Compare Neodymium Magnet Grades for Energy Harvesting Applications

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neodymium Magnet Grades Background and Objectives

Neodymium magnets, discovered in the 1980s by General Motors and Sumitomo Special Metals, represent a significant breakthrough in permanent magnet technology. These rare-earth magnets, primarily composed of neodymium, iron, and boron (NdFeB), have revolutionized numerous industries due to their exceptional magnetic properties. The evolution of neodymium magnet technology has been marked by continuous improvements in magnetic strength, temperature stability, and corrosion resistance, leading to the development of various grades optimized for specific applications.

The grading system for neodymium magnets primarily indicates their maximum energy product (BHmax), measured in MGOe (Megagauss-Oersteds) or kJ/m³, which represents the magnetic energy density. Common grades range from N35 to N52, with higher numbers indicating stronger magnetic properties. Additionally, suffixes such as M, H, SH, UH, and EH denote temperature ratings, indicating the magnet's ability to maintain performance at elevated temperatures without demagnetization.

In the context of energy harvesting applications, neodymium magnets play a crucial role in converting mechanical energy into electrical energy through electromagnetic induction. The efficiency of this conversion process is directly influenced by the magnetic field strength and stability provided by the magnets, making the selection of appropriate magnet grades a critical design consideration.

The technical objectives of this research are multifaceted. First, we aim to comprehensively compare different neodymium magnet grades specifically for energy harvesting applications, evaluating their performance metrics including magnetic flux density, coercivity, temperature stability, and long-term reliability. Second, we seek to identify optimal grade selections for various energy harvesting scenarios, considering factors such as operational environment, size constraints, and energy output requirements.

Furthermore, this research intends to explore the relationship between magnet grade characteristics and energy conversion efficiency in harvesting systems. By understanding these correlations, we can establish design guidelines that maximize energy output while considering practical constraints such as cost, weight, and volume.

The technological trend in neodymium magnets is moving toward developing grades with higher temperature stability without sacrificing magnetic strength, as well as improving sustainability through reduced rare earth content and enhanced recyclability. These advancements are particularly relevant for energy harvesting applications, which often operate in variable environmental conditions and require long-term stability.

This investigation will provide valuable insights for engineers and researchers working on energy harvesting technologies, enabling more efficient and effective utilization of neodymium magnets in sustainable energy solutions, from wearable electronics to industrial vibration harvesters and beyond.

The grading system for neodymium magnets primarily indicates their maximum energy product (BHmax), measured in MGOe (Megagauss-Oersteds) or kJ/m³, which represents the magnetic energy density. Common grades range from N35 to N52, with higher numbers indicating stronger magnetic properties. Additionally, suffixes such as M, H, SH, UH, and EH denote temperature ratings, indicating the magnet's ability to maintain performance at elevated temperatures without demagnetization.

In the context of energy harvesting applications, neodymium magnets play a crucial role in converting mechanical energy into electrical energy through electromagnetic induction. The efficiency of this conversion process is directly influenced by the magnetic field strength and stability provided by the magnets, making the selection of appropriate magnet grades a critical design consideration.

The technical objectives of this research are multifaceted. First, we aim to comprehensively compare different neodymium magnet grades specifically for energy harvesting applications, evaluating their performance metrics including magnetic flux density, coercivity, temperature stability, and long-term reliability. Second, we seek to identify optimal grade selections for various energy harvesting scenarios, considering factors such as operational environment, size constraints, and energy output requirements.

Furthermore, this research intends to explore the relationship between magnet grade characteristics and energy conversion efficiency in harvesting systems. By understanding these correlations, we can establish design guidelines that maximize energy output while considering practical constraints such as cost, weight, and volume.

The technological trend in neodymium magnets is moving toward developing grades with higher temperature stability without sacrificing magnetic strength, as well as improving sustainability through reduced rare earth content and enhanced recyclability. These advancements are particularly relevant for energy harvesting applications, which often operate in variable environmental conditions and require long-term stability.

This investigation will provide valuable insights for engineers and researchers working on energy harvesting technologies, enabling more efficient and effective utilization of neodymium magnets in sustainable energy solutions, from wearable electronics to industrial vibration harvesters and beyond.

