Why Material Selection is Crucial for Ammonia Processes

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia Process Materials: Background and Objectives

Ammonia production represents one of the most significant industrial processes globally, with its roots dating back to the early 20th century when Fritz Haber and Carl Bosch developed the revolutionary Haber-Bosch process. This innovation fundamentally transformed agricultural practices by enabling large-scale production of nitrogen fertilizers, addressing food security challenges worldwide. The evolution of ammonia technology has been marked by continuous improvements in process efficiency, energy consumption, and environmental impact reduction.

Material selection has emerged as a critical factor in this technological evolution. The harsh operating conditions of ammonia synthesis—typically 400-500°C temperatures and 150-300 bar pressures—create an extremely demanding environment for process equipment. Early implementations faced significant challenges with material degradation, leading to frequent shutdowns, safety incidents, and economic losses. These historical challenges have driven extensive research into specialized materials capable of withstanding these severe conditions.

The primary technical objective in ammonia process material selection centers on identifying and developing materials that demonstrate exceptional resistance to hydrogen embrittlement, nitrogen attack, and stress corrosion cracking. These phenomena represent the most common failure mechanisms in ammonia plants, directly impacting operational reliability and safety. Additionally, materials must maintain mechanical integrity under cyclic loading conditions and thermal fluctuations inherent to industrial-scale operations.

Current technological trends in this field focus on developing advanced alloys and composite materials that offer superior performance characteristics while reducing overall lifecycle costs. The industry is witnessing a shift toward materials that not only withstand harsh conditions but also contribute to process intensification and efficiency improvements. This includes catalytic materials that enable lower operating temperatures and pressures, thereby reducing energy requirements and carbon footprint.

The global push toward green ammonia production—using renewable energy sources instead of fossil fuels—introduces new material challenges and opportunities. Electrolysis-based ammonia production systems require materials compatible with different chemical environments and operating parameters compared to conventional processes. This technological transition necessitates a comprehensive reevaluation of material selection criteria and performance requirements.

Material innovation for ammonia processes aims to address multiple objectives simultaneously: extending equipment lifespan, improving process safety, reducing maintenance requirements, enhancing energy efficiency, and enabling more sustainable production methods. The interdisciplinary nature of these objectives requires collaboration between materials scientists, chemical engineers, and process designers to develop holistic solutions that consider both immediate performance needs and long-term sustainability goals.

Material selection has emerged as a critical factor in this technological evolution. The harsh operating conditions of ammonia synthesis—typically 400-500°C temperatures and 150-300 bar pressures—create an extremely demanding environment for process equipment. Early implementations faced significant challenges with material degradation, leading to frequent shutdowns, safety incidents, and economic losses. These historical challenges have driven extensive research into specialized materials capable of withstanding these severe conditions.

The primary technical objective in ammonia process material selection centers on identifying and developing materials that demonstrate exceptional resistance to hydrogen embrittlement, nitrogen attack, and stress corrosion cracking. These phenomena represent the most common failure mechanisms in ammonia plants, directly impacting operational reliability and safety. Additionally, materials must maintain mechanical integrity under cyclic loading conditions and thermal fluctuations inherent to industrial-scale operations.

Current technological trends in this field focus on developing advanced alloys and composite materials that offer superior performance characteristics while reducing overall lifecycle costs. The industry is witnessing a shift toward materials that not only withstand harsh conditions but also contribute to process intensification and efficiency improvements. This includes catalytic materials that enable lower operating temperatures and pressures, thereby reducing energy requirements and carbon footprint.

The global push toward green ammonia production—using renewable energy sources instead of fossil fuels—introduces new material challenges and opportunities. Electrolysis-based ammonia production systems require materials compatible with different chemical environments and operating parameters compared to conventional processes. This technological transition necessitates a comprehensive reevaluation of material selection criteria and performance requirements.

Material innovation for ammonia processes aims to address multiple objectives simultaneously: extending equipment lifespan, improving process safety, reducing maintenance requirements, enhancing energy efficiency, and enabling more sustainable production methods. The interdisciplinary nature of these objectives requires collaboration between materials scientists, chemical engineers, and process designers to develop holistic solutions that consider both immediate performance needs and long-term sustainability goals.

