Market and Regulatory Dynamics in Green Ammonia Conversion

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Green Ammonia Technology Background and Objectives

Green ammonia represents a revolutionary approach to sustainable energy storage and transportation, emerging as a critical component in the global transition to a low-carbon economy. The concept of green ammonia refers to ammonia (NH3) produced using renewable energy sources, with hydrogen derived from water electrolysis rather than fossil fuels, and nitrogen separated from air. This production method eliminates carbon emissions traditionally associated with conventional ammonia synthesis through the Haber-Bosch process, which currently accounts for approximately 1.8% of global CO2 emissions.

The evolution of green ammonia technology has accelerated significantly over the past decade, driven by increasing urgency to decarbonize hard-to-abate sectors and the rapid cost reduction of renewable energy technologies. Initially conceptualized in the early 2000s, green ammonia has transitioned from theoretical research to pilot projects, with the first demonstration plants coming online around 2018-2019.

The primary technical objective in green ammonia development is achieving cost parity with conventional ammonia production. This requires advancements in electrolysis efficiency, integration of variable renewable energy sources, and optimization of the Haber-Bosch process for smaller-scale, intermittent operation. Current production costs for green ammonia range from $900-1,600 per tonne, compared to $200-450 per tonne for conventional ammonia.

Another critical objective is scaling production capacity to meet projected demand across multiple sectors. The International Energy Agency estimates that ammonia demand could increase from current levels of approximately 180 million tonnes annually to over 400 million tonnes by 2050, with green ammonia potentially comprising 60-70% of this total.

Energy efficiency represents a third key objective, as the current green ammonia production pathway requires approximately 10-12 MWh of electricity per tonne of ammonia. Research aims to reduce this to 7-8 MWh/tonne through improved electrolysis technologies and process integration.

The technological trajectory is increasingly focused on developing flexible production systems that can operate effectively with variable renewable energy inputs, addressing the intermittency challenge of wind and solar power. This includes innovations in dynamic operation of electrolyzers and modified Haber-Bosch processes that can handle fluctuating hydrogen supply.

Regulatory frameworks and market mechanisms are evolving to support green ammonia development, with carbon pricing, renewable energy mandates, and sector-specific decarbonization targets creating incentives for investment. The European Union's Hydrogen Strategy and various national hydrogen roadmaps explicitly include green ammonia as a key vector for renewable energy storage and transportation.

The evolution of green ammonia technology has accelerated significantly over the past decade, driven by increasing urgency to decarbonize hard-to-abate sectors and the rapid cost reduction of renewable energy technologies. Initially conceptualized in the early 2000s, green ammonia has transitioned from theoretical research to pilot projects, with the first demonstration plants coming online around 2018-2019.

The primary technical objective in green ammonia development is achieving cost parity with conventional ammonia production. This requires advancements in electrolysis efficiency, integration of variable renewable energy sources, and optimization of the Haber-Bosch process for smaller-scale, intermittent operation. Current production costs for green ammonia range from $900-1,600 per tonne, compared to $200-450 per tonne for conventional ammonia.

Another critical objective is scaling production capacity to meet projected demand across multiple sectors. The International Energy Agency estimates that ammonia demand could increase from current levels of approximately 180 million tonnes annually to over 400 million tonnes by 2050, with green ammonia potentially comprising 60-70% of this total.

Energy efficiency represents a third key objective, as the current green ammonia production pathway requires approximately 10-12 MWh of electricity per tonne of ammonia. Research aims to reduce this to 7-8 MWh/tonne through improved electrolysis technologies and process integration.

The technological trajectory is increasingly focused on developing flexible production systems that can operate effectively with variable renewable energy inputs, addressing the intermittency challenge of wind and solar power. This includes innovations in dynamic operation of electrolyzers and modified Haber-Bosch processes that can handle fluctuating hydrogen supply.

Regulatory frameworks and market mechanisms are evolving to support green ammonia development, with carbon pricing, renewable energy mandates, and sector-specific decarbonization targets creating incentives for investment. The European Union's Hydrogen Strategy and various national hydrogen roadmaps explicitly include green ammonia as a key vector for renewable energy storage and transportation.

