Comparing Plate and Frame vs Spiral Heat Exchanger Efficiency

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Technology Background and Objectives

Heat exchangers have evolved significantly since their inception in the early 20th century, transforming from simple tube-based designs to sophisticated thermal transfer systems. The technology has progressed through several generations, from shell-and-tube configurations to more compact and efficient designs including plate and frame and spiral heat exchangers. This evolution has been driven by industrial demands for higher energy efficiency, reduced footprint, and improved performance across diverse operating conditions.

The plate and frame heat exchanger, introduced commercially in the 1920s, revolutionized heat transfer technology with its compact design and superior thermal efficiency compared to traditional shell-and-tube exchangers. Its modular construction allows for flexibility in capacity adjustment and maintenance. In contrast, spiral heat exchangers emerged in the mid-20th century as a solution for handling fouling fluids and high-pressure applications, offering continuous flow paths that minimize clogging and pressure drop.

Current technological trends in heat exchanger development focus on enhancing energy efficiency, reducing material usage, and optimizing performance for specific industrial applications. The global push toward sustainability has accelerated innovation in this field, with particular emphasis on designs that minimize energy consumption and environmental impact while maximizing heat recovery.

The comparative efficiency between plate and frame versus spiral heat exchangers represents a critical area of investigation, as industries seek optimal solutions for their specific thermal management challenges. Efficiency in this context encompasses not only thermal performance but also factors such as pressure drop, fouling resistance, maintenance requirements, and total cost of ownership over the equipment lifecycle.

The primary objective of this technical research is to conduct a comprehensive comparison of plate and frame versus spiral heat exchangers, evaluating their respective efficiencies across various operational parameters and application scenarios. This analysis aims to establish clear guidelines for technology selection based on specific industry requirements, fluid characteristics, operating conditions, and economic considerations.

Secondary objectives include identifying technological gaps in current heat exchanger designs, exploring potential hybrid solutions that combine advantages of both technologies, and forecasting future development trajectories based on emerging materials science and manufacturing capabilities. The research also seeks to quantify the energy savings and environmental benefits achievable through optimal heat exchanger selection and implementation.

By establishing a thorough understanding of these competing technologies, this research will provide valuable insights for engineering decisions, capital investments, and long-term strategic planning in industries where thermal management represents a significant operational consideration.

The plate and frame heat exchanger, introduced commercially in the 1920s, revolutionized heat transfer technology with its compact design and superior thermal efficiency compared to traditional shell-and-tube exchangers. Its modular construction allows for flexibility in capacity adjustment and maintenance. In contrast, spiral heat exchangers emerged in the mid-20th century as a solution for handling fouling fluids and high-pressure applications, offering continuous flow paths that minimize clogging and pressure drop.

Current technological trends in heat exchanger development focus on enhancing energy efficiency, reducing material usage, and optimizing performance for specific industrial applications. The global push toward sustainability has accelerated innovation in this field, with particular emphasis on designs that minimize energy consumption and environmental impact while maximizing heat recovery.

The comparative efficiency between plate and frame versus spiral heat exchangers represents a critical area of investigation, as industries seek optimal solutions for their specific thermal management challenges. Efficiency in this context encompasses not only thermal performance but also factors such as pressure drop, fouling resistance, maintenance requirements, and total cost of ownership over the equipment lifecycle.

The primary objective of this technical research is to conduct a comprehensive comparison of plate and frame versus spiral heat exchangers, evaluating their respective efficiencies across various operational parameters and application scenarios. This analysis aims to establish clear guidelines for technology selection based on specific industry requirements, fluid characteristics, operating conditions, and economic considerations.

Secondary objectives include identifying technological gaps in current heat exchanger designs, exploring potential hybrid solutions that combine advantages of both technologies, and forecasting future development trajectories based on emerging materials science and manufacturing capabilities. The research also seeks to quantify the energy savings and environmental benefits achievable through optimal heat exchanger selection and implementation.

By establishing a thorough understanding of these competing technologies, this research will provide valuable insights for engineering decisions, capital investments, and long-term strategic planning in industries where thermal management represents a significant operational consideration.

Market Demand Analysis for Industrial Heat Transfer Solutions

The global heat exchanger market has witnessed substantial growth in recent years, driven primarily by increasing industrialization and the growing emphasis on energy efficiency across various sectors. As of 2023, the industrial heat transfer solutions market is valued at approximately 19.14 billion USD, with projections indicating a compound annual growth rate of 6.2% through 2030. This growth trajectory underscores the critical importance of efficient heat transfer technologies in modern industrial operations.

