Comparing PNP Transistors vs NPN Transistors: Which to Use?

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Transistor Evolution

The evolution of transistors has been a cornerstone in the development of modern electronics. From their inception in the mid-20th century to the present day, transistors have undergone significant transformations, leading to the diverse array of options available today, including PNP and NPN transistors.

The journey began with the invention of the point-contact transistor in 1947 by John Bardeen, Walter Brattain, and William Shockley at Bell Labs. This breakthrough marked the beginning of the semiconductor era, revolutionizing the field of electronics. However, the point-contact transistor was quickly superseded by the more reliable and easier-to-manufacture bipolar junction transistor (BJT) in 1948.

The introduction of BJTs paved the way for the development of PNP and NPN transistors. These two types of transistors, differentiated by their internal structure and charge carrier movement, became fundamental building blocks in electronic circuits. PNP transistors use holes as the majority charge carriers, while NPN transistors use electrons.

Throughout the 1950s and 1960s, continuous improvements in manufacturing processes led to enhanced performance and reliability of both PNP and NPN transistors. The development of planar technology in 1959 by Jean Hoerni at Fairchild Semiconductor was a significant milestone, allowing for more efficient mass production of transistors.

The 1970s saw the rise of metal-oxide-semiconductor field-effect transistors (MOSFETs), which offered advantages in terms of power consumption and scalability. This development did not replace BJTs but rather complemented them, as each type of transistor had its own strengths in different applications.

As technology progressed, the miniaturization of transistors became a key focus. The advent of integrated circuits in the late 1950s and their rapid development in subsequent decades led to the ability to pack thousands, then millions, and eventually billions of transistors onto a single chip. This trend, famously described by Moore's Law, has been a driving force in the continuous improvement of electronic devices.

In recent years, the evolution of transistors has focused on overcoming physical limitations and exploring new materials and designs. Advanced manufacturing techniques have allowed for the creation of transistors at the nanoscale, pushing the boundaries of what is possible in terms of performance and energy efficiency.

The ongoing development of transistor technology continues to shape the landscape of electronics, influencing the choice between PNP and NPN transistors in various applications. As we look to the future, emerging technologies such as quantum computing and neuromorphic computing may introduce new paradigms in transistor design and usage, potentially redefining the roles of PNP and NPN transistors in electronic systems.

The journey began with the invention of the point-contact transistor in 1947 by John Bardeen, Walter Brattain, and William Shockley at Bell Labs. This breakthrough marked the beginning of the semiconductor era, revolutionizing the field of electronics. However, the point-contact transistor was quickly superseded by the more reliable and easier-to-manufacture bipolar junction transistor (BJT) in 1948.

The introduction of BJTs paved the way for the development of PNP and NPN transistors. These two types of transistors, differentiated by their internal structure and charge carrier movement, became fundamental building blocks in electronic circuits. PNP transistors use holes as the majority charge carriers, while NPN transistors use electrons.

Throughout the 1950s and 1960s, continuous improvements in manufacturing processes led to enhanced performance and reliability of both PNP and NPN transistors. The development of planar technology in 1959 by Jean Hoerni at Fairchild Semiconductor was a significant milestone, allowing for more efficient mass production of transistors.

The 1970s saw the rise of metal-oxide-semiconductor field-effect transistors (MOSFETs), which offered advantages in terms of power consumption and scalability. This development did not replace BJTs but rather complemented them, as each type of transistor had its own strengths in different applications.

As technology progressed, the miniaturization of transistors became a key focus. The advent of integrated circuits in the late 1950s and their rapid development in subsequent decades led to the ability to pack thousands, then millions, and eventually billions of transistors onto a single chip. This trend, famously described by Moore's Law, has been a driving force in the continuous improvement of electronic devices.

In recent years, the evolution of transistors has focused on overcoming physical limitations and exploring new materials and designs. Advanced manufacturing techniques have allowed for the creation of transistors at the nanoscale, pushing the boundaries of what is possible in terms of performance and energy efficiency.

