Comparison of Green Ammonia vs. Fossil-Based Synthesis Techniques

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Green Ammonia Evolution and Objectives

Ammonia production has been a cornerstone of industrial chemistry since the early 20th century, with the Haber-Bosch process revolutionizing fertilizer production and supporting global food security. This fossil-based synthesis technique has dominated the industry for over a century, utilizing natural gas or coal as feedstock and producing significant carbon emissions. The conventional process typically generates 1.8-3.0 tons of CO2 per ton of ammonia produced, contributing approximately 1.8% of global CO2 emissions.

Green ammonia represents a paradigm shift in this established industry, defined by production methods that eliminate carbon emissions through the use of renewable energy sources. The concept emerged in the early 2000s but gained significant momentum after the 2015 Paris Climate Agreement, which catalyzed research into decarbonization strategies across major industries. Green ammonia utilizes hydrogen produced via water electrolysis powered by renewable electricity, combined with nitrogen separated from air, fundamentally altering the carbon footprint of ammonia production.

The evolution of green ammonia technology has accelerated dramatically in recent years, with pilot projects expanding from laboratory scale to industrial demonstrations. Between 2018 and 2023, announced green ammonia production capacity grew from negligible levels to over 30 million tons per annum in planned projects worldwide. This rapid scaling reflects both technological advancements and increasing recognition of ammonia's potential as an energy carrier and carbon-free fuel.

The primary objective driving green ammonia development is environmental sustainability, specifically the reduction of greenhouse gas emissions associated with conventional ammonia production. Secondary objectives include energy independence, as green ammonia production can utilize locally available renewable resources rather than imported fossil fuels. Additionally, green ammonia presents opportunities for energy storage and transport, potentially serving as a hydrogen carrier in the emerging hydrogen economy.

Technical objectives focus on improving electrolysis efficiency, reducing capital costs, and developing integrated systems that optimize the interface between variable renewable energy sources and ammonia synthesis requirements. Economic viability remains a critical goal, with current green ammonia production costs approximately 2-4 times higher than conventional methods, though this gap is expected to narrow significantly by 2030 as renewable electricity costs continue to decline and carbon pricing mechanisms mature.

The trajectory of green ammonia technology suggests a transition period where both conventional and green production methods will coexist, with green ammonia gradually capturing market share as technology improves and policy support strengthens. The ultimate objective is complete replacement of fossil-based ammonia production, representing one of the most significant industrial decarbonization opportunities of the 21st century.

Green ammonia represents a paradigm shift in this established industry, defined by production methods that eliminate carbon emissions through the use of renewable energy sources. The concept emerged in the early 2000s but gained significant momentum after the 2015 Paris Climate Agreement, which catalyzed research into decarbonization strategies across major industries. Green ammonia utilizes hydrogen produced via water electrolysis powered by renewable electricity, combined with nitrogen separated from air, fundamentally altering the carbon footprint of ammonia production.

The evolution of green ammonia technology has accelerated dramatically in recent years, with pilot projects expanding from laboratory scale to industrial demonstrations. Between 2018 and 2023, announced green ammonia production capacity grew from negligible levels to over 30 million tons per annum in planned projects worldwide. This rapid scaling reflects both technological advancements and increasing recognition of ammonia's potential as an energy carrier and carbon-free fuel.

The primary objective driving green ammonia development is environmental sustainability, specifically the reduction of greenhouse gas emissions associated with conventional ammonia production. Secondary objectives include energy independence, as green ammonia production can utilize locally available renewable resources rather than imported fossil fuels. Additionally, green ammonia presents opportunities for energy storage and transport, potentially serving as a hydrogen carrier in the emerging hydrogen economy.

Technical objectives focus on improving electrolysis efficiency, reducing capital costs, and developing integrated systems that optimize the interface between variable renewable energy sources and ammonia synthesis requirements. Economic viability remains a critical goal, with current green ammonia production costs approximately 2-4 times higher than conventional methods, though this gap is expected to narrow significantly by 2030 as renewable electricity costs continue to decline and carbon pricing mechanisms mature.

The trajectory of green ammonia technology suggests a transition period where both conventional and green production methods will coexist, with green ammonia gradually capturing market share as technology improves and policy support strengthens. The ultimate objective is complete replacement of fossil-based ammonia production, representing one of the most significant industrial decarbonization opportunities of the 21st century.

