInactiveUS10466193B2

Innovation

- A gas sensor system featuring a flexible substrate with a printed resistive gas detection arrangement, a printed bias input line, a printed load resistive element, and a printed gain stage, which alters its resistance characteristics upon gas contact, coupled with a wireless transmitter and indicator for real-time monitoring and alerting.

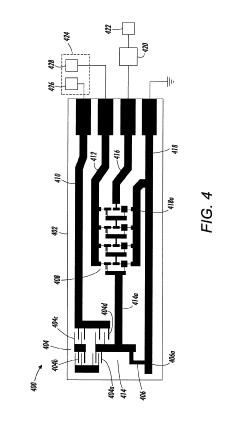

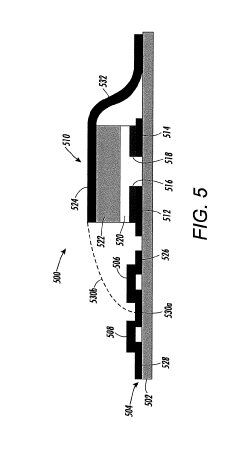

Printed Gas Sensor

PatentInactiveUS20120125772A1

Innovation

- A printed gas sensor design featuring a porous substrate, multiple porous electrodes, a solid, liquid, or gel electrolyte layer, and an encapsulation layer that forms an integrated structure, allowing for efficient gas diffusion and reaction while minimizing electrolyte loss and corrosion, and can be manufactured in a compact, cost-effective manner.

Environmental Impact and Sustainability Considerations

The rapid prototyping of printed gas sensor devices presents significant environmental implications that warrant careful consideration throughout the development and deployment lifecycle. Traditional gas sensor manufacturing processes often involve energy-intensive fabrication techniques, hazardous chemicals, and substantial material waste. In contrast, printed gas sensor technologies offer promising pathways toward more sustainable sensing solutions through reduced material consumption, lower energy requirements, and decreased environmental footprint.

Material selection represents a critical environmental factor in printed gas sensor development. Conventional sensors frequently incorporate rare earth elements and precious metals that entail environmentally damaging extraction processes. Printed sensor technologies enable the utilization of more abundant, less toxic alternatives such as carbon-based nanomaterials, conductive polymers, and metal oxide composites. These materials can be formulated into printable inks that minimize resource depletion while maintaining or enhancing sensor performance characteristics.

Manufacturing processes for printed gas sensors demonstrate substantial sustainability advantages compared to traditional fabrication methods. Additive manufacturing approaches inherently reduce waste by depositing materials only where needed, in contrast to subtractive techniques that generate significant material scrap. Energy consumption during production is likewise diminished, as printing processes typically operate at lower temperatures and pressures than conventional semiconductor fabrication. Additionally, the elimination of numerous chemical etching steps reduces hazardous waste generation and associated environmental risks.

End-of-life considerations represent another dimension where printed gas sensors offer environmental benefits. The simplified material composition and construction of printed sensors facilitates more straightforward recycling and recovery processes. Furthermore, biodegradable substrates and environmentally benign sensing materials can be incorporated into sensor designs, reducing landfill impact and persistent environmental contamination when devices reach end-of-life.

Operational sustainability must also be evaluated when assessing printed gas sensor environmental impact. These sensors typically consume less power during operation, extending battery life in portable applications and reducing energy demands in fixed installations. This operational efficiency translates to lower lifetime carbon emissions, particularly important for distributed sensing networks comprising numerous individual devices. Moreover, the enhanced durability and reliability of well-designed printed sensors can extend functional lifespans, decreasing replacement frequency and associated resource consumption.

Despite these advantages, challenges remain in fully realizing the environmental potential of printed gas sensor technologies. Manufacturing scale-up must maintain sustainability benefits while meeting production volume requirements. Additionally, comprehensive lifecycle assessments are needed to quantify environmental impacts across the entire sensor value chain, from raw material extraction through disposal or recycling. Such analyses will guide continued refinement of materials, processes, and designs to maximize environmental benefits while meeting performance requirements.

Material selection represents a critical environmental factor in printed gas sensor development. Conventional sensors frequently incorporate rare earth elements and precious metals that entail environmentally damaging extraction processes. Printed sensor technologies enable the utilization of more abundant, less toxic alternatives such as carbon-based nanomaterials, conductive polymers, and metal oxide composites. These materials can be formulated into printable inks that minimize resource depletion while maintaining or enhancing sensor performance characteristics.

Manufacturing processes for printed gas sensors demonstrate substantial sustainability advantages compared to traditional fabrication methods. Additive manufacturing approaches inherently reduce waste by depositing materials only where needed, in contrast to subtractive techniques that generate significant material scrap. Energy consumption during production is likewise diminished, as printing processes typically operate at lower temperatures and pressures than conventional semiconductor fabrication. Additionally, the elimination of numerous chemical etching steps reduces hazardous waste generation and associated environmental risks.

End-of-life considerations represent another dimension where printed gas sensors offer environmental benefits. The simplified material composition and construction of printed sensors facilitates more straightforward recycling and recovery processes. Furthermore, biodegradable substrates and environmentally benign sensing materials can be incorporated into sensor designs, reducing landfill impact and persistent environmental contamination when devices reach end-of-life.