Market Demand Analysis for Green Ammonia

The global market for green ammonia is experiencing unprecedented growth, driven by the urgent need to decarbonize various industrial sectors. Current market assessments indicate that the green ammonia market, valued at approximately 11 million USD in 2021, is projected to expand at a compound annual growth rate (CAGR) of over 70% through 2030, potentially reaching a market valuation of 5.4 billion USD by the end of the decade. This remarkable growth trajectory is primarily fueled by increasing environmental regulations and the push for sustainable alternatives to conventional ammonia production methods.

The fertilizer industry remains the dominant consumer of ammonia, accounting for roughly 80% of global ammonia usage. With mounting pressure to reduce carbon footprints across agricultural value chains, demand for green ammonia as a fertilizer feedstock is expected to surge significantly. Major agricultural markets in Europe, North America, and increasingly in Asia-Pacific regions are implementing stricter sustainability requirements, creating substantial market pull for green alternatives.

Beyond fertilizers, emerging applications are expanding the market potential for green ammonia. The maritime shipping industry has identified ammonia as a promising zero-carbon fuel, with major shipping companies announcing plans to deploy ammonia-powered vessels by 2025. This sector alone could generate demand for millions of tons of green ammonia annually by 2040 as the industry works toward meeting International Maritime Organization (IMO) emissions reduction targets.

The power generation sector presents another significant growth avenue, with green ammonia increasingly viewed as an effective energy carrier and storage medium. Several pilot projects in Japan, Australia, and Europe are exploring ammonia co-firing in conventional power plants and dedicated ammonia-to-power systems. Market analysts predict that power sector demand could reach 25 million tons annually by 2035, representing a substantial market opportunity.

Regional market dynamics reveal varying adoption rates and drivers. Europe leads in policy support and investment commitments, with the European Union's Green Deal and Hydrogen Strategy explicitly supporting green ammonia development. The Asia-Pacific region, particularly Japan, South Korea, and increasingly China, shows strong demand potential driven by energy security concerns and decarbonization targets. The Middle East and North Africa are positioning themselves as future export hubs, leveraging abundant renewable energy resources.

Price sensitivity remains a critical market factor. Current production costs for green ammonia range between 600-1,200 USD per ton, compared to 200-450 USD per ton for conventional ammonia. However, this price gap is expected to narrow significantly by 2030 as renewable electricity costs decline and electrolyzer technologies mature, potentially reaching cost parity in regions with optimal renewable resources.

The fertilizer industry remains the dominant consumer of ammonia, accounting for roughly 80% of global ammonia usage. With mounting pressure to reduce carbon footprints across agricultural value chains, demand for green ammonia as a fertilizer feedstock is expected to surge significantly. Major agricultural markets in Europe, North America, and increasingly in Asia-Pacific regions are implementing stricter sustainability requirements, creating substantial market pull for green alternatives.

Beyond fertilizers, emerging applications are expanding the market potential for green ammonia. The maritime shipping industry has identified ammonia as a promising zero-carbon fuel, with major shipping companies announcing plans to deploy ammonia-powered vessels by 2025. This sector alone could generate demand for millions of tons of green ammonia annually by 2040 as the industry works toward meeting International Maritime Organization (IMO) emissions reduction targets.

The power generation sector presents another significant growth avenue, with green ammonia increasingly viewed as an effective energy carrier and storage medium. Several pilot projects in Japan, Australia, and Europe are exploring ammonia co-firing in conventional power plants and dedicated ammonia-to-power systems. Market analysts predict that power sector demand could reach 25 million tons annually by 2035, representing a substantial market opportunity.

Regional market dynamics reveal varying adoption rates and drivers. Europe leads in policy support and investment commitments, with the European Union's Green Deal and Hydrogen Strategy explicitly supporting green ammonia development. The Asia-Pacific region, particularly Japan, South Korea, and increasingly China, shows strong demand potential driven by energy security concerns and decarbonization targets. The Middle East and North Africa are positioning themselves as future export hubs, leveraging abundant renewable energy resources.

Price sensitivity remains a critical market factor. Current production costs for green ammonia range between 600-1,200 USD per ton, compared to 200-450 USD per ton for conventional ammonia. However, this price gap is expected to narrow significantly by 2030 as renewable electricity costs decline and electrolyzer technologies mature, potentially reaching cost parity in regions with optimal renewable resources.