The ongoing development of transistor technology continues to shape the landscape of electronics, influencing the choice between PNP and NPN transistors in various applications. As we look to the future, emerging technologies such as quantum computing and neuromorphic computing may introduce new paradigms in transistor design and usage, potentially redefining the roles of PNP and NPN transistors in electronic systems.

Market Demand Analysis

The market demand for transistors, including both PNP and NPN types, continues to grow steadily due to the increasing complexity and miniaturization of electronic devices. The global transistor market is expected to reach significant value in the coming years, driven by the expansion of consumer electronics, automotive electronics, and industrial automation sectors.

PNP and NPN transistors serve complementary roles in circuit design, with each type having specific advantages in different applications. The demand for PNP transistors is particularly strong in analog circuits, power management systems, and high-frequency applications. These transistors are valued for their ability to handle high voltages and their suitability for use in current source configurations.

On the other hand, NPN transistors dominate the market in terms of volume due to their widespread use in digital circuits, amplifiers, and switching applications. The higher electron mobility in NPN transistors makes them preferred for high-speed operations, contributing to their popularity in computer and telecommunications equipment.

The automotive industry is a significant driver of demand for both PNP and NPN transistors. As vehicles become more electrified and incorporate advanced driver assistance systems (ADAS), the need for reliable and efficient transistors increases. PNP transistors find applications in power management and motor control circuits, while NPN transistors are crucial in sensor interfaces and signal processing units.

In the consumer electronics sector, the trend towards smaller, more powerful devices is fueling demand for both transistor types. Smartphones, tablets, and wearable devices require a mix of PNP and NPN transistors for various functions, including power management, audio amplification, and RF signal processing.

The industrial automation sector is another key market for transistors. PNP transistors are often used in proximity sensors and control systems, while NPN transistors are common in logic circuits and motor drivers. The growth of Industry 4.0 and smart manufacturing initiatives is expected to further boost demand for both transistor types in this sector.

Emerging technologies such as 5G networks, Internet of Things (IoT) devices, and artificial intelligence (AI) hardware are creating new opportunities for transistor manufacturers. These applications require high-performance transistors capable of operating at higher frequencies and with greater energy efficiency, driving innovation in both PNP and NPN designs.

The choice between PNP and NPN transistors in specific applications is influenced by factors such as circuit design requirements, power consumption, noise performance, and cost considerations. As a result, manufacturers and designers must carefully evaluate the strengths and limitations of each type to optimize their products for performance and market competitiveness.

PNP and NPN transistors serve complementary roles in circuit design, with each type having specific advantages in different applications. The demand for PNP transistors is particularly strong in analog circuits, power management systems, and high-frequency applications. These transistors are valued for their ability to handle high voltages and their suitability for use in current source configurations.

On the other hand, NPN transistors dominate the market in terms of volume due to their widespread use in digital circuits, amplifiers, and switching applications. The higher electron mobility in NPN transistors makes them preferred for high-speed operations, contributing to their popularity in computer and telecommunications equipment.

The automotive industry is a significant driver of demand for both PNP and NPN transistors. As vehicles become more electrified and incorporate advanced driver assistance systems (ADAS), the need for reliable and efficient transistors increases. PNP transistors find applications in power management and motor control circuits, while NPN transistors are crucial in sensor interfaces and signal processing units.

In the consumer electronics sector, the trend towards smaller, more powerful devices is fueling demand for both transistor types. Smartphones, tablets, and wearable devices require a mix of PNP and NPN transistors for various functions, including power management, audio amplification, and RF signal processing.

The industrial automation sector is another key market for transistors. PNP transistors are often used in proximity sensors and control systems, while NPN transistors are common in logic circuits and motor drivers. The growth of Industry 4.0 and smart manufacturing initiatives is expected to further boost demand for both transistor types in this sector.

Emerging technologies such as 5G networks, Internet of Things (IoT) devices, and artificial intelligence (AI) hardware are creating new opportunities for transistor manufacturers. These applications require high-performance transistors capable of operating at higher frequencies and with greater energy efficiency, driving innovation in both PNP and NPN designs.