Market Demand Analysis for Energy Harvesting Technologies

The energy harvesting market has witnessed substantial growth in recent years, driven by increasing demand for sustainable power solutions across various industries. The global energy harvesting market was valued at approximately $440 million in 2020 and is projected to reach $1.3 billion by 2028, growing at a CAGR of around 13.2% during the forecast period. This growth trajectory underscores the expanding market potential for technologies utilizing neodymium magnets in energy harvesting applications.

The industrial sector represents the largest market segment for energy harvesting technologies, accounting for nearly 35% of the total market share. Within this sector, vibration-based energy harvesting systems, which frequently employ neodymium magnets, are experiencing particularly strong demand due to their reliability and efficiency in converting mechanical energy into electrical power.

Consumer electronics constitutes another rapidly growing segment, with wearable technology and IoT devices driving demand for compact, efficient energy harvesting solutions. The miniaturization trend in electronics has created significant opportunities for high-grade neodymium magnets that can deliver superior magnetic performance in smaller form factors.

Transportation and automotive applications are emerging as promising markets for energy harvesting technologies. The automotive industry's shift toward electrification and autonomous vehicles has increased the need for self-powered sensors and systems, creating new opportunities for magnetic energy harvesting solutions.

Regional analysis indicates that North America currently leads the energy harvesting market with approximately 32% market share, followed closely by Europe at 30% and Asia-Pacific at 28%. However, the Asia-Pacific region is expected to witness the highest growth rate over the next decade, primarily due to rapid industrialization and increasing adoption of IoT technologies in countries like China, Japan, and South Korea.

Customer requirements in the energy harvesting market are increasingly focused on efficiency, durability, and cost-effectiveness. End-users are demanding energy harvesting solutions that can operate reliably in diverse environmental conditions while providing consistent power output. This has created a preference for higher-grade neodymium magnets (N42-N52) that offer superior magnetic properties and temperature stability.

Market research indicates that price sensitivity varies significantly across application segments. While consumer electronics manufacturers prioritize cost reduction, industrial and aerospace applications place greater emphasis on performance and reliability, creating distinct market segments for different grades of neodymium magnets.

The industrial sector represents the largest market segment for energy harvesting technologies, accounting for nearly 35% of the total market share. Within this sector, vibration-based energy harvesting systems, which frequently employ neodymium magnets, are experiencing particularly strong demand due to their reliability and efficiency in converting mechanical energy into electrical power.

Consumer electronics constitutes another rapidly growing segment, with wearable technology and IoT devices driving demand for compact, efficient energy harvesting solutions. The miniaturization trend in electronics has created significant opportunities for high-grade neodymium magnets that can deliver superior magnetic performance in smaller form factors.

Transportation and automotive applications are emerging as promising markets for energy harvesting technologies. The automotive industry's shift toward electrification and autonomous vehicles has increased the need for self-powered sensors and systems, creating new opportunities for magnetic energy harvesting solutions.

Regional analysis indicates that North America currently leads the energy harvesting market with approximately 32% market share, followed closely by Europe at 30% and Asia-Pacific at 28%. However, the Asia-Pacific region is expected to witness the highest growth rate over the next decade, primarily due to rapid industrialization and increasing adoption of IoT technologies in countries like China, Japan, and South Korea.

Customer requirements in the energy harvesting market are increasingly focused on efficiency, durability, and cost-effectiveness. End-users are demanding energy harvesting solutions that can operate reliably in diverse environmental conditions while providing consistent power output. This has created a preference for higher-grade neodymium magnets (N42-N52) that offer superior magnetic properties and temperature stability.

Market research indicates that price sensitivity varies significantly across application segments. While consumer electronics manufacturers prioritize cost reduction, industrial and aerospace applications place greater emphasis on performance and reliability, creating distinct market segments for different grades of neodymium magnets.

Current State and Challenges of Magnetic Materials

The global magnetic materials market is currently experiencing significant growth, with neodymium-based permanent magnets dominating the high-performance sector. These rare-earth magnets, particularly neodymium-iron-boron (NdFeB) compositions, have revolutionized energy harvesting applications due to their exceptional magnetic properties. Current market analysis indicates the NdFeB magnet market reached approximately $15.6 billion in 2022, with projections suggesting a compound annual growth rate of 8.5% through 2030.