Technical Challenges in Green Ammonia Conversion

Green ammonia conversion faces significant technical hurdles despite its promising potential as a carbon-neutral energy carrier. The Haber-Bosch process, traditionally used for ammonia synthesis, requires high temperatures (400-500°C) and pressures (150-300 bar), making it energy-intensive and challenging to integrate with renewable energy sources that are inherently intermittent. This mismatch between continuous industrial processes and variable renewable energy supply represents a fundamental technical barrier.

Electrolysis-based hydrogen production, a critical component of green ammonia synthesis, suffers from efficiency limitations. Current electrolyzers typically achieve 60-80% efficiency, with significant energy losses occurring during operation. Additionally, the durability of electrolyzer components under fluctuating power conditions remains problematic, with degradation accelerating when systems operate under variable loads from renewable sources.

Catalyst development presents another major challenge. Traditional iron-based catalysts for nitrogen reduction require extreme conditions to break the strong N≡N triple bond. Research into novel catalysts using ruthenium, cobalt, or molybdenum shows promise but faces issues with stability, selectivity, and cost-effectiveness at industrial scales. Electrochemical ammonia synthesis approaches, while theoretically more compatible with renewable energy, struggle with low conversion rates and competing hydrogen evolution reactions.

Heat management systems for green ammonia production require sophisticated engineering solutions. The exothermic nature of ammonia synthesis necessitates effective heat recovery systems to maintain energy efficiency, while the integration with renewable energy sources demands innovative approaches to thermal storage and management during production fluctuations.

Storage and transportation infrastructure for ammonia presents additional technical challenges. While liquid ammonia has a higher energy density than hydrogen, it requires refrigeration to -33°C or pressurization to 10 bar. Materials compatibility issues arise as ammonia is corrosive to certain metals, particularly copper and copper alloys, necessitating specialized containment materials and handling protocols.

Safety systems for ammonia handling require significant technical development. Ammonia's toxicity and potential flammability in certain concentrations demand robust detection systems, emergency protocols, and containment technologies. These safety requirements add complexity and cost to green ammonia implementation.

Process integration and system optimization represent perhaps the most complex technical challenge. Creating efficient, resilient systems that integrate renewable energy generation, hydrogen production, nitrogen separation, ammonia synthesis, and storage/distribution requires sophisticated control systems and operational strategies that can respond to fluctuating inputs while maintaining product quality and system integrity.

Electrolysis-based hydrogen production, a critical component of green ammonia synthesis, suffers from efficiency limitations. Current electrolyzers typically achieve 60-80% efficiency, with significant energy losses occurring during operation. Additionally, the durability of electrolyzer components under fluctuating power conditions remains problematic, with degradation accelerating when systems operate under variable loads from renewable sources.

Catalyst development presents another major challenge. Traditional iron-based catalysts for nitrogen reduction require extreme conditions to break the strong N≡N triple bond. Research into novel catalysts using ruthenium, cobalt, or molybdenum shows promise but faces issues with stability, selectivity, and cost-effectiveness at industrial scales. Electrochemical ammonia synthesis approaches, while theoretically more compatible with renewable energy, struggle with low conversion rates and competing hydrogen evolution reactions.

Heat management systems for green ammonia production require sophisticated engineering solutions. The exothermic nature of ammonia synthesis necessitates effective heat recovery systems to maintain energy efficiency, while the integration with renewable energy sources demands innovative approaches to thermal storage and management during production fluctuations.

Storage and transportation infrastructure for ammonia presents additional technical challenges. While liquid ammonia has a higher energy density than hydrogen, it requires refrigeration to -33°C or pressurization to 10 bar. Materials compatibility issues arise as ammonia is corrosive to certain metals, particularly copper and copper alloys, necessitating specialized containment materials and handling protocols.

Safety systems for ammonia handling require significant technical development. Ammonia's toxicity and potential flammability in certain concentrations demand robust detection systems, emergency protocols, and containment technologies. These safety requirements add complexity and cost to green ammonia implementation.

