Comparing Neodymium Magnet Handling Protocols Across Industries

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neodymium Magnet Technology Background and Objectives

Neodymium magnets, discovered in the 1980s by General Motors and Sumitomo Special Metals, represent a significant advancement in permanent magnet technology. These rare-earth magnets, composed primarily of neodymium, iron, and boron (NdFeB), have revolutionized numerous industries due to their exceptional magnetic properties. With magnetic energy products reaching up to 52 MGOe, they are the strongest commercially available permanent magnets, offering approximately ten times the magnetic strength of traditional ferrite magnets.

The evolution of neodymium magnet technology has been marked by continuous improvements in manufacturing processes, coating technologies, and compositional refinements. Initially limited by poor temperature stability and corrosion resistance, modern neodymium magnets now incorporate dysprosium and terbium to enhance high-temperature performance, while various coating methods have been developed to address oxidation concerns.

Industry adoption of neodymium magnets has expanded dramatically across sectors including electronics, automotive, renewable energy, medical devices, and aerospace. This widespread implementation has driven the need for standardized handling protocols that address the unique challenges these powerful magnets present, including physical safety risks, equipment damage potential, and demagnetization concerns.

Current technological trends indicate a growing focus on developing handling protocols that balance safety, efficiency, and preservation of magnetic properties. The divergence in handling practices across industries has created a fragmented landscape of protocols, with varying degrees of formalization and scientific validation. This inconsistency presents both challenges and opportunities for standardization and best practice development.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of neodymium magnet handling protocols across diverse industries. This analysis aims to identify common principles, industry-specific requirements, and emerging best practices that could inform the development of more unified, scientifically-grounded handling standards.

Secondary objectives include evaluating the effectiveness of current handling protocols in preventing accidents, maintaining magnet integrity, and optimizing operational efficiency; identifying technological gaps in current handling equipment and methodologies; and forecasting future developments in handling technologies that may address current limitations, particularly for increasingly powerful grades of neodymium magnets being developed.

The technological trajectory suggests continued refinement of neodymium magnets with higher energy products, improved temperature stability, and reduced rare earth content. These advancements will necessitate corresponding evolution in handling protocols to address new challenges while maintaining practicality across diverse industrial applications.

The evolution of neodymium magnet technology has been marked by continuous improvements in manufacturing processes, coating technologies, and compositional refinements. Initially limited by poor temperature stability and corrosion resistance, modern neodymium magnets now incorporate dysprosium and terbium to enhance high-temperature performance, while various coating methods have been developed to address oxidation concerns.

Industry adoption of neodymium magnets has expanded dramatically across sectors including electronics, automotive, renewable energy, medical devices, and aerospace. This widespread implementation has driven the need for standardized handling protocols that address the unique challenges these powerful magnets present, including physical safety risks, equipment damage potential, and demagnetization concerns.

Current technological trends indicate a growing focus on developing handling protocols that balance safety, efficiency, and preservation of magnetic properties. The divergence in handling practices across industries has created a fragmented landscape of protocols, with varying degrees of formalization and scientific validation. This inconsistency presents both challenges and opportunities for standardization and best practice development.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of neodymium magnet handling protocols across diverse industries. This analysis aims to identify common principles, industry-specific requirements, and emerging best practices that could inform the development of more unified, scientifically-grounded handling standards.

Secondary objectives include evaluating the effectiveness of current handling protocols in preventing accidents, maintaining magnet integrity, and optimizing operational efficiency; identifying technological gaps in current handling equipment and methodologies; and forecasting future developments in handling technologies that may address current limitations, particularly for increasingly powerful grades of neodymium magnets being developed.

The technological trajectory suggests continued refinement of neodymium magnets with higher energy products, improved temperature stability, and reduced rare earth content. These advancements will necessitate corresponding evolution in handling protocols to address new challenges while maintaining practicality across diverse industrial applications.