Despite their commercial success, neodymium magnets face several critical challenges. Temperature stability remains a primary concern, with standard N grades experiencing significant performance degradation above 80°C. While high-temperature grades (SH, UH, EH, and AH) offer improved thermal resistance up to 200°C, this comes at the expense of reduced maximum energy product (BHmax) values. This trade-off creates significant design constraints for energy harvesting applications in automotive, industrial, and outdoor environments.

Corrosion susceptibility represents another major limitation. Uncoated neodymium magnets deteriorate rapidly in humid or corrosive environments, necessitating protective coatings such as nickel, zinc, epoxy, or gold. These coatings add manufacturing complexity and cost while potentially reducing the effective magnetic field strength at the surface. Recent research indicates that advanced multi-layer coating technologies can extend service life by up to 300% in harsh environments, though implementation challenges persist.

Supply chain vulnerabilities constitute a growing concern for neodymium magnet production. China currently controls approximately 85% of the global rare earth element processing capacity, creating geopolitical dependencies. Recent export restrictions have accelerated research into alternative magnetic materials and recycling technologies. However, the performance gap between neodymium magnets and non-rare-earth alternatives remains substantial, with the best ferrite magnets achieving only about 25% of the energy density of mid-grade NdFeB options.

Manufacturing consistency presents ongoing challenges, particularly for miniaturized energy harvesting applications. Production variations in magnetic properties can reach ±5% even within the same batch, complicating precise energy output predictions. Advanced manufacturing techniques utilizing artificial intelligence for process control have demonstrated potential to reduce this variation to ±2%, though widespread implementation remains limited.

Demagnetization resistance varies significantly across neodymium grades, with higher coercivity grades (H, SH, UH) offering superior performance in applications with opposing magnetic fields. However, these grades typically command price premiums of 15-40% over standard grades, creating cost-benefit considerations for energy harvesting system designers seeking to optimize performance within budget constraints.

Despite their commercial success, neodymium magnets face several critical challenges. Temperature stability remains a primary concern, with standard N grades experiencing significant performance degradation above 80°C. While high-temperature grades (SH, UH, EH, and AH) offer improved thermal resistance up to 200°C, this comes at the expense of reduced maximum energy product (BHmax) values. This trade-off creates significant design constraints for energy harvesting applications in automotive, industrial, and outdoor environments.

Corrosion susceptibility represents another major limitation. Uncoated neodymium magnets deteriorate rapidly in humid or corrosive environments, necessitating protective coatings such as nickel, zinc, epoxy, or gold. These coatings add manufacturing complexity and cost while potentially reducing the effective magnetic field strength at the surface. Recent research indicates that advanced multi-layer coating technologies can extend service life by up to 300% in harsh environments, though implementation challenges persist.

Supply chain vulnerabilities constitute a growing concern for neodymium magnet production. China currently controls approximately 85% of the global rare earth element processing capacity, creating geopolitical dependencies. Recent export restrictions have accelerated research into alternative magnetic materials and recycling technologies. However, the performance gap between neodymium magnets and non-rare-earth alternatives remains substantial, with the best ferrite magnets achieving only about 25% of the energy density of mid-grade NdFeB options.

Manufacturing consistency presents ongoing challenges, particularly for miniaturized energy harvesting applications. Production variations in magnetic properties can reach ±5% even within the same batch, complicating precise energy output predictions. Advanced manufacturing techniques utilizing artificial intelligence for process control have demonstrated potential to reduce this variation to ±2%, though widespread implementation remains limited.

Demagnetization resistance varies significantly across neodymium grades, with higher coercivity grades (H, SH, UH) offering superior performance in applications with opposing magnetic fields. However, these grades typically command price premiums of 15-40% over standard grades, creating cost-benefit considerations for energy harvesting system designers seeking to optimize performance within budget constraints.

Comparative Analysis of Neodymium Magnet Grades

01 Composition and manufacturing of neodymium magnet grades

Different grades of neodymium magnets are classified based on their composition, particularly the ratio of neodymium, iron, and boron. Manufacturing processes, including sintering and heat treatment, significantly affect the magnetic properties and grade classification. Higher-grade magnets typically contain more precise compositions and undergo more controlled manufacturing processes to achieve superior magnetic performance.- Classification and properties of neodymium magnet grades: Neodymium magnets are classified into different grades based on their magnetic properties and composition. The grade designation typically includes a letter (N, M, H, SH, UH, EH) followed by a number indicating the maximum energy product. Higher numbers represent stronger magnetic properties. Different grades offer varying levels of coercivity, remanence, and temperature resistance, allowing for selection based on specific application requirements.