Market Analysis of Ammonia Production Technologies

The global ammonia market is experiencing significant growth, with production capacity expected to reach 235 million metric tons by 2025, driven primarily by agricultural demand for fertilizers which accounts for approximately 80% of total consumption. Beyond traditional agricultural applications, emerging uses in energy storage, hydrogen carriers, and clean fuel are creating new market segments with projected compound annual growth rates of 5-7% through 2030.

The ammonia production technology landscape is currently dominated by the century-old Haber-Bosch process, which holds over 90% market share despite its energy-intensive nature. This process typically operates at high temperatures (400-500°C) and pressures (150-300 bar), consuming 1-2% of global energy production and generating substantial carbon emissions—approximately 1.8 tons of CO2 per ton of ammonia produced.

Recent technological innovations are reshaping market dynamics, with green ammonia production technologies gaining momentum. Electrolysis-based ammonia synthesis, which utilizes renewable electricity, has seen investment growth of 300% since 2018. Major industrial gas companies and chemical manufacturers are actively developing pilot plants with capacities ranging from 10,000 to 50,000 tons per year, signaling a shift toward sustainable production methods.

Regional market analysis reveals Asia-Pacific as the dominant producer, accounting for 60% of global capacity, with China alone representing 30%. North America and Europe follow with 15% and 12% market share respectively. The Middle East is emerging as a significant player due to natural gas availability and strategic positioning for export markets.

Material selection directly impacts production economics, with catalyst materials representing 15-25% of initial plant costs and significantly affecting operational efficiency. Advanced materials can reduce energy requirements by 20-30% and extend equipment lifespan by 2-3 times under harsh operating conditions. The market for specialized materials in ammonia production is valued at approximately 3 billion USD annually.

Industry forecasts indicate a bifurcation in technology adoption: large-scale conventional plants will continue dominating in regions with cheap natural gas, while distributed, smaller-scale green ammonia facilities will proliferate in areas with abundant renewable energy. This technological diversification is expected to reshape supply chains and create new market opportunities for specialized equipment manufacturers and material science companies focusing on corrosion-resistant alloys, advanced catalysts, and membrane technologies.

The ammonia production technology landscape is currently dominated by the century-old Haber-Bosch process, which holds over 90% market share despite its energy-intensive nature. This process typically operates at high temperatures (400-500°C) and pressures (150-300 bar), consuming 1-2% of global energy production and generating substantial carbon emissions—approximately 1.8 tons of CO2 per ton of ammonia produced.

Recent technological innovations are reshaping market dynamics, with green ammonia production technologies gaining momentum. Electrolysis-based ammonia synthesis, which utilizes renewable electricity, has seen investment growth of 300% since 2018. Major industrial gas companies and chemical manufacturers are actively developing pilot plants with capacities ranging from 10,000 to 50,000 tons per year, signaling a shift toward sustainable production methods.

Regional market analysis reveals Asia-Pacific as the dominant producer, accounting for 60% of global capacity, with China alone representing 30%. North America and Europe follow with 15% and 12% market share respectively. The Middle East is emerging as a significant player due to natural gas availability and strategic positioning for export markets.

Material selection directly impacts production economics, with catalyst materials representing 15-25% of initial plant costs and significantly affecting operational efficiency. Advanced materials can reduce energy requirements by 20-30% and extend equipment lifespan by 2-3 times under harsh operating conditions. The market for specialized materials in ammonia production is valued at approximately 3 billion USD annually.

Industry forecasts indicate a bifurcation in technology adoption: large-scale conventional plants will continue dominating in regions with cheap natural gas, while distributed, smaller-scale green ammonia facilities will proliferate in areas with abundant renewable energy. This technological diversification is expected to reshape supply chains and create new market opportunities for specialized equipment manufacturers and material science companies focusing on corrosion-resistant alloys, advanced catalysts, and membrane technologies.

Current Material Challenges in Ammonia Processing

Ammonia processing facilities face significant material challenges due to the corrosive and demanding nature of the production environment. The Haber-Bosch process, which remains the dominant method for ammonia synthesis, operates under extreme conditions including temperatures of 400-500°C and pressures of 150-300 bar. These harsh conditions create a particularly aggressive environment for materials, leading to accelerated degradation mechanisms including hydrogen embrittlement, nitriding, and stress corrosion cracking.