The choice between PNP and NPN transistors in specific applications is influenced by factors such as circuit design requirements, power consumption, noise performance, and cost considerations. As a result, manufacturers and designers must carefully evaluate the strengths and limitations of each type to optimize their products for performance and market competitiveness.

PNP vs NPN Challenges

When comparing PNP and NPN transistors, several key challenges emerge that influence their selection and application in electronic circuits. One of the primary challenges is the difference in charge carrier movement. In PNP transistors, holes are the majority carriers, while in NPN transistors, electrons are the majority carriers. This fundamental distinction affects the direction of current flow and voltage polarities, requiring careful consideration in circuit design.

Power supply requirements present another significant challenge. PNP transistors typically require a negative voltage supply, while NPN transistors operate with a positive voltage supply. This difference can impact the overall power management strategy and component selection in a circuit, especially when dealing with mixed-signal designs or systems with multiple power domains.

The availability and cost of components also pose challenges. Historically, NPN transistors have been more readily available and less expensive than their PNP counterparts. This disparity in availability can influence design decisions, particularly in high-volume production scenarios where cost and supply chain reliability are critical factors.

Performance characteristics differ between PNP and NPN transistors, presenting additional challenges. NPN transistors generally offer higher switching speeds and better high-frequency performance compared to PNP transistors. This performance gap can be a crucial consideration in applications requiring rapid switching or high-frequency operation, such as in RF circuits or high-speed digital systems.

Heat dissipation and thermal management also present challenges when comparing PNP and NPN transistors. Due to differences in charge carrier mobility, PNP transistors typically generate more heat than NPN transistors under similar operating conditions. This thermal behavior necessitates careful consideration in circuit layout and cooling strategies, especially in high-power applications.

Noise performance is another area where challenges arise. PNP transistors often exhibit higher noise levels compared to NPN transistors, which can be problematic in sensitive analog circuits or low-noise amplifier designs. This difference in noise characteristics requires designers to carefully evaluate the trade-offs between using PNP or NPN transistors in noise-critical applications.

Lastly, the integration of PNP and NPN transistors in complementary designs presents its own set of challenges. While complementary circuits can offer advantages in terms of power efficiency and circuit simplicity, they also require careful matching of PNP and NPN characteristics to achieve optimal performance. This matching process can be complex and time-consuming, particularly in precision analog applications or when designing integrated circuits.

Power supply requirements present another significant challenge. PNP transistors typically require a negative voltage supply, while NPN transistors operate with a positive voltage supply. This difference can impact the overall power management strategy and component selection in a circuit, especially when dealing with mixed-signal designs or systems with multiple power domains.

The availability and cost of components also pose challenges. Historically, NPN transistors have been more readily available and less expensive than their PNP counterparts. This disparity in availability can influence design decisions, particularly in high-volume production scenarios where cost and supply chain reliability are critical factors.

Performance characteristics differ between PNP and NPN transistors, presenting additional challenges. NPN transistors generally offer higher switching speeds and better high-frequency performance compared to PNP transistors. This performance gap can be a crucial consideration in applications requiring rapid switching or high-frequency operation, such as in RF circuits or high-speed digital systems.

Heat dissipation and thermal management also present challenges when comparing PNP and NPN transistors. Due to differences in charge carrier mobility, PNP transistors typically generate more heat than NPN transistors under similar operating conditions. This thermal behavior necessitates careful consideration in circuit layout and cooling strategies, especially in high-power applications.

Noise performance is another area where challenges arise. PNP transistors often exhibit higher noise levels compared to NPN transistors, which can be problematic in sensitive analog circuits or low-noise amplifier designs. This difference in noise characteristics requires designers to carefully evaluate the trade-offs between using PNP or NPN transistors in noise-critical applications.

Lastly, the integration of PNP and NPN transistors in complementary designs presents its own set of challenges. While complementary circuits can offer advantages in terms of power efficiency and circuit simplicity, they also require careful matching of PNP and NPN characteristics to achieve optimal performance. This matching process can be complex and time-consuming, particularly in precision analog applications or when designing integrated circuits.