Market Demand Analysis for Sustainable Ammonia

The global ammonia market is experiencing a significant shift towards sustainable production methods, driven by increasing environmental concerns and regulatory pressures. Traditional fossil-based ammonia production accounts for approximately 1.8% of global CO2 emissions, creating an urgent need for greener alternatives. Market research indicates that the sustainable ammonia market is projected to grow at a compound annual growth rate of 9.5% through 2030, substantially outpacing the conventional ammonia market's growth rate of 3.2%.

This accelerated growth is primarily fueled by the expanding application of ammonia as a carbon-free energy carrier and potential fuel for shipping and power generation. The International Energy Agency has identified ammonia as one of the most promising hydrogen carriers for long-distance transport, creating additional demand beyond traditional fertilizer applications which currently consume about 80% of global ammonia production.

Industrial sectors are increasingly committing to carbon neutrality targets, with major players like BASF, Yara, and CF Industries announcing significant investments in green ammonia production facilities. These commitments are reshaping market dynamics and creating new demand segments for sustainable ammonia.

Regional analysis reveals varying demand patterns, with Europe leading in policy support through initiatives like the European Green Deal and the Hydrogen Strategy. The Asia-Pacific region, particularly Japan and South Korea, is emerging as a significant market for green ammonia as a marine fuel and power generation feedstock, driven by limited domestic renewable energy resources and strong decarbonization commitments.

Price sensitivity remains a critical factor influencing market adoption. Currently, green ammonia production costs range between $600-1,200 per ton, compared to $200-450 per ton for conventional ammonia. However, this gap is expected to narrow significantly by 2030 as renewable electricity costs decline and electrolyzer technologies mature, potentially reaching cost parity in regions with abundant renewable resources.

End-user industries are demonstrating increasing willingness to pay premium prices for sustainable ammonia, particularly in sectors facing stringent emission regulations or consumer pressure for sustainable products. Survey data indicates that 67% of large agricultural cooperatives and fertilizer distributors are exploring green ammonia options to meet sustainability commitments, despite current price premiums.

The market is also witnessing the emergence of innovative business models, including ammonia offtake agreements and green premium structures, designed to bridge the current cost gap while supporting the scaling of production capacity. These developments suggest a robust and growing market demand for sustainable ammonia across multiple sectors.

This accelerated growth is primarily fueled by the expanding application of ammonia as a carbon-free energy carrier and potential fuel for shipping and power generation. The International Energy Agency has identified ammonia as one of the most promising hydrogen carriers for long-distance transport, creating additional demand beyond traditional fertilizer applications which currently consume about 80% of global ammonia production.

Industrial sectors are increasingly committing to carbon neutrality targets, with major players like BASF, Yara, and CF Industries announcing significant investments in green ammonia production facilities. These commitments are reshaping market dynamics and creating new demand segments for sustainable ammonia.

Regional analysis reveals varying demand patterns, with Europe leading in policy support through initiatives like the European Green Deal and the Hydrogen Strategy. The Asia-Pacific region, particularly Japan and South Korea, is emerging as a significant market for green ammonia as a marine fuel and power generation feedstock, driven by limited domestic renewable energy resources and strong decarbonization commitments.

Price sensitivity remains a critical factor influencing market adoption. Currently, green ammonia production costs range between $600-1,200 per ton, compared to $200-450 per ton for conventional ammonia. However, this gap is expected to narrow significantly by 2030 as renewable electricity costs decline and electrolyzer technologies mature, potentially reaching cost parity in regions with abundant renewable resources.

End-user industries are demonstrating increasing willingness to pay premium prices for sustainable ammonia, particularly in sectors facing stringent emission regulations or consumer pressure for sustainable products. Survey data indicates that 67% of large agricultural cooperatives and fertilizer distributors are exploring green ammonia options to meet sustainability commitments, despite current price premiums.

The market is also witnessing the emergence of innovative business models, including ammonia offtake agreements and green premium structures, designed to bridge the current cost gap while supporting the scaling of production capacity. These developments suggest a robust and growing market demand for sustainable ammonia across multiple sectors.