Conventional carbon steel, while economical, exhibits limited durability in ammonia synthesis environments, particularly in areas exposed to high concentrations of hydrogen. This has necessitated the use of specialized alloys such as 25-35 chromium-nickel stainless steels and nickel-based alloys in critical components. However, these materials significantly increase capital expenditure and may present supply chain vulnerabilities due to their reliance on strategic metals.

Catalyst containment systems present another major challenge, as they must withstand not only the process conditions but also the additional stresses of thermal cycling and catalyst poisoning effects. The iron-based catalysts commonly used in ammonia synthesis can interact with their containment materials, leading to premature degradation and potential catastrophic failure if not properly managed.

Heat exchanger materials face dual challenges of thermal fatigue and corrosion resistance. The efficiency of ammonia production is heavily dependent on effective heat recovery, yet the materials must simultaneously resist ammonia-induced stress corrosion cracking while maintaining thermal conductivity properties over extended operational periods.

Gasket and sealing materials represent a persistent challenge, with traditional materials like asbestos having been phased out due to health concerns. Modern alternatives such as graphite-reinforced and PTFE-based composites offer improved safety profiles but may exhibit reduced service life or require more frequent maintenance interventions.

Emerging green ammonia production methods, which aim to use renewable energy sources and electrolysis rather than natural gas reforming, introduce new material challenges. Electrolyzers require specialized materials capable of withstanding both highly alkaline or acidic environments while maintaining electrical conductivity and catalytic activity. These materials must also resist degradation from impurities in water feedstocks and maintain performance over thousands of operational hours.

The economic implications of these material challenges are substantial, with material failures accounting for approximately 15-20% of unplanned downtime in ammonia facilities globally. This translates to millions in lost production and maintenance costs, highlighting the critical importance of advanced material selection and development for next-generation ammonia processing technologies.

Conventional carbon steel, while economical, exhibits limited durability in ammonia synthesis environments, particularly in areas exposed to high concentrations of hydrogen. This has necessitated the use of specialized alloys such as 25-35 chromium-nickel stainless steels and nickel-based alloys in critical components. However, these materials significantly increase capital expenditure and may present supply chain vulnerabilities due to their reliance on strategic metals.

Catalyst containment systems present another major challenge, as they must withstand not only the process conditions but also the additional stresses of thermal cycling and catalyst poisoning effects. The iron-based catalysts commonly used in ammonia synthesis can interact with their containment materials, leading to premature degradation and potential catastrophic failure if not properly managed.

Heat exchanger materials face dual challenges of thermal fatigue and corrosion resistance. The efficiency of ammonia production is heavily dependent on effective heat recovery, yet the materials must simultaneously resist ammonia-induced stress corrosion cracking while maintaining thermal conductivity properties over extended operational periods.

Gasket and sealing materials represent a persistent challenge, with traditional materials like asbestos having been phased out due to health concerns. Modern alternatives such as graphite-reinforced and PTFE-based composites offer improved safety profiles but may exhibit reduced service life or require more frequent maintenance interventions.

Emerging green ammonia production methods, which aim to use renewable energy sources and electrolysis rather than natural gas reforming, introduce new material challenges. Electrolyzers require specialized materials capable of withstanding both highly alkaline or acidic environments while maintaining electrical conductivity and catalytic activity. These materials must also resist degradation from impurities in water feedstocks and maintain performance over thousands of operational hours.

The economic implications of these material challenges are substantial, with material failures accounting for approximately 15-20% of unplanned downtime in ammonia facilities globally. This translates to millions in lost production and maintenance costs, highlighting the critical importance of advanced material selection and development for next-generation ammonia processing technologies.

Current Material Solutions for Ammonia Processes

01 Corrosion-resistant materials for ammonia processes

Corrosion-resistant materials are essential for ammonia processing equipment due to the highly corrosive nature of ammonia and its intermediates. These materials include specific stainless steel alloys, nickel-based alloys, and specialized coatings that can withstand the harsh conditions of ammonia synthesis and handling. The selection of appropriate corrosion-resistant materials extends the lifespan of equipment and reduces maintenance costs while ensuring safety in ammonia production facilities.- Corrosion-resistant materials for ammonia processes: Corrosion-resistant materials are essential for ammonia processing equipment due to the highly corrosive nature of ammonia and its intermediates. These materials include specific stainless steel alloys, nickel-based alloys, and specialized coatings that can withstand the harsh conditions of ammonia synthesis and handling. The selection of appropriate corrosion-resistant materials extends the lifespan of equipment and reduces maintenance costs while ensuring safety in ammonia production facilities.