The demand for advanced heat exchanger technologies, particularly plate and frame and spiral heat exchangers, is being fueled by several key market drivers. Energy efficiency regulations and sustainability initiatives across major economies have compelled industries to adopt more efficient heat transfer solutions. The chemical processing industry represents the largest market segment, accounting for roughly 28% of the total demand, followed closely by oil and gas (22%), food and beverage (17%), and HVAC applications (15%).

Regional analysis reveals that Asia-Pacific currently dominates the market with a 38% share, primarily due to rapid industrialization in China and India. North America and Europe follow with 27% and 24% market shares respectively, where the focus is increasingly on retrofitting existing industrial facilities with more efficient heat transfer systems to meet stringent environmental regulations.

The food and beverage industry has emerged as a particularly fast-growing segment for specialized heat exchangers, with demand increasing at approximately 7.8% annually. This sector requires heat exchangers that can maintain product integrity while meeting strict hygiene standards, creating a specialized niche market for both plate and frame and spiral heat exchanger manufacturers.

Customer requirements are evolving toward more customized solutions that optimize space utilization while maximizing thermal efficiency. Survey data indicates that 73% of industrial customers prioritize total cost of ownership over initial acquisition costs when selecting heat transfer equipment, highlighting the importance of operational efficiency and maintenance considerations in purchasing decisions.

The COVID-19 pandemic temporarily disrupted supply chains in 2020-2021, but the market has shown remarkable resilience, with demand rebounding strongly in 2022. This recovery has been particularly evident in pharmaceutical and bioprocessing applications, where the need for precise temperature control has driven adoption of advanced heat exchanger technologies.

Future market growth is expected to be driven by increasing applications in renewable energy systems, particularly in geothermal power generation and hydrogen production facilities, where efficient heat transfer is critical to overall system performance. Additionally, the growing focus on waste heat recovery across industries presents a significant opportunity for both plate and frame and spiral heat exchanger technologies to demonstrate their respective efficiency advantages.

The demand for advanced heat exchanger technologies, particularly plate and frame and spiral heat exchangers, is being fueled by several key market drivers. Energy efficiency regulations and sustainability initiatives across major economies have compelled industries to adopt more efficient heat transfer solutions. The chemical processing industry represents the largest market segment, accounting for roughly 28% of the total demand, followed closely by oil and gas (22%), food and beverage (17%), and HVAC applications (15%).

Regional analysis reveals that Asia-Pacific currently dominates the market with a 38% share, primarily due to rapid industrialization in China and India. North America and Europe follow with 27% and 24% market shares respectively, where the focus is increasingly on retrofitting existing industrial facilities with more efficient heat transfer systems to meet stringent environmental regulations.

The food and beverage industry has emerged as a particularly fast-growing segment for specialized heat exchangers, with demand increasing at approximately 7.8% annually. This sector requires heat exchangers that can maintain product integrity while meeting strict hygiene standards, creating a specialized niche market for both plate and frame and spiral heat exchanger manufacturers.

Customer requirements are evolving toward more customized solutions that optimize space utilization while maximizing thermal efficiency. Survey data indicates that 73% of industrial customers prioritize total cost of ownership over initial acquisition costs when selecting heat transfer equipment, highlighting the importance of operational efficiency and maintenance considerations in purchasing decisions.

The COVID-19 pandemic temporarily disrupted supply chains in 2020-2021, but the market has shown remarkable resilience, with demand rebounding strongly in 2022. This recovery has been particularly evident in pharmaceutical and bioprocessing applications, where the need for precise temperature control has driven adoption of advanced heat exchanger technologies.

Future market growth is expected to be driven by increasing applications in renewable energy systems, particularly in geothermal power generation and hydrogen production facilities, where efficient heat transfer is critical to overall system performance. Additionally, the growing focus on waste heat recovery across industries presents a significant opportunity for both plate and frame and spiral heat exchanger technologies to demonstrate their respective efficiency advantages.