Market Demand Analysis for High-Performance Magnets

The global market for high-performance magnets, particularly neodymium magnets, has experienced substantial growth over the past decade, driven by increasing applications across multiple industries. The current market value exceeds $15 billion and is projected to grow at a compound annual growth rate of 8.5% through 2028, according to industry analyses.

Electronics and automotive sectors represent the largest demand segments, collectively accounting for approximately 60% of the total market. The rapid expansion of electric vehicles has created unprecedented demand for neodymium magnets in motor applications, with each typical EV requiring 1-2 kg of these materials. Major automotive manufacturers have reported supply constraints affecting production schedules, highlighting the strategic importance of these components.

Renewable energy applications, particularly wind turbines, constitute another significant growth sector. Direct-drive wind turbine generators can contain over 600 kg of neodymium magnets per megawatt of capacity. With global wind energy installation targets increasing annually, this sector's demand for high-performance magnets is expected to triple by 2030.

Healthcare applications represent a premium segment with stringent handling requirements. MRI machines typically contain 1,500-3,000 kg of neodymium material, while smaller medical devices increasingly incorporate these magnets for precision applications. The medical sector demands the highest grade materials with specialized handling protocols to ensure patient safety and equipment reliability.

Industrial automation and robotics applications are expanding rapidly, with an estimated 40% increase in magnet consumption over the past five years. As manufacturing facilities worldwide implement Industry 4.0 technologies, the demand for precision motors and actuators containing neodymium magnets continues to accelerate.

Supply chain considerations have become increasingly critical in market analysis. China currently controls approximately 85% of global neodymium production and processing, creating significant geopolitical implications. Recent trade tensions and export restrictions have prompted major consuming nations to develop alternative supply strategies, including recycling initiatives and research into substitute materials.

Price volatility remains a significant market factor, with neodymium prices fluctuating by up to 200% in recent years. This volatility has driven interest in standardized handling protocols that can extend magnet lifespan and improve recycling efficiency, potentially reducing long-term demand pressures and stabilizing prices.

Electronics and automotive sectors represent the largest demand segments, collectively accounting for approximately 60% of the total market. The rapid expansion of electric vehicles has created unprecedented demand for neodymium magnets in motor applications, with each typical EV requiring 1-2 kg of these materials. Major automotive manufacturers have reported supply constraints affecting production schedules, highlighting the strategic importance of these components.

Renewable energy applications, particularly wind turbines, constitute another significant growth sector. Direct-drive wind turbine generators can contain over 600 kg of neodymium magnets per megawatt of capacity. With global wind energy installation targets increasing annually, this sector's demand for high-performance magnets is expected to triple by 2030.

Healthcare applications represent a premium segment with stringent handling requirements. MRI machines typically contain 1,500-3,000 kg of neodymium material, while smaller medical devices increasingly incorporate these magnets for precision applications. The medical sector demands the highest grade materials with specialized handling protocols to ensure patient safety and equipment reliability.

Industrial automation and robotics applications are expanding rapidly, with an estimated 40% increase in magnet consumption over the past five years. As manufacturing facilities worldwide implement Industry 4.0 technologies, the demand for precision motors and actuators containing neodymium magnets continues to accelerate.

Supply chain considerations have become increasingly critical in market analysis. China currently controls approximately 85% of global neodymium production and processing, creating significant geopolitical implications. Recent trade tensions and export restrictions have prompted major consuming nations to develop alternative supply strategies, including recycling initiatives and research into substitute materials.

Price volatility remains a significant market factor, with neodymium prices fluctuating by up to 200% in recent years. This volatility has driven interest in standardized handling protocols that can extend magnet lifespan and improve recycling efficiency, potentially reducing long-term demand pressures and stabilizing prices.