Technical Status and Barriers in Ammonia Synthesis

Ammonia synthesis technology has evolved significantly since the development of the Haber-Bosch process in the early 20th century. Currently, approximately 80% of global ammonia production relies on fossil fuel-based methods, primarily using natural gas as feedstock. The conventional process operates at high temperatures (400-500°C) and pressures (100-300 bar), requiring substantial energy input and generating significant carbon emissions—approximately 1.8 tons of CO2 per ton of ammonia produced.

Green ammonia synthesis technologies are emerging as promising alternatives but remain at various stages of technological readiness. Electrolysis-based methods using renewable electricity have reached pilot scale demonstrations, while solid-state ammonia synthesis and photocatalytic approaches remain largely in laboratory research phases. The technical efficiency of green methods currently ranges from 40-60% compared to conventional processes, presenting a significant barrier to widespread adoption.

A critical challenge in ammonia synthesis is the energy intensity of nitrogen fixation. Breaking the triple bond in N₂ molecules requires substantial energy input, which conventional systems address through high-pressure, high-temperature conditions. Green ammonia technologies face additional challenges in achieving stable catalytic performance under variable renewable energy inputs and maintaining efficiency at scale.

Catalyst development represents another significant barrier. While conventional synthesis relies on iron-based catalysts, green ammonia approaches require novel materials that can operate at lower temperatures and pressures. Current research focuses on ruthenium-based catalysts, metal nitrides, and advanced nanomaterials, but these alternatives often involve rare elements with limited availability and high costs.

Geographically, conventional ammonia technology is concentrated in regions with abundant natural gas resources, including North America, Russia, and the Middle East. Green ammonia research and pilot projects are primarily located in countries with strong renewable energy sectors, such as Australia, Japan, Denmark, and Germany. This geographic distribution reflects both resource availability and policy environments supporting decarbonization initiatives.

Infrastructure compatibility presents another significant barrier. Existing ammonia production facilities represent massive capital investments optimized for fossil-based synthesis. Retrofitting these facilities for green ammonia production or building entirely new infrastructure requires substantial investment and faces economic hurdles given the current cost differential between conventional and green production methods.

Water electrolysis, a key component of most green ammonia pathways, faces its own technical challenges, including electrode degradation, membrane durability issues, and efficiency losses. Improvements in electrolyzer technology are progressing rapidly but remain a limiting factor in the overall system efficiency of green ammonia production.

Green ammonia synthesis technologies are emerging as promising alternatives but remain at various stages of technological readiness. Electrolysis-based methods using renewable electricity have reached pilot scale demonstrations, while solid-state ammonia synthesis and photocatalytic approaches remain largely in laboratory research phases. The technical efficiency of green methods currently ranges from 40-60% compared to conventional processes, presenting a significant barrier to widespread adoption.

A critical challenge in ammonia synthesis is the energy intensity of nitrogen fixation. Breaking the triple bond in N₂ molecules requires substantial energy input, which conventional systems address through high-pressure, high-temperature conditions. Green ammonia technologies face additional challenges in achieving stable catalytic performance under variable renewable energy inputs and maintaining efficiency at scale.

Catalyst development represents another significant barrier. While conventional synthesis relies on iron-based catalysts, green ammonia approaches require novel materials that can operate at lower temperatures and pressures. Current research focuses on ruthenium-based catalysts, metal nitrides, and advanced nanomaterials, but these alternatives often involve rare elements with limited availability and high costs.

Geographically, conventional ammonia technology is concentrated in regions with abundant natural gas resources, including North America, Russia, and the Middle East. Green ammonia research and pilot projects are primarily located in countries with strong renewable energy sectors, such as Australia, Japan, Denmark, and Germany. This geographic distribution reflects both resource availability and policy environments supporting decarbonization initiatives.

Infrastructure compatibility presents another significant barrier. Existing ammonia production facilities represent massive capital investments optimized for fossil-based synthesis. Retrofitting these facilities for green ammonia production or building entirely new infrastructure requires substantial investment and faces economic hurdles given the current cost differential between conventional and green production methods.

Water electrolysis, a key component of most green ammonia pathways, faces its own technical challenges, including electrode degradation, membrane durability issues, and efficiency losses. Improvements in electrolyzer technology are progressing rapidly but remain a limiting factor in the overall system efficiency of green ammonia production.