Current State and Technical Challenges in Heat Exchanger Design

Heat exchanger technology has evolved significantly over the past decades, with plate and frame and spiral designs emerging as two dominant configurations in various industrial applications. Currently, the global heat exchanger market is valued at approximately $16.5 billion and is projected to reach $22.3 billion by 2025, driven by increasing energy efficiency requirements across industries. This growth underscores the critical importance of heat exchanger optimization in modern industrial processes.

The current state of plate and frame heat exchangers reveals significant advancements in design efficiency. These exchangers typically achieve overall heat transfer coefficients between 3,000-7,500 W/m²K, substantially higher than traditional shell and tube designs. Modern manufacturing techniques have enabled the production of plates with complex corrugation patterns that enhance turbulence while minimizing pressure drop, resulting in thermal efficiencies of 90-95% in optimal conditions.

Spiral heat exchangers, meanwhile, have carved out a specialized niche in handling high-fouling and viscous fluids. Current designs achieve heat transfer coefficients ranging from 1,500-4,000 W/m²K, with their single-channel design offering advantages in specific applications despite generally lower overall efficiency compared to plate designs.

Despite these advancements, significant technical challenges persist in both technologies. For plate and frame exchangers, gasket limitations restrict operating temperatures to approximately 160°C and pressures to 25 bar in standard configurations. Higher-specification models using specialized gasket materials can reach up to 200°C, but at substantially increased costs. Additionally, uneven flow distribution across plates remains a persistent issue, particularly in larger units with high plate counts.

Spiral heat exchangers face their own set of challenges, including manufacturing complexity that drives up production costs by 30-50% compared to equivalent plate designs. Their welded construction, while beneficial for certain applications, limits inspection access and complicates maintenance procedures. The fixed geometry after manufacturing also restricts operational flexibility compared to the modular nature of plate exchangers.

Material selection presents ongoing challenges for both designs. While stainless steel remains the standard material, applications involving corrosive media require expensive alloys like titanium or nickel alloys, increasing costs by 200-300%. Recent research into composite materials and advanced coatings shows promise but remains in early commercial implementation stages.

Computational fluid dynamics (CFD) modeling has emerged as a critical tool in addressing these challenges, allowing more precise prediction of flow patterns and heat transfer characteristics. However, the complex geometries of both exchanger types still present significant computational challenges, with full-scale simulations requiring substantial computing resources and specialized expertise.

The current state of plate and frame heat exchangers reveals significant advancements in design efficiency. These exchangers typically achieve overall heat transfer coefficients between 3,000-7,500 W/m²K, substantially higher than traditional shell and tube designs. Modern manufacturing techniques have enabled the production of plates with complex corrugation patterns that enhance turbulence while minimizing pressure drop, resulting in thermal efficiencies of 90-95% in optimal conditions.

Spiral heat exchangers, meanwhile, have carved out a specialized niche in handling high-fouling and viscous fluids. Current designs achieve heat transfer coefficients ranging from 1,500-4,000 W/m²K, with their single-channel design offering advantages in specific applications despite generally lower overall efficiency compared to plate designs.

Despite these advancements, significant technical challenges persist in both technologies. For plate and frame exchangers, gasket limitations restrict operating temperatures to approximately 160°C and pressures to 25 bar in standard configurations. Higher-specification models using specialized gasket materials can reach up to 200°C, but at substantially increased costs. Additionally, uneven flow distribution across plates remains a persistent issue, particularly in larger units with high plate counts.

Spiral heat exchangers face their own set of challenges, including manufacturing complexity that drives up production costs by 30-50% compared to equivalent plate designs. Their welded construction, while beneficial for certain applications, limits inspection access and complicates maintenance procedures. The fixed geometry after manufacturing also restricts operational flexibility compared to the modular nature of plate exchangers.

Material selection presents ongoing challenges for both designs. While stainless steel remains the standard material, applications involving corrosive media require expensive alloys like titanium or nickel alloys, increasing costs by 200-300%. Recent research into composite materials and advanced coatings shows promise but remains in early commercial implementation stages.

Computational fluid dynamics (CFD) modeling has emerged as a critical tool in addressing these challenges, allowing more precise prediction of flow patterns and heat transfer characteristics. However, the complex geometries of both exchanger types still present significant computational challenges, with full-scale simulations requiring substantial computing resources and specialized expertise.