Current Transistor Apps

01 Structure and fabrication of PNP and NPN transistors

PNP and NPN transistors are fundamental semiconductor devices with different structures and fabrication processes. PNP transistors consist of a P-type emitter, N-type base, and P-type collector, while NPN transistors have an N-type emitter, P-type base, and N-type collector. The fabrication process involves doping, epitaxial growth, and various other techniques to create the desired structure and electrical characteristics.- Structural differences between PNP and NPN transistors: PNP and NPN transistors have different structures and doping configurations. PNP transistors consist of a layer of N-type semiconductor between two P-type layers, while NPN transistors have a P-type layer between two N-type layers. This fundamental difference affects their operation and applications in electronic circuits.

- Manufacturing processes for PNP and NPN transistors: Various manufacturing techniques are employed to create PNP and NPN transistors, including epitaxial growth, ion implantation, and diffusion processes. These methods allow for precise control of doping profiles and junction characteristics, enabling the production of high-performance transistors for different applications.

- Applications of PNP and NPN transistors in electronic circuits: PNP and NPN transistors are used in a wide range of electronic circuits, including amplifiers, switches, and logic gates. Their complementary nature allows for the design of push-pull amplifiers and other efficient circuit configurations. The choice between PNP and NPN transistors depends on the specific requirements of the application.

- Integration of PNP and NPN transistors in semiconductor devices: Modern semiconductor devices often integrate both PNP and NPN transistors on the same chip, enabling the creation of complex circuits with complementary functionality. This integration presents challenges in terms of fabrication processes and device isolation but allows for more compact and efficient electronic systems.

- Performance characteristics and optimization of PNP and NPN transistors: The performance of PNP and NPN transistors can be optimized through various techniques, including adjusting doping profiles, improving contact structures, and refining device geometries. These optimizations aim to enhance parameters such as current gain, switching speed, and power handling capabilities, tailoring the transistors for specific applications.

02 Applications of PNP and NPN transistors in electronic circuits

PNP and NPN transistors are widely used in various electronic circuits for amplification, switching, and signal processing. They are essential components in analog and digital circuits, power supplies, and communication systems. The choice between PNP and NPN transistors depends on the specific circuit requirements and design considerations.Expand Specific Solutions03 Complementary PNP and NPN transistor configurations

Complementary PNP and NPN transistor configurations, such as complementary bipolar transistors (CBT) and complementary metal-oxide-semiconductor (CMOS) structures, are used to improve circuit performance and reduce power consumption. These configurations utilize both PNP and NPN transistors in a single device or circuit to achieve better symmetry and efficiency.Expand Specific Solutions04 Integration of PNP and NPN transistors in integrated circuits

The integration of PNP and NPN transistors in integrated circuits (ICs) is crucial for creating complex electronic systems on a single chip. This integration involves optimizing the fabrication process to accommodate both transistor types, managing parasitic effects, and ensuring proper isolation between devices. Advanced IC designs often incorporate both PNP and NPN transistors to achieve desired functionality and performance.Expand Specific Solutions05 Performance optimization and characterization of PNP and NPN transistors

Optimizing the performance of PNP and NPN transistors involves various techniques such as adjusting doping profiles, improving contact resistance, and enhancing carrier mobility. Characterization methods are used to measure and analyze important parameters like current gain, breakdown voltage, and frequency response. These efforts aim to improve the overall efficiency and reliability of transistor-based electronic devices and systems.Expand Specific Solutions

Key Semiconductor Players

The competition landscape for PNP vs NPN transistors is characterized by a mature market with established players and widespread adoption across various industries. The global transistor market, including both PNP and NPN types, is substantial, with key players like Infineon Technologies, ROHM, Texas Instruments, and NXP leading the field. These companies, along with others such as ON Semiconductor and STMicroelectronics, have developed advanced manufacturing processes and offer a wide range of transistor products. The technology is well-established, with ongoing innovations focusing on improving performance, reducing size, and enhancing energy efficiency. Both PNP and NPN transistors continue to be crucial components in electronic circuits, with selection depending on specific application requirements.