Current Green vs. Fossil-Based Ammonia Solutions

01 Low-carbon ammonia synthesis methods

Various techniques have been developed to reduce carbon emissions in ammonia production processes. These include electrolysis-based synthesis using renewable electricity, green hydrogen utilization, and innovative catalytic processes that operate at lower temperatures and pressures than traditional Haber-Bosch. These methods significantly reduce greenhouse gas emissions associated with conventional ammonia production, which typically relies on natural gas or coal as feedstock and energy source.- Low-carbon ammonia synthesis technologies: Modern ammonia synthesis technologies focus on reducing carbon emissions by utilizing renewable energy sources and developing catalysts that operate at lower temperatures and pressures compared to traditional Haber-Bosch process. These technologies aim to minimize the carbon footprint associated with ammonia production, which traditionally accounts for significant greenhouse gas emissions. Innovations include electrolysis-based processes and systems that can operate intermittently with renewable energy inputs.

- Catalytic improvements for environmental efficiency: Advanced catalysts are being developed to improve the environmental performance of ammonia synthesis. These catalysts enable reactions at lower temperatures and pressures, reducing energy consumption and associated emissions. Innovations include novel metal compositions, support structures, and activation methods that enhance catalytic activity while minimizing environmental impact. These improvements directly address the high energy demands of traditional ammonia production processes.

- Waste reduction and circular economy approaches: Ammonia synthesis techniques are being redesigned to incorporate waste reduction principles and circular economy approaches. These methods focus on utilizing byproducts from the synthesis process, recovering heat energy, and recycling catalysts and other materials. By implementing closed-loop systems, these techniques minimize waste discharge to the environment and reduce the consumption of raw materials, thereby decreasing the overall environmental footprint of ammonia production.

- Integration with renewable energy systems: Innovative ammonia synthesis techniques are being developed to integrate with renewable energy systems, enabling the production of green ammonia. These systems utilize electricity from solar, wind, or hydroelectric sources to power electrolysis for hydrogen production, which is then combined with nitrogen for ammonia synthesis. This integration helps to balance intermittent renewable energy generation and provides a pathway for energy storage and transportation while significantly reducing greenhouse gas emissions compared to conventional fossil fuel-based production.

- Life cycle assessment and environmental monitoring: Comprehensive life cycle assessment methodologies are being implemented to evaluate the environmental impact of different ammonia synthesis techniques. These assessments consider factors such as energy consumption, greenhouse gas emissions, water usage, and potential for environmental contamination throughout the entire production chain. Advanced monitoring systems are also being developed to track emissions and environmental performance in real-time, enabling continuous improvement and regulatory compliance in ammonia production facilities.

02 Energy efficiency improvements in ammonia production

Innovations focused on reducing the energy intensity of ammonia synthesis processes help minimize environmental impact. These include advanced heat recovery systems, improved catalysts that function at lower activation energies, and process optimizations that reduce energy consumption. Such improvements directly translate to lower greenhouse gas emissions and reduced resource consumption in ammonia manufacturing facilities.Expand Specific Solutions03 Catalyst innovations for sustainable ammonia synthesis

Novel catalyst formulations enable more environmentally friendly ammonia production by increasing reaction efficiency, reducing required temperatures and pressures, and minimizing byproduct formation. These catalysts include non-noble metal alternatives, nanostructured materials, and composite systems that can operate under milder conditions. By improving catalytic performance, these innovations reduce the environmental footprint of ammonia synthesis through lower energy requirements and fewer emissions.Expand Specific Solutions04 Waste reduction and circular economy approaches

Technologies that minimize waste generation or enable waste recovery in ammonia production processes contribute to reduced environmental impact. These include closed-loop systems that recycle unreacted gases, methods for capturing and utilizing byproducts, and techniques for recovering heat and materials throughout the production chain. Such approaches align with circular economy principles by maximizing resource efficiency and minimizing discharge to the environment.Expand Specific Solutions05 Emission control and monitoring systems

Advanced systems for controlling, capturing, and monitoring emissions from ammonia synthesis facilities help mitigate environmental impacts. These technologies include selective catalytic reduction for NOx control, advanced scrubbers for particulate matter, real-time monitoring equipment, and integrated control systems that optimize process conditions to minimize emissions. Implementation of these systems ensures compliance with environmental regulations while reducing the overall ecological footprint of ammonia production.Expand Specific Solutions