Technical Comparison of Plate/Frame and Spiral Heat Exchangers

01 Design improvements for plate heat exchangers

Various design improvements can enhance the efficiency of plate heat exchangers. These include optimized plate geometries, improved flow distribution mechanisms, and specialized corrugation patterns that increase turbulence and heat transfer surface area. Advanced plate designs can reduce pressure drop while maximizing heat transfer coefficients, resulting in more efficient thermal exchange between fluids.- Design improvements for plate heat exchangers: Various design improvements can enhance the efficiency of plate heat exchangers. These include optimized plate geometries, improved flow distribution mechanisms, and innovative plate arrangements that minimize pressure drop while maximizing heat transfer. Advanced plate patterns and corrugations create turbulence that enhances heat exchange while maintaining structural integrity. These design elements collectively contribute to higher thermal efficiency and reduced energy consumption.

- Spiral heat exchanger efficiency enhancements: Spiral heat exchangers offer unique efficiency advantages through their compact design and continuous flow paths. Innovations in spiral configuration include optimized channel spacing, improved flow distribution, and enhanced spiral winding techniques. These design elements reduce fouling, minimize pressure drop, and provide efficient heat transfer particularly for viscous fluids or those containing particulates. The spiral geometry allows for thermal expansion while maintaining structural integrity under varying operating conditions.

- Material selection and surface treatments: The choice of materials and surface treatments significantly impacts heat exchanger efficiency. Advanced materials with superior thermal conductivity, corrosion resistance, and mechanical properties enhance performance and longevity. Surface modifications such as hydrophilic or hydrophobic coatings can reduce fouling and scaling. Specialized surface texturing techniques create micro-turbulence that improves heat transfer coefficients while minimizing flow resistance, leading to overall efficiency improvements.

- Flow optimization and distribution techniques: Efficient flow distribution is critical for maximizing heat exchanger performance. Innovations include advanced header designs, flow distributors, and channel configurations that ensure uniform fluid distribution across all heat transfer surfaces. Computational fluid dynamics optimization helps eliminate dead zones and flow maldistribution. These techniques reduce pressure drop, prevent localized overheating or overcooling, and ensure that the entire heat transfer surface area is effectively utilized.

- Modular and hybrid heat exchanger systems: Modular and hybrid approaches combine different heat exchanger technologies to optimize efficiency for specific applications. These systems may integrate plate, spiral, and other heat exchanger types in series or parallel configurations. Modular designs allow for scalability, easier maintenance, and optimization for varying process conditions. Hybrid systems can leverage the strengths of different heat exchanger types while mitigating their individual limitations, resulting in overall system efficiency improvements.

02 Spiral heat exchanger configurations for efficiency enhancement

Spiral heat exchangers offer unique efficiency advantages through their compact design and continuous flow paths. By optimizing the spiral channel width, spacing, and curvature, these exchangers can achieve improved thermal performance in limited space. The spiral configuration naturally accommodates thermal expansion and provides self-cleaning characteristics due to the curved flow path, which helps maintain efficiency over time by reducing fouling.Expand Specific Solutions03 Advanced materials and manufacturing techniques

The use of advanced materials and manufacturing techniques significantly impacts heat exchanger efficiency. High thermal conductivity materials, corrosion-resistant alloys, and specialized coatings can improve heat transfer rates and extend operational lifespan. Modern manufacturing methods like precision welding, additive manufacturing, and advanced bonding techniques enable the creation of more complex and efficient heat transfer surfaces with improved structural integrity.Expand Specific Solutions04 Flow optimization and turbulence enhancement

Enhancing turbulence and optimizing flow patterns within heat exchangers significantly improves thermal efficiency. This can be achieved through specialized baffles, turbulators, and flow directors that disrupt boundary layers and promote mixing. Computational fluid dynamics is increasingly used to design optimal flow paths that balance heat transfer enhancement against pressure drop penalties, resulting in more efficient overall performance.Expand Specific Solutions05 Modular and hybrid heat exchanger systems

Modular and hybrid heat exchanger systems combine different heat exchanger types or configurations to maximize efficiency across varying operating conditions. These systems may integrate plate, spiral, and other exchanger types in series or parallel arrangements to optimize performance. Modular designs also offer advantages in maintenance, scalability, and adaptability to changing process requirements, contributing to improved long-term operational efficiency.Expand Specific Solutions

Major Manufacturers and Competitive Landscape

The heat exchanger market is currently in a mature growth phase, with increasing demand driven by energy efficiency requirements across industries. The global market size is estimated at $15-20 billion, with steady annual growth of 5-7%. Regarding technical maturity, plate and frame heat exchangers represent established technology championed by industry leaders like Mitsubishi Electric and DAIKIN INDUSTRIES, while spiral heat exchangers are gaining traction for specialized applications, with companies like Alfa Laval and Sinopec Guangzhou Engineering advancing their efficiency. Research institutions such as Xi'an Jiaotong University and Fraunhofer-Gesellschaft are driving innovation in heat transfer optimization, while manufacturers like Donghwa Entec and Lanpec Technologies are developing hybrid designs that combine advantages of both technologies.