Current Handling Protocols and Industry Challenges

Neodymium magnet handling protocols vary significantly across industries, reflecting the diverse applications and risk profiles associated with these powerful magnetic materials. In manufacturing environments, standardized protocols typically include designated handling zones with non-ferrous workbenches and specialized tools made from aluminum, brass, or plastic to prevent accidental attraction. Workers are required to wear protective equipment including cut-resistant gloves and eye protection, with strict prohibitions against loose metal objects in handling areas.

Electronics and medical device industries implement particularly stringent protocols due to precision requirements and safety concerns. Clean room environments are often utilized with specialized ESD-safe tools and fixtures designed specifically for neodymium magnet placement. These industries commonly employ vacuum pick-and-place systems or mechanical grippers to minimize direct handling and potential contamination of magnetic surfaces.

Automotive and heavy machinery sectors face unique challenges related to the scale of magnets used. Their protocols emphasize mechanical assistance through custom-designed lifting fixtures and non-magnetic cranes. Workspaces are typically segregated from general manufacturing areas, with clear demarcation of magnetic field zones and restricted access policies for personnel with medical implants.

Despite established protocols, significant challenges persist across industries. The lack of universal standards creates inconsistency in safety practices, with smaller operations often implementing inadequate measures due to cost constraints or knowledge gaps. The increasing strength of modern neodymium magnets (exceeding 52 MGOe in some applications) has outpaced many existing handling protocols, creating new safety risks not addressed in older guidelines.

Personnel training represents another critical challenge, with many industries reporting insufficient education regarding magnetic field risks, proper handling techniques, and emergency procedures. This is particularly problematic in facilities where temporary workers or contractors may encounter magnets without specialized training.

The healthcare sector faces unique challenges related to MRI environments, where protocols must address not only staff safety but also patient screening for implanted ferromagnetic materials. Similarly, transportation and logistics companies struggle with developing consistent protocols for shipping neodymium magnets that comply with varying international regulations while maintaining magnetic integrity.

Technical challenges include accurate field strength measurement in dynamic work environments, development of effective shielding solutions, and creation of handling tools that balance functionality with safety. The absence of standardized testing methodologies for validating protocol effectiveness further complicates industry-wide improvements in handling practices.

Electronics and medical device industries implement particularly stringent protocols due to precision requirements and safety concerns. Clean room environments are often utilized with specialized ESD-safe tools and fixtures designed specifically for neodymium magnet placement. These industries commonly employ vacuum pick-and-place systems or mechanical grippers to minimize direct handling and potential contamination of magnetic surfaces.

Automotive and heavy machinery sectors face unique challenges related to the scale of magnets used. Their protocols emphasize mechanical assistance through custom-designed lifting fixtures and non-magnetic cranes. Workspaces are typically segregated from general manufacturing areas, with clear demarcation of magnetic field zones and restricted access policies for personnel with medical implants.

Despite established protocols, significant challenges persist across industries. The lack of universal standards creates inconsistency in safety practices, with smaller operations often implementing inadequate measures due to cost constraints or knowledge gaps. The increasing strength of modern neodymium magnets (exceeding 52 MGOe in some applications) has outpaced many existing handling protocols, creating new safety risks not addressed in older guidelines.

Personnel training represents another critical challenge, with many industries reporting insufficient education regarding magnetic field risks, proper handling techniques, and emergency procedures. This is particularly problematic in facilities where temporary workers or contractors may encounter magnets without specialized training.

The healthcare sector faces unique challenges related to MRI environments, where protocols must address not only staff safety but also patient screening for implanted ferromagnetic materials. Similarly, transportation and logistics companies struggle with developing consistent protocols for shipping neodymium magnets that comply with varying international regulations while maintaining magnetic integrity.

Technical challenges include accurate field strength measurement in dynamic work environments, development of effective shielding solutions, and creation of handling tools that balance functionality with safety. The absence of standardized testing methodologies for validating protocol effectiveness further complicates industry-wide improvements in handling practices.