- Catalyst materials for ammonia synthesis: Specialized catalyst materials play a crucial role in ammonia synthesis processes, particularly in the Haber-Bosch process. These catalysts typically include iron-based materials with promoters such as potassium, aluminum, and calcium oxides. Advanced catalyst formulations may incorporate ruthenium, cobalt, or nickel to improve efficiency and reduce energy requirements. The proper selection of catalyst materials significantly impacts conversion rates, energy consumption, and overall process economics in ammonia production.

- High-pressure equipment materials: Ammonia synthesis typically occurs under extreme pressure conditions, requiring specialized materials for reactors, compressors, and piping systems. These materials must maintain structural integrity while resisting hydrogen embrittlement and stress corrosion cracking. High-strength alloy steels, often containing chromium and molybdenum, are commonly used for pressure vessels. The selection of appropriate materials for high-pressure applications ensures operational safety and reliability in ammonia production facilities.

- Heat-resistant materials for ammonia processes: Heat-resistant materials are critical for components exposed to high temperatures in ammonia production, including reformers, waste heat boilers, and heat exchangers. These materials must maintain mechanical properties and resist oxidation at elevated temperatures. Refractory materials for furnace linings, high-temperature alloys for process tubes, and specialized ceramics are selected based on their thermal stability and resistance to thermal cycling. Proper material selection for high-temperature applications improves energy efficiency and extends equipment service life.

- Innovative materials for green ammonia production: Emerging materials are being developed for sustainable ammonia production methods that use renewable energy sources instead of fossil fuels. These include advanced electrocatalysts for electrochemical ammonia synthesis, novel membrane materials for separation processes, and specialized materials for solid-state ammonia synthesis. These innovative materials aim to reduce the carbon footprint of ammonia production while maintaining or improving efficiency. The development of these materials is crucial for transitioning to more environmentally friendly ammonia production methods.

02 Catalyst materials for ammonia synthesis

Specialized catalyst materials play a crucial role in ammonia synthesis processes, particularly in the Haber-Bosch process. These catalysts typically contain iron with promoters such as potassium, aluminum, and calcium oxides, or ruthenium-based materials for newer processes. The selection of appropriate catalyst materials significantly impacts conversion efficiency, energy consumption, and overall process economics. Advanced catalyst formulations can operate at lower temperatures and pressures, reducing the energy requirements of ammonia production.Expand Specific Solutions03 High-pressure equipment materials

Ammonia synthesis typically occurs under extreme pressure conditions, requiring specialized materials that can withstand these demanding environments. Materials used in high-pressure ammonia equipment include high-strength alloy steels, specialized valve components, and pressure vessel materials with specific mechanical properties. These materials must maintain structural integrity while resisting hydrogen embrittlement and stress corrosion cracking under the combined effects of pressure, temperature, and chemical exposure in ammonia production facilities.Expand Specific Solutions04 Heat-resistant materials for ammonia processes

Heat-resistant materials are critical for components exposed to high temperatures in ammonia production facilities, including reformers, waste heat boilers, and synthesis converters. These materials include high-temperature alloys, ceramic components, and specialized refractory materials that maintain their mechanical properties and chemical resistance at elevated temperatures. The selection of appropriate heat-resistant materials ensures operational reliability, thermal efficiency, and extended service life of equipment used in the high-temperature zones of ammonia production processes.Expand Specific Solutions05 Novel materials for green ammonia production

Emerging materials are being developed specifically for green ammonia production processes that use renewable energy sources instead of fossil fuels. These include advanced electrocatalysts for nitrogen reduction reactions, specialized membrane materials for separation processes, and novel electrode materials for electrochemical ammonia synthesis. These materials enable more sustainable ammonia production with lower carbon footprints by facilitating processes that can operate efficiently using renewable electricity rather than traditional hydrocarbon-based feedstocks.Expand Specific Solutions

Leading Companies in Ammonia Production Materials

The ammonia process technology landscape is currently in a mature growth phase, with an estimated global market size of $70-80 billion. The competitive field features established industrial players like ThyssenKrupp, BASF, and Casale dominating commercial applications through decades of process optimization and materials expertise. Technical maturity varies significantly across application segments, with traditional ammonia production being highly mature while green ammonia technologies remain in early commercialization stages. Research institutions including Dalian Institute of Chemical Physics, Zhejiang University, and CNRS are advancing novel catalyst and material solutions to address corrosion challenges in ammonia environments. Material selection innovation is primarily driven by collaborative efforts between industrial leaders and research organizations focused on improving process efficiency, safety, and sustainability in both conventional and emerging ammonia technologies.