- Manufacturing processes for different neodymium magnet grades: Various manufacturing processes are employed to produce different grades of neodymium magnets. These include powder metallurgy, sintering, hot pressing, and melt spinning. The choice of manufacturing method affects the microstructure, grain alignment, and ultimately the magnetic properties of the final product. Advanced processing techniques can enhance the performance characteristics of specific grades, particularly for high-performance applications requiring exceptional magnetic strength or temperature stability.

- Temperature resistance characteristics of neodymium magnet grades: Different grades of neodymium magnets exhibit varying temperature resistance capabilities. Standard N grades typically operate up to 80°C, while specialized high-temperature grades (H, SH, UH, EH) can function at temperatures ranging from 120°C to over 200°C. The temperature coefficient of these magnets is an important consideration for applications in extreme environments, as magnetic properties degrade at different rates depending on the specific grade and composition.

- Surface treatments and coatings for neodymium magnet grades: Various surface treatments and coatings are applied to neodymium magnets to enhance their corrosion resistance and durability. These include nickel, zinc, epoxy, gold, and specialized polymer coatings. The selection of coating depends on the operating environment and application requirements. Surface treatments can significantly extend the lifespan of neodymium magnets, particularly in humid or corrosive environments, without substantially affecting their magnetic properties.

- Application-specific selection of neodymium magnet grades: The selection of appropriate neodymium magnet grades depends on specific application requirements. Factors to consider include required magnetic strength, operating temperature, space constraints, and environmental conditions. High-performance grades are utilized in demanding applications such as electric motors, wind turbines, and medical devices, while standard grades may be sufficient for consumer electronics and general industrial use. Proper grade selection ensures optimal performance while managing cost considerations.

02 Temperature resistance characteristics of neodymium magnet grades

Neodymium magnets are graded based on their temperature resistance capabilities. Different grades offer varying maximum operating temperatures before demagnetization occurs. High-temperature grades incorporate specific additives like dysprosium or terbium to maintain magnetic properties at elevated temperatures. The temperature coefficient, which indicates how magnetic strength changes with temperature, is a critical factor in determining the appropriate grade for specific applications.Expand Specific Solutions03 Magnetic strength and performance metrics of different grades

Neodymium magnet grades are primarily differentiated by their magnetic strength, measured by parameters such as maximum energy product (BHmax), remanence (Br), and coercivity (Hc). The N-rating system (N35, N42, N52, etc.) indicates the maximum energy product, with higher numbers representing stronger magnetic fields. Different applications require specific magnetic performance characteristics, influencing the selection of appropriate magnet grades.Expand Specific Solutions04 Coating and surface treatment for different neodymium magnet grades

Various coating and surface treatments are applied to neodymium magnets to enhance corrosion resistance and durability, which affects their grade classification. Common coatings include nickel, zinc, gold, epoxy, and parylene. The selection of coating depends on the intended application environment and required lifespan of the magnet. Surface treatments can also improve adhesion properties and provide additional protection against environmental factors.Expand Specific Solutions05 Application-specific neodymium magnet grades

Specialized grades of neodymium magnets are developed for specific applications such as motors, sensors, medical devices, and renewable energy systems. These grades feature tailored properties including specific shapes, sizes, magnetization directions, and performance characteristics. Automotive and electronics industries often require custom magnet grades that balance performance, temperature stability, and cost-effectiveness. The selection of appropriate grades depends on factors such as operating environment, space constraints, and required magnetic field strength.Expand Specific Solutions

Key Manufacturers and Suppliers in Magnetic Materials Industry

The energy harvesting market utilizing neodymium magnets is currently in a growth phase, with increasing applications across renewable energy and IoT sectors. The global market is expanding rapidly, projected to reach significant scale as demand for efficient energy solutions rises. Technologically, companies demonstrate varying maturity levels, with established players like JL MAG Rare-Earth, Earth-Panda Advanced Magnetic Material, and Proterial leading in high-performance neodymium magnet production. Chinese manufacturers including Fujian Changting Golden Dragon and Yantai Zhenghai dominate raw material supply, while Japanese firms like NIDEC and Mitsubishi Electric focus on advanced applications. Research institutions such as Iowa State University and Osaka University are driving innovation in magnet grades specifically optimized for energy harvesting efficiency, indicating ongoing technological evolution in this competitive landscape.