Cross-Industry Handling Solution Comparison

01 Safety protocols for handling neodymium magnets

Handling neodymium magnets requires specific safety protocols due to their strong magnetic fields. These protocols include wearing protective equipment such as gloves and eye protection, maintaining safe distances between magnets and electronic devices, and using non-magnetic tools for handling. Proper training for personnel is essential to prevent injuries from sudden attraction forces between magnets or between magnets and ferromagnetic objects.- Safety protocols for handling neodymium magnets: Neodymium magnets require specific safety protocols due to their strong magnetic fields. These protocols include wearing protective equipment such as gloves and eye protection, maintaining safe distances between magnets and electronic devices, and using non-magnetic tools for handling. Proper training for personnel is essential to prevent injuries from magnetic attraction forces, which can cause pinching or crushing injuries when magnets snap together unexpectedly.

- Storage and transportation guidelines: Proper storage and transportation of neodymium magnets is critical to maintain their properties and prevent accidents. Guidelines include using shielded containers with magnetic insulation, separating magnets with non-magnetic spacers, and clearly labeling packages with magnetic warning symbols. For transportation, specialized packaging that prevents movement and interaction between magnets is required, along with compliance with shipping regulations for magnetic materials.

- Manufacturing and processing procedures: Manufacturing and processing neodymium magnets involves specialized procedures to ensure quality and safety. These include controlled environment processing to prevent contamination, precise temperature management during sintering and coating processes, and automated handling systems to minimize direct contact. Quality control protocols involve testing magnetic strength, uniformity, and coating integrity before packaging and distribution.

- Environmental and health considerations: Handling neodymium magnets requires attention to environmental and health factors. Protocols address potential health risks from magnet dust or particles, which can be harmful if inhaled or ingested. Environmental considerations include proper disposal methods for damaged magnets, recycling procedures for end-of-life products, and containment strategies to prevent contamination. Workplace monitoring for magnetic field exposure and regular health assessments for workers are also recommended.

- Equipment and facility requirements: Facilities handling neodymium magnets need specialized equipment and infrastructure. This includes designated work areas with non-magnetic surfaces, magnetic field detection systems to monitor exposure levels, and emergency response equipment for handling accidents. Facilities should be designed with adequate spacing between workstations to prevent magnetic interference, proper ventilation systems for dust control, and demagnetization equipment for tools and components that may become magnetized during handling.

02 Storage and transportation guidelines

Neodymium magnets require specialized storage and transportation methods to maintain their magnetic properties and ensure safety. Guidelines include using magnetic shielding materials, separating magnets with non-magnetic spacers, and employing secure packaging to prevent movement during transport. Proper labeling and documentation are necessary for shipping compliance, particularly for air transport where magnetic field restrictions apply.Expand Specific Solutions03 Manufacturing and assembly processes

Manufacturing and assembly processes involving neodymium magnets require specialized handling protocols. These include controlled environment conditions to prevent corrosion, precise alignment techniques during assembly, and automated systems for handling larger magnets. Magnetization should occur at specific stages of production to minimize handling difficulties, and demagnetization protocols may be necessary for certain assembly operations.Expand Specific Solutions04 Maintenance and disposal procedures

Proper maintenance and disposal procedures are critical for neodymium magnets. Maintenance includes regular inspection for cracks or corrosion, cleaning with appropriate non-abrasive materials, and recoating when necessary to prevent degradation. Disposal requires demagnetization before discarding or recycling to prevent interference with waste processing equipment and to recover valuable rare earth materials according to environmental regulations.Expand Specific Solutions05 Risk assessment and mitigation strategies

Risk assessment and mitigation strategies are essential when working with neodymium magnets. This includes identifying potential hazards such as pinch points, magnetic interference with medical devices, and data corruption in electronic equipment. Mitigation strategies involve establishing exclusion zones, implementing warning systems, conducting regular safety audits, and developing emergency response procedures for accidents involving magnetic materials.Expand Specific Solutions