Industry Leaders and Competitive Landscape

The green ammonia market is in an early growth phase, characterized by rapid technological development and increasing commercial interest as industries seek to decarbonize. The global market is projected to expand significantly, driven by clean energy transitions and stringent emissions regulations. Technologically, established players like Topsoe A/S and Air Products & Chemicals are advancing electrolysis-based green ammonia production, while academic institutions including Tianjin University and KU Leuven are researching catalytic improvements. Traditional ammonia producers such as UOP LLC and SABIC Global Technologies are adapting their fossil-based synthesis expertise toward greener alternatives. Companies like Climeworks and ACWA Power are exploring integrated renewable energy solutions, while Synata Bio is developing alternative fermentation pathways, creating a diverse competitive landscape across the green-to-conventional ammonia spectrum.

Topsoe A/S

Technical Solution: Topsoe has developed the SynCOR Ammonia™ technology, a revolutionary green ammonia synthesis process that integrates renewable hydrogen production with their proprietary solid oxide electrolyzer cells (SOEC). Their system achieves up to 88% energy efficiency compared to 76% in conventional Haber-Bosch processes. The technology incorporates a dynamic load response capability, allowing seamless integration with intermittent renewable energy sources like wind and solar. Topsoe's process operates at lower temperatures (400-450°C) than conventional methods (500°C+) and utilizes advanced catalysts that reduce the activation energy required for nitrogen fixation. Their modular design approach enables scalable implementation from small distributed facilities to large centralized production plants, with capacities ranging from 50 to 1,200 tons per day.

Strengths: Industry-leading energy efficiency (88%), excellent integration with renewable energy sources, scalable modular design, and reduced operating temperatures. Weaknesses: Higher initial capital investment compared to conventional plants, technology still being scaled to industrial levels, and requires reliable renewable energy infrastructure.

Ammonia Casale SpA

Technical Solution: Ammonia Casale has pioneered the "Casale Green Ammonia Process," which combines their proprietary axial-radial catalyst technology with renewable hydrogen production. Their system features a novel ruthenium-based catalyst that operates at pressures of 60-80 bar, significantly lower than conventional iron catalysts requiring 150-300 bar. The process incorporates a sophisticated heat recovery system that captures and reuses over 90% of process heat, dramatically improving energy efficiency. Ammonia Casale's technology includes a patented synthesis loop design that achieves conversion rates up to 25% per pass compared to 15% in traditional systems. Their process also features advanced process control systems that optimize production based on renewable energy availability, enabling dynamic operation that can adjust to fluctuating renewable inputs while maintaining stable ammonia output.

Strengths: Lower operating pressure requirements (60-80 bar vs 150-300 bar), superior heat recovery systems, higher per-pass conversion efficiency, and advanced control systems for renewable integration. Weaknesses: Higher catalyst costs due to ruthenium usage, technology primarily focused on large-scale applications with limited options for small-scale deployment.

Key Innovations in Sustainable Ammonia Production

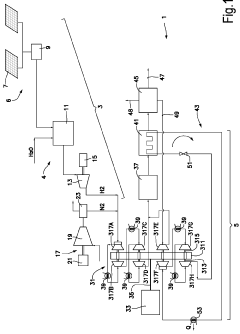

Multi-compression unit for ammonia production

PatentWO2023165739A1

Innovation

- A multi-stage compressor is used, where one set of compressor stages compresses syngas and another set compresses the refrigerant, integrated into a single unit to simplify the ammonia production system, reducing the number of compressor casings and units.