Infineon Technologies AG

Technical Solution: Infineon Technologies has developed cutting-edge BJT solutions for both PNP and NPN configurations. Their approach focuses on high-reliability and high-performance transistors for automotive, industrial, and consumer electronics applications. Infineon's PNP transistors utilize advanced vertical structures with optimized doping profiles, resulting in improved current handling capabilities and reduced on-state resistance[7]. For NPN transistors, Infineon employs innovative collector designs that enhance breakdown voltage and switching performance[8]. The company's BJTs typically feature current gains (hFE) ranging from 100 to 500, with some specialized high-gain devices exceeding 800. Infineon also offers transistors with integrated ESD protection and temperature sensing capabilities for robust system designs[9].

Strengths: High-reliability solutions, excellent performance in harsh environments, and integrated protection features. Weaknesses: Potentially higher cost for specialized devices, and may be overspecified for simple applications.

ROHM Co., Ltd.

Technical Solution: ROHM has developed a comprehensive line of BJT solutions, offering both PNP and NPN transistors with a focus on miniaturization and high-efficiency performance. Their approach emphasizes low saturation voltage and high-speed switching capabilities. ROHM's PNP transistors utilize advanced vertical structures with optimized base widths, resulting in improved current gain and reduced parasitic capacitances[13]. For NPN transistors, ROHM employs innovative collector designs that enhance breakdown voltage and reduce on-resistance[14]. The company's BJTs typically feature current gains (hFE) ranging from 70 to 600, with some specialized devices offering gains over 800. ROHM also provides ultra-compact packages, such as their PMDE series, which are up to 53% smaller than conventional packages while maintaining high power dissipation capabilities[15].

Strengths: Excellent miniaturization options, low saturation voltage designs, and high-speed switching capabilities. Weaknesses: Some ultra-compact packages may have thermal management challenges in high-power applications, and specialized devices might have higher costs.

Core PNP/NPN Innovations

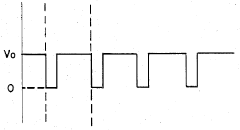

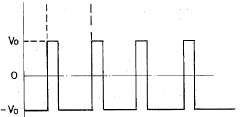

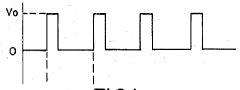

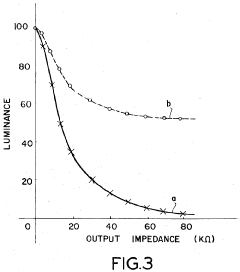

Driving circuit for a plasma display panel comprising PNP and NPN transistors

PatentInactiveUS3808501A

Innovation

- A circuit arrangement using a combination of PNP and NPN transistors with control signal generating means to deliver high-frequency pulse voltage to plasma discharge cells, ensuring negligible output impedance and maximizing the slope of the discharge starting pulse for enhanced luminance.

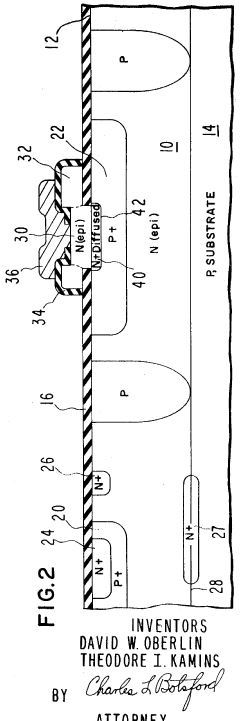

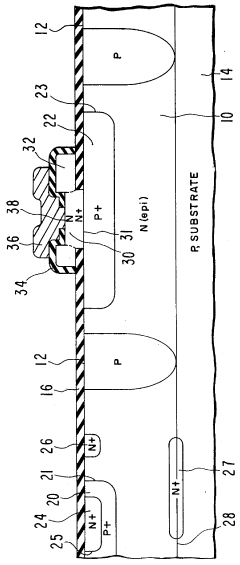

Complementary NPN/PNP structure for monolithic integrated circuits

PatentInactiveUS3611067A

Innovation

- A semiconductor substrate is divided into isolated areas with a double-diffused NPN transistor and a PNP transistor featuring a diffused emitter, an epitaxial base, and a Schottky-barrier collector-base junction, where the emitter of the PNP transistor is formed during the base diffusion of the NPN transistor, avoiding additional high-temperature processing steps and enabling a vertical structure for the PNP transistor with a frequency response of up to 50 MegaHertz.