Dalian Institute of Chemical Physics of CAS

Technical Solution: The Dalian Institute has developed innovative material solutions for ammonia synthesis focusing on novel catalyst materials and reactor designs. Their research has pioneered the use of ruthenium-based catalysts supported on specially engineered carbon materials that significantly reduce the energy requirements for ammonia synthesis while maintaining structural integrity under reaction conditions. Their material selection approach includes the development of specialized ceramic-metal composite materials for reactor internals that resist hydrogen embrittlement while providing enhanced heat transfer characteristics. The Institute has demonstrated that their novel material combinations can reduce the operating temperature of ammonia synthesis by approximately 100°C while maintaining conversion efficiency[8]. Additionally, they have developed specialized coating technologies for heat exchangers that prevent fouling and corrosion in ammonia environments, extending equipment lifespan by up to 50% compared to conventional materials[9]. Their research also encompasses novel membrane materials for ammonia separation that can withstand the harsh conditions of synthesis.

Strengths: Cutting-edge research in novel catalyst materials specifically designed for low-temperature ammonia synthesis; strong focus on sustainable materials with reduced environmental impact. Weaknesses: Some advanced materials remain in research phase with limited industrial-scale implementation; higher production costs for specialized materials compared to conventional options.

BASF Corp.

Technical Solution: BASF has developed comprehensive material solutions for ammonia processes, focusing on both catalyst materials and process equipment. Their approach includes specialized iron-based catalyst formulations with proprietary promoters that enhance ammonia synthesis efficiency while maintaining structural integrity under high-pressure conditions. BASF's material selection strategy encompasses specialized stainless steel alloys for synthesis loops that resist hydrogen attack and nitrogen embrittlement, extending equipment lifespan by up to 30% compared to conventional materials[4]. They have pioneered the use of specialized ceramic materials for catalyst supports that optimize surface area while minimizing pressure drop. Additionally, BASF has developed proprietary coating technologies for heat exchangers and other critical components that prevent corrosion and fouling in ammonia-rich environments, reducing maintenance requirements by approximately 25% compared to uncoated alternatives[5].

Strengths: Integrated approach combining catalyst material expertise with process equipment material selection; extensive research facilities for material testing under actual ammonia synthesis conditions. Weaknesses: Some specialized materials require precise operating conditions to maintain performance; higher initial investment costs compared to conventional materials.

Critical Material Properties for Ammonia Compatibility

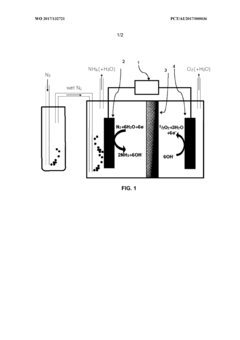

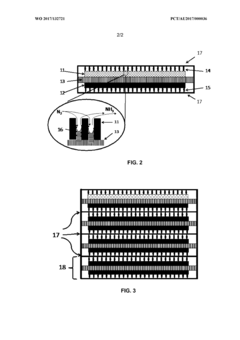

Method and cell for conversion of dinitrogen into ammonia

PatentWO2017132721A1

Innovation

- An electrochemical cell using a nanostructured catalyst and a specific liquid salt electrolyte with high nitrogen solubility, formed by certain cations and anions, operates at ambient conditions, enhancing dinitrogen reduction to ammonia with high Faradaic efficiency and reduced undesirable side reactions.