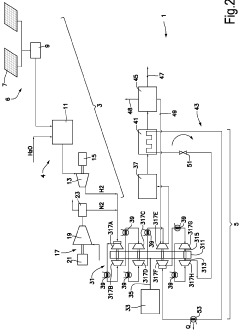

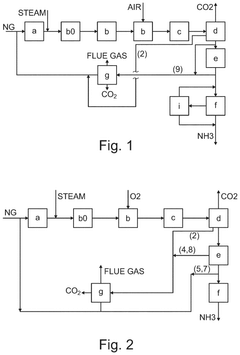

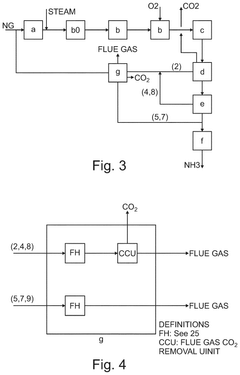

Method for production of blue ammonia

PatentPendingUS20250296845A1

Innovation

- The method involves utilizing off-gases and hydrogen-rich streams as fuel in a preheating system, reducing natural gas firing, and incorporating a CO2 capture unit in fired heaters to achieve >98% carbon recovery, thereby minimizing NOx emissions.

Environmental Impact Assessment

The environmental impact assessment of ammonia production methods reveals stark contrasts between green ammonia and fossil-based synthesis techniques. Traditional ammonia production via the Haber-Bosch process using natural gas or coal as feedstock generates significant greenhouse gas emissions, estimated at 1.8-3.0 tons of CO2 per ton of ammonia produced. This accounts for approximately 1.8% of global CO2 emissions, making conventional ammonia production one of the most carbon-intensive industrial processes worldwide.

Green ammonia production, powered by renewable electricity sources such as wind, solar, or hydropower, demonstrates substantial environmental advantages. Life cycle assessments indicate potential carbon emission reductions of 80-95% compared to fossil-based methods when utilizing fully renewable energy sources. The carbon footprint can be as low as 0.2-0.5 tons of CO2 equivalent per ton of ammonia, representing a transformative improvement in environmental performance.

Water consumption patterns also differ significantly between the two approaches. Fossil-based ammonia production requires approximately 1-3 cubic meters of water per ton of ammonia, primarily for cooling and steam generation. Green ammonia production may require additional water for electrolysis, potentially increasing water consumption to 5-10 cubic meters per ton, though this varies considerably depending on the specific technology employed and local conditions.

Air quality impacts present another critical environmental distinction. Conventional ammonia plants emit nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter, contributing to local air pollution and associated health impacts. Green ammonia production virtually eliminates these air pollutants, offering significant co-benefits for communities surrounding production facilities.

Land use considerations reveal that while green ammonia requires minimal direct land for production facilities, the renewable energy infrastructure needed to power electrolysis can have substantial land requirements. Wind farms may require 30-140 km² per GW of capacity, while solar installations need approximately 20-50 km² per GW, depending on technology and location specifics.

Resource efficiency metrics indicate that fossil-based ammonia production consumes approximately 28-37 GJ of primary energy per ton of ammonia, while green ammonia currently requires 35-50 GJ of electricity per ton. However, as electrolysis and renewable energy technologies continue to improve, the efficiency gap is expected to narrow significantly over the coming decade.

Green ammonia production, powered by renewable electricity sources such as wind, solar, or hydropower, demonstrates substantial environmental advantages. Life cycle assessments indicate potential carbon emission reductions of 80-95% compared to fossil-based methods when utilizing fully renewable energy sources. The carbon footprint can be as low as 0.2-0.5 tons of CO2 equivalent per ton of ammonia, representing a transformative improvement in environmental performance.

Water consumption patterns also differ significantly between the two approaches. Fossil-based ammonia production requires approximately 1-3 cubic meters of water per ton of ammonia, primarily for cooling and steam generation. Green ammonia production may require additional water for electrolysis, potentially increasing water consumption to 5-10 cubic meters per ton, though this varies considerably depending on the specific technology employed and local conditions.

Air quality impacts present another critical environmental distinction. Conventional ammonia plants emit nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter, contributing to local air pollution and associated health impacts. Green ammonia production virtually eliminates these air pollutants, offering significant co-benefits for communities surrounding production facilities.

Land use considerations reveal that while green ammonia requires minimal direct land for production facilities, the renewable energy infrastructure needed to power electrolysis can have substantial land requirements. Wind farms may require 30-140 km² per GW of capacity, while solar installations need approximately 20-50 km² per GW, depending on technology and location specifics.

Resource efficiency metrics indicate that fossil-based ammonia production consumes approximately 28-37 GJ of primary energy per ton of ammonia, while green ammonia currently requires 35-50 GJ of electricity per ton. However, as electrolysis and renewable energy technologies continue to improve, the efficiency gap is expected to narrow significantly over the coming decade.