Key Industry Players and Protocol Developers

The neodymium magnet handling protocols market is in a growth phase, with increasing demand across automotive, electronics, and renewable energy sectors driving a global market expected to reach $40 billion by 2030. Chinese companies dominate the competitive landscape, with JL MAG Rare-Earth, Baotou Tianhe Magnetics, and Fujian Changting Golden Dragon leading in production capacity and technological advancement. Western players like NIDEC Corp and Cardiovascular Systems focus on specialized applications with higher safety standards. Research institutions including CNRS and Tokyo University of Science are advancing handling protocols for stronger magnets, while companies like RarEarth Srl are developing recycling technologies to address sustainability concerns. The industry is moving toward standardization of handling protocols as magnet strength and applications continue to evolve.

Baotou Tianhe Magnetics Technology Co., Ltd.

Technical Solution: Baotou Tianhe has pioneered a handling protocol specifically designed for high-performance neodymium magnets used in industrial applications. Their system employs a combination of specialized non-magnetic handling equipment and advanced magnetic field management techniques. The company has developed proprietary magnetic field neutralization chambers where powerful neodymium magnets can be safely manipulated without risk of sudden attraction or repulsion forces. Their protocol includes the use of custom-designed aluminum and polymer-based tools that resist magnetization, along with specialized workstations featuring integrated magnetic field barriers. For transportation, they utilize multi-layered shielding containers with graduated magnetic isolation that prevents field leakage while maintaining structural integrity. The company also implements strict personnel training programs focused on proper handling techniques and emergency procedures specific to different magnet grades and sizes.

Strengths: Their specialized magnetic field neutralization technology allows for safer handling of extremely powerful magnets. The comprehensive training program ensures consistent safety practices across operations. Weaknesses: The system is primarily optimized for industrial-scale operations and may be less adaptable to medical or research applications where different handling requirements exist.

JL MAG Rare-Earth Co., Ltd.

Technical Solution: JL MAG has developed comprehensive neodymium magnet handling protocols that integrate automated systems with strict environmental controls. Their approach includes specialized robotic handling equipment that minimizes direct human contact with large neodymium magnets, reducing workplace hazards. The company employs a multi-stage demagnetization process for safe transportation and processing, where magnets are temporarily demagnetized during critical handling phases and then remagnetized after placement. Their facilities feature designated magnetic-safe zones with non-ferrous tools and equipment, while workers utilize specialized non-magnetic handling devices and wear protective gear including specialized gloves with magnetic shielding properties. JL MAG's protocol includes detailed emergency response procedures for magnet-related incidents and regular safety training programs specific to rare earth magnet handling.

Strengths: Industry-leading automation reduces workplace injuries and improves handling efficiency. Their integrated safety systems provide comprehensive protection throughout the manufacturing process. Weaknesses: The sophisticated handling systems require significant capital investment and specialized maintenance, potentially limiting implementation in smaller operations.

Critical Safety Protocol Innovations and Patents

Procedure to manufacture and use beer and other types liquids treated with neodimium magnet

PatentWO2008102188A1

Innovation

- The use of Neodimium magnets with a magnetic field strength of 12000.00-40000.00 Gauss integrated into the bottling process to treat beer, enhancing its dielectric constant, surface tension, and pH value, thereby improving its energy and physical parameters.

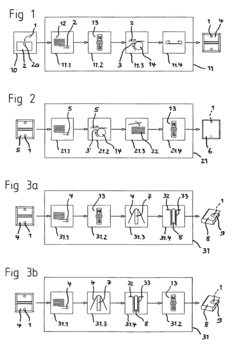

Method and device for producing packages, boxes, folders, book covers and similar

PatentInactiveEP2468639A1

Innovation

- Neodymium magnets are only magnetized during or after the laminating process using an external magnetic field, reducing attractive forces and allowing easier insertion and handling, with magnetization occurring at the final manufacturing step or during further processing.