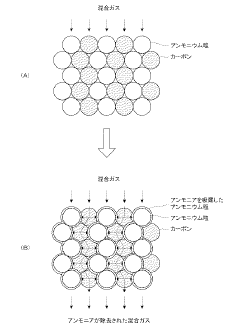

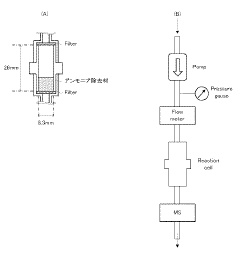

Ammonia removal material and ammonia removal method using the same

PatentInactiveJP2016135722A

Innovation

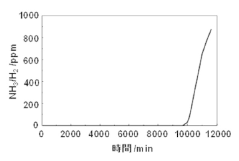

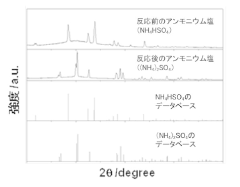

- A mixture of granular ammonium salt and granular carbon is used to enhance ammonia absorption, with a preferred compounding ratio of 50:50 to 90:10, allowing ammonia to be effectively occluded and reduced to concentrations below 0.1 ppm by increasing the contact area and maintaining gas flow paths.

Environmental Impact of Material Selection

Material selection in ammonia processes carries significant environmental implications that extend throughout the entire lifecycle of production facilities. The materials chosen for reactors, pipelines, and storage systems directly influence the environmental footprint of ammonia manufacturing through multiple pathways.

The durability and corrosion resistance of selected materials determine the frequency of maintenance and replacement cycles. Materials with superior longevity reduce waste generation and resource consumption associated with equipment replacement. For instance, high-nickel alloys in critical components may require higher initial resource investment but significantly extend service life compared to conventional steel alternatives, resulting in lower lifetime environmental impact.

Energy efficiency represents another crucial environmental consideration in material selection. Thermal conductivity properties of materials used in heat exchangers and reactor vessels directly affect energy consumption patterns. Materials that enable more efficient heat transfer can reduce the overall energy requirements of ammonia synthesis by 15-20%, translating to substantial reductions in greenhouse gas emissions from power generation.

Catalytic performance is intrinsically linked to material choices, particularly for reactor vessels and catalyst supports. Materials that maintain structural integrity under extreme conditions allow for more efficient catalytic processes, reducing both energy inputs and unwanted byproduct formation. This optimization can decrease the carbon footprint of ammonia production while minimizing the release of nitrogen oxides and other harmful emissions.

The environmental impact extends to end-of-life considerations as well. Materials selected should ideally be recyclable or repurposable to minimize waste streams. Specialized alloys containing rare elements may offer superior performance but present recycling challenges compared to more common materials. This tradeoff must be carefully evaluated within the context of circular economy principles.

Water consumption and contamination risks are additional environmental factors influenced by material selection. Certain materials may require water-intensive cleaning processes or pose greater risks of leaching contaminants. Selecting materials that minimize these impacts is particularly important in water-stressed regions where ammonia production facilities operate.

Climate resilience must also be considered as extreme weather events become more frequent. Materials must withstand increasingly variable operating conditions while maintaining safety and performance standards. This adaptation requirement adds another dimension to environmental impact assessment of material choices in modern ammonia facilities.

The durability and corrosion resistance of selected materials determine the frequency of maintenance and replacement cycles. Materials with superior longevity reduce waste generation and resource consumption associated with equipment replacement. For instance, high-nickel alloys in critical components may require higher initial resource investment but significantly extend service life compared to conventional steel alternatives, resulting in lower lifetime environmental impact.

Energy efficiency represents another crucial environmental consideration in material selection. Thermal conductivity properties of materials used in heat exchangers and reactor vessels directly affect energy consumption patterns. Materials that enable more efficient heat transfer can reduce the overall energy requirements of ammonia synthesis by 15-20%, translating to substantial reductions in greenhouse gas emissions from power generation.

Catalytic performance is intrinsically linked to material choices, particularly for reactor vessels and catalyst supports. Materials that maintain structural integrity under extreme conditions allow for more efficient catalytic processes, reducing both energy inputs and unwanted byproduct formation. This optimization can decrease the carbon footprint of ammonia production while minimizing the release of nitrogen oxides and other harmful emissions.

The environmental impact extends to end-of-life considerations as well. Materials selected should ideally be recyclable or repurposable to minimize waste streams. Specialized alloys containing rare elements may offer superior performance but present recycling challenges compared to more common materials. This tradeoff must be carefully evaluated within the context of circular economy principles.

Water consumption and contamination risks are additional environmental factors influenced by material selection. Certain materials may require water-intensive cleaning processes or pose greater risks of leaching contaminants. Selecting materials that minimize these impacts is particularly important in water-stressed regions where ammonia production facilities operate.