Process integration and system optimization represent perhaps the most complex technical challenge. Creating efficient, resilient systems that integrate renewable energy generation, hydrogen production, nitrogen separation, ammonia synthesis, and storage/distribution requires sophisticated control systems and operational strategies that can respond to fluctuating inputs while maintaining product quality and system integrity.

Current Green Ammonia Conversion Solutions

01 Catalytic conversion processes for green ammonia

Various catalytic processes are employed to convert green ammonia into useful products or energy. These processes typically involve specialized catalysts that facilitate the decomposition or transformation of ammonia under controlled conditions. The catalysts may include transition metals, metal oxides, or composite materials designed to optimize conversion efficiency while minimizing energy requirements. These catalytic systems are crucial for enabling the practical use of green ammonia as an energy carrier or chemical feedstock.- Catalytic conversion processes for green ammonia: Various catalytic processes have been developed for the efficient conversion of green ammonia. These processes typically involve specialized catalysts that facilitate the decomposition or transformation of ammonia under controlled conditions. The catalysts can enhance reaction rates, improve selectivity, and operate at lower temperatures, making the overall conversion process more energy-efficient. These catalytic approaches are crucial for utilizing green ammonia as an energy carrier or chemical feedstock.

- Ammonia cracking technologies for hydrogen production: Green ammonia can be cracked to produce hydrogen through various technologies. These cracking processes typically involve thermal decomposition of ammonia into nitrogen and hydrogen gases. The technologies focus on optimizing reaction conditions, heat management, and separation techniques to maximize hydrogen yield and purity. Such approaches enable green ammonia to serve as a hydrogen carrier, facilitating the storage and transport of renewable energy in chemical form.

- Integration of green ammonia in power generation systems: Green ammonia can be integrated into power generation systems as a carbon-free fuel. These systems may include modified gas turbines, fuel cells, or combustion engines that can utilize ammonia directly or in combination with other fuels. The integration requires specialized equipment for ammonia handling, storage, and conversion to address challenges related to ammonia's combustion properties. Such systems enable the use of green ammonia as a sustainable alternative to fossil fuels in electricity generation.

- Electrochemical conversion methods for green ammonia: Electrochemical methods offer promising approaches for green ammonia conversion. These techniques utilize electrochemical cells with specialized electrodes and electrolytes to facilitate ammonia oxidation or reduction reactions. The processes can operate at ambient conditions and can be powered directly by renewable electricity. Electrochemical conversion enables the direct transformation of ammonia into valuable products or energy, providing efficient pathways for utilizing green ammonia in various applications.

- Process optimization and system integration for ammonia conversion: Optimizing green ammonia conversion processes involves integrating various components into efficient systems. This includes heat recovery systems, pressure management, reaction control strategies, and product purification techniques. Advanced process designs focus on minimizing energy consumption, reducing capital costs, and enhancing operational flexibility. System integration approaches also address safety considerations and environmental impacts associated with ammonia handling and conversion, ensuring sustainable implementation of green ammonia technologies.

02 Ammonia cracking for hydrogen production

Green ammonia can be cracked or decomposed to produce hydrogen, which can then be used as a clean fuel or chemical feedstock. This process typically involves thermal decomposition of ammonia over specialized catalysts at elevated temperatures. The technology enables the use of ammonia as a hydrogen carrier, allowing for the storage and transport of renewable energy in chemical form. The hydrogen produced through this method is considered carbon-free when the original ammonia is produced using renewable energy sources.Expand Specific Solutions03 Integration of green ammonia in power generation systems

Green ammonia can be integrated into power generation systems as a carbon-free fuel. This includes direct combustion in modified gas turbines, use in fuel cells, or as part of hybrid energy systems. The integration often requires specialized equipment and control systems to handle ammonia's unique combustion properties. These systems enable the use of green ammonia as a sustainable alternative to fossil fuels in electricity generation, contributing to decarbonization efforts in the energy sector.Expand Specific Solutions04 Ammonia conversion for sustainable transportation fuels

Green ammonia can be converted into sustainable fuels suitable for transportation applications. This includes processes for transforming ammonia into hydrogen for fuel cells, direct use in internal combustion engines with appropriate modifications, or conversion to other liquid fuels. These conversion technologies address the challenges of using ammonia in mobile applications, including storage density, safety, and compatibility with existing infrastructure. The resulting fuels offer reduced or zero carbon emissions compared to conventional fossil fuels.Expand Specific Solutions05 Process optimization and efficiency improvements