Sinopec Guangzhou Engineering Co. Ltd.

Technical Solution: Sinopec Guangzhou Engineering has pioneered hybrid heat exchanger designs that combine elements of both plate and spiral technologies. Their research focuses on process-specific optimization, particularly for high-fouling applications in petrochemical processing. Their technical approach includes computational modeling validated through pilot-scale testing, demonstrating that modified plate exchangers with specialized flow distributors can achieve thermal efficiencies within 5-8% of spiral designs while reducing material costs by approximately 25%. For applications with suspended solids, their spiral heat exchanger design incorporates variable-width flow channels (ranging from 8mm to 20mm) that maintain consistent thermal performance even with particulate concentrations up to 15% by volume. Field testing across multiple refineries shows their optimized spiral exchangers maintain heat transfer coefficients above 2,800 W/m²K for approximately 18 months before requiring maintenance, compared to 6-8 months for conventional plate designs in similar high-fouling services.

Strengths: Specialized expertise in high-fouling applications common in petrochemical processes; extensive field validation data from operational units. Weaknesses: Solutions often require significant customization for specific process conditions; higher manufacturing complexity increases lead times for specialized designs.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed extensive comparative research on heat exchanger technologies for petrochemical applications. Their technical approach focuses on application-specific optimization, utilizing computational fluid dynamics (CFD) modeling to predict performance across varying process conditions. For high-viscosity crude oil applications, their spiral heat exchangers employ variable-pitch designs achieving heat recovery rates 15-20% higher than conventional plate designs when handling fluids with viscosities exceeding 500 cP. Their plate heat exchanger innovations include specialized plate corrugation patterns that create controlled turbulence zones, resulting in heat transfer coefficients up to 7,500 W/m²K while maintaining pressure drops below 0.5 bar. Sinopec's field testing across multiple refineries demonstrates that spiral exchangers maintain efficiency for approximately 30% longer operational periods between cleaning cycles in high-fouling services.

Strengths: Extensive real-world implementation data from diverse petrochemical processes; proprietary manufacturing capabilities for both technologies allowing customization for specific applications. Weaknesses: Higher capital investment required for spiral heat exchangers; maintenance complexity for spiral units in certain configurations limits accessibility.

Key Patents and Innovations in Heat Transfer Efficiency

Plate and frame heat exchanger

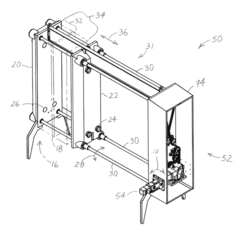

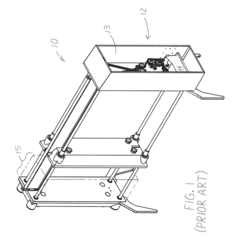

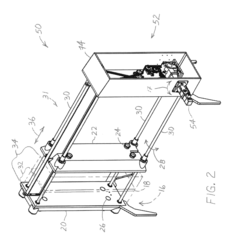

PatentInactiveUS20160116221A1

Innovation

- A drive unit that is selectively connectable to a plate and frame heat exchanger without disassembly, allowing for synchronized movement of end frame portions to form compressed or uncompressed plate packages, enabling individual plate removal and shared use across multiple heat exchangers, reducing the need for multiple drive units.