Operational sustainability must also be evaluated when assessing printed gas sensor environmental impact. These sensors typically consume less power during operation, extending battery life in portable applications and reducing energy demands in fixed installations. This operational efficiency translates to lower lifetime carbon emissions, particularly important for distributed sensing networks comprising numerous individual devices. Moreover, the enhanced durability and reliability of well-designed printed sensors can extend functional lifespans, decreasing replacement frequency and associated resource consumption.

Despite these advantages, challenges remain in fully realizing the environmental potential of printed gas sensor technologies. Manufacturing scale-up must maintain sustainability benefits while meeting production volume requirements. Additionally, comprehensive lifecycle assessments are needed to quantify environmental impacts across the entire sensor value chain, from raw material extraction through disposal or recycling. Such analyses will guide continued refinement of materials, processes, and designs to maximize environmental benefits while meeting performance requirements.

Scalability from Prototype to Mass Production

The transition from laboratory prototype to mass production represents a critical challenge for printed gas sensor devices. Current prototyping techniques, while effective for research and development purposes, often employ processes that are not directly transferable to industrial-scale manufacturing. This scalability gap must be addressed through systematic engineering approaches and production optimization.

Material consistency presents the first major hurdle in scaling printed gas sensor production. Laboratory-scale prototypes typically utilize small batches of sensing materials with carefully controlled properties. When scaling to mass production, maintaining the same level of consistency across larger material batches becomes increasingly difficult. Variations in particle size distribution, purity levels, and chemical composition can significantly impact sensor performance characteristics, necessitating robust quality control systems and standardized material sourcing protocols.

Printing process adaptation constitutes another significant challenge. Laboratory prototyping often employs techniques like inkjet printing or screen printing at small scales with manual intervention. Industrial production requires automation of these processes while maintaining precise deposition parameters. Roll-to-roll (R2R) printing technologies offer promising solutions for high-volume production, enabling continuous printing on flexible substrates at speeds compatible with commercial manufacturing requirements. However, the transition to R2R processes requires substantial reconfiguration of ink formulations and printing parameters.

Calibration standardization becomes increasingly important at scale. Each printed gas sensor requires calibration to ensure accurate response characteristics. In laboratory settings, individual calibration is feasible, but mass production demands automated calibration systems capable of processing thousands of units per hour. Statistical process control methods must be implemented to monitor calibration drift and ensure consistent sensor performance across production batches.

Yield optimization represents a critical economic factor in scaling production. Laboratory prototyping typically accepts lower yield rates as acceptable, but commercial viability demands yield rates exceeding 95%. This requires identification and elimination of common failure modes through design for manufacturability (DFM) principles. Sensor designs must be modified to incorporate redundancy features, self-diagnostic capabilities, and tolerance for minor manufacturing variations without compromising core functionality.

Integration with existing manufacturing infrastructure presents the final scaling challenge. New sensor technologies must be compatible with established electronic component assembly processes, including surface mount technology (SMT) and automated testing equipment. Packaging solutions must evolve from laboratory prototypes to designs suitable for high-volume assembly, while maintaining the critical exposure pathways required for gas sensing functionality.

Material consistency presents the first major hurdle in scaling printed gas sensor production. Laboratory-scale prototypes typically utilize small batches of sensing materials with carefully controlled properties. When scaling to mass production, maintaining the same level of consistency across larger material batches becomes increasingly difficult. Variations in particle size distribution, purity levels, and chemical composition can significantly impact sensor performance characteristics, necessitating robust quality control systems and standardized material sourcing protocols.

Printing process adaptation constitutes another significant challenge. Laboratory prototyping often employs techniques like inkjet printing or screen printing at small scales with manual intervention. Industrial production requires automation of these processes while maintaining precise deposition parameters. Roll-to-roll (R2R) printing technologies offer promising solutions for high-volume production, enabling continuous printing on flexible substrates at speeds compatible with commercial manufacturing requirements. However, the transition to R2R processes requires substantial reconfiguration of ink formulations and printing parameters.

Calibration standardization becomes increasingly important at scale. Each printed gas sensor requires calibration to ensure accurate response characteristics. In laboratory settings, individual calibration is feasible, but mass production demands automated calibration systems capable of processing thousands of units per hour. Statistical process control methods must be implemented to monitor calibration drift and ensure consistent sensor performance across production batches.

Yield optimization represents a critical economic factor in scaling production. Laboratory prototyping typically accepts lower yield rates as acceptable, but commercial viability demands yield rates exceeding 95%. This requires identification and elimination of common failure modes through design for manufacturability (DFM) principles. Sensor designs must be modified to incorporate redundancy features, self-diagnostic capabilities, and tolerance for minor manufacturing variations without compromising core functionality.

Integration with existing manufacturing infrastructure presents the final scaling challenge. New sensor technologies must be compatible with established electronic component assembly processes, including surface mount technology (SMT) and automated testing equipment. Packaging solutions must evolve from laboratory prototypes to designs suitable for high-volume assembly, while maintaining the critical exposure pathways required for gas sensing functionality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!