Various technologies focus on optimizing the efficiency of green ammonia conversion processes. These include advanced reactor designs, heat integration systems, process intensification techniques, and control strategies. Such optimizations aim to reduce energy consumption, increase conversion rates, and improve the economic viability of green ammonia as an energy carrier. These advancements are critical for scaling up green ammonia technologies and making them competitive with conventional fossil fuel-based alternatives.Expand Specific Solutions

Key Industry Players in Green Ammonia Production

The green ammonia conversion market is currently in an early growth phase, characterized by increasing investments and technological advancements. The global market is projected to expand significantly as decarbonization efforts intensify, with estimates suggesting multi-billion dollar growth potential by 2030. Technologically, the sector shows varying maturity levels, with established players like thyssenkrupp AG, Topsoe A/S, and Air Products & Chemicals leading commercial deployment of conversion technologies. Academic institutions including Tsinghua University and Colorado School of Mines are advancing fundamental research, while industrial players such as CHN ENERGY and Wacker Chemie AG focus on scaling applications. The regulatory landscape is evolving rapidly, with government policies increasingly supporting green ammonia as a key component of hydrogen economy strategies and industrial decarbonization pathways.

thyssenkrupp AG

Technical Solution: Thyssenkrupp has developed the uhde® green ammonia technology, an integrated solution for renewable hydrogen-based ammonia production. Their system incorporates alkaline water electrolysis (AWE) technology with capacities ranging from 20 MW to multi-GW scale, achieving electrolysis efficiencies of 70-75%. The company's approach features a specially adapted Uhde ammonia synthesis process that accommodates variable hydrogen production from renewable sources. Their technology includes advanced process control systems that optimize ammonia synthesis under fluctuating input conditions, maintaining catalyst performance despite load variations between 25-100%. Thyssenkrupp's green ammonia plants incorporate proprietary heat recovery systems that reduce energy consumption by approximately 4-6 GJ/ton of ammonia produced. The company has also developed modular skid-mounted designs for smaller capacity installations (1,000-50,000 tons/year), enabling distributed production models closer to renewable energy sources or ammonia consumption points. Their technology roadmap includes integration with direct air capture for carbon-neutral ammonia derivatives.

Strengths: Extensive experience in conventional ammonia plant engineering; modular scalable technology suitable for various project sizes; comprehensive technology package including electrolysis and synthesis. Weaknesses: Higher specific energy consumption compared to some competitors; limited large-scale reference projects specifically for green ammonia; technology still evolving for optimal integration with variable renewable energy sources.

Topsoe A/S

Technical Solution: Topsoe has developed the SynCOR Ammonia™ technology, a revolutionary green ammonia production process that integrates renewable hydrogen with their proprietary catalysts and process designs. Their system utilizes solid oxide electrolysis cells (SOECs) for hydrogen production coupled with an optimized Haber-Bosch synthesis loop specifically designed for fluctuating renewable energy inputs. The technology achieves up to 22% energy efficiency improvement compared to conventional ammonia production methods. Topsoe's Power-to-Ammonia solutions incorporate dynamic load management capabilities that can adjust production rates based on renewable energy availability, with response times under 15 minutes for partial load adjustments. Their catalysts demonstrate exceptional nitrogen activation at lower pressures (15-80 bar) and temperatures (350-450°C), enabling more flexible operation with intermittent renewable energy sources. Topsoe has also developed advanced heat integration systems that recover up to 85% of process heat, significantly reducing the overall energy footprint of green ammonia production.

Strengths: Industry-leading catalyst technology with superior performance at variable loads; integrated system approach addressing the entire value chain; proven commercial-scale implementation experience. Weaknesses: Higher capital costs compared to conventional systems; still requires significant renewable electricity infrastructure; technology performance at very small scales remains challenging.