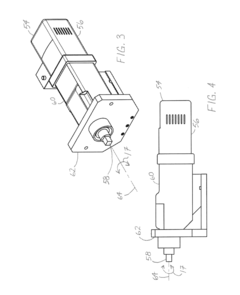

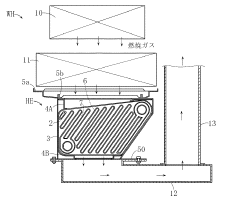

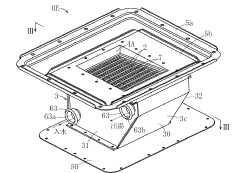

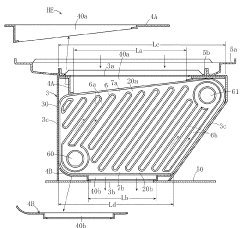

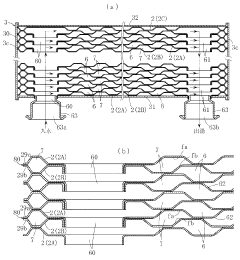

Plate type heat exchanger and hot water device including the same

PatentActiveJP2020070938A

Innovation

- A plate heat exchanger design with a smaller gas outlet opening than inlet opening, upright plates with inclined ends, and optimized liquid channels to maintain flow velocity and enhance heat exchange efficiency, while reducing size and weight, and using minimal brazing to save costs.

Total Cost of Ownership Analysis

When evaluating heat exchanger technologies, the Total Cost of Ownership (TCO) extends far beyond the initial purchase price. For plate and frame heat exchangers, the acquisition costs typically range from $5,000 to $50,000 depending on size and materials, representing a lower initial investment compared to spiral heat exchangers which generally cost between $15,000 and $100,000 for comparable capacity.

Installation expenses differ significantly between these technologies. Plate and frame units require less specialized equipment and labor, with installation costs averaging 15-25% of the purchase price. Spiral heat exchangers demand more complex installation procedures, specialized lifting equipment, and precise positioning, pushing installation costs to 25-40% of the initial investment.

Operational efficiency creates substantial long-term cost differentials. Plate and frame exchangers typically achieve U-values of 2,000-5,000 W/m²K, while spiral units operate at 1,000-3,000 W/m²K. This efficiency gap translates to energy consumption differences of 10-30% over the equipment lifecycle, with plate and frame designs generally providing lower operational costs in clean service applications.

Maintenance requirements represent another critical TCO component. Plate and frame units allow easy disassembly for cleaning and inspection, with maintenance costs averaging 5-10% of the initial price annually. Spiral heat exchangers, while requiring less frequent cleaning in fouling services, present more complex maintenance procedures when needed, with annual maintenance costs typically reaching 3-8% of the purchase price.

Lifespan considerations reveal that spiral heat exchangers generally offer 20-30 years of service with proper maintenance, compared to 15-25 years for plate and frame units. This extended operational life partially offsets the higher initial investment of spiral designs in certain applications.

Downtime costs during maintenance vary significantly. Plate and frame exchangers can often be serviced in 1-3 days, while spiral units may require 3-7 days for comparable maintenance operations. In high-value production environments, this difference can represent tens of thousands in lost production value per maintenance cycle.

Replacement part availability and costs also impact TCO calculations. Plate and frame gaskets require replacement every 2-5 years at approximately 10-15% of the initial unit cost, while spiral exchangers typically need less frequent but more expensive component replacements, averaging 15-25% of initial cost when required.

Installation expenses differ significantly between these technologies. Plate and frame units require less specialized equipment and labor, with installation costs averaging 15-25% of the purchase price. Spiral heat exchangers demand more complex installation procedures, specialized lifting equipment, and precise positioning, pushing installation costs to 25-40% of the initial investment.

Operational efficiency creates substantial long-term cost differentials. Plate and frame exchangers typically achieve U-values of 2,000-5,000 W/m²K, while spiral units operate at 1,000-3,000 W/m²K. This efficiency gap translates to energy consumption differences of 10-30% over the equipment lifecycle, with plate and frame designs generally providing lower operational costs in clean service applications.

Maintenance requirements represent another critical TCO component. Plate and frame units allow easy disassembly for cleaning and inspection, with maintenance costs averaging 5-10% of the initial price annually. Spiral heat exchangers, while requiring less frequent cleaning in fouling services, present more complex maintenance procedures when needed, with annual maintenance costs typically reaching 3-8% of the purchase price.

Lifespan considerations reveal that spiral heat exchangers generally offer 20-30 years of service with proper maintenance, compared to 15-25 years for plate and frame units. This extended operational life partially offsets the higher initial investment of spiral designs in certain applications.

Downtime costs during maintenance vary significantly. Plate and frame exchangers can often be serviced in 1-3 days, while spiral units may require 3-7 days for comparable maintenance operations. In high-value production environments, this difference can represent tens of thousands in lost production value per maintenance cycle.