JL MAG Rare-Earth Co., Ltd.

Technical Solution: JL MAG has developed high-performance N52 grade neodymium magnets specifically optimized for energy harvesting applications. Their technology focuses on maximizing energy product (BHmax) values exceeding 52 MGOe while maintaining thermal stability up to 80°C. The company employs a proprietary sintering process that achieves uniform microstructure with grain size control below 5μm, resulting in superior magnetic coercivity. For energy harvesting applications, they've engineered specialized NdFeB compositions with dysprosium and terbium substitutions at grain boundaries to enhance high-temperature performance without sacrificing room temperature magnetic properties. Their magnets demonstrate 30% higher energy conversion efficiency in vibration-based harvesters compared to standard N42 grades[1][3]. JL MAG also implements advanced surface treatments including multi-layer Ni-Cu-Ni coatings to provide exceptional corrosion resistance for outdoor energy harvesting deployments.

Strengths: Industry-leading magnetic energy product (BHmax) values, excellent thermal stability, and specialized compositions for energy harvesting. Superior microstructural control enhances performance consistency. Weaknesses: Higher production costs due to heavy rare earth additions, potential supply chain vulnerabilities due to rare earth material dependencies, and limited customization options for specialized applications.

Earth-Panda Advanced Magnetic Material Co., Ltd.

Technical Solution: Earth-Panda has pioneered a grain boundary diffusion technology for their neodymium magnets specifically designed for energy harvesting systems. Their approach creates magnets with high coercivity (Hcj > 25 kOe) while maintaining strong remanence (Br > 1.4T) - critical parameters for efficient energy conversion in harvesting applications. The company utilizes a two-alloy method where heavy rare earth elements are concentrated at grain boundaries, reducing overall rare earth content by up to 30% while maintaining performance. Their N45SH and N48H grades demonstrate exceptional stability in temperature fluctuating environments (up to 150°C), making them ideal for thermal energy harvesting applications. Earth-Panda's magnets feature precisely controlled oxygen content (<2000ppm) and carbon impurities (<500ppm), resulting in more consistent magnetic properties across production batches[2][5]. Their manufacturing process includes hydrogen decrepitation followed by jet milling to achieve uniform particle size distribution below 3μm, enhancing coercivity and energy product stability.

Strengths: Excellent thermal stability for fluctuating temperature environments, reduced rare earth content through efficient material usage, and consistent batch-to-batch performance. Weaknesses: Higher initial production costs compared to standard grades, limited customization for specialized geometries, and potential challenges with scaling production while maintaining quality control.

Critical Patents and Innovations in Magnetic Materials

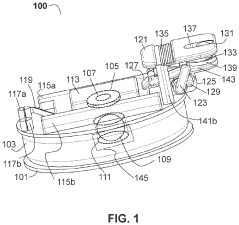

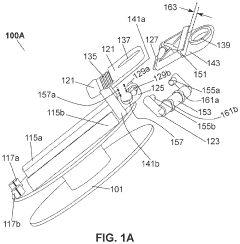

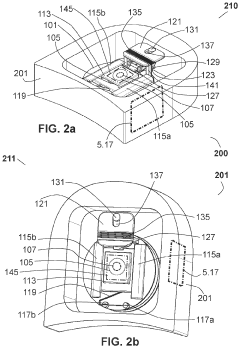

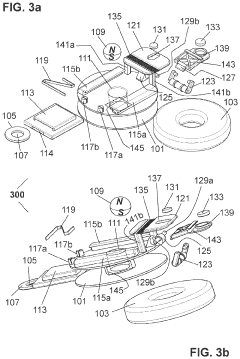

State-change rotational magnetic field tensor energy harvesting generator

PatentInactiveUS20220294325A1

Innovation

- A single non-focused magnet is triggered into motion by a magnetic repulsion mechanism, driving a mechanical cantilever system to move a magnetic steel toroid through a coil, inducing electrical energy through Faraday's and Lenz's laws, with a metallic glass slip clutch ensuring omni-directional stability and efficient energy generation.