Core Patents and Innovations in Green Ammonia Technology

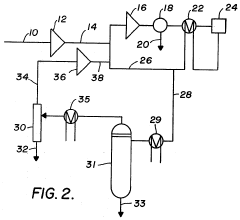

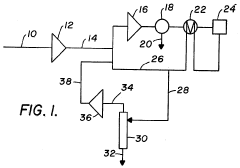

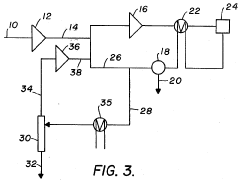

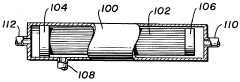

Process for hydrogen recovery from ammonia purge gases

PatentInactiveUS4180553A

Innovation

- The process involves using a separation membrane to selectively permeate hydrogen and ammonia from the ammonia synthesis loop purge stream at superatmospheric pressures, allowing for high hydrogen and ammonia recovery without significant energy consumption or equipment modifications, and utilizing the permeating gas directly in the synthesis loop to enhance ammonia production.

Regulatory Framework and Policy Incentives

The global regulatory landscape for green ammonia is rapidly evolving, with significant variations across regions reflecting different policy priorities and environmental commitments. The European Union leads with its ambitious Green Deal, which includes specific provisions for low-carbon hydrogen and ammonia production. The EU's Renewable Energy Directive II (RED II) and the forthcoming RED III establish frameworks for renewable fuels of non-biological origin (RFNBOs), directly impacting green ammonia development. Additionally, the EU Emissions Trading System (ETS) provides economic incentives by putting a price on carbon emissions, making green alternatives more competitive.

In North America, the United States has introduced transformative legislation through the Inflation Reduction Act (IRA) of 2022, which allocates approximately $369 billion for climate and energy initiatives. The IRA includes production tax credits for clean hydrogen that can reach up to $3/kg, significantly improving the economics of green ammonia production. Canada complements this with its own Clean Fuel Regulations and carbon pricing mechanisms, creating a coordinated North American approach.

Asia-Pacific nations are implementing varied but increasingly ambitious policies. Japan's Green Growth Strategy targets carbon neutrality by 2050 with specific hydrogen and ammonia utilization goals. South Korea's Hydrogen Economy Roadmap similarly emphasizes low-carbon hydrogen production. China has incorporated green ammonia into its 14th Five-Year Plan, signaling strong governmental support for the sector's development.

Financial incentives across these regions take multiple forms, including direct subsidies, tax credits, loan guarantees, and preferential financing terms for green projects. The EU's Innovation Fund and various national green investment programs provide capital for demonstration projects and commercial scaling. Public procurement policies increasingly favor low-carbon solutions, creating guaranteed markets for green ammonia producers.

Certification schemes and standards are emerging as critical regulatory tools. The EU is developing a comprehensive certification system for renewable and low-carbon hydrogen that will likely extend to ammonia derivatives. These standards establish clear criteria for what qualifies as "green" ammonia, typically requiring renewable energy sources and maximum carbon intensity thresholds throughout the production lifecycle.

Regulatory harmonization efforts are underway through international bodies like the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE) and industry associations. These initiatives aim to create globally recognized standards that would facilitate international trade in green ammonia while preventing regulatory arbitrage between regions with differing environmental requirements.

In North America, the United States has introduced transformative legislation through the Inflation Reduction Act (IRA) of 2022, which allocates approximately $369 billion for climate and energy initiatives. The IRA includes production tax credits for clean hydrogen that can reach up to $3/kg, significantly improving the economics of green ammonia production. Canada complements this with its own Clean Fuel Regulations and carbon pricing mechanisms, creating a coordinated North American approach.

Asia-Pacific nations are implementing varied but increasingly ambitious policies. Japan's Green Growth Strategy targets carbon neutrality by 2050 with specific hydrogen and ammonia utilization goals. South Korea's Hydrogen Economy Roadmap similarly emphasizes low-carbon hydrogen production. China has incorporated green ammonia into its 14th Five-Year Plan, signaling strong governmental support for the sector's development.

Financial incentives across these regions take multiple forms, including direct subsidies, tax credits, loan guarantees, and preferential financing terms for green projects. The EU's Innovation Fund and various national green investment programs provide capital for demonstration projects and commercial scaling. Public procurement policies increasingly favor low-carbon solutions, creating guaranteed markets for green ammonia producers.