Replacement part availability and costs also impact TCO calculations. Plate and frame gaskets require replacement every 2-5 years at approximately 10-15% of the initial unit cost, while spiral exchangers typically need less frequent but more expensive component replacements, averaging 15-25% of initial cost when required.

Environmental Impact and Sustainability Considerations

The environmental impact of heat exchangers is becoming increasingly important as industries strive for sustainability. Plate and frame heat exchangers demonstrate significant environmental advantages due to their compact design, which requires less material for construction and reduces the overall carbon footprint of manufacturing processes. Their smaller size also means reduced transportation emissions and less space required for installation, contributing to more efficient use of industrial facilities.

From an operational perspective, plate and frame exchangers typically achieve higher thermal efficiency with lower approach temperatures, resulting in reduced energy consumption. This energy efficiency translates directly to lower greenhouse gas emissions over the equipment's lifecycle. Additionally, their design allows for easier cleaning and maintenance, which helps maintain optimal performance and energy efficiency throughout their operational life.

Spiral heat exchangers offer different environmental benefits, particularly in applications involving fouling fluids. Their self-cleaning design reduces the frequency of chemical cleaning procedures, thereby minimizing the use of potentially harmful cleaning agents and the associated wastewater treatment requirements. This characteristic is particularly valuable in industries where environmental regulations regarding chemical discharge are becoming increasingly stringent.

Both exchanger types can be manufactured using recyclable materials such as stainless steel, contributing to circular economy principles. However, plate and frame exchangers typically contain more gaskets and seals made from elastomers or other non-metallic materials, which may present recycling challenges at end-of-life compared to the predominantly metallic construction of spiral exchangers.

Water consumption for cleaning and maintenance represents another important sustainability consideration. Spiral heat exchangers generally require less frequent cleaning and potentially less water usage for maintenance operations in fouling applications, while plate and frame units may require more regular cleaning but can be disassembled for more thorough and efficient cleaning processes.

From a refrigerant perspective, both exchanger types can be designed to work with natural refrigerants or low-GWP (Global Warming Potential) alternatives, supporting the global transition away from high-impact refrigerants. The higher efficiency of plate and frame units may allow for smaller refrigerant charges in some applications, reducing potential environmental impact from refrigerant leakage.

Lifecycle assessment studies indicate that the operational phase typically accounts for the largest environmental impact of heat exchangers, emphasizing the importance of selecting the most efficient technology for each specific application rather than focusing solely on manufacturing or end-of-life considerations.

From an operational perspective, plate and frame exchangers typically achieve higher thermal efficiency with lower approach temperatures, resulting in reduced energy consumption. This energy efficiency translates directly to lower greenhouse gas emissions over the equipment's lifecycle. Additionally, their design allows for easier cleaning and maintenance, which helps maintain optimal performance and energy efficiency throughout their operational life.

Spiral heat exchangers offer different environmental benefits, particularly in applications involving fouling fluids. Their self-cleaning design reduces the frequency of chemical cleaning procedures, thereby minimizing the use of potentially harmful cleaning agents and the associated wastewater treatment requirements. This characteristic is particularly valuable in industries where environmental regulations regarding chemical discharge are becoming increasingly stringent.

Both exchanger types can be manufactured using recyclable materials such as stainless steel, contributing to circular economy principles. However, plate and frame exchangers typically contain more gaskets and seals made from elastomers or other non-metallic materials, which may present recycling challenges at end-of-life compared to the predominantly metallic construction of spiral exchangers.

Water consumption for cleaning and maintenance represents another important sustainability consideration. Spiral heat exchangers generally require less frequent cleaning and potentially less water usage for maintenance operations in fouling applications, while plate and frame units may require more regular cleaning but can be disassembled for more thorough and efficient cleaning processes.

From a refrigerant perspective, both exchanger types can be designed to work with natural refrigerants or low-GWP (Global Warming Potential) alternatives, supporting the global transition away from high-impact refrigerants. The higher efficiency of plate and frame units may allow for smaller refrigerant charges in some applications, reducing potential environmental impact from refrigerant leakage.

Lifecycle assessment studies indicate that the operational phase typically accounts for the largest environmental impact of heat exchangers, emphasizing the importance of selecting the most efficient technology for each specific application rather than focusing solely on manufacturing or end-of-life considerations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!