Climate resilience must also be considered as extreme weather events become more frequent. Materials must withstand increasingly variable operating conditions while maintaining safety and performance standards. This adaptation requirement adds another dimension to environmental impact assessment of material choices in modern ammonia facilities.

Safety Standards and Regulatory Compliance

The ammonia production industry operates under stringent safety standards and regulatory frameworks due to the hazardous nature of the processes involved. Material selection directly impacts compliance with these regulations, as inappropriate materials can lead to catastrophic failures that violate safety codes. Regulatory bodies such as OSHA in the United States, the Health and Safety Executive in the UK, and similar organizations worldwide have established comprehensive guidelines specifically addressing materials used in ammonia processing equipment.

These regulations typically mandate regular inspection protocols for materials used in ammonia service, with particular emphasis on pressure vessels, piping systems, and storage facilities. For instance, ASME Boiler and Pressure Vessel Code Section VIII provides detailed requirements for materials suitable for ammonia pressure vessels, while API 510 outlines inspection codes that consider material degradation mechanisms specific to ammonia environments.

Material certification requirements form another critical aspect of regulatory compliance. Materials used in ammonia processes must be accompanied by documentation verifying their chemical composition, mechanical properties, and testing history. This traceability is essential for demonstrating compliance during regulatory audits and inspections. Non-compliant materials can result in substantial fines, facility shutdowns, or even criminal liability in cases of serious incidents.

Environmental regulations also influence material selection decisions. Materials that minimize the risk of ammonia leaks and emissions help facilities comply with environmental protection standards such as the EPA's Risk Management Program in the US or the Seveso III Directive in Europe. These regulations establish threshold quantities for ammonia storage and mandate specific risk assessment procedures that consider material integrity as a key factor.

Insurance requirements further reinforce the importance of proper material selection. Insurers typically require adherence to industry standards such as NACE MR0175/ISO 15156 for materials resistant to sulfide stress cracking in environments containing hydrogen sulfide, which can be present in some ammonia processes. Compliance with these standards is often a prerequisite for obtaining coverage at reasonable premium rates.

The global harmonization of safety standards has led to the development of international codes such as ISO 15649 for process piping and IEC 60079 for equipment in explosive atmospheres, both of which contain provisions relevant to material selection in ammonia facilities. As regulatory frameworks continue to evolve toward more stringent requirements, particularly regarding risk assessment methodologies and predictive maintenance approaches, material selection becomes increasingly critical for maintaining long-term compliance.

These regulations typically mandate regular inspection protocols for materials used in ammonia service, with particular emphasis on pressure vessels, piping systems, and storage facilities. For instance, ASME Boiler and Pressure Vessel Code Section VIII provides detailed requirements for materials suitable for ammonia pressure vessels, while API 510 outlines inspection codes that consider material degradation mechanisms specific to ammonia environments.

Material certification requirements form another critical aspect of regulatory compliance. Materials used in ammonia processes must be accompanied by documentation verifying their chemical composition, mechanical properties, and testing history. This traceability is essential for demonstrating compliance during regulatory audits and inspections. Non-compliant materials can result in substantial fines, facility shutdowns, or even criminal liability in cases of serious incidents.

Environmental regulations also influence material selection decisions. Materials that minimize the risk of ammonia leaks and emissions help facilities comply with environmental protection standards such as the EPA's Risk Management Program in the US or the Seveso III Directive in Europe. These regulations establish threshold quantities for ammonia storage and mandate specific risk assessment procedures that consider material integrity as a key factor.

Insurance requirements further reinforce the importance of proper material selection. Insurers typically require adherence to industry standards such as NACE MR0175/ISO 15156 for materials resistant to sulfide stress cracking in environments containing hydrogen sulfide, which can be present in some ammonia processes. Compliance with these standards is often a prerequisite for obtaining coverage at reasonable premium rates.

The global harmonization of safety standards has led to the development of international codes such as ISO 15649 for process piping and IEC 60079 for equipment in explosive atmospheres, both of which contain provisions relevant to material selection in ammonia facilities. As regulatory frameworks continue to evolve toward more stringent requirements, particularly regarding risk assessment methodologies and predictive maintenance approaches, material selection becomes increasingly critical for maintaining long-term compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!