Certification schemes and standards are emerging as critical regulatory tools. The EU is developing a comprehensive certification system for renewable and low-carbon hydrogen that will likely extend to ammonia derivatives. These standards establish clear criteria for what qualifies as "green" ammonia, typically requiring renewable energy sources and maximum carbon intensity thresholds throughout the production lifecycle.

Regulatory harmonization efforts are underway through international bodies like the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE) and industry associations. These initiatives aim to create globally recognized standards that would facilitate international trade in green ammonia while preventing regulatory arbitrage between regions with differing environmental requirements.

Environmental Impact Assessment

The environmental impact assessment of green ammonia conversion reveals significant potential for reducing greenhouse gas emissions compared to conventional ammonia production methods. Traditional ammonia synthesis via the Haber-Bosch process accounts for approximately 1.8% of global CO2 emissions, consuming 1-2% of worldwide energy production. Green ammonia production, utilizing renewable electricity for hydrogen generation through water electrolysis, can reduce these emissions by up to 80-90% when fully implemented.

Life cycle assessments indicate that the carbon footprint of green ammonia ranges from 0.2-0.5 tons CO2-equivalent per ton of ammonia, compared to 1.8-3.0 tons for conventional methods. This substantial reduction represents a critical pathway for decarbonizing the chemical industry and agricultural sectors that rely heavily on ammonia-based fertilizers.

Water consumption presents both challenges and opportunities. While electrolysis requires significant water inputs (approximately 9 tons of water per ton of ammonia), this represents a potential improvement over conventional production when considering the total water footprint across the value chain. Proper water management strategies must be implemented, particularly in water-stressed regions where green ammonia facilities might be located to capitalize on abundant renewable energy resources.

Land use considerations vary significantly based on the renewable energy source powering green ammonia production. Solar-powered facilities require approximately 10-15 hectares per megawatt of capacity, while wind power installations need 0.3-1.0 hectares per megawatt, though with less exclusive land use. These spatial requirements must be balanced against the environmental benefits when planning facility locations.

Air quality improvements represent another significant environmental benefit. Green ammonia production eliminates NOx emissions associated with conventional production methods, which contribute to smog formation and respiratory health issues. Additionally, the reduction in fossil fuel extraction activities further decreases associated environmental degradation.

Potential environmental risks include ammonia leakage and safety concerns, as ammonia is toxic to aquatic organisms and can cause localized air quality issues if released. Robust safety protocols, monitoring systems, and emergency response procedures are essential components of environmentally responsible green ammonia facilities. Regulatory frameworks are evolving to address these specific concerns while facilitating the transition to this lower-carbon technology.

Life cycle assessments indicate that the carbon footprint of green ammonia ranges from 0.2-0.5 tons CO2-equivalent per ton of ammonia, compared to 1.8-3.0 tons for conventional methods. This substantial reduction represents a critical pathway for decarbonizing the chemical industry and agricultural sectors that rely heavily on ammonia-based fertilizers.

Water consumption presents both challenges and opportunities. While electrolysis requires significant water inputs (approximately 9 tons of water per ton of ammonia), this represents a potential improvement over conventional production when considering the total water footprint across the value chain. Proper water management strategies must be implemented, particularly in water-stressed regions where green ammonia facilities might be located to capitalize on abundant renewable energy resources.

Land use considerations vary significantly based on the renewable energy source powering green ammonia production. Solar-powered facilities require approximately 10-15 hectares per megawatt of capacity, while wind power installations need 0.3-1.0 hectares per megawatt, though with less exclusive land use. These spatial requirements must be balanced against the environmental benefits when planning facility locations.

Air quality improvements represent another significant environmental benefit. Green ammonia production eliminates NOx emissions associated with conventional production methods, which contribute to smog formation and respiratory health issues. Additionally, the reduction in fossil fuel extraction activities further decreases associated environmental degradation.

Potential environmental risks include ammonia leakage and safety concerns, as ammonia is toxic to aquatic organisms and can cause localized air quality issues if released. Robust safety protocols, monitoring systems, and emergency response procedures are essential components of environmentally responsible green ammonia facilities. Regulatory frameworks are evolving to address these specific concerns while facilitating the transition to this lower-carbon technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!