Regulatory Compliance Across Different Sectors

Regulatory compliance for neodymium magnet handling varies significantly across different industrial sectors, reflecting the diverse applications and associated risks of these powerful permanent magnets. In the medical device industry, the FDA has established stringent guidelines under 21 CFR Part 820 specifically addressing the integration of neodymium magnets in medical equipment, with particular emphasis on MRI compatibility testing and potential interference with implantable devices such as pacemakers.

The electronics manufacturing sector follows IEC 62474 standards, which mandate detailed documentation of magnetic material composition and require specific handling protocols to prevent damage to sensitive electronic components. These regulations are complemented by ANSI/ESD S20.20 standards that address the management of electrostatic discharge risks when handling neodymium magnets in proximity to electronic assemblies.

Automotive manufacturers must adhere to ISO/TS 16949 quality management standards, which include specific provisions for magnetic components used in vehicle systems. These standards emphasize temperature stability testing and corrosion resistance verification, recognizing the challenging operational environments that automotive magnetic components must withstand.

The aerospace industry implements the most rigorous compliance framework through AS9100 certification requirements, which mandate extensive documentation of magnetic material properties, strict batch testing protocols, and comprehensive traceability systems. Additionally, aerospace applications require specialized testing for vibration resistance and performance under extreme temperature variations.

Consumer product regulations, governed primarily by CPSC guidelines in the United States and the General Product Safety Directive in the European Union, focus heavily on preventing ingestion hazards, particularly in toys and household items. These regulations mandate warning labels, specific packaging requirements, and mechanical integrity testing to ensure magnets remain securely embedded in consumer products.

Occupational safety regulations, including OSHA Standard 1910.132 in the United States, require comprehensive risk assessments for workplaces handling neodymium magnets, with particular attention to crushing hazards, appropriate personal protective equipment, and specialized training for workers. Similar frameworks exist internationally, such as the EU Directive 89/391/EEC, which emphasizes employer responsibility for magnetic field exposure assessment and mitigation.

Cross-sector harmonization efforts are emerging through ISO 14001 environmental management standards, which address the full lifecycle management of neodymium magnets, including extraction, processing, and end-of-life considerations, reflecting growing concerns about the environmental impact of rare earth element mining and processing.

The electronics manufacturing sector follows IEC 62474 standards, which mandate detailed documentation of magnetic material composition and require specific handling protocols to prevent damage to sensitive electronic components. These regulations are complemented by ANSI/ESD S20.20 standards that address the management of electrostatic discharge risks when handling neodymium magnets in proximity to electronic assemblies.

Automotive manufacturers must adhere to ISO/TS 16949 quality management standards, which include specific provisions for magnetic components used in vehicle systems. These standards emphasize temperature stability testing and corrosion resistance verification, recognizing the challenging operational environments that automotive magnetic components must withstand.

The aerospace industry implements the most rigorous compliance framework through AS9100 certification requirements, which mandate extensive documentation of magnetic material properties, strict batch testing protocols, and comprehensive traceability systems. Additionally, aerospace applications require specialized testing for vibration resistance and performance under extreme temperature variations.

Consumer product regulations, governed primarily by CPSC guidelines in the United States and the General Product Safety Directive in the European Union, focus heavily on preventing ingestion hazards, particularly in toys and household items. These regulations mandate warning labels, specific packaging requirements, and mechanical integrity testing to ensure magnets remain securely embedded in consumer products.

Occupational safety regulations, including OSHA Standard 1910.132 in the United States, require comprehensive risk assessments for workplaces handling neodymium magnets, with particular attention to crushing hazards, appropriate personal protective equipment, and specialized training for workers. Similar frameworks exist internationally, such as the EU Directive 89/391/EEC, which emphasizes employer responsibility for magnetic field exposure assessment and mitigation.