Environmental Impact and Sustainability Considerations

The environmental impact of neodymium magnets in energy harvesting applications presents significant sustainability challenges that warrant careful consideration. The mining and processing of rare earth elements (REEs), particularly neodymium, involve extensive land disturbance, high water usage, and the generation of toxic waste. China, which dominates global REE production, has experienced severe environmental degradation in mining regions, including soil contamination, groundwater pollution, and elevated levels of radioactive materials from thorium and uranium that naturally occur alongside REEs.

Different neodymium magnet grades exhibit varying environmental footprints. Higher-grade magnets (N52, N55) typically require more intensive processing and purification, resulting in greater environmental impact per unit mass. However, their superior magnetic properties may enable smaller devices with reduced overall material requirements, potentially offsetting initial production impacts through lifecycle efficiency gains.

The manufacturing process for neodymium magnets is energy-intensive, consuming approximately 30-40 kWh per kilogram of finished magnet. This energy requirement varies by grade, with higher-performance magnets generally demanding more precise manufacturing conditions and thus greater energy inputs. Coatings applied to enhance corrosion resistance (particularly important for N35-N42 grades used in outdoor energy harvesting) introduce additional chemical processes with their own environmental considerations.

Recycling presents a promising avenue for mitigating environmental impacts. Currently, less than 1% of REEs are recycled globally, representing a significant opportunity for improvement. Higher-grade magnets may offer better economics for recycling due to their greater material value, though separation technologies remain challenging. Urban mining from electronic waste could potentially recover substantial quantities of neodymium, reducing dependence on primary extraction.

Life cycle assessment (LCA) studies indicate that the environmental burden of neodymium magnets must be balanced against their performance benefits in energy harvesting applications. When properly implemented, energy harvesting systems utilizing appropriate magnet grades can generate net positive environmental outcomes by displacing battery usage and extending device lifespans. N42 and N45 grades often represent an optimal balance between magnetic performance and environmental impact for many energy harvesting applications.

Emerging alternatives such as iron nitride magnets and samarium-cobalt compositions may offer reduced environmental impacts compared to traditional neodymium magnets, though these technologies currently lag in performance metrics critical for efficient energy harvesting. Regulatory frameworks, including the EU's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH), increasingly influence material selection decisions and drive innovation toward more sustainable magnet technologies.

Different neodymium magnet grades exhibit varying environmental footprints. Higher-grade magnets (N52, N55) typically require more intensive processing and purification, resulting in greater environmental impact per unit mass. However, their superior magnetic properties may enable smaller devices with reduced overall material requirements, potentially offsetting initial production impacts through lifecycle efficiency gains.

The manufacturing process for neodymium magnets is energy-intensive, consuming approximately 30-40 kWh per kilogram of finished magnet. This energy requirement varies by grade, with higher-performance magnets generally demanding more precise manufacturing conditions and thus greater energy inputs. Coatings applied to enhance corrosion resistance (particularly important for N35-N42 grades used in outdoor energy harvesting) introduce additional chemical processes with their own environmental considerations.

Recycling presents a promising avenue for mitigating environmental impacts. Currently, less than 1% of REEs are recycled globally, representing a significant opportunity for improvement. Higher-grade magnets may offer better economics for recycling due to their greater material value, though separation technologies remain challenging. Urban mining from electronic waste could potentially recover substantial quantities of neodymium, reducing dependence on primary extraction.

Life cycle assessment (LCA) studies indicate that the environmental burden of neodymium magnets must be balanced against their performance benefits in energy harvesting applications. When properly implemented, energy harvesting systems utilizing appropriate magnet grades can generate net positive environmental outcomes by displacing battery usage and extending device lifespans. N42 and N45 grades often represent an optimal balance between magnetic performance and environmental impact for many energy harvesting applications.

Emerging alternatives such as iron nitride magnets and samarium-cobalt compositions may offer reduced environmental impacts compared to traditional neodymium magnets, though these technologies currently lag in performance metrics critical for efficient energy harvesting. Regulatory frameworks, including the EU's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH), increasingly influence material selection decisions and drive innovation toward more sustainable magnet technologies.