Design Considerations

When considering the choice between PNP and NPN transistors in circuit design, several key factors come into play. The primary distinction lies in their current flow direction and voltage polarity requirements, which significantly impact their application in various electronic systems.

For NPN transistors, the current flows from the collector to the emitter when a positive voltage is applied to the base. This makes them ideal for low-side switching applications, where the load is connected between the power supply and the transistor. NPN transistors are generally preferred in digital circuits due to their faster switching speeds and lower on-resistance, resulting in improved efficiency and performance.

PNP transistors, conversely, conduct current from the emitter to the collector when a negative voltage is applied to the base. They are commonly used in high-side switching applications, where the load is connected between the transistor and ground. PNP transistors often find use in power supply circuits and analog amplifiers, particularly in situations where a positive ground is required.

The choice between PNP and NPN transistors also depends on the available power supply voltages in the system. NPN transistors are typically easier to use with positive voltage supplies, while PNP transistors are more suitable for negative voltage supplies. This consideration is crucial in battery-powered devices or systems with specific power constraints.

Temperature sensitivity is another factor to consider. NPN transistors generally exhibit better temperature stability compared to their PNP counterparts, making them more suitable for applications where consistent performance across varying temperatures is critical.

Noise characteristics differ between the two types as well. NPN transistors tend to have lower noise levels, making them preferable in low-noise amplifier designs and sensitive analog circuits. PNP transistors, while slightly noisier, can still be effectively used in many analog applications with proper circuit design techniques.

The availability and cost of components also play a role in the selection process. NPN transistors are more widely available and often less expensive due to their higher production volumes, which can be a deciding factor in large-scale manufacturing or cost-sensitive projects.

Ultimately, the decision between PNP and NPN transistors should be based on a thorough analysis of the specific circuit requirements, including voltage levels, current flow, switching speed, noise tolerance, and overall system architecture. In many cases, a combination of both types may be used to optimize circuit performance and functionality.

For NPN transistors, the current flows from the collector to the emitter when a positive voltage is applied to the base. This makes them ideal for low-side switching applications, where the load is connected between the power supply and the transistor. NPN transistors are generally preferred in digital circuits due to their faster switching speeds and lower on-resistance, resulting in improved efficiency and performance.

PNP transistors, conversely, conduct current from the emitter to the collector when a negative voltage is applied to the base. They are commonly used in high-side switching applications, where the load is connected between the transistor and ground. PNP transistors often find use in power supply circuits and analog amplifiers, particularly in situations where a positive ground is required.

The choice between PNP and NPN transistors also depends on the available power supply voltages in the system. NPN transistors are typically easier to use with positive voltage supplies, while PNP transistors are more suitable for negative voltage supplies. This consideration is crucial in battery-powered devices or systems with specific power constraints.

Temperature sensitivity is another factor to consider. NPN transistors generally exhibit better temperature stability compared to their PNP counterparts, making them more suitable for applications where consistent performance across varying temperatures is critical.

Noise characteristics differ between the two types as well. NPN transistors tend to have lower noise levels, making them preferable in low-noise amplifier designs and sensitive analog circuits. PNP transistors, while slightly noisier, can still be effectively used in many analog applications with proper circuit design techniques.

The availability and cost of components also play a role in the selection process. NPN transistors are more widely available and often less expensive due to their higher production volumes, which can be a deciding factor in large-scale manufacturing or cost-sensitive projects.

Ultimately, the decision between PNP and NPN transistors should be based on a thorough analysis of the specific circuit requirements, including voltage levels, current flow, switching speed, noise tolerance, and overall system architecture. In many cases, a combination of both types may be used to optimize circuit performance and functionality.

Performance Benchmarking

Performance benchmarking is a critical aspect when comparing PNP and NPN transistors to determine which type is more suitable for specific applications. Both transistor types have distinct characteristics that influence their performance in various circuit designs.