Economic Viability and Scaling Challenges

The economic viability of green ammonia production compared to conventional fossil-based synthesis presents significant challenges that must be addressed for widespread adoption. Currently, green ammonia production costs range between $650-1,400 per ton, approximately 2-4 times higher than conventional methods which average $300-450 per ton. This substantial cost differential stems primarily from the capital expenditure required for renewable energy infrastructure and electrolysis equipment, which can represent up to 70% of the total production cost for green ammonia.

Energy efficiency remains a critical economic factor, with green ammonia production requiring approximately 10-12 MWh of electricity per ton of ammonia. At current renewable electricity prices of $40-60 per MWh in optimal locations, energy costs alone contribute $400-720 to each ton of green ammonia produced. This highlights the dependency on continued reductions in renewable energy costs to achieve economic parity.

Scale-up challenges further complicate the economic equation. While conventional ammonia plants typically operate at capacities of 1,000-3,000 tons per day, most green ammonia projects remain at pilot scale, producing less than 100 tons per day. This lack of scale prevents the realization of economies that have benefited traditional production methods for decades. Industry projections suggest that reaching cost parity will require green ammonia facilities to achieve similar production scales, necessitating multi-billion dollar investments per facility.

Infrastructure limitations present additional scaling barriers. Green ammonia production requires integration of intermittent renewable energy sources with electrolysis systems that prefer continuous operation, creating technical challenges that impact operational efficiency. Furthermore, the geographical disconnect between optimal renewable energy locations and traditional ammonia consumption centers necessitates significant investments in transportation and storage infrastructure.

Policy support mechanisms vary significantly across regions, creating an uneven playing field for investment decisions. Carbon pricing mechanisms, renewable energy subsidies, and regulatory frameworks for hydrogen and ammonia production differ substantially between jurisdictions, complicating multinational deployment strategies. Analysis indicates that carbon prices of $100-150 per ton CO2e would be necessary to make green ammonia competitive with conventional production in most markets without additional subsidies.

Despite these challenges, learning curve effects are expected to reduce costs significantly. Electrolyzer costs have declined by approximately 60% over the past decade and are projected to decrease by an additional 40-60% by 2030. Combined with anticipated reductions in renewable electricity costs, these improvements could bring green ammonia production costs below $500 per ton by 2030, approaching competitive levels with fossil-based production.

Energy efficiency remains a critical economic factor, with green ammonia production requiring approximately 10-12 MWh of electricity per ton of ammonia. At current renewable electricity prices of $40-60 per MWh in optimal locations, energy costs alone contribute $400-720 to each ton of green ammonia produced. This highlights the dependency on continued reductions in renewable energy costs to achieve economic parity.

Scale-up challenges further complicate the economic equation. While conventional ammonia plants typically operate at capacities of 1,000-3,000 tons per day, most green ammonia projects remain at pilot scale, producing less than 100 tons per day. This lack of scale prevents the realization of economies that have benefited traditional production methods for decades. Industry projections suggest that reaching cost parity will require green ammonia facilities to achieve similar production scales, necessitating multi-billion dollar investments per facility.

Infrastructure limitations present additional scaling barriers. Green ammonia production requires integration of intermittent renewable energy sources with electrolysis systems that prefer continuous operation, creating technical challenges that impact operational efficiency. Furthermore, the geographical disconnect between optimal renewable energy locations and traditional ammonia consumption centers necessitates significant investments in transportation and storage infrastructure.

Policy support mechanisms vary significantly across regions, creating an uneven playing field for investment decisions. Carbon pricing mechanisms, renewable energy subsidies, and regulatory frameworks for hydrogen and ammonia production differ substantially between jurisdictions, complicating multinational deployment strategies. Analysis indicates that carbon prices of $100-150 per ton CO2e would be necessary to make green ammonia competitive with conventional production in most markets without additional subsidies.

Despite these challenges, learning curve effects are expected to reduce costs significantly. Electrolyzer costs have declined by approximately 60% over the past decade and are projected to decrease by an additional 40-60% by 2030. Combined with anticipated reductions in renewable electricity costs, these improvements could bring green ammonia production costs below $500 per ton by 2030, approaching competitive levels with fossil-based production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!