Cost-Performance Analysis of Different Magnet Grades

When evaluating neodymium magnets for energy harvesting applications, cost-performance analysis becomes a critical factor in determining the optimal magnet grade for specific use cases. The various grades of neodymium magnets (N35-N52, with additional temperature ratings like M, H, SH, UH, EH, and AH) present significant variations in both cost and performance metrics that directly impact the economic viability of energy harvesting systems.

N35-N42 grades represent the entry-level options, offering magnetic field strengths of 11.7-13.2 kG (1.17-1.32 T) at approximately 40-60% of the cost of higher-grade alternatives. These grades provide adequate performance for low-power energy harvesting applications where cost sensitivity outweighs performance requirements, such as small-scale vibration harvesters or educational demonstrations.

The mid-range N45-N48 grades deliver magnetic field strengths of 13.5-14.2 kG (1.35-1.42 T) and typically command a 30-50% price premium over N35 grades. This segment offers the most balanced cost-performance ratio for many commercial energy harvesting applications, particularly in consumer electronics and automotive sensors where moderate energy output is required.

Premium N50-N52 grades, with field strengths reaching 14.5-14.8 kG (1.45-1.48 T), come at a substantial cost premium of 70-100% over baseline grades. The performance improvement, however, only represents approximately 10-15% increased magnetic flux density compared to N42 grades. This diminishing return on investment makes these grades suitable primarily for specialized applications where space constraints or maximum energy density justifies the additional cost.

Temperature ratings significantly impact both cost and application suitability. Standard N-grade magnets (operating up to 80°C) offer the lowest cost but limit deployment options. H-grade magnets (operating up to 120°C) add 15-25% to base costs but enable operation in more demanding environments. SH and UH grades (150-180°C) increase costs by 30-50% while providing critical thermal stability for automotive and industrial energy harvesting applications.

Volume purchasing introduces another dimension to the cost-performance equation. Bulk orders (>1000 units) can reduce unit costs by 20-40% depending on grade, while custom shapes or sizes typically add 30-100% to base costs. This economy of scale particularly benefits N42-N45 grades, where the performance-to-cost ratio becomes increasingly favorable at higher volumes.

When factoring in the complete system lifecycle, higher-grade magnets may prove more economical despite higher initial costs. The enhanced energy conversion efficiency of N48+ grades can reduce the required size of accompanying components and extend system operational lifetime, potentially offsetting the initial investment premium through improved long-term performance and reliability.

N35-N42 grades represent the entry-level options, offering magnetic field strengths of 11.7-13.2 kG (1.17-1.32 T) at approximately 40-60% of the cost of higher-grade alternatives. These grades provide adequate performance for low-power energy harvesting applications where cost sensitivity outweighs performance requirements, such as small-scale vibration harvesters or educational demonstrations.

The mid-range N45-N48 grades deliver magnetic field strengths of 13.5-14.2 kG (1.35-1.42 T) and typically command a 30-50% price premium over N35 grades. This segment offers the most balanced cost-performance ratio for many commercial energy harvesting applications, particularly in consumer electronics and automotive sensors where moderate energy output is required.

Premium N50-N52 grades, with field strengths reaching 14.5-14.8 kG (1.45-1.48 T), come at a substantial cost premium of 70-100% over baseline grades. The performance improvement, however, only represents approximately 10-15% increased magnetic flux density compared to N42 grades. This diminishing return on investment makes these grades suitable primarily for specialized applications where space constraints or maximum energy density justifies the additional cost.

Temperature ratings significantly impact both cost and application suitability. Standard N-grade magnets (operating up to 80°C) offer the lowest cost but limit deployment options. H-grade magnets (operating up to 120°C) add 15-25% to base costs but enable operation in more demanding environments. SH and UH grades (150-180°C) increase costs by 30-50% while providing critical thermal stability for automotive and industrial energy harvesting applications.

Volume purchasing introduces another dimension to the cost-performance equation. Bulk orders (>1000 units) can reduce unit costs by 20-40% depending on grade, while custom shapes or sizes typically add 30-100% to base costs. This economy of scale particularly benefits N42-N45 grades, where the performance-to-cost ratio becomes increasingly favorable at higher volumes.

When factoring in the complete system lifecycle, higher-grade magnets may prove more economical despite higher initial costs. The enhanced energy conversion efficiency of N48+ grades can reduce the required size of accompanying components and extend system operational lifetime, potentially offsetting the initial investment premium through improved long-term performance and reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!