NPN transistors generally exhibit higher switching speeds compared to PNP transistors. This advantage is primarily due to the higher mobility of electrons (the majority carriers in NPN) compared to holes (the majority carriers in PNP). As a result, NPN transistors are often preferred in high-frequency applications where rapid switching is essential.

In terms of current handling capacity, NPN transistors typically outperform their PNP counterparts. This superiority is attributed to the larger emitter area that can be achieved in NPN designs, allowing for higher current flow. Consequently, NPN transistors are commonly used in power amplification stages and other high-current applications.

Voltage breakdown characteristics also differ between the two transistor types. NPN transistors generally have higher breakdown voltages, making them more suitable for high-voltage applications. This property is particularly advantageous in power supply circuits and voltage regulation systems.

When considering noise performance, PNP transistors often have a slight edge over NPN transistors. The lower noise figure of PNP devices makes them preferable in low-noise amplifier designs, especially in audio and sensitive instrumentation applications.

Temperature stability is another crucial factor in transistor performance. NPN transistors typically demonstrate better temperature stability compared to PNP transistors. This characteristic makes NPN devices more reliable in circuits exposed to varying temperature conditions, such as automotive electronics or industrial control systems.

Power dissipation capabilities also differ between the two transistor types. NPN transistors generally have superior power handling capabilities, allowing them to operate efficiently in high-power applications. This advantage is particularly evident in power amplifiers and voltage regulators.

In terms of input impedance, PNP transistors often exhibit higher values compared to NPN transistors. This property can be beneficial in certain circuit designs where minimal loading of the input signal is desired, such as in some sensor interfaces or signal conditioning stages.

Gain characteristics also play a role in transistor selection. While both types can achieve similar current gains (hFE), NPN transistors typically offer higher transconductance (gm) values. This property contributes to their superior performance in high-frequency amplification and switching applications.

When considering ease of integration, NPN transistors have historically been favored in integrated circuit designs. The manufacturing processes for NPN transistors are generally simpler and more cost-effective, leading to their widespread use in various semiconductor devices.

NPN transistors generally exhibit higher switching speeds compared to PNP transistors. This advantage is primarily due to the higher mobility of electrons (the majority carriers in NPN) compared to holes (the majority carriers in PNP). As a result, NPN transistors are often preferred in high-frequency applications where rapid switching is essential.

In terms of current handling capacity, NPN transistors typically outperform their PNP counterparts. This superiority is attributed to the larger emitter area that can be achieved in NPN designs, allowing for higher current flow. Consequently, NPN transistors are commonly used in power amplification stages and other high-current applications.

Voltage breakdown characteristics also differ between the two transistor types. NPN transistors generally have higher breakdown voltages, making them more suitable for high-voltage applications. This property is particularly advantageous in power supply circuits and voltage regulation systems.

When considering noise performance, PNP transistors often have a slight edge over NPN transistors. The lower noise figure of PNP devices makes them preferable in low-noise amplifier designs, especially in audio and sensitive instrumentation applications.

Temperature stability is another crucial factor in transistor performance. NPN transistors typically demonstrate better temperature stability compared to PNP transistors. This characteristic makes NPN devices more reliable in circuits exposed to varying temperature conditions, such as automotive electronics or industrial control systems.

Power dissipation capabilities also differ between the two transistor types. NPN transistors generally have superior power handling capabilities, allowing them to operate efficiently in high-power applications. This advantage is particularly evident in power amplifiers and voltage regulators.

In terms of input impedance, PNP transistors often exhibit higher values compared to NPN transistors. This property can be beneficial in certain circuit designs where minimal loading of the input signal is desired, such as in some sensor interfaces or signal conditioning stages.

Gain characteristics also play a role in transistor selection. While both types can achieve similar current gains (hFE), NPN transistors typically offer higher transconductance (gm) values. This property contributes to their superior performance in high-frequency amplification and switching applications.

When considering ease of integration, NPN transistors have historically been favored in integrated circuit designs. The manufacturing processes for NPN transistors are generally simpler and more cost-effective, leading to their widespread use in various semiconductor devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!