Cross-sector harmonization efforts are emerging through ISO 14001 environmental management standards, which address the full lifecycle management of neodymium magnets, including extraction, processing, and end-of-life considerations, reflecting growing concerns about the environmental impact of rare earth element mining and processing.

Environmental Impact of Neodymium Magnet Lifecycle

The environmental footprint of neodymium magnets spans their entire lifecycle, from mining raw materials to disposal. The extraction process of rare earth elements, particularly neodymium, involves significant environmental degradation including soil erosion, water contamination, and habitat destruction. Mining operations in regions like China's Baiyun Obo mine generate approximately 10 million tons of wastewater annually, containing radioactive elements and heavy metals that pose serious ecological risks.

Processing and refining neodymium requires substantial energy consumption and chemical treatments. The separation of rare earth elements typically demands strong acids and organic solvents, resulting in toxic byproducts. Studies indicate that producing one ton of rare earth oxides generates 2,000 tons of toxic waste, highlighting the disproportionate environmental burden relative to production volume.

Manufacturing neodymium magnets involves sintering or bonding processes that consume considerable energy and release greenhouse gases. The coating procedures, essential for preventing oxidation, often utilize nickel, zinc, or epoxy resins that introduce additional environmental concerns through chemical waste streams and air emissions.

During their operational phase, neodymium magnets contribute to environmental sustainability through applications in renewable energy technologies. Wind turbines utilizing these magnets increase energy conversion efficiency by 20-30% compared to conventional alternatives. Similarly, electric vehicles with neodymium magnet motors demonstrate 15-25% greater efficiency than induction motor counterparts, reducing overall carbon footprints despite the initial production impacts.

End-of-life management presents significant challenges due to the lack of established recycling infrastructure. Less than 1% of rare earth elements are currently recovered globally, with most neodymium magnets ending up in landfills. When improperly disposed, these magnets can leach heavy metals and other contaminants into soil and groundwater systems.

Recent industry initiatives have begun addressing these concerns through improved handling protocols. Closed-loop manufacturing systems have demonstrated potential to reduce waste by up to 30%, while hydrogen decrepitation recycling methods show promise for recovering up to 90% of neodymium from end-of-life magnets. These advancements suggest pathways toward mitigating the environmental impact across the neodymium magnet lifecycle, though implementation remains inconsistent across different industrial sectors.

Processing and refining neodymium requires substantial energy consumption and chemical treatments. The separation of rare earth elements typically demands strong acids and organic solvents, resulting in toxic byproducts. Studies indicate that producing one ton of rare earth oxides generates 2,000 tons of toxic waste, highlighting the disproportionate environmental burden relative to production volume.

Manufacturing neodymium magnets involves sintering or bonding processes that consume considerable energy and release greenhouse gases. The coating procedures, essential for preventing oxidation, often utilize nickel, zinc, or epoxy resins that introduce additional environmental concerns through chemical waste streams and air emissions.

During their operational phase, neodymium magnets contribute to environmental sustainability through applications in renewable energy technologies. Wind turbines utilizing these magnets increase energy conversion efficiency by 20-30% compared to conventional alternatives. Similarly, electric vehicles with neodymium magnet motors demonstrate 15-25% greater efficiency than induction motor counterparts, reducing overall carbon footprints despite the initial production impacts.

End-of-life management presents significant challenges due to the lack of established recycling infrastructure. Less than 1% of rare earth elements are currently recovered globally, with most neodymium magnets ending up in landfills. When improperly disposed, these magnets can leach heavy metals and other contaminants into soil and groundwater systems.

Recent industry initiatives have begun addressing these concerns through improved handling protocols. Closed-loop manufacturing systems have demonstrated potential to reduce waste by up to 30%, while hydrogen decrepitation recycling methods show promise for recovering up to 90% of neodymium from end-of-life magnets. These advancements suggest pathways toward mitigating the environmental impact across the neodymium magnet lifecycle, though implementation remains inconsistent across